Quick replacement sub-board for impeller part

A technology of sub-boards and parts, applied in the field of rapid replacement sub-boards of impeller parts, can solve the problems of impeller parts clamping and positioning accuracy not meeting process requirements, scrapping, product size out of tolerance, etc., to improve repeat positioning accuracy and distribution. Symmetry and uniformity, the effect of improving contact stiffness and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

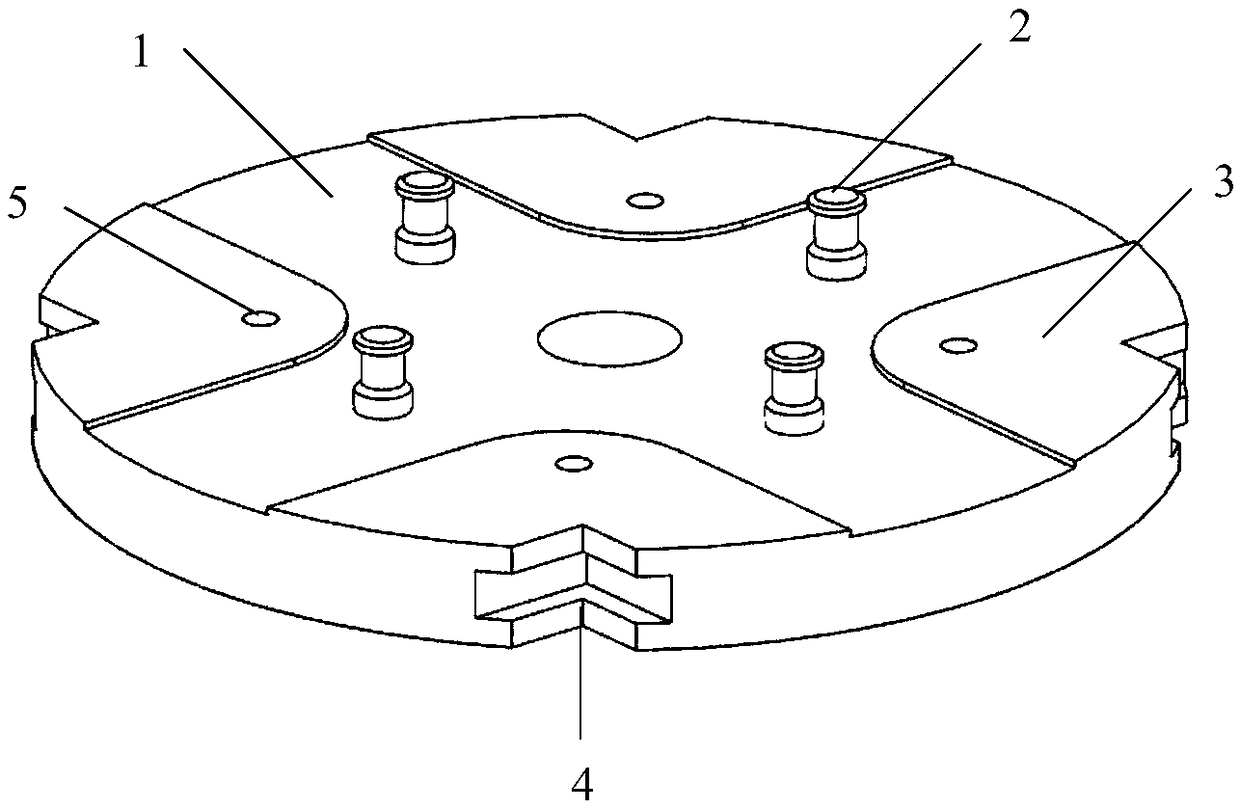

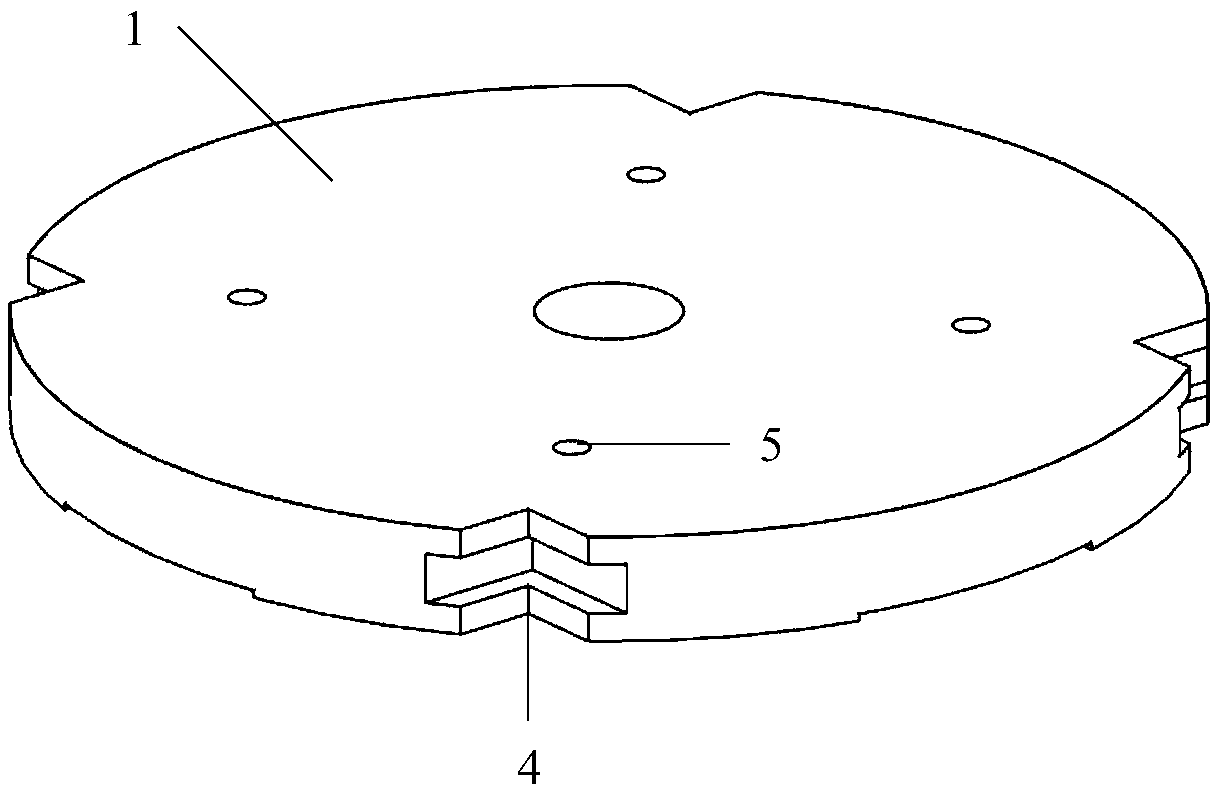

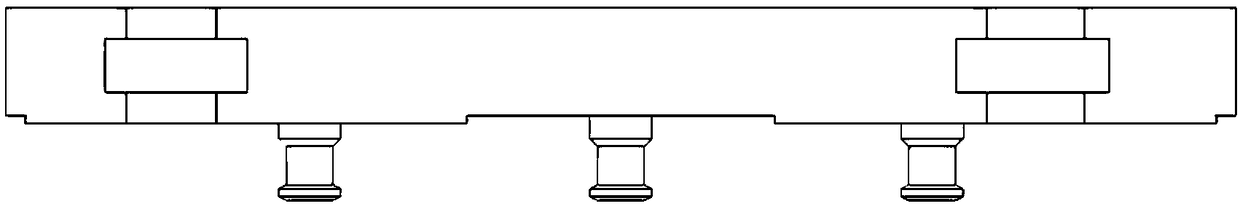

[0016] The invention provides a sub-board for quick replacement of impeller parts, one side of the sub-board 1 is fixedly connected with the tooling, the tooling and the impeller parts are clamped together, and the other side of the sub-board 1 is installed in cooperation with the mother board, as shown in FIG. figure 1 As shown, the sub-board 1 is processed with a "ten"-shaped concave surface to form a matching installation surface with the motherboard, that is, four positioning contact surfaces 3. The number is determined by the mounting holes on the motherboard. The verticality of the pull stud 2 is 0.01 mm. The pull studs 2 are evenly distributed around the circumference, and the center of the circle around which the pull studs 2 surround coincides with the center of the sub-board 1 .

[0017] The outer peripheral surface of the sub-board 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com