Environmental-protection decorative composite board and its making method

A production method and composite board technology are applied in the field of building decorative boards and houses, which can solve the problems of difficult production process, complex production process, poor flatness, etc., and achieve environmental protection, reduce glue coating, and improve flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

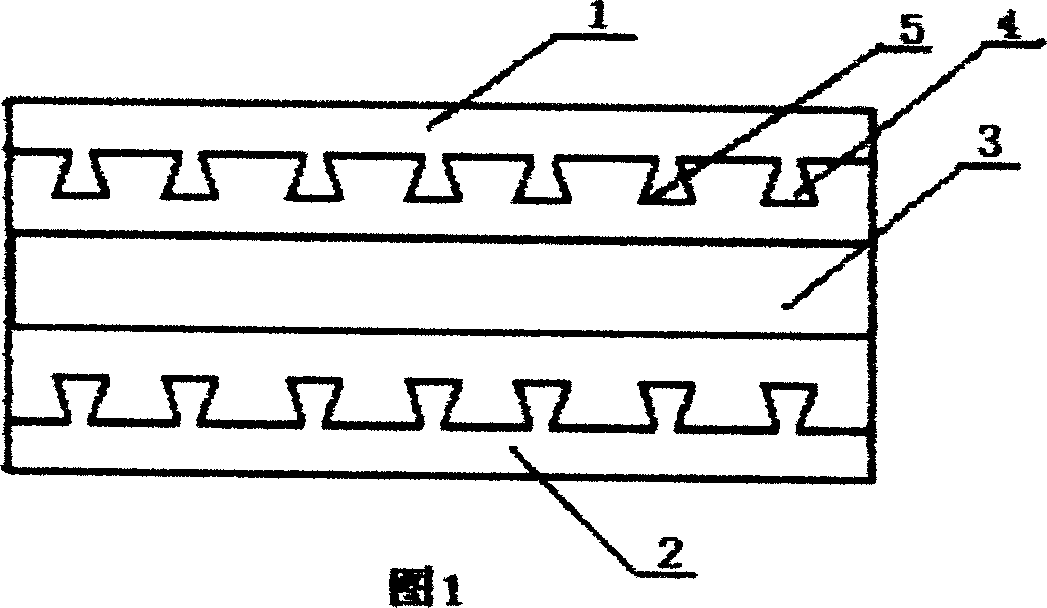

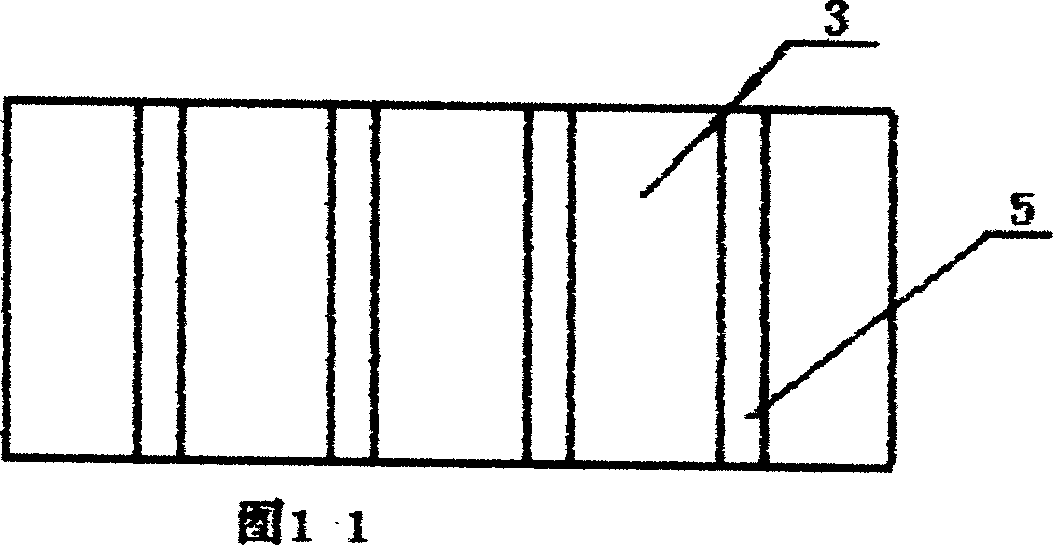

[0022] Embodiment 1 As shown in Figures 1 and 2, the environmentally friendly decorative composite board is a three-layer composite board. The composite board is composed of an upper panel 1, a lower panel 2, and a middle board 3. The lower panel 2 is a concave-convex groove mosaic plug-in connection respectively. The upper panel 1 and the lower panel 2 are fiberboards or solid wood boards, and the bottom surface has dovetail protrusions 4. The middle board 3 is a spliced board with symmetrical dovetail grooves 5 on both sides. The specifications of the composite board are boards with a length of 2440cm, a width of 1220cm, and a thickness of 3cm. Slot 5 corresponds. The height of the dovetail protrusion 4 is 5mm, the width of the top surface of the protrusion 4 is 5mm, and the width of the bottom surface is 3mm, and the bottom distance between two adjacent dovetail grooves 5 is 100mm; the manufacturing method of the composite board is: splicing wooden strips Formed boards...

Embodiment 2

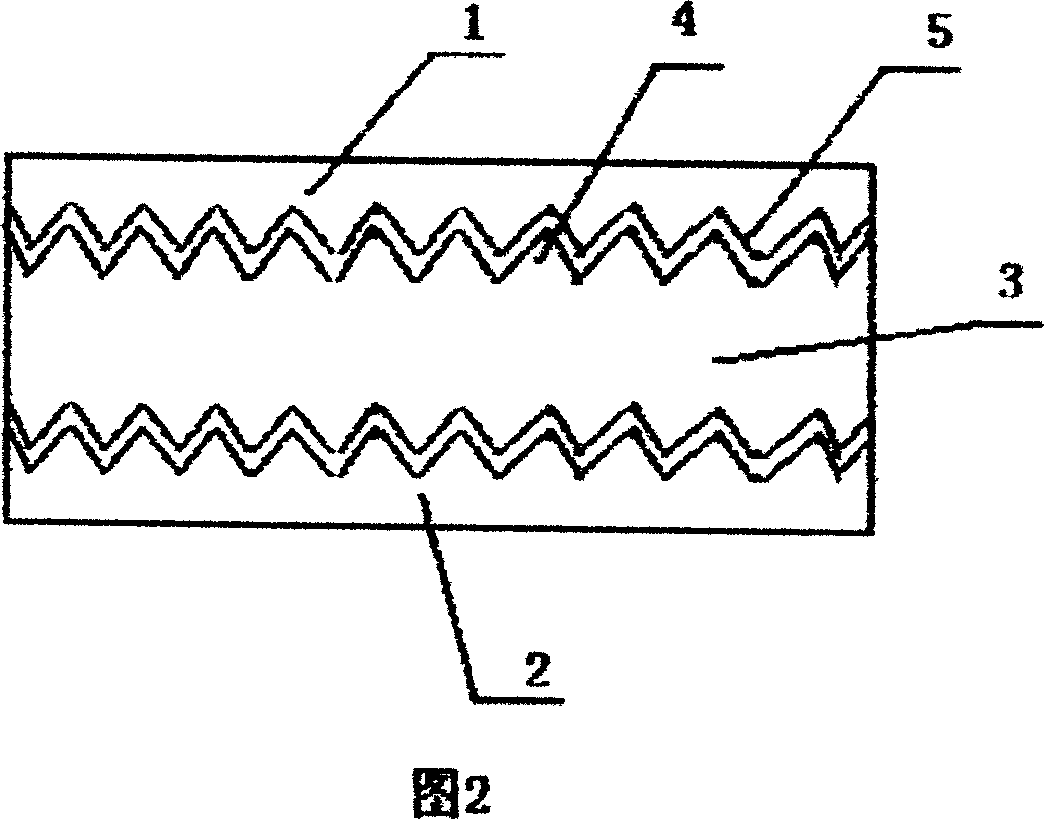

[0023] Embodiment 2 As shown in Figure 2, the upper panel 1 and the lower panel 2 are fiberboards or solid wood boards, and the bottom surfaces of the upper panel 1 and the lower panel 2 have zigzag grooves 5, but the zigzag grooves 5 on the bottom surface of the upper panel 1 and the The zigzag groove 5 on the bottom surface of the lower panel 2 is mutually misplaced, and the middle plate 3 is a zigzag projection 4 splicing boards with dislocation on both sides. The height of its protrusion 4 is 1.5mm, the width of its bottom surface is 6mm, and the distance between the bottoms of adjacent zigzag grooves 5 is 6mm. Due to the use of concave-convex groove mosaic insertion, the strength of the composite board can be increased, and its Flatness, so that it is stable without deformation, and the board is not easy to crack. A small amount of adhesive is coated between the upper panel 1, the middle panel 3 and the lower panel 2. The adhesive is white non-toxic latex, which is a comm...

Embodiment 3

[0024] Embodiment 3 As shown in Figure 3, there are protrusions 4 on both sides of the middle plate, which are rectangular waves, and it is basically the same as Embodiment 2, except that the bottom surface of the upper panel 1 and the lower panel 2 has a rectangular wave groove 5, and the height of the rectangular wave 3 mm, the width of the rectangular wave is 10 mm, and the distance between the bottoms of adjacent rectangular wave grooves 5 is 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com