Automatic footwear production line with saved use space

An automatic production line and footwear technology, applied in the direction of footwear, application, and bonding shoe parts, etc., can solve problems such as inaccurate positioning, glue spraying, and poor consistency of glue spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

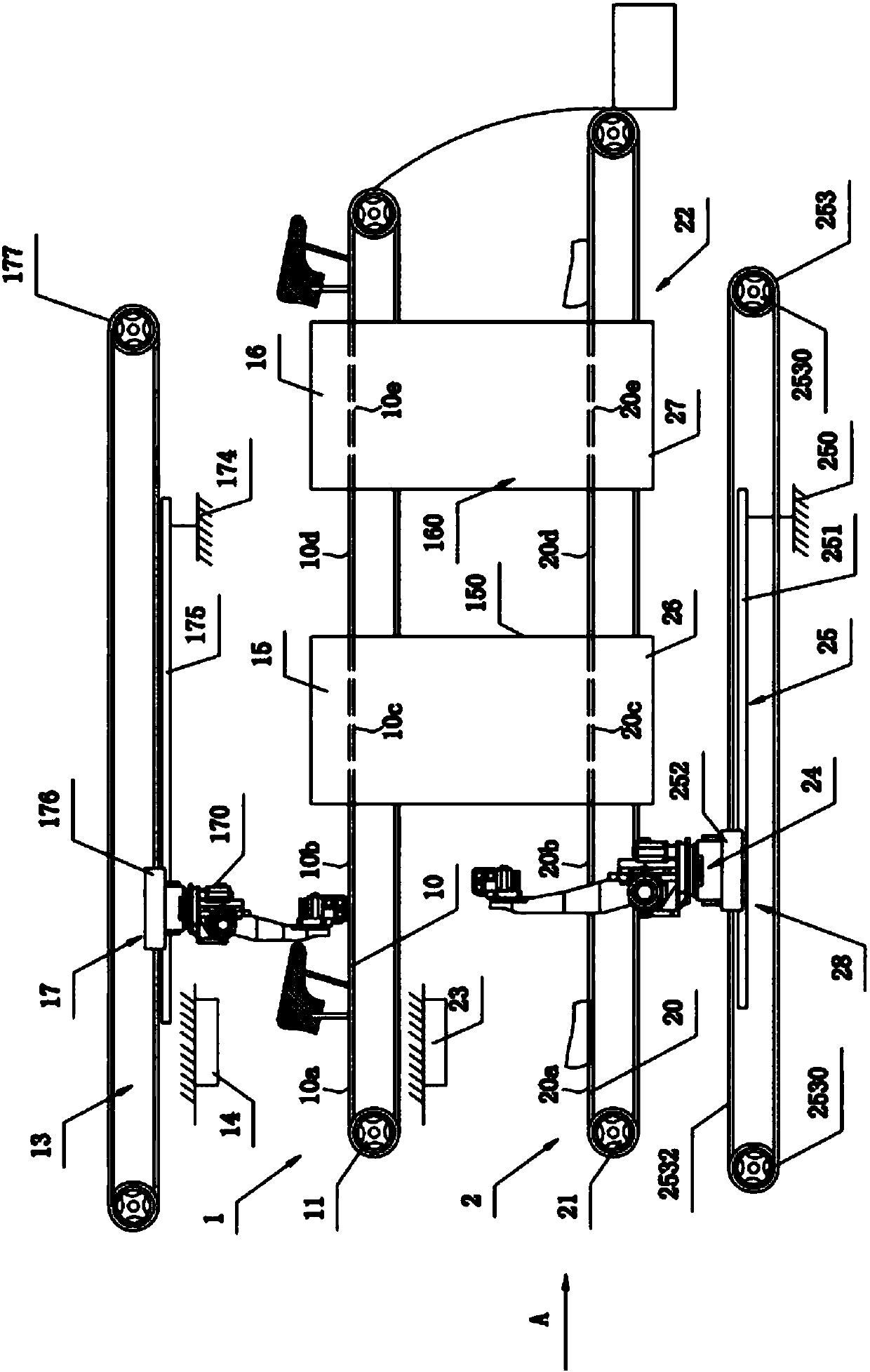

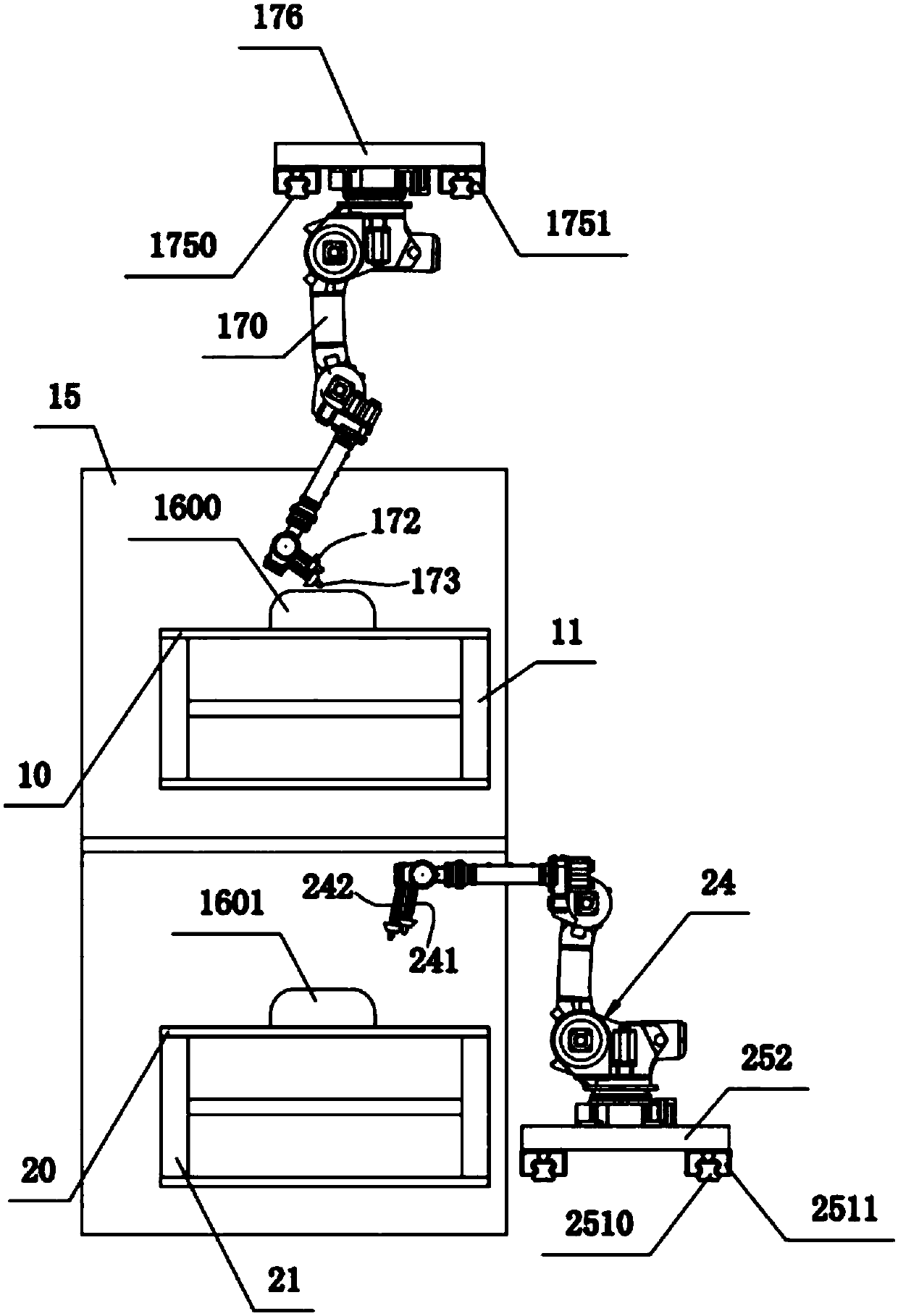

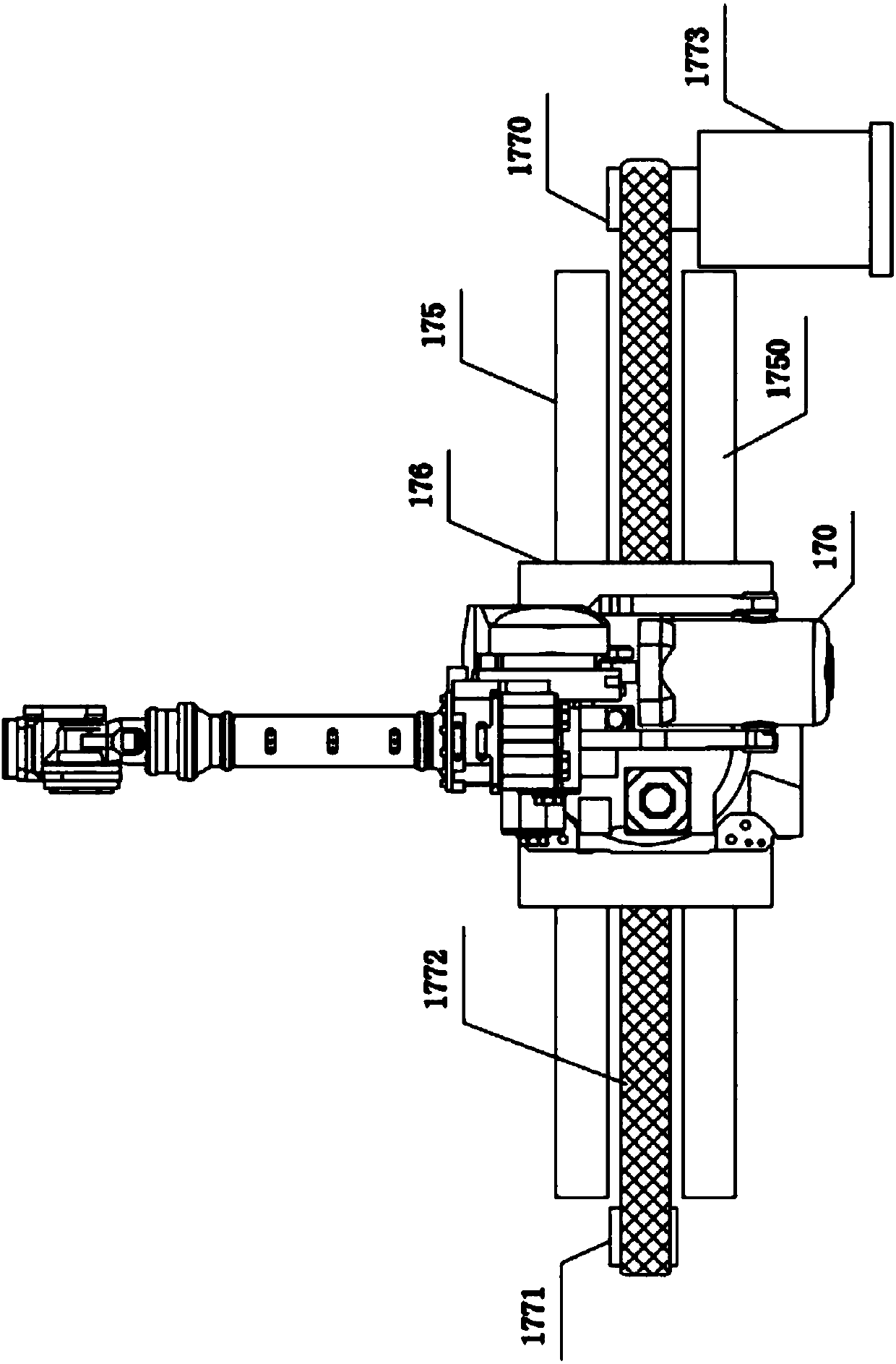

[0044] refer to figure 1 , figure 2 , image 3 and Figure 4 . A space-saving automatic production line for footwear, comprising an automatic vamp gluing device 1 and an automatic sole gluing device 2 located below the automatic vamp gluing device 1, the automatic vamp gluing device 1 and the automatic vamp gluing device 1 The sole automatic gluing device 2 is in the shape of a long strip, and is adjacently arranged up and down on the same vertical plane. The automatic shoe upper gluing device 1 includes a first conveyor belt 10, a first conveyor belt 10 that drives the first conveyor belt 10 to move at a uniform speed A driving assembly 11 and a first automatic glue spraying control assembly 13, above the first conveyor belt 10 are arranged successively adjacent three-dimensional scanning station 10a, first treatment water spraying station 10b, first treatment water drying station 10c, the first glue spraying execution station 10d and the first glue drying station 10e; t...

Embodiment 2

[0063] refer to Figure 5 and Figure 6 . This embodiment is substantially the same as the implementation of Embodiment 1, the difference is that the three-dimensional scanning mechanism 14 in this embodiment includes a shoe upper scanning unit 140, an image processing unit 141, a data acquisition unit 142 and a model generation unit 143, the shoe upper scanning unit 140 is used to take images of the top side of the shoe upper, the left side of the shoe upper, and the right side of the shoe upper, which includes a gantry-shaped bracket arranged at the shoe upper scanning position on the first conveyor belt 10 144, two first cameras 145 are installed on the top of the gantry-shaped support 144, two second cameras 146 are installed on the lower left, two third cameras 147 are installed on the lower right, and the two first cameras 145 are all aimed at the top side of the vamp and are correspondingly used to collect the top side images of the two vamps; the two second cameras 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com