Composite blank, composite fabric for power sunroof and production process of composite fabric

A technology of composite blanks and composite fabrics, applied in the textile field, can solve the problems of many VOCs, affecting the odor level, and many small molecular organic substances, and achieves the effects of good hand feeling, reduced pollution and less pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

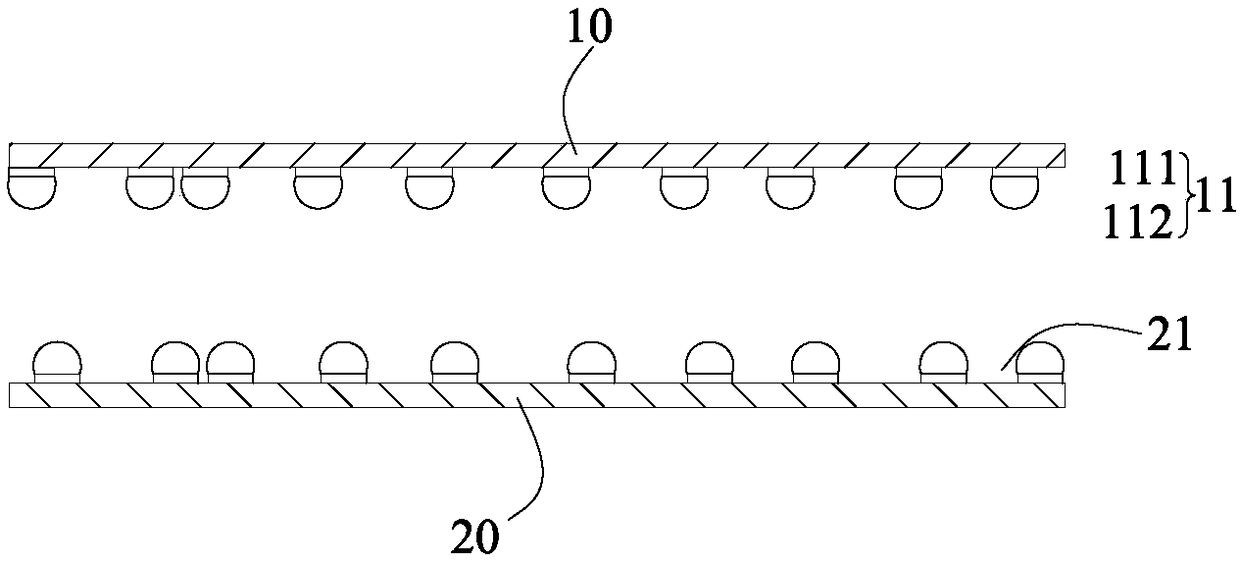

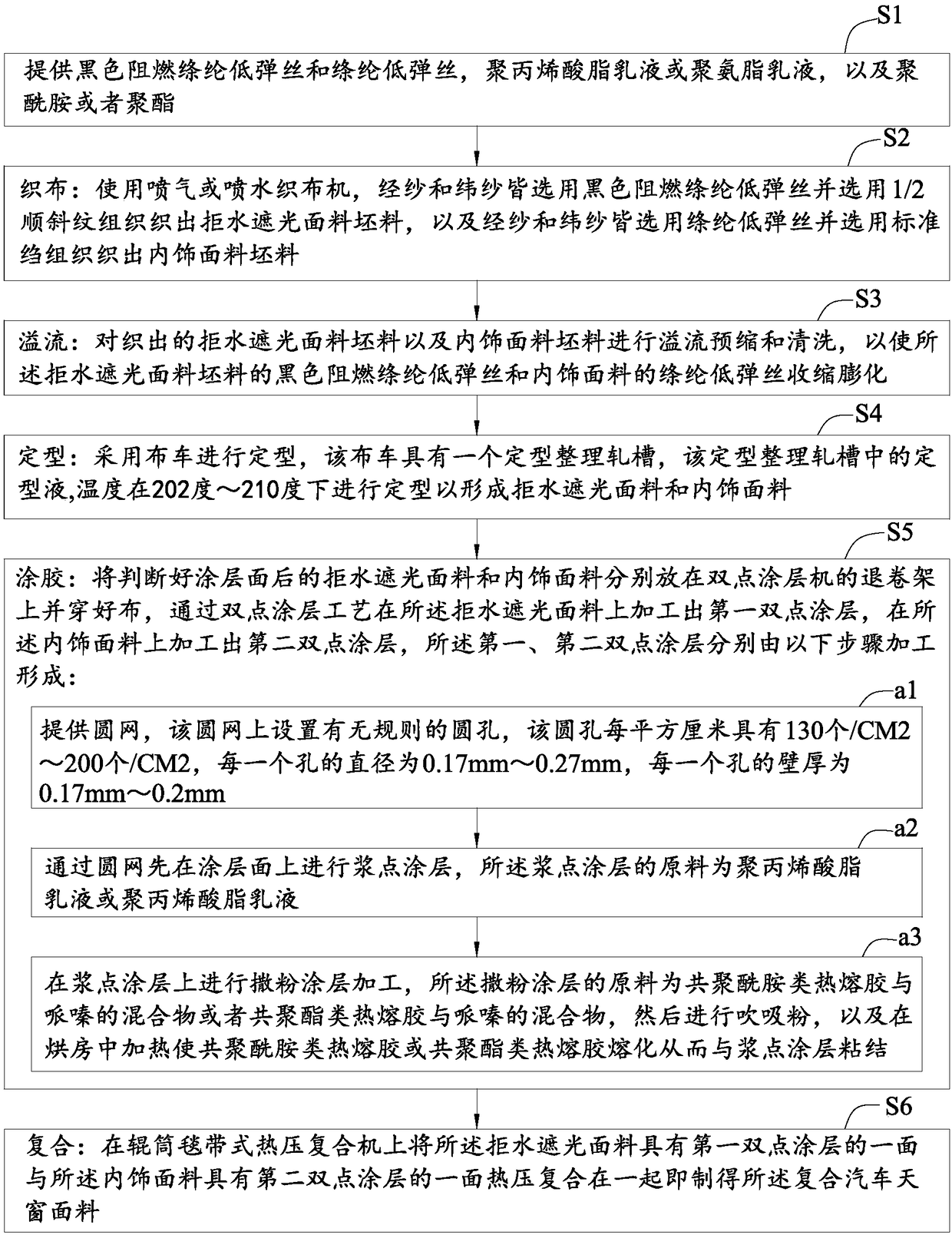

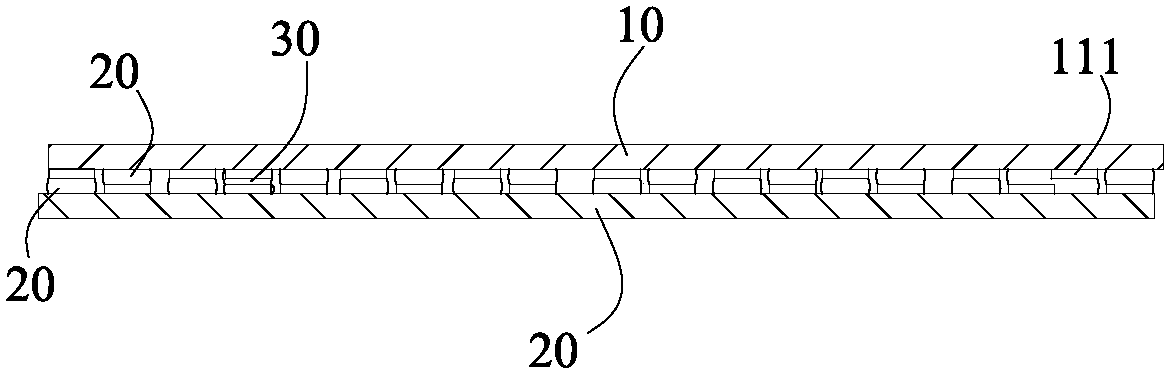

[0030] Such as figure 1 As shown, it is a structural schematic diagram of a composite blank provided by the present invention. The composite blank includes a layer of water-repellent shade fabric 10 and a layer of interior fabric 20 . The water-repellent light-shielding fabric 10 is made of black flame-retardant polyester low-elasticity yarn and is woven with 1 / 2 twill weave. After finishing, the fabric fiber surface can repel and alienate oil and water liquid media, Thereby, the special protective fabric that does not hinder the ventilation and comfort, and can effectively resist the erosion of such liquids to underwear and human body is achieved. It is a prior art and will not be repeated here. The water-repellen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com