Automobile friction abnormal sound risk prediction method and device

A technology of risk prediction and abnormal noise, applied in special data processing applications, geometric CAD, computer-aided design, etc., can solve the problems of increasing development cycle and waste of development cost, and achieve the effect of ensuring consistency

Pending Publication Date: 2021-11-09

CHINA AUTOMOTIVE ENG RES INST

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention intends to provide a method for predicting the risk of abnormal friction noise of automobiles, so as to solve the problem that in the prior art, it is impossible to judge whether to redesign, optimize and test the location based on the occupant's perception of the abnormal friction noise in the vehicle, resulting in development costs waste and technical problems that increase the development cycle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

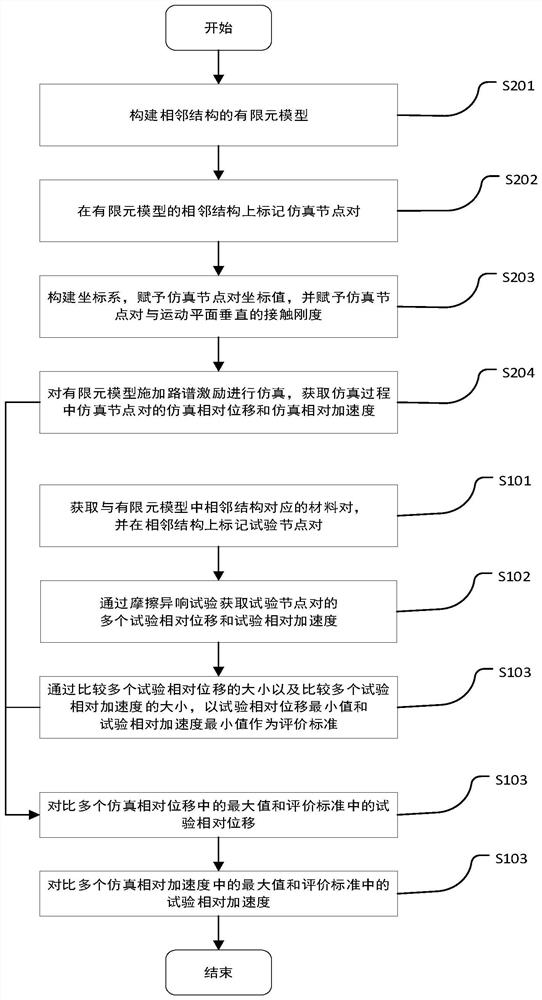

[0035] A risk prediction method for abnormal noise of automobile friction, as attached figure 1 shown, including the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

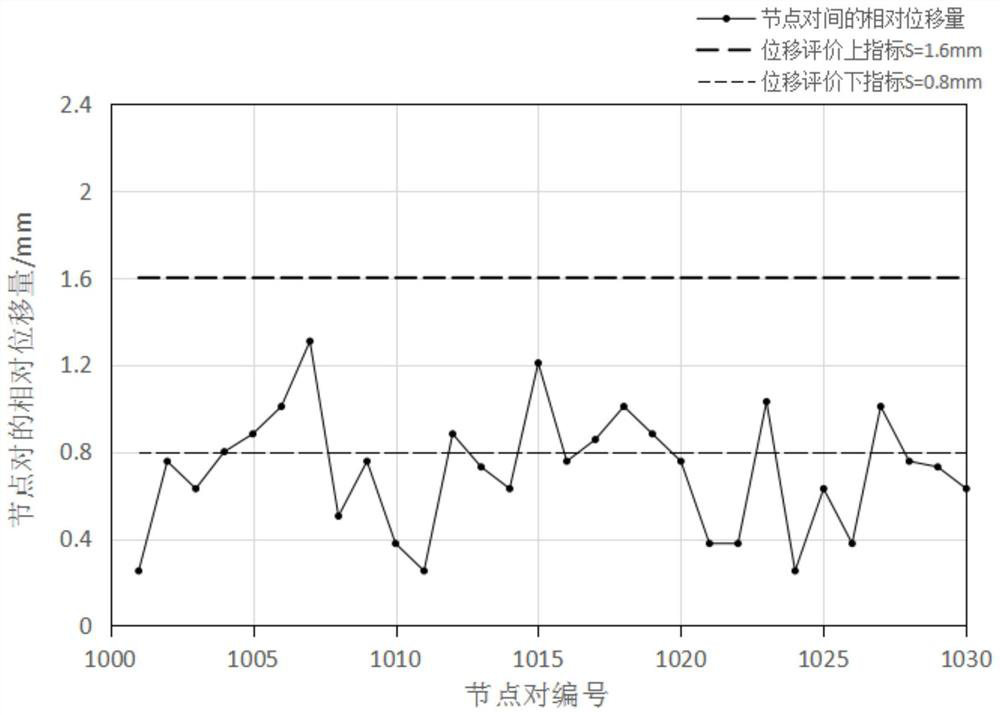

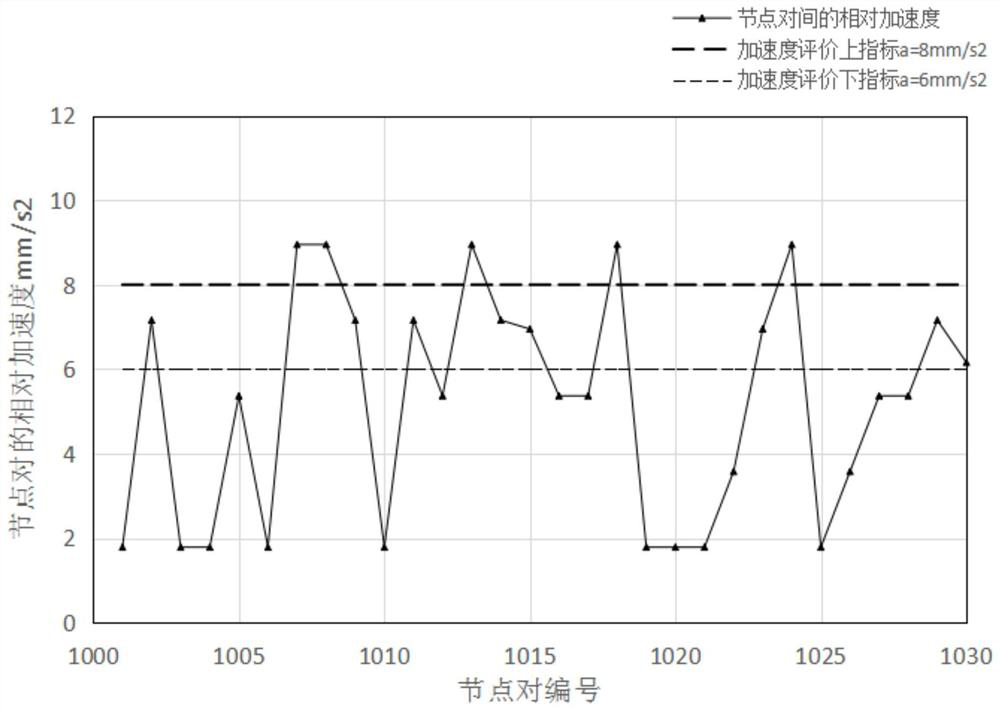

The invention relates to the technical field of vehicle friction abnormal sound prediction, in particular to an automobile friction abnormal sound risk prediction method and device, and the method comprises the following steps: S200, obtaining simulation relative displacement and simulation relative acceleration of a simulation node pair in a simulation process; S100, obtaining the test relative displacement and the test relative acceleration of the simulation node pairs through the friction abnormal sound test to serve as evaluation standards, wherein the test node pairs and the simulation node pairs are in one-to-one correspondence; S200, S200 and S100 being used only for distinguishing and not representing the sequence of the steps, and executing S300 after the S100 and S200 are executed; S300, judging the simulation relative displacement and the simulation relative acceleration according to the evaluation standard to generate a prediction result. By adopting the scheme, the technical problems that in the prior art, whether the position is redesigned, optimized and tested or not cannot be judged according to the sensing condition of the passenger in the vehicle on the friction abnormal sound, so that the development cost is wasted, and the development period is prolonged can be solved.

Description

technical field [0001] The invention relates to the technical field of vehicle friction noise prediction, in particular to a method and device for risk prediction of vehicle friction noise. Background technique [0002] Vehicle abnormal noise mainly includes friction abnormal noise, impact abnormal noise and resonance abnormal noise, which is a common indicator for evaluating vehicles. In the prior art, the main test method for vehicle abnormal noise is to conduct a road test on the prototype vehicle after the prototype vehicle is produced, so as to detect the location where the abnormal noise occurs in the vehicle, and then redesign and optimize the location where the abnormal noise occurs. However, since the detection of abnormal noise needs to be carried out after the prototype vehicle is produced, the waiting time for abnormal noise detection is too long, and when the abnormal noise occurs in the prototype vehicle, the structure of the vehicle needs to be redesigned and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/15G06F30/23G06F119/10

CPCG06F30/15G06F30/23G06F2119/10

Inventor 李添翼李沛然邱斌蒋大勇

Owner CHINA AUTOMOTIVE ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com