Pressure flange

A pressure method, annular groove technology, applied in flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of medium leakage, decreased pipe hardness, easy pipe breakage, etc. Increased connection firmness and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

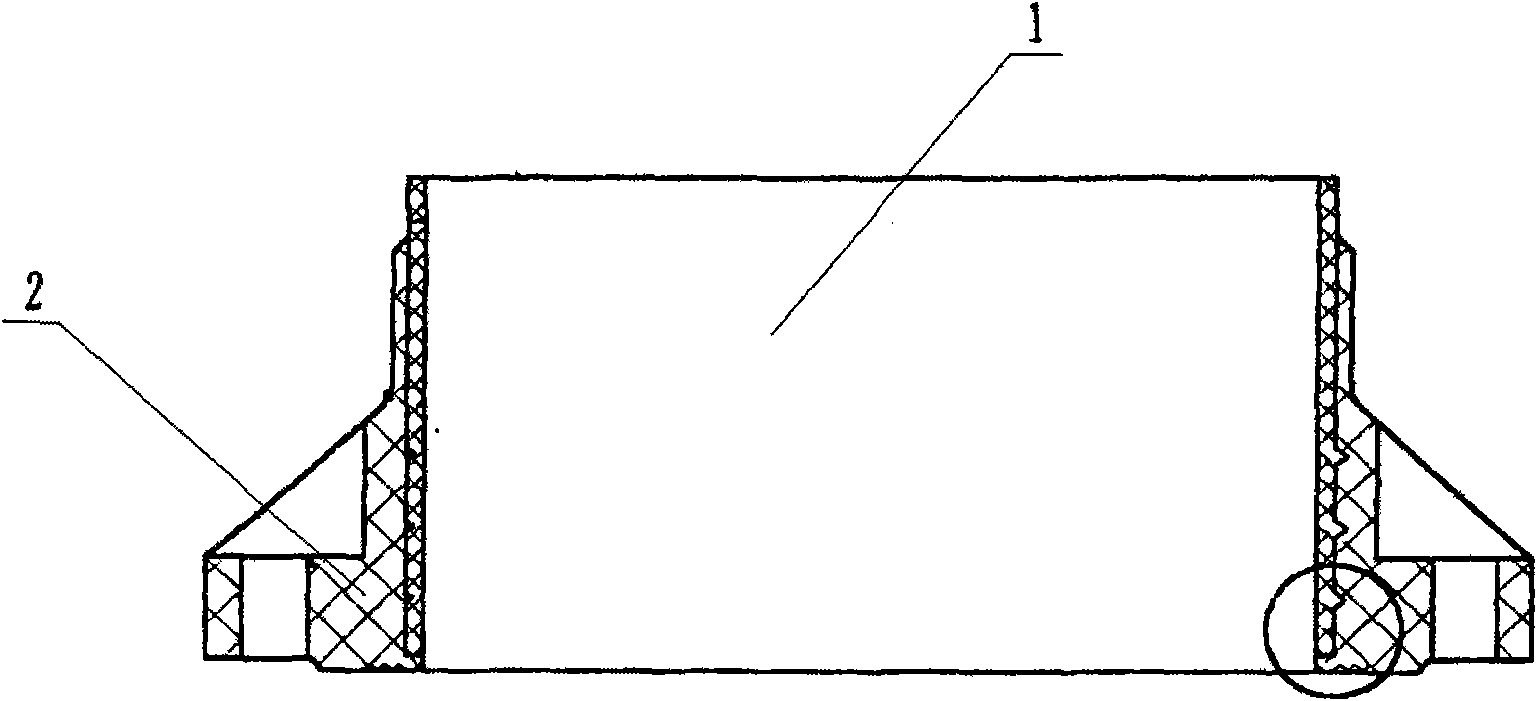

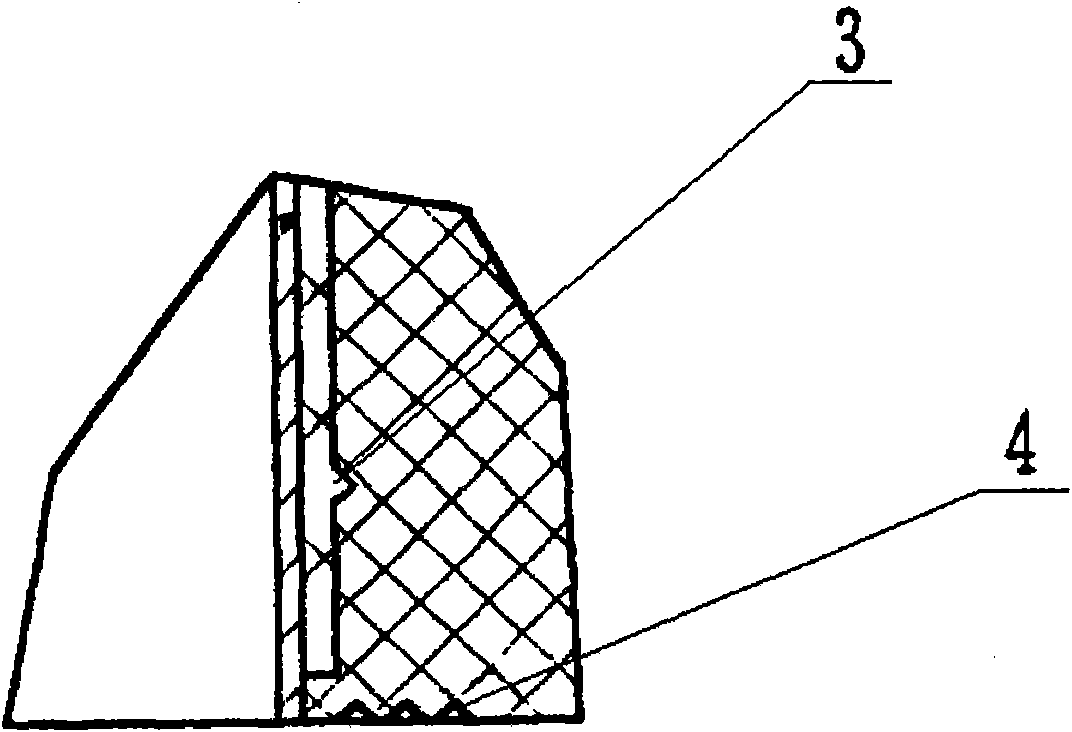

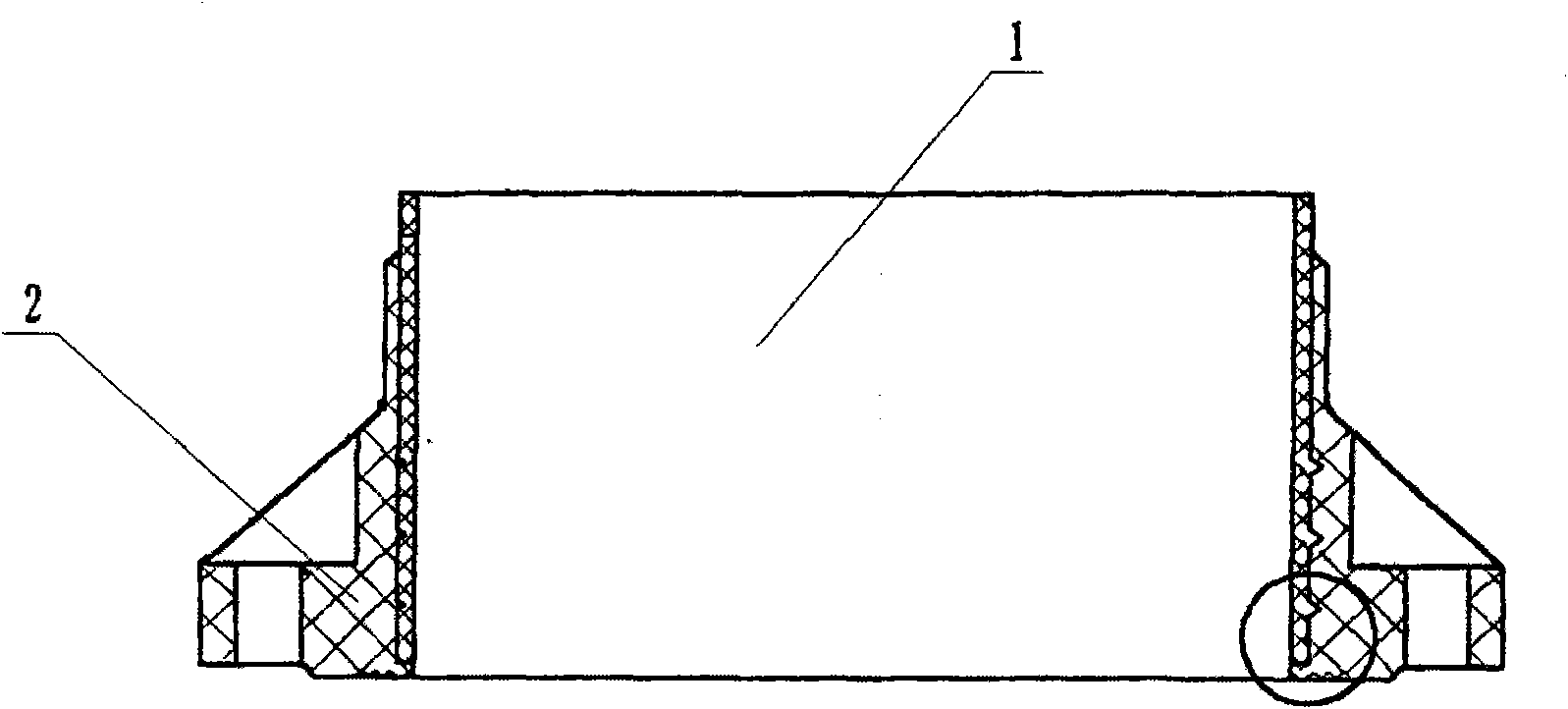

[0018] according to figure 1 , 2 It can be seen that the pressure flange of the present invention includes a pipeline 1 and a flange 2 connected to the outer periphery of the pipeline 1. The inner circumference of the flange 2 is provided with an annular groove 3; the working surface of the flange 2 is There are at least two annular grooves 4 centered on the pipe 1 on the surface; the annular grooves 4 are concentrically distributed with the pipe 1 as the center; the planes formed by the annular grooves 3 are parallel to each other and distributed at equal intervals ; The longitudinal section shape of the annular grooves 3 and 4 is an isosceles triangle. The outer circumference of the pipe and the flange, and the working surface of the flange are fixedly connected by bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com