Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

A brazing process and vacuum tube technology, applied in the direction of manufacturing tools, tubular objects, welding equipment, etc., can solve the problems of large activation effect, neutron pollution, etc., and achieve the effect of reducing stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

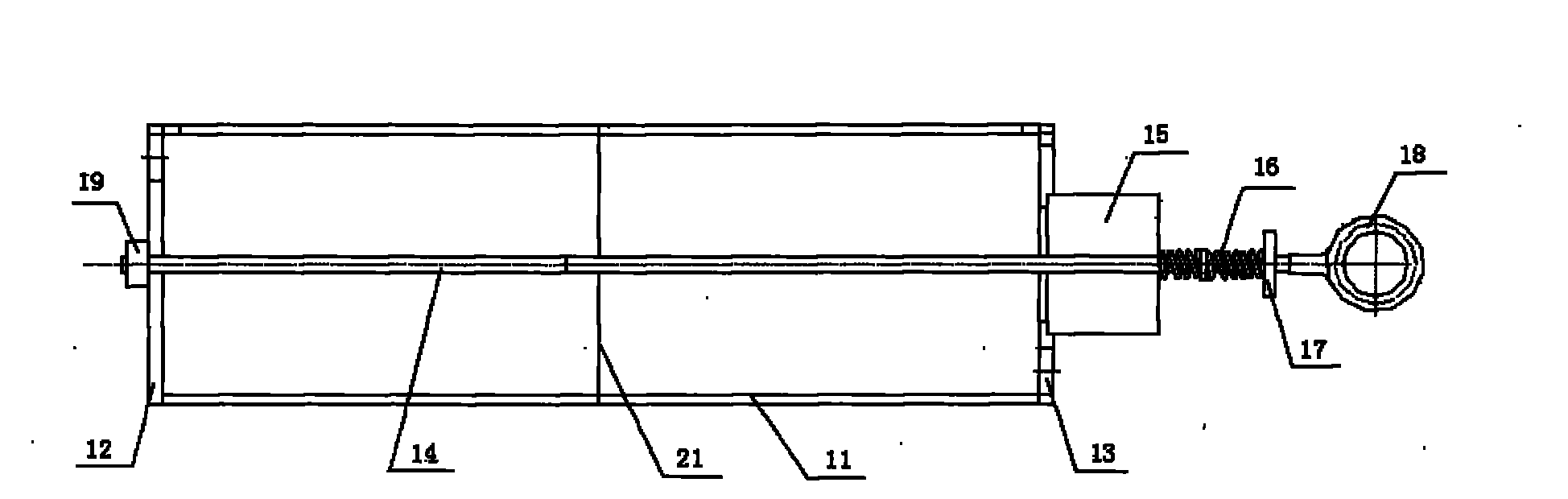

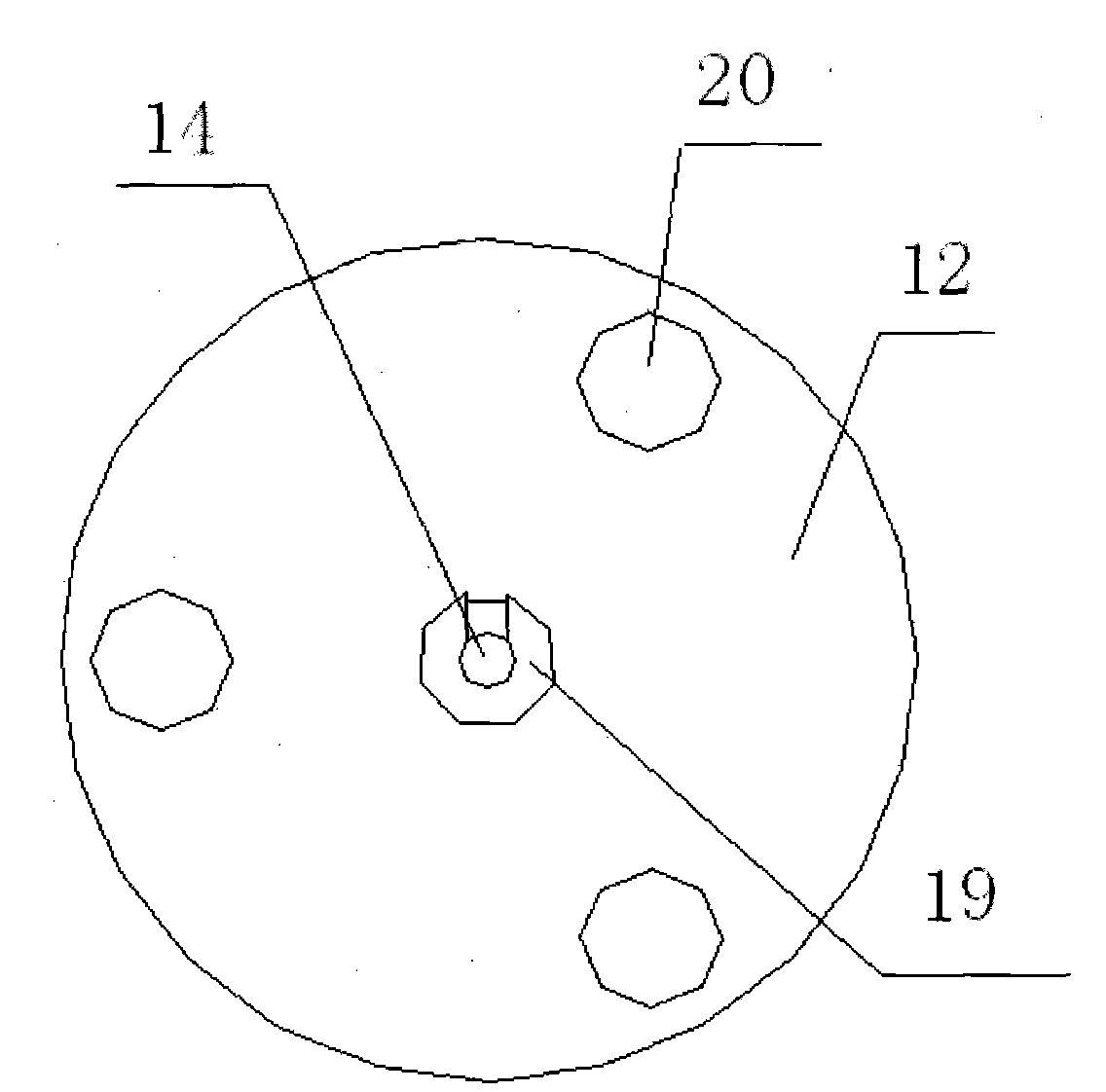

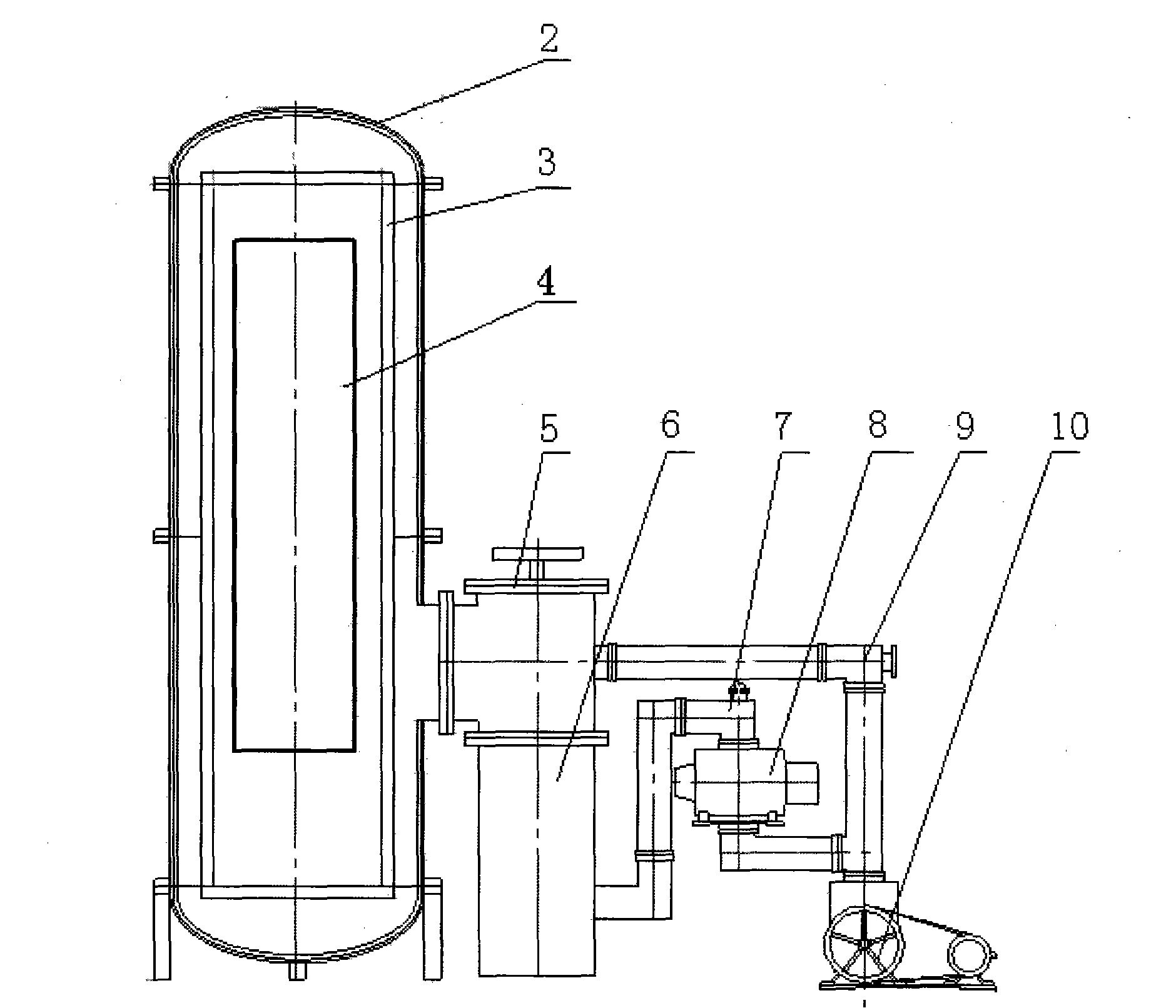

[0018] Such as figure 2 and image 3 As shown, a device for brazing ceramic vacuum tubes with a diameter greater than 300 mm provided by the present invention includes a vertical vacuum furnace body 2, a workpiece 4 is placed in the vacuum furnace body 2, and a heating system 3 is provided in the vacuum furnace body 2 , the heating system 3 is distributed around the workpiece 4, the heating system 3 is respectively connected to the controller and the power supply of the furnace body, the first valve 5 is connected to the vacuum furnace body 2, one end of the first valve 5 is connected to the diffusion pump 6, and the first valve 5 The other end of the pipe is connected to the third valve 9, the third valve 9 is connected to the mechanical pump 10, one end of the Roots pump 8 is connected to the diffusion pump 6 through the second valve 7, and the other end of the Roots pump 8 is connected to the third valve 9 Pipeline between mechanical pump 10. The heating system 3 is an e...

Embodiment 2

[0026] The device of this embodiment is the same as that of Example 1, and the difference in the steps is that the drying temperature in step 1 is 100°C and the time is 10 minutes; the drying temperature in step 2 is 100°C and the time is 10 minutes; step 4, for Vacuum the furnace until vacuum 10 -5 Start heating after Pa, raise the temperature to 510°C at 50°C / hour, keep it warm for 25 minutes, then raise the temperature to 852°C at a rate of 150°C / hour, confirm that the solder is melted, keep it warm for 25 minutes, then cool naturally to 160°C, and flush with argon Gas, out of the oven.

[0027] After testing, the vacuum leak rate at the weld of the ceramic pipe is less than 5*10- 12 Pa. M 3 / s, after a long time vacuum test, there is no crack at the joint of the pipe.

Embodiment 3

[0029] The device of this embodiment is the same as that of Example 1, and the difference in the steps is: the drying temperature in step 1 is 120°C, and the time is 5 minutes; the drying temperature in step 2 is 120°C, and the time is 5 minutes; step 4, for Vacuum the furnace until vacuum 10 -3 After Pa, start heating, raise the temperature to 500°C, keep it warm for 20 minutes, then raise the temperature to 850°C, confirm that the solder is melted, keep it warm for 20 minutes, then cool naturally to 150°C, flush with nitrogen, and take it out of the oven. The other steps in this example are the same as in Example 1. same. After testing, the vacuum leak rate at the weld of the ceramic pipe is less than 5*10- 12 Pa. M 3 / s, after a long time vacuum test, there is no crack at the joint of the pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com