Corner three-way connector and mounting method thereof

A technology of corner tees and connectors, which is applied in the direction of connecting components, rods, mechanical equipment, etc., can solve the problems of poor stability of the connection structure and easy sloshing, etc., so as to improve the connection rigidity, increase the contact rigidity, and make it difficult to connect The effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

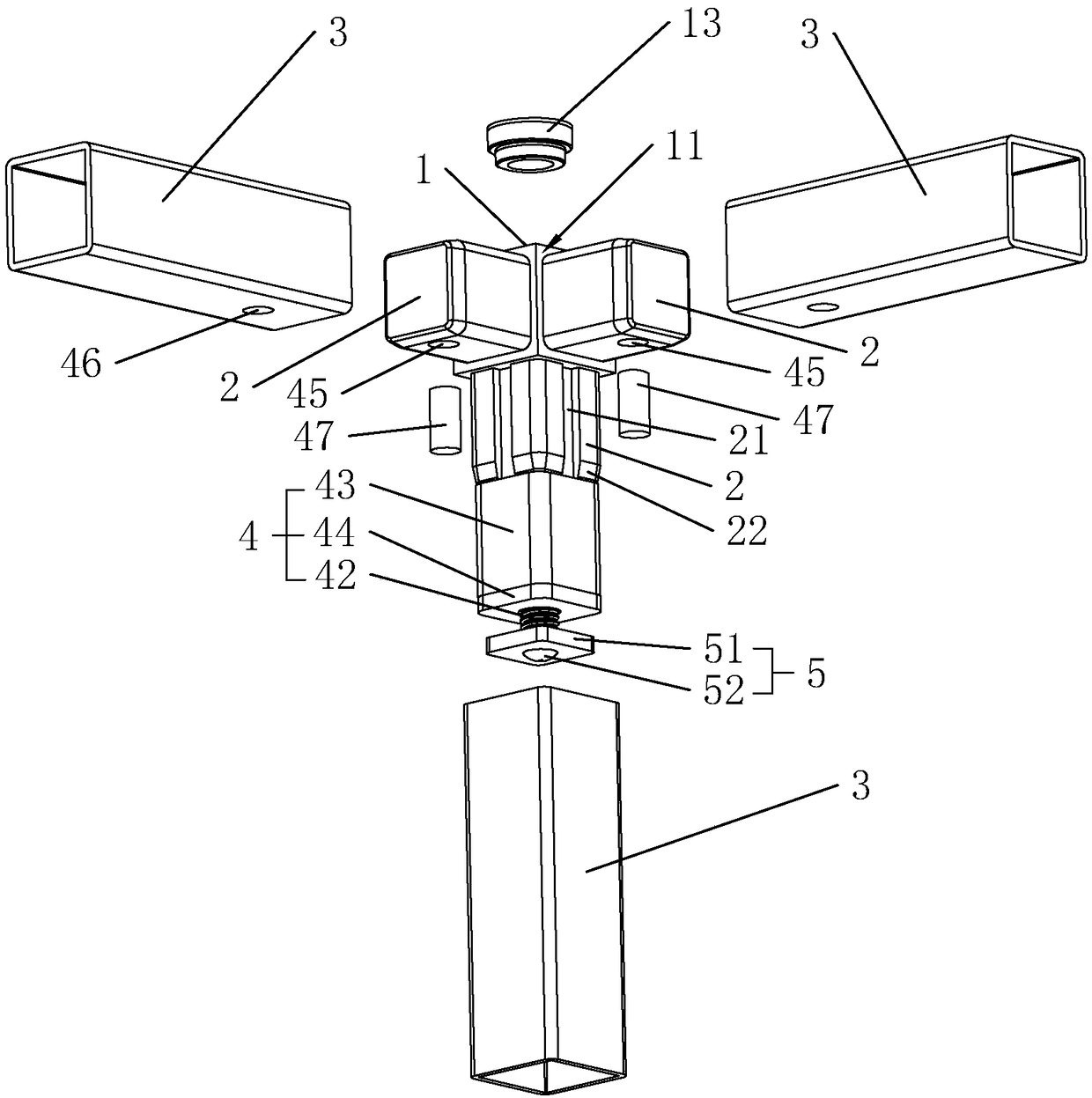

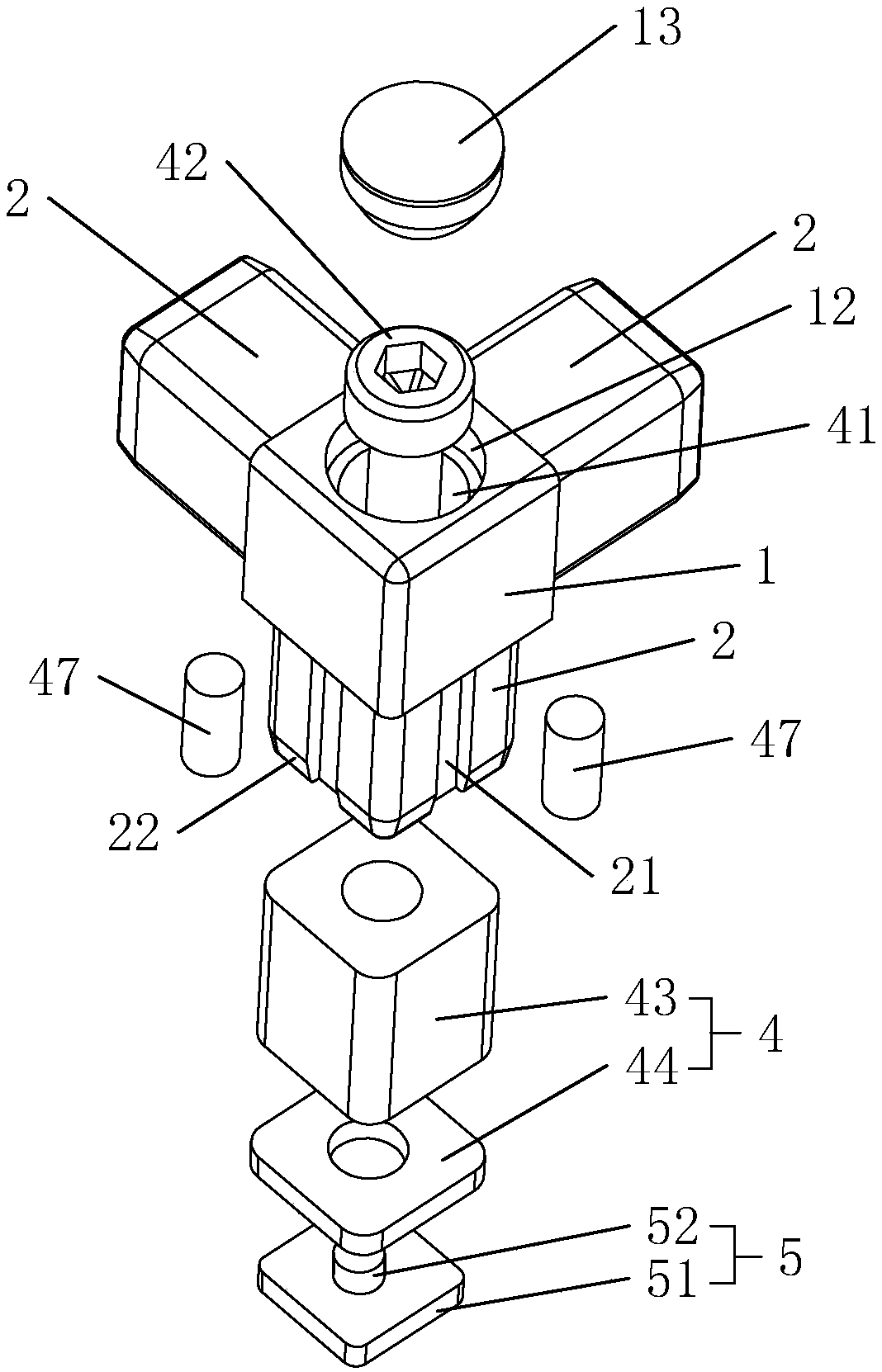

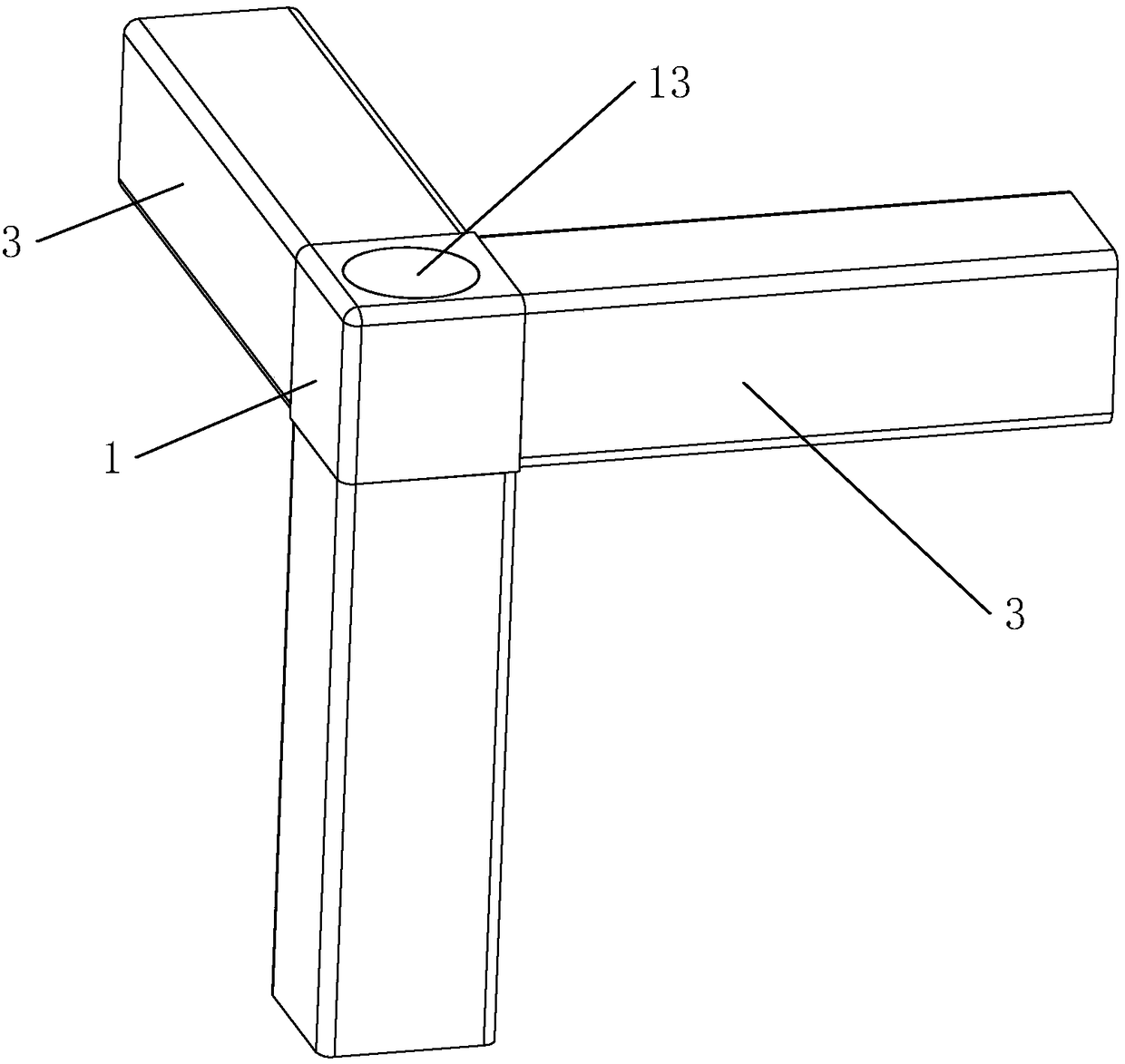

[0040] Such as figure 1 As shown, a corner tee connector is formed by integral die-casting of hard aluminum alloy, which includes a connecting main body 1 and three connecting legs 2. On each side wall, and between the connecting leg 2 and the connecting main body 1, there is a stop step 11 for the steel pipe 3 to resist; on each side wall of one of the connecting legs 2, there is a lengthwise direction parallel to the connecting leg 2. The deformation groove 21 in the length direction, after the deformation groove 21 is opened, a chamfer 22 surrounding the connection foot 2 is provided on the end of the connection foot 2 away from the connection body 1 .

[0041] Such as figure 1 with figure 2 As shown, it also includes a fixed structure 4 for fixedly connecting the connecting leg 2 with the steel pipe 3. The fixed structure 4 includes a mounting hole 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com