Building material and preparation method thereof

A technology for building materials and raw materials, which is applied in the field of construction to achieve the effects of improving tensile strength, excellent thermal insulation and thermal stability, and improving the firmness of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

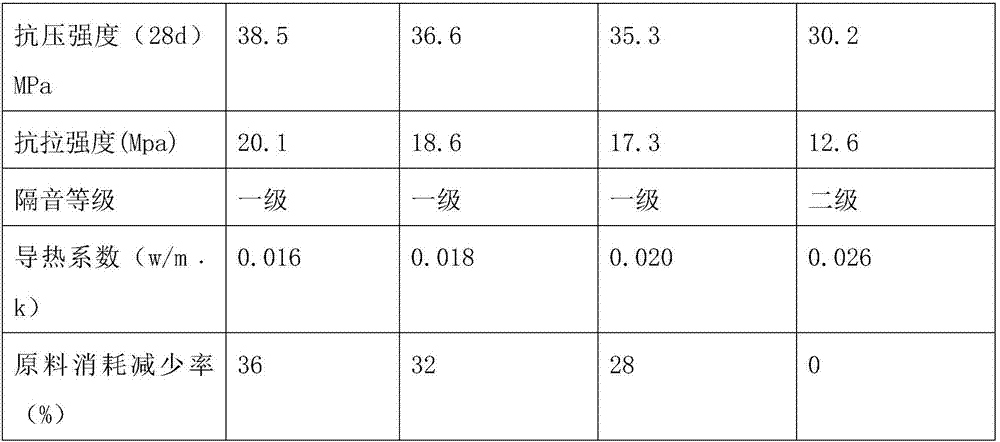

Embodiment 1

[0038] A building material comprising the following raw materials in parts by weight: 32.5kg of yellow sand, 25kg of expanded perlite, 27.5kg of polyphenylene particles, 26kg of polyurethane foam, 25kg of lime calcium powder, 17.5kg of quartz sand, 17kg of bentonite, and 20kg of aluminum silicate , stearic acid 13kg, sodium formate 7kg, synthetic fiber 11kg, cement 6kg, electric furnace slag powder 20kg, filler 12.5kg, retarder 0.4kg, water reducing agent 0.4kg and water 5 parts.

[0039] The building material prepared under the raw material formula has reached the best in terms of energy saving, environmental protection, sound insulation, tensile strength, compressive strength and thermal insulation.

[0040] Polyphenylene particles are added to the raw materials, which have the effect of heat preservation and heat insulation.

[0041] Polyurethane foam is added to the raw materials, and polyurethane foam has excellent elasticity, softness, expansion rate and thermal insulati...

Embodiment 2

[0056] A building material comprising the following raw materials in parts by weight: 25kg of yellow sand, 20kg of expanded perlite, 25kg of polystyrene particles, 24kg of polyurethane foam, 20kg of lime calcium powder, 15kg of quartz sand, 13kg of bentonite, 15kg of aluminum silicate, stearin 11kg of acid, 5kg of sodium formate, 8kg of synthetic fiber, 5kg of cement, 18kg of electric furnace slag powder, 10kg of filler, 0.2kg of retarder, 0.3kg of water reducing agent and 4kg of water.

[0057] Polyphenylene particles are added to the raw materials, which have the effect of heat preservation and heat insulation.

[0058] Polyurethane foam is added to the raw materials, and polyurethane foam has excellent elasticity, softness, expansion rate and thermal insulation performance.

[0059] Bentonite is added to the raw material, and the bentonite can be dispersed into a gelled state and a suspended state in the water medium, has a certain viscosity, and can improve the bonding fir...

Embodiment 3

[0073] A building material comprising the following raw materials in parts by weight: 40kg of yellow sand, 30kg of expanded perlite, 30kg of polystyrene particles, 28kg of polyurethane foam, 30kg of lime calcium powder, 20kg of quartz sand, 21kg of bentonite, 25kg of aluminum silicate, stearin 15kg of acid, 9kg of sodium formate, 14kg of synthetic fiber, 7kg of cement, 22kg of electric furnace slag powder, 15kg of filler, 0.6kg of retarder, 0.5kg of water reducing agent and 6kg of water.

[0074] Polyphenylene particles are added to the raw materials, which have the effect of heat preservation and heat insulation.

[0075] Polyurethane foam is added to the raw materials, and polyurethane foam has excellent elasticity, softness, expansion rate and thermal insulation performance.

[0076] Bentonite is added to the raw material, and the bentonite can be dispersed into a gelled state and a suspended state in the water medium, has a certain viscosity, and can improve the bonding fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com