Laminated wood (laminated material) artistic wood door

A technology of layered timber and layered building blocks, which is applied in the arrangement of door leaves and wing leaves, etc., can solve the problems of inconvenient access and handling of items, and increased space occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

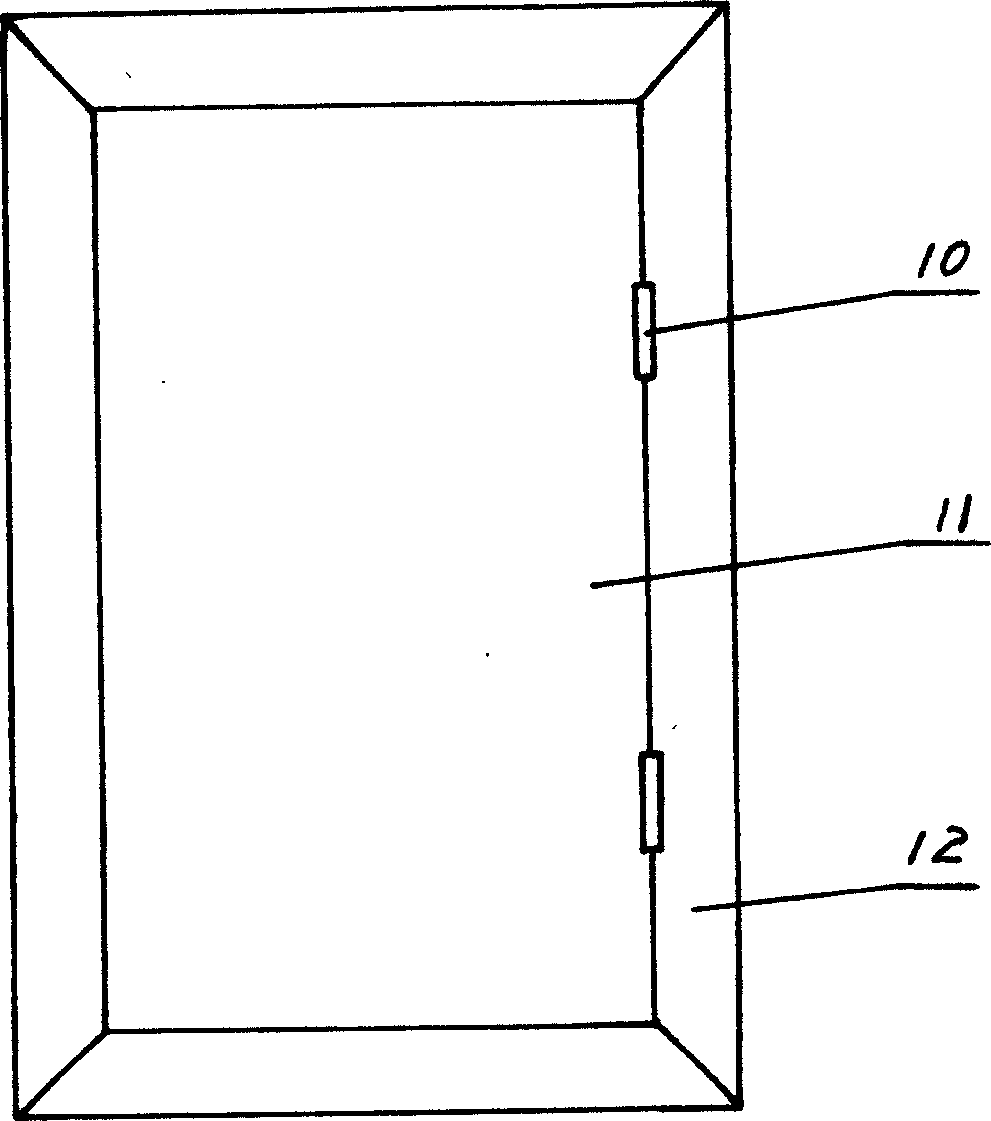

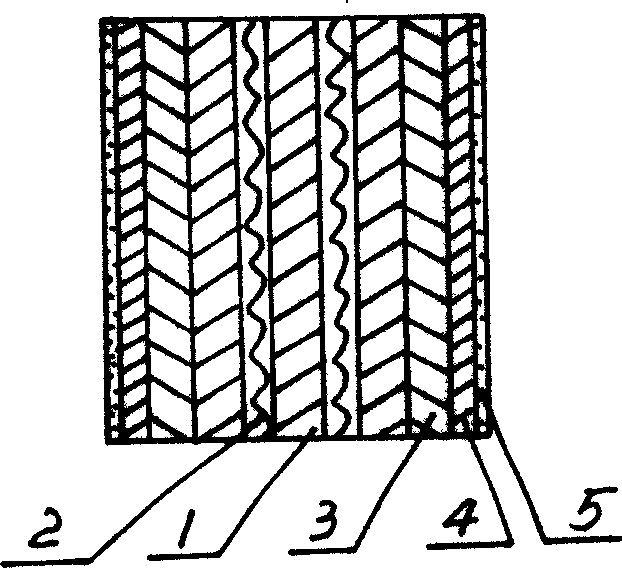

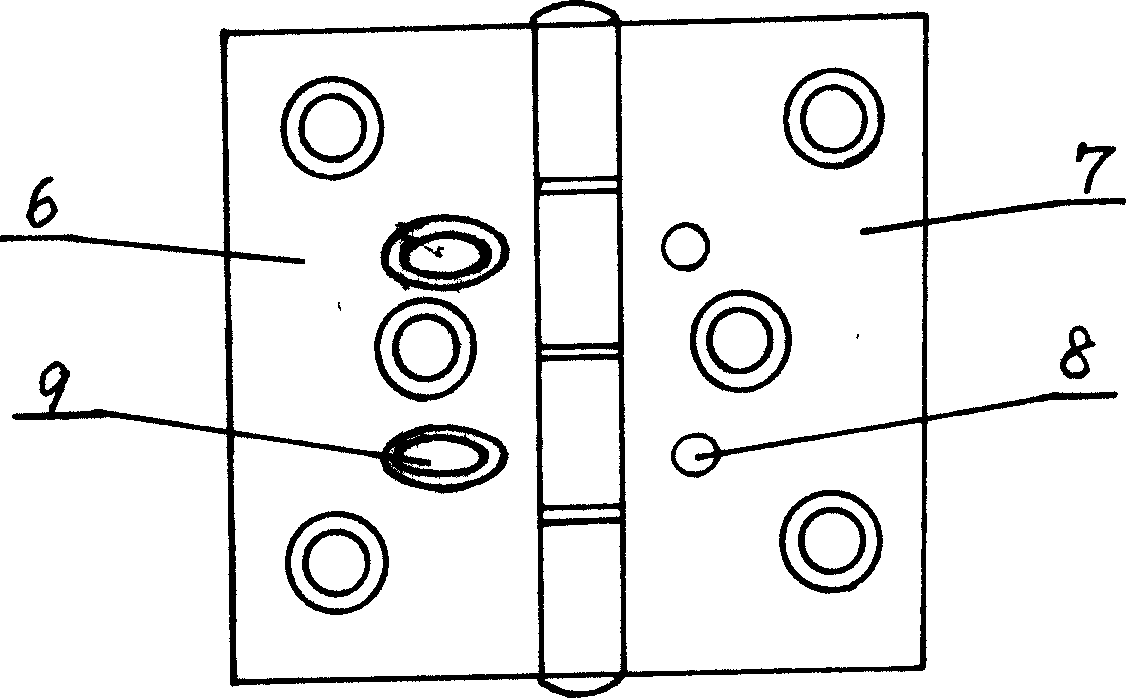

[0013] see Figure 1 to Figure 3 As shown, the material of the door leaf 11 in the figure is laminated wood (laminated wood), which is formed by pressing the core board 1, the process panel 4, and the like. The number of core boards 1 is generally 3 pieces, all of which are thick core veneers of rotary cut, adopting the invention patent "Spinless Wood Rotary Cutting Machine" applied by the inventor on April 20, 2000 (invention patent No.: ZL00106076.6) after rotary cutting, then the utility model patent "Wood Rotary Cutting Veneer Stress Degradation Machine" (utility model patent number: ZL01280006.6) applied by the inventor on December 30, 2001 for stress degradation , the thickness of each board is 5-8mm. During pressing, the wood grain direction of each core board 1 is consistent, that is, along the same direction. The specific structure is as follows: from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com