Injection-molded component manufacturing method

A manufacturing method and component technology, which is applied in the field of injection molding parts processing and injection molding parts production machinery, can solve problems affecting production efficiency, high cost, and difficult operation, and achieve the effect of cost saving and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments describe the composition, structure, connection and positional relationship of the insert placement system of the present invention, the working principle and the method of use in conjunction with the accompanying drawings. Make specific explanations.

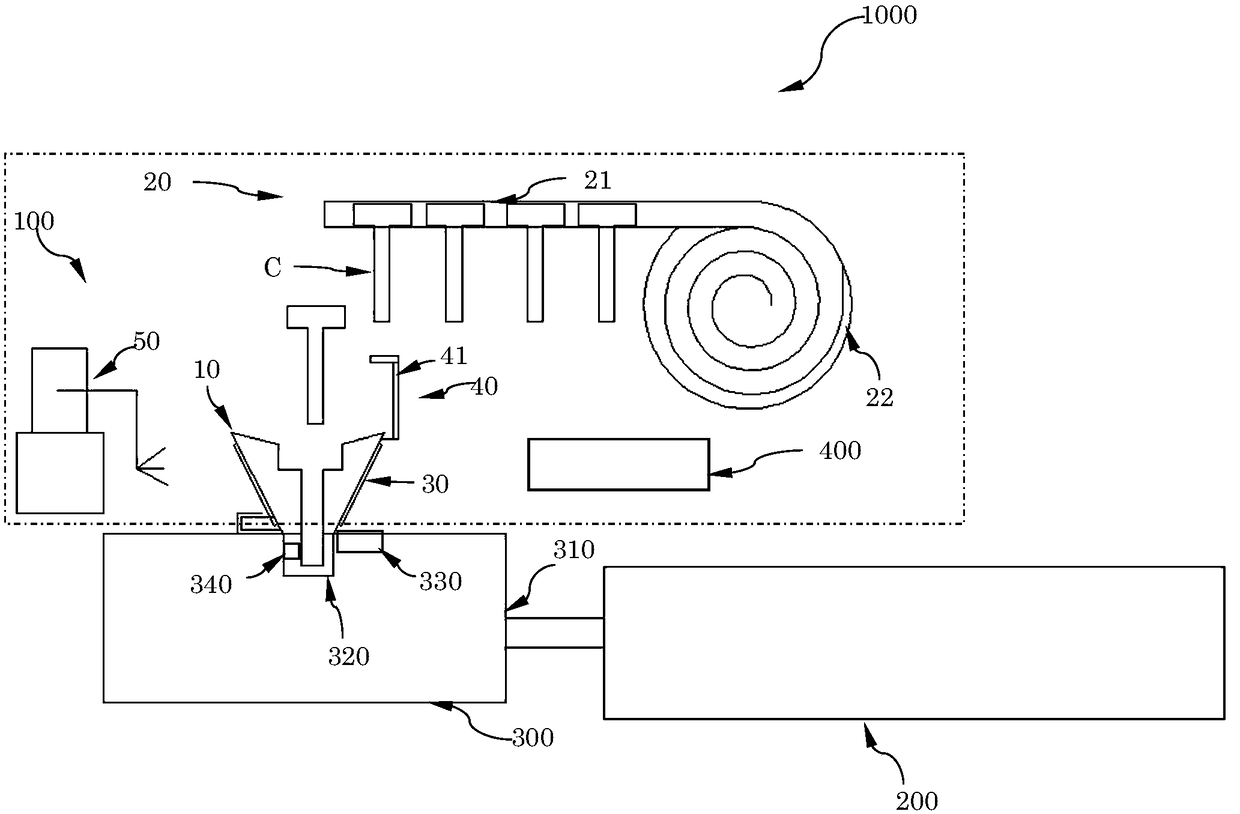

[0034] figure 1 It is a structural schematic diagram of the insert placing system in the embodiment of the present invention.

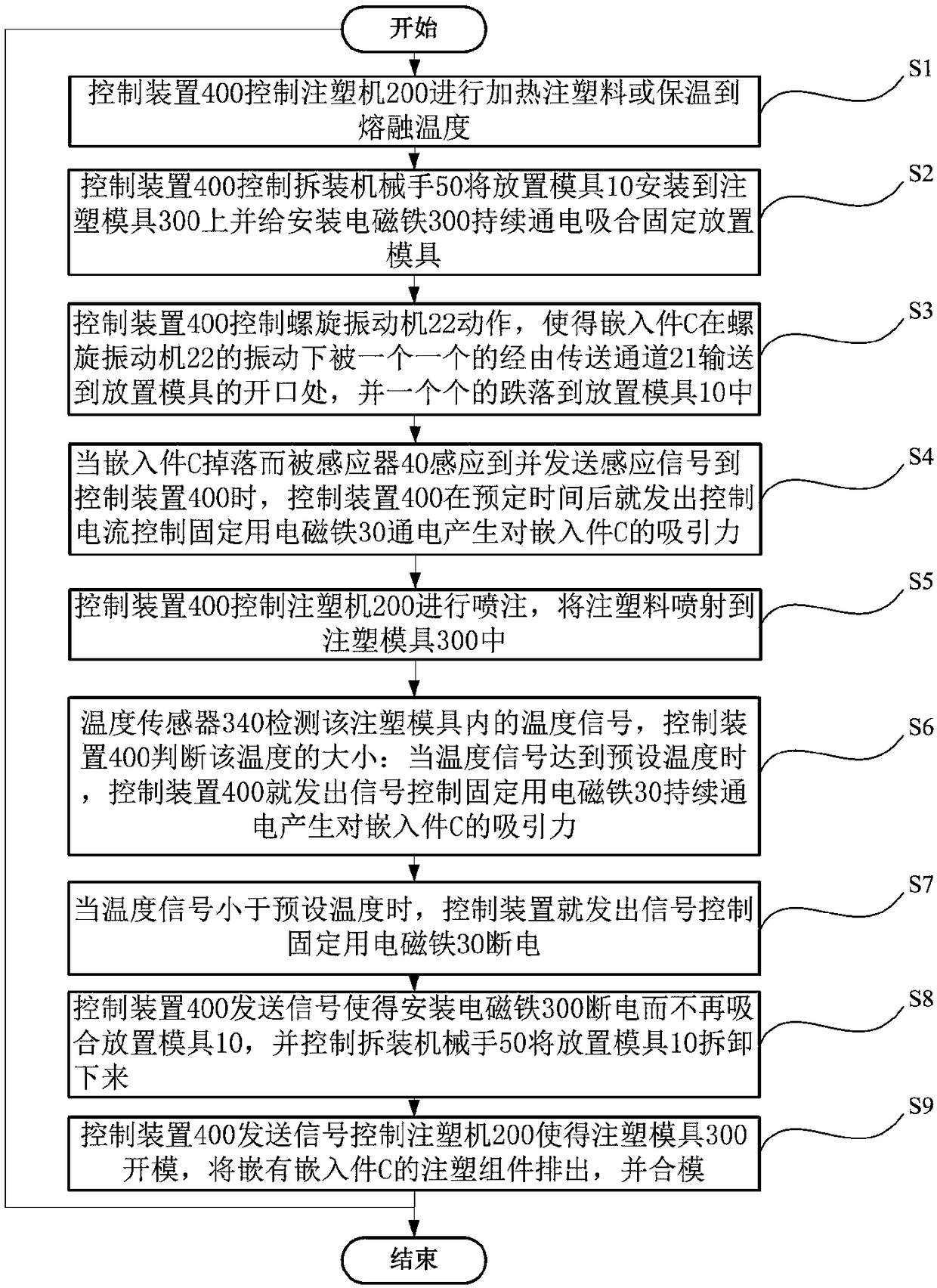

[0035] Such as figure 1 As shown, the injection molding component manufacturing system 1000 includes an insert placement device 100 , an injection molding machine 200 , an injection mold 300 connected to the injection molding machine, and a control device 400 .

[0036] The injection molding machine 200 is connected with the injection mold 300 and is used for heating the injection material and injecting the molten injection material into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com