Solar cell backboard

A technology for solar cells and backsheets, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low adhesion, coating peeling, and high water vapor permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

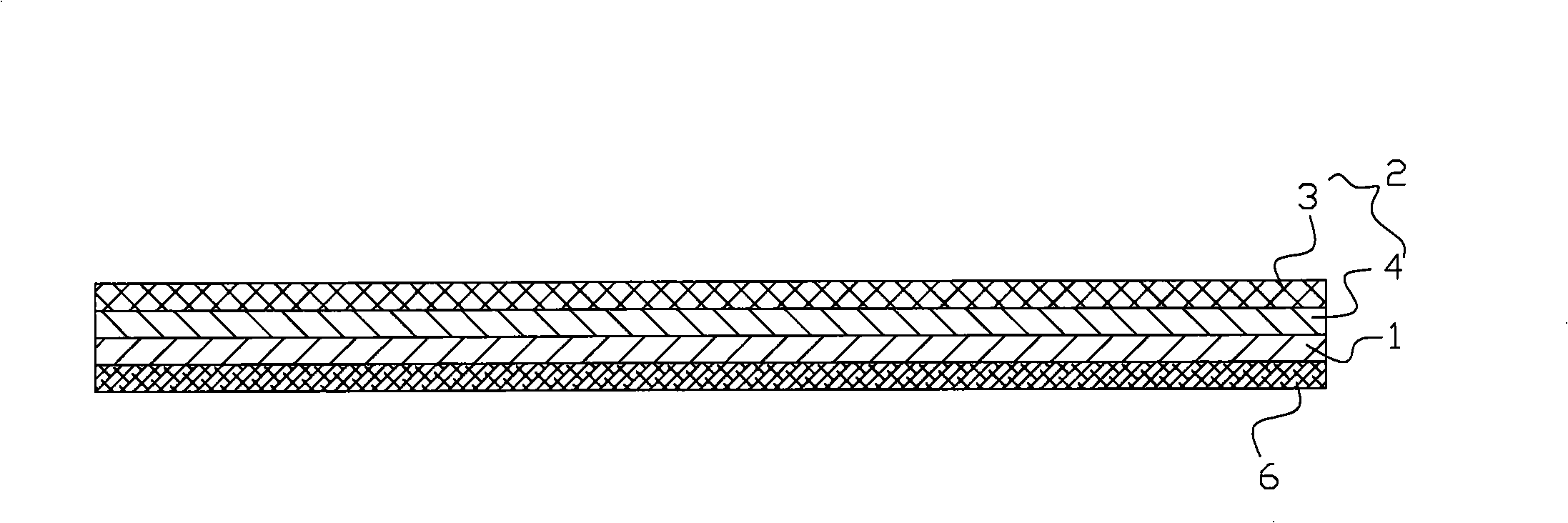

[0032] The structure of the solar battery back sheet in this embodiment is that both sides of the base layer 1 are coated with a protective layer 2, but the protective layer 2 at the bottom layer is only a layer of fluorine-containing film 6 directly covering the base layer 1, Its material is PVF. The protective layer 2 located on the surface is composed of an adhesive layer 4 and a fluorine-containing coating 3 .

[0033] In the present embodiment, the coating formula of adhesive layer 4 is as follows (mass parts):

[0034] Hydroxyl-containing polyester binder (XK-908, manufactured by Dalian Institute of Light Industry) 100;

[0035] Curing agent N3390 (manufactured by Bayer, Germany) 5;

[0036] Curing accelerator dibutyltin dilaurate 0.5;

[0037] Anti-hydrolysis stabilizer (P200, the Stabaxol series of German Rhine Company) 0.5;

[0038] Solvent butyl acetate 15;

[0039] Silane coupling agent NCO-C 3 h 6 -Si(OCH 3 ) 3 0.5.

[0040] The ...

Embodiment 2

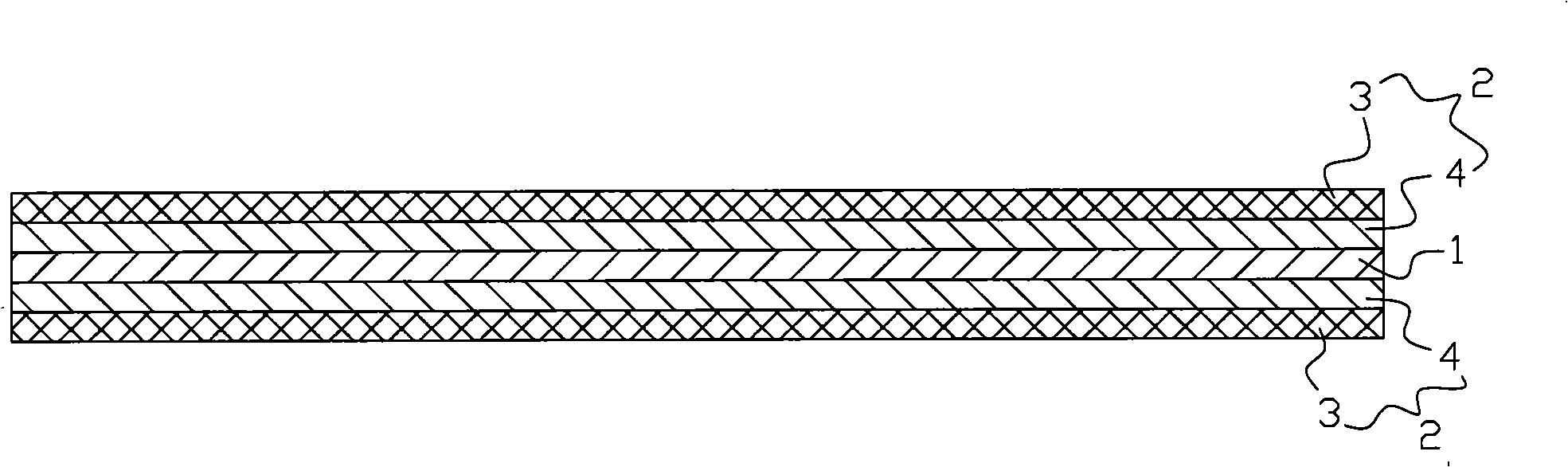

[0050] In this embodiment, the protective layer 2 on the surface layer and the bottom layer are both composed of an adhesive layer 4 and a fluorine-containing coating 3 . Wherein, the coating formulation of bonding layer 4 is as follows (mass parts):

[0051] Hydroxyl-containing acrylic adhesive (8723, manufactured by Nippon Synthetic Chemicals) 100;

[0052] Curing agent D201 (manufactured by Duo Naide) 5;

[0053] Curing accelerator dibutyltin dilaurate 0.5;

[0054] Anti-hydrolysis stabilizer (P200, the Stabaxol series of German Rhine Company) 0.5;

[0055] Solvent butyl acetate 15;

[0056] Silane coupling agent NCO-C 3 h 6 -Si(OCH 3 ) 3 0.5.

[0057] The manufacturing method of this embodiment is basically the same as that of Embodiment 1. After the protective layer 2 on the surface is prepared, the protective layer 2 on the bottom layer is prepared in the same way. Its structure is as attached figure 2 shown.

Embodiment 3

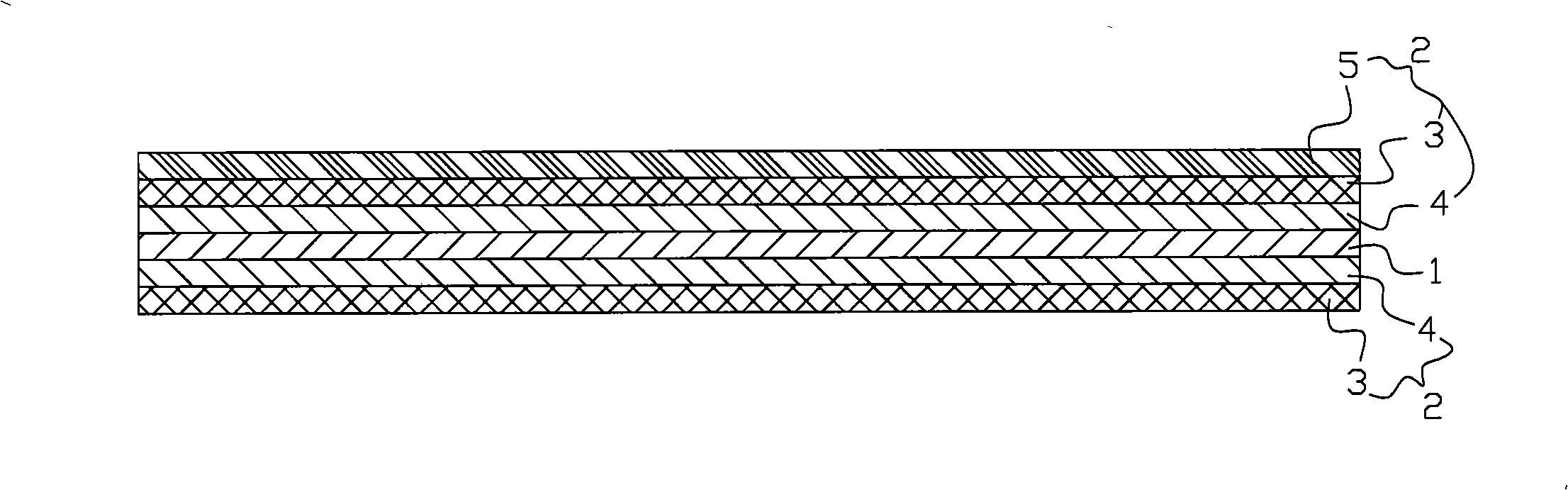

[0059] The difference between the present embodiment and embodiment 2 is that the coating formula of the adhesive layer 4 is as follows (mass parts):

[0060] Hydroxyl-containing polyester binder (TYA, manufactured by Shanghai Liri Technology) 100;

[0061] Curing agent V-05 (manufactured by Nisshinbo) 5;

[0062] Curing accelerator dibutyltin dilaurate 0.5;

[0063] Anti-hydrolysis stabilizer (P200, the Stabaxol series of German Rhine Company) 0.5;

[0064] Solvent butyl acetate 15;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com