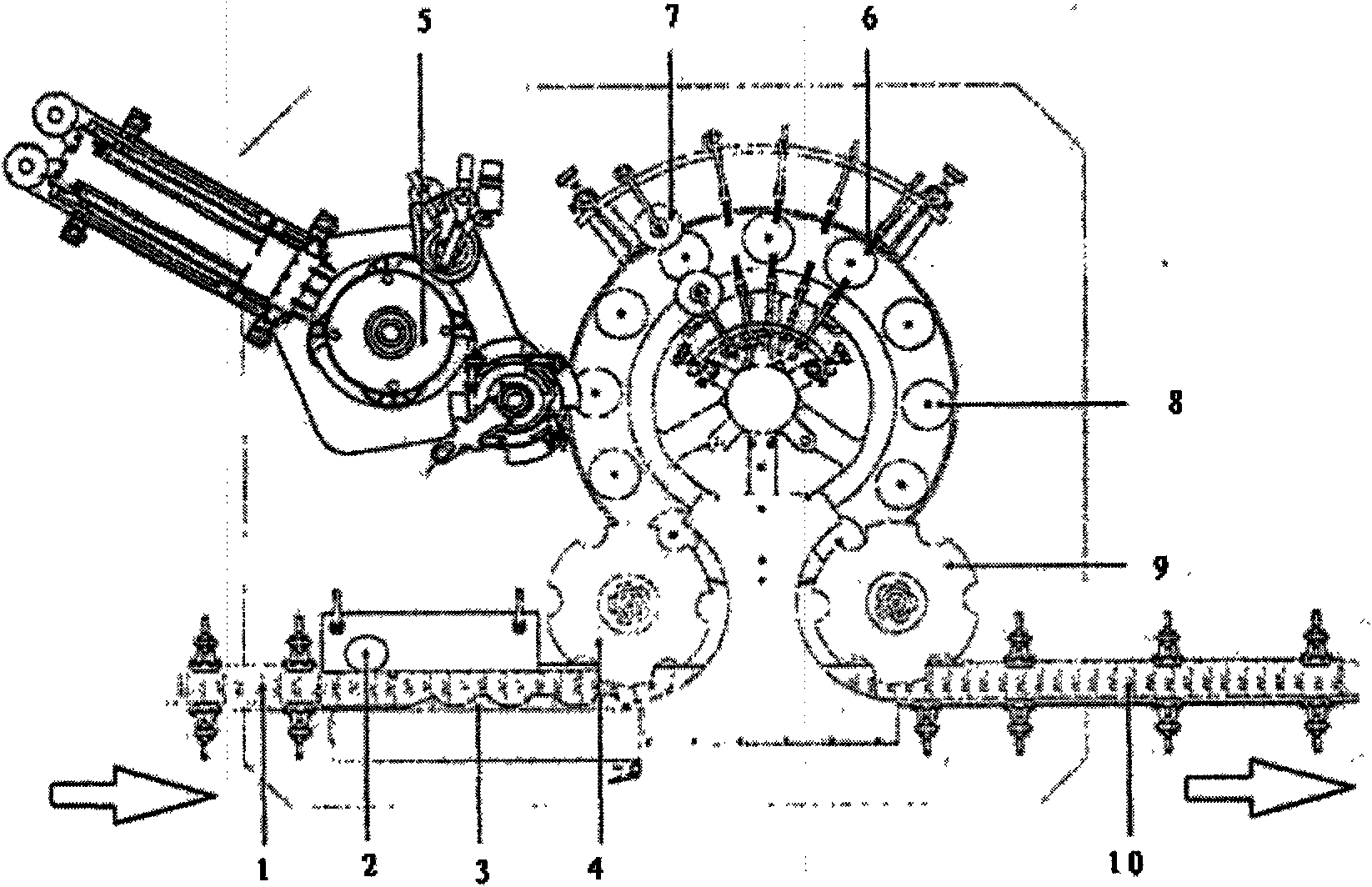

Labeling device of labeler and working method thereof

A working method and labeling machine technology, which is applied in the field of labeling devices of labeling machines, can solve the problems of reducing production costs, product appearance wrinkles, etc., and achieve the effect of solving wrinkles and saving the amount of glue applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

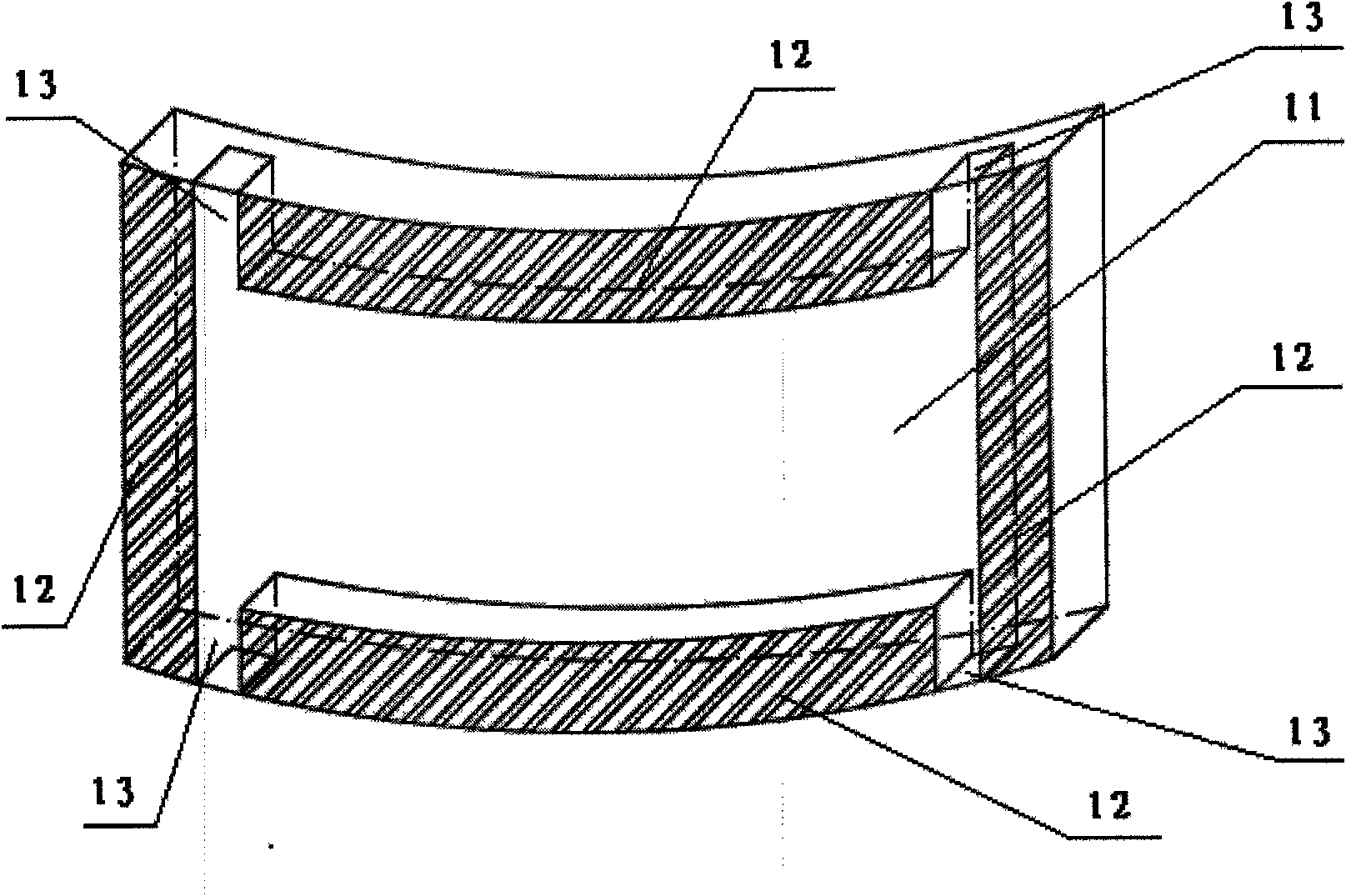

[0018] Embodiment: A labeling device of a labeling machine, characterized in that a groove 11 smaller than the outer edge of the label is opened on the label palm of the labeling device, and the outer edge of the groove 11 of the label palm is a boss serving as a gluing surface. side 12. (See figure 2 )

[0019] The depth of the aforementioned groove 11 of the palm is 65% of the thickness of the palm.

[0020] The above-mentioned boss edge 12 serving as the gluing surface is provided with an opening groove 13 which is beneficial to the leveling of the label.

[0021] There are four evenly distributed opening grooves 13 on the side of the boss 12 serving as the gluing surface, which are favorable for the leveling of the label, and the width thereof is 8 mm.

[0022] A working method of the labeling device of the above-mentioned labeling machine, characterized in that it comprises the following steps:

[0023] (1) Start the label palm of the labeling device of the labeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com