Preparation method for modified white carbon black tread rubber

A technology of white carbon black and tread rubber, which is applied in the field of preparation of modified white carbon black tread rubber, can solve the problems of increased rolling resistance, energy dissipation, poor compatibility of tread rubber, etc. The effect of dispersing stress and dispersing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

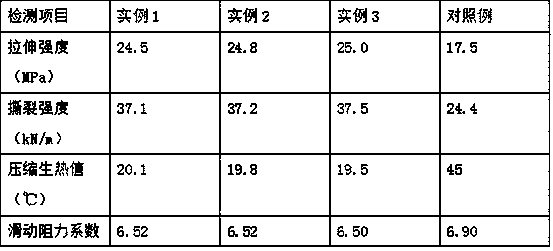

Examples

example 1

[0023] Weigh the bagasse and put it into the steam explosion tank, feed saturated steam into the steam explosion tank until the pressure in the steam explosion tank reaches 3.0MPa, keep the pressure and let it stand for 30 minutes, then open the outlet of the steam explosion tank to make the steam explosion tank instantly Release the pressure, collect the ejected blasting sugarcane fiber; mix the blasting sugarcane fiber and the sodium silicate solution with a mass fraction of 20% in a mass ratio of 1:10 to obtain a mixed solution and put it into an ultrasonic oscillator with a concentration of 1mol / L hydrochloric acid to adjust the pH of the mixed solution to 4.0, and react with ultrasonic oscillation at a frequency of 25kHz for 15 minutes to obtain the reactant; put the reactant into a high-temperature reaction kettle, heat up to 100°C, and perform a high-temperature dehydration reaction for 1 hour. Filter and separate to obtain the filter residue, put the filter residue in ...

example 2

[0025]Weigh the bagasse and put it into the steam explosion tank, feed saturated steam into the steam explosion tank until the pressure in the steam explosion tank reaches 3.3MPa, keep the pressure and let stand for 40min, then open the discharge port of the steam explosion tank to make the steam explosion tank instantly Release the pressure, collect the ejected blasting sugarcane fiber; mix the blasting sugarcane fiber and the sodium silicate solution with a mass fraction of 20% in a mass ratio of 1:10 to obtain a mixed solution and put it into an ultrasonic oscillator with a concentration of 1mol / L hydrochloric acid to adjust the pH of the mixed liquid to 4.5, react with ultrasonic oscillation at a frequency of 30kHz for 18min, and obtain the reactant; put the reactant into a high-temperature reaction kettle, heat up to 150°C, and perform a high-temperature dehydration reaction for 1h. Filter and separate to obtain the filter residue, put the filter residue in an oven, and d...

example 3

[0027] Weigh the bagasse and put it into the steam explosion tank, feed saturated steam into the steam explosion tank until the pressure in the steam explosion tank reaches 3.5MPa, keep the pressure and let stand for 50min, then open the outlet of the steam explosion tank to make the steam explosion tank instantly Release the pressure, collect the ejected blasting sugarcane fiber; mix the blasting sugarcane fiber and the sodium silicate solution with a mass fraction of 20% in a mass ratio of 1:10 to obtain a mixed solution and put it into an ultrasonic oscillator with a concentration of 1mol / L hydrochloric acid to adjust the pH of the mixture to 5.0, and react with ultrasonic oscillation at a frequency of 35kHz for 20 minutes to obtain the reactant; put the reactant into a high-temperature reactor, heat up to 200°C, and dehydrate the reaction for 2 hours at high temperature. Filter and separate to obtain the filter residue, put the filter residue in an oven, and dry at 110°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com