Glue application and drying production line for soles

A production line and gluing technology, which is applied in footwear, bonding shoe parts, shoe-making machinery, etc., can solve the problems of high labor cost, low production efficiency, unstable quality, etc., to improve service life and quality, improve adhesion. The degree of firmness and the reduction of the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

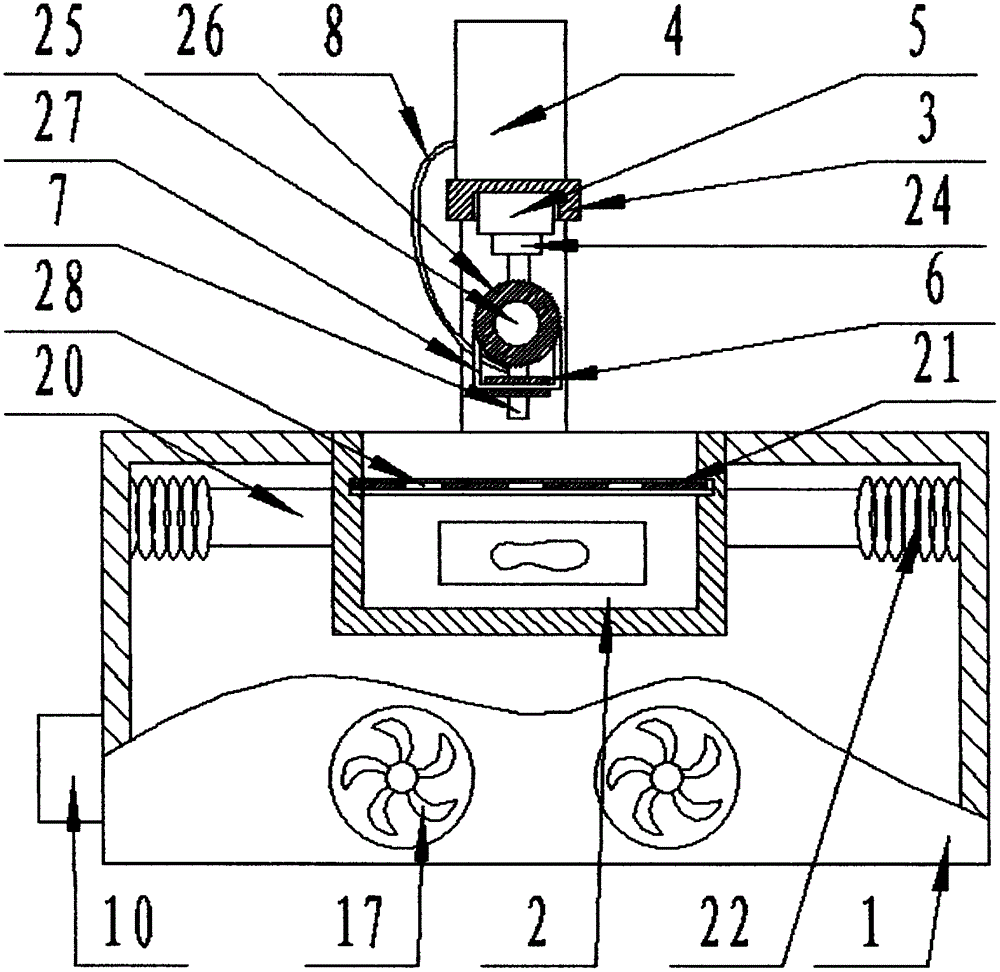

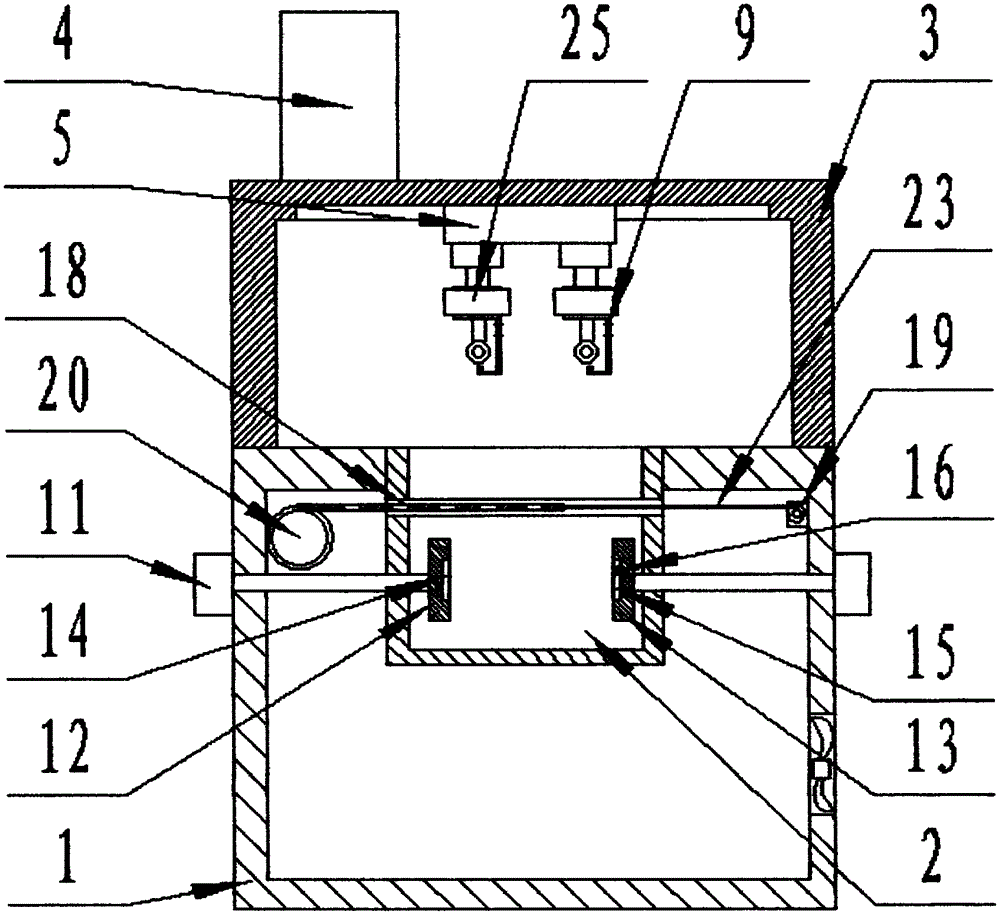

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a production line for gluing and drying shoe soles includes a workbench (1), the inside of the workbench (1) is a cavity structure, and the workbench (1) is provided with a rectangular working groove (2). The cavity structure is provided with a drying unit connected to the interior of the rectangular working tank (2), the workbench (1) is provided with a support beam (3), and the upper end of the support beam (3) is provided with a storage A rubber bucket (4), the support beam (3) is provided with a slideway, the slideway is provided with a hydraulic cylinder (5) that can move along its length direction, and the hydraulic cylinder (5) is provided with a glue coating unit, the rectangular working tank (2) is provided with a plurality of bonding units, and the gluing unit is a pair of telescopic arms fixedly installed on the hydraulic cylinder (5), resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com