Axial line correction method of cylindrical workpiece and diameter measurement method of sectioned section of cylindrical workpiece

A technology of cylindrical workpiece and correction method, which is applied to measuring devices, instruments, etc., can solve the problem of low correction accuracy of axis line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

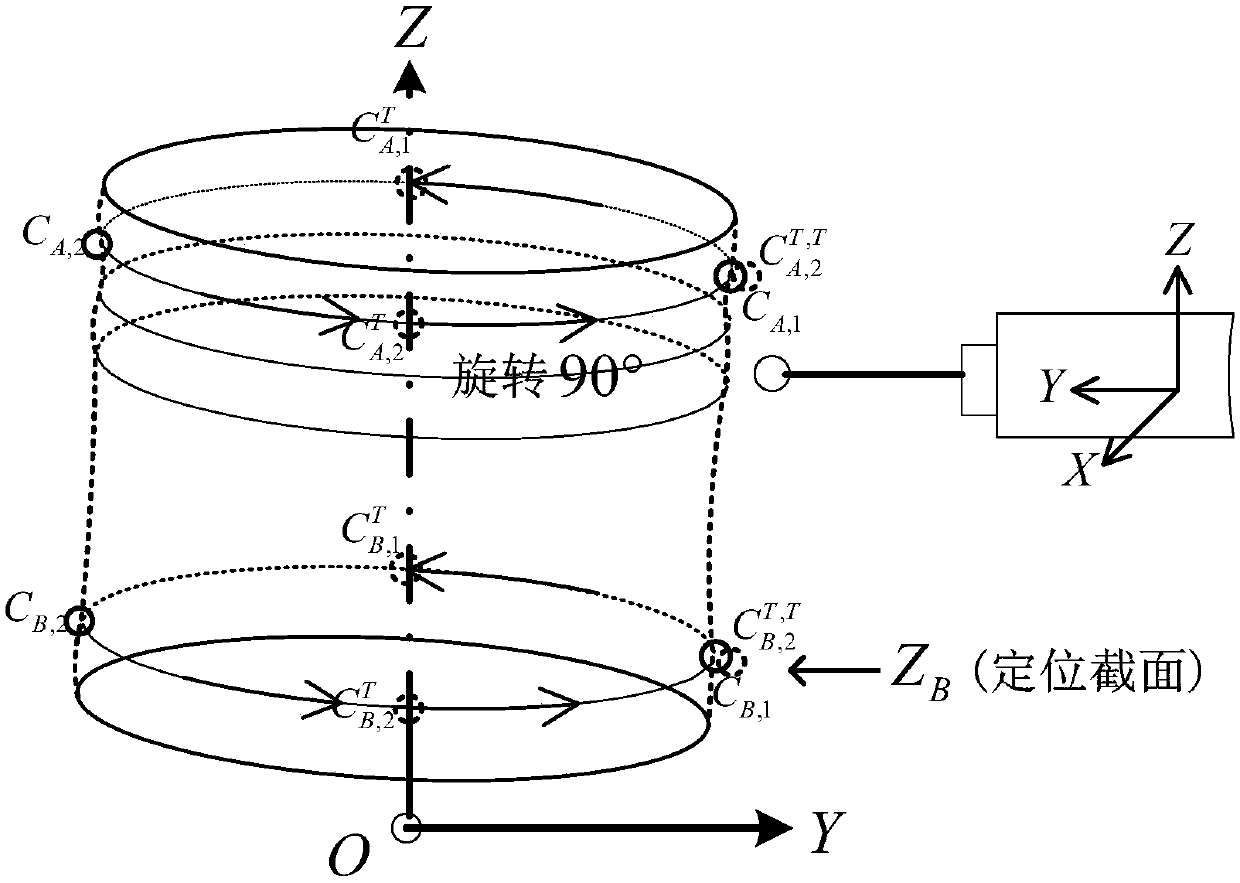

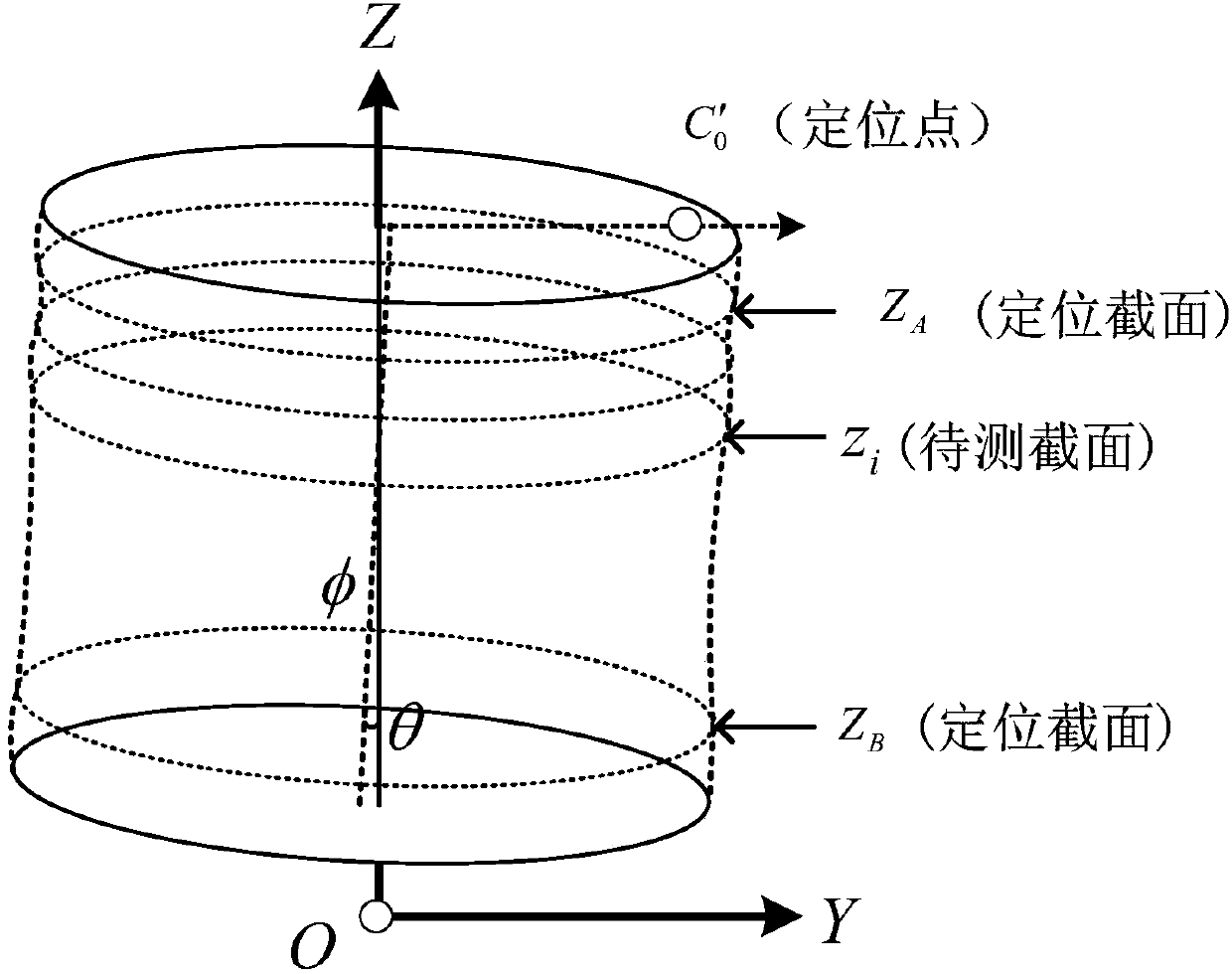

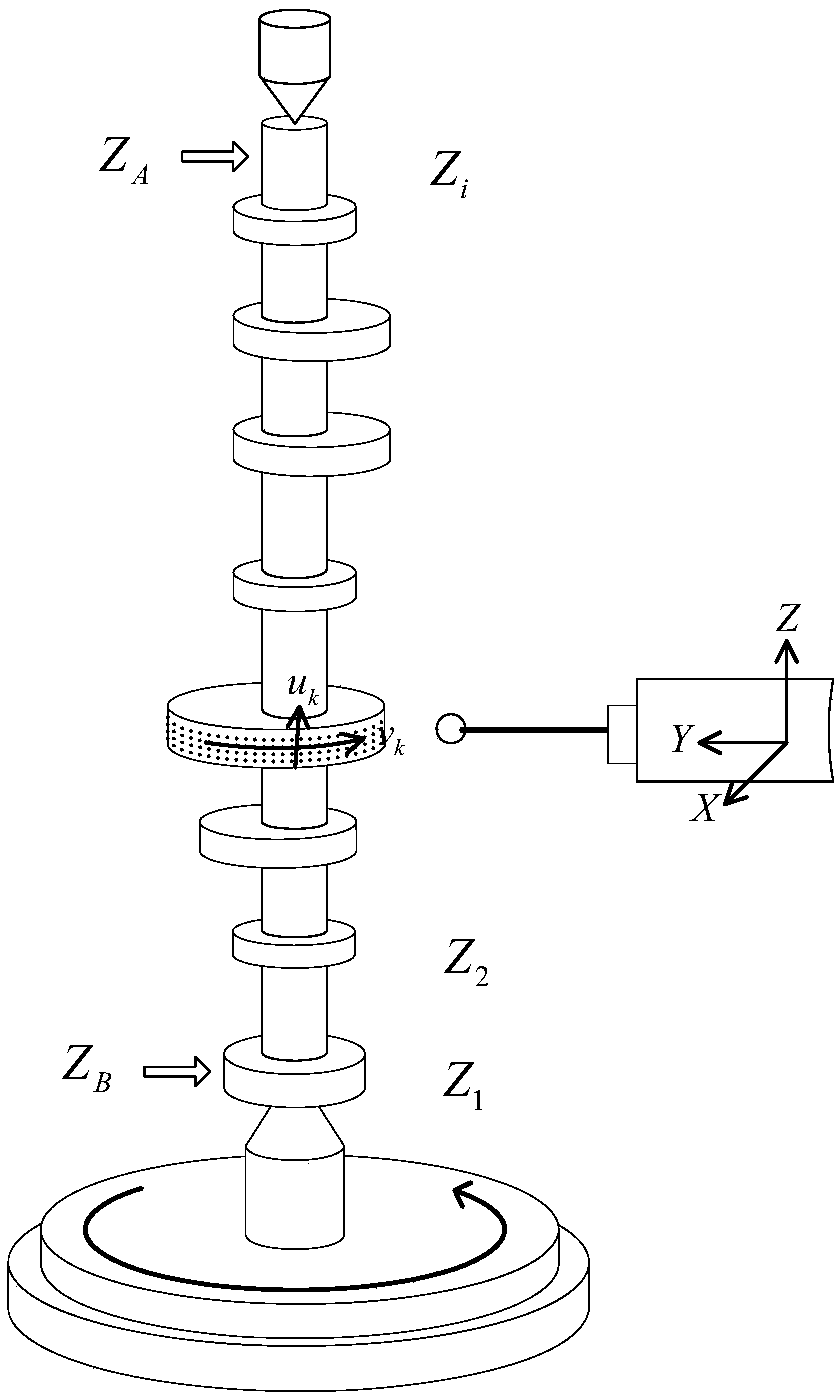

[0051] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] Such as Figure 1 to Figure 2 As shown, a method for correcting the axis line of a cylindrical workpiece includes the following steps:

[0053] Step 101: Install the cylindrical workpiece to be measured on the turntable of the contact three-coordinate measuring machine: the cylindrical workpiece is placed vertically, and the upper and lower ends of the cylindrical workpiece are respectively fixed by the upper tip and the lower tip; Any point on the center line is used as the origin O of the measurement coordinate system, and the axis of the lower tip is used as the Z axis; the nominal length l of the cylindrical workpiece to be measured and the nominal radius r of the upper end surface 0 is a known quantity;

[0054] Step 102: Input the preset reference point C on the coordinate measuring machine 0 (x c0 ,y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com