Silicon rubber for encapsulating electronic tube and encapsulating method

A technology of silicon rubber and electronic tubes, applied in the field of electronic tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The silicone rubber for electronic tube potting described above, wherein the catalyst is dibutyltin dilaurate. The curing agent is ethyl orthosilicate.

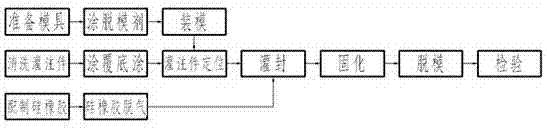

[0043] 2. The potting method of electron tube silicone rubber includes the following steps:

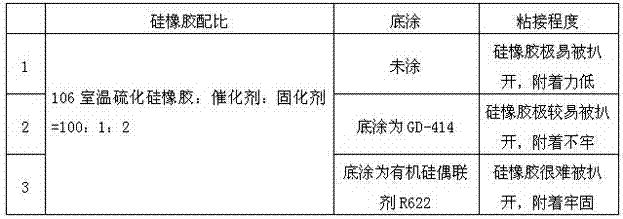

[0044] like figure 1 As shown, (1) clean the electronic tube perfusion part with ethanol, coat the silicone coupling agent primer on the surface of the electronic tube perfusion part, then coat the vaseline release agent on the surface of the potting mold, and then fix the electronic tube perfusion part on the potting in the mold;

[0045] (2) prepare silicone rubber with 100 parts by weight of 106 room temperature vulcanized silicone rubber, 1 part of catalyst, and 2 parts by weight of curing agent, then carry out degassing treatment to the prepared silicone rubber, and set aside;

[0046] (3) Slowly pour the silicone rubber degassed in step (2) into the potting mold in one direction, let it stand to solidify, and demould...

Embodiment 2

[0050]The above-mentioned silicone rubber for electronic tube potting, wherein the catalyst is dibutyltin dilaurate. The curing agent is ethyl orthosilicate.

[0051] 2. The potting method of electron tube silicone rubber includes the following steps:

[0052] like figure 1 As shown, (1) clean the electronic tube perfusion part with ethanol, coat the silicone coupling agent R622 primer on the surface of the electronic tube perfusion part, then coat the vaseline release agent on the surface of the potting mold, and then fix the electronic tube perfusion part on the potting In the sealing mold;

[0053] (2) Prepare silicone rubber with 110 parts of 106 room temperature vulcanized silicone rubber, 1.5 parts of catalyst, and 2 parts by weight of curing agent, then carry out degassing treatment to the prepared silicone rubber, and set aside;

[0054] (3) Then slowly potting the silicone rubber degassed in step (2) in the potting mold in one direction, let it stand to solidify, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com