Rubber tube extrusion device and method

A technology of extrusion device and rubber tube, applied in the field of rubber tube extrusion device, can solve problems such as affecting the processing efficiency of rubber tube, and achieve the effects of facilitating molding processing, improving processing efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

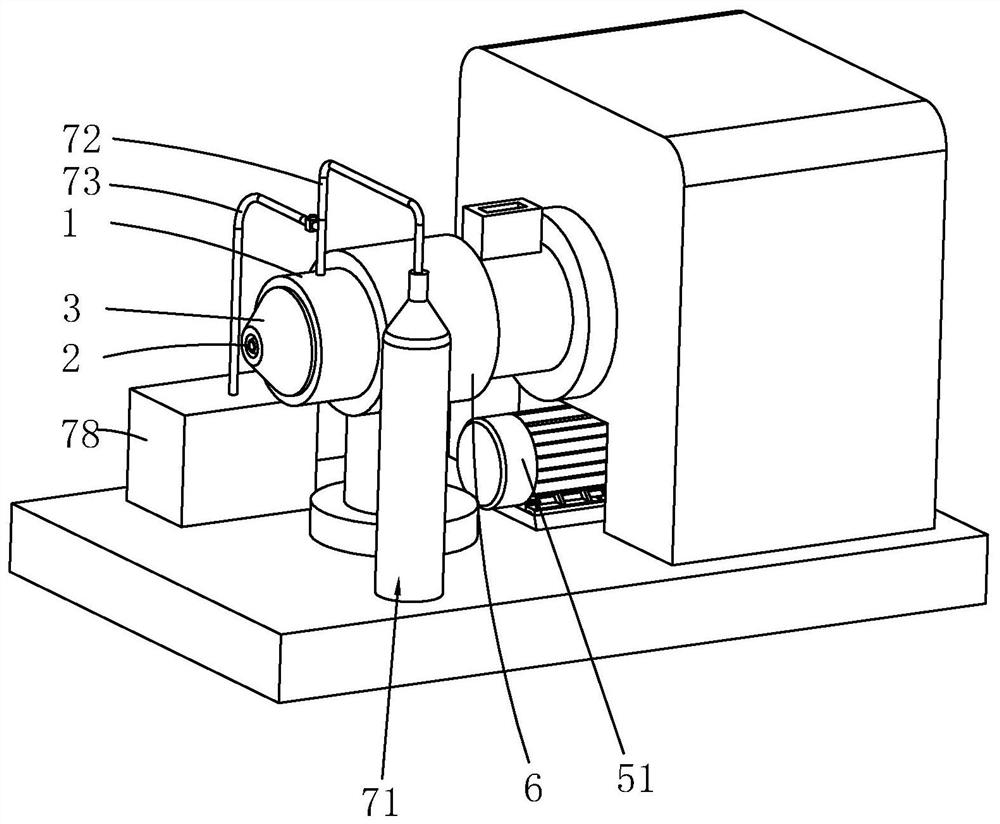

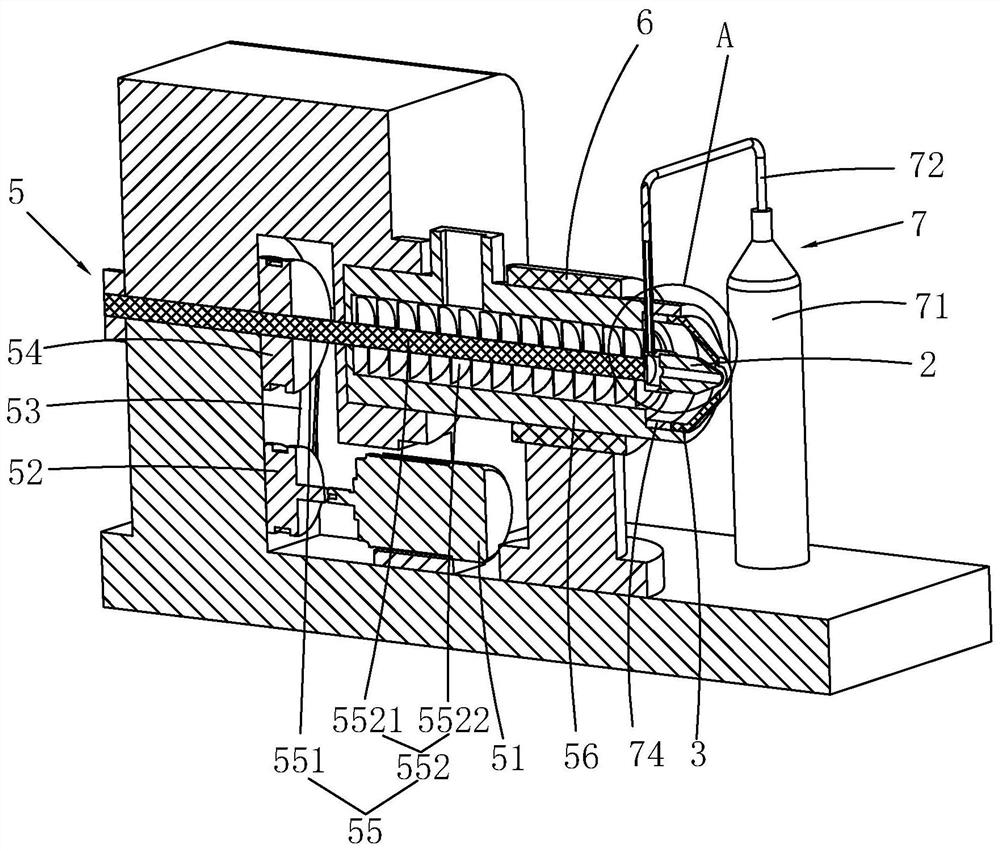

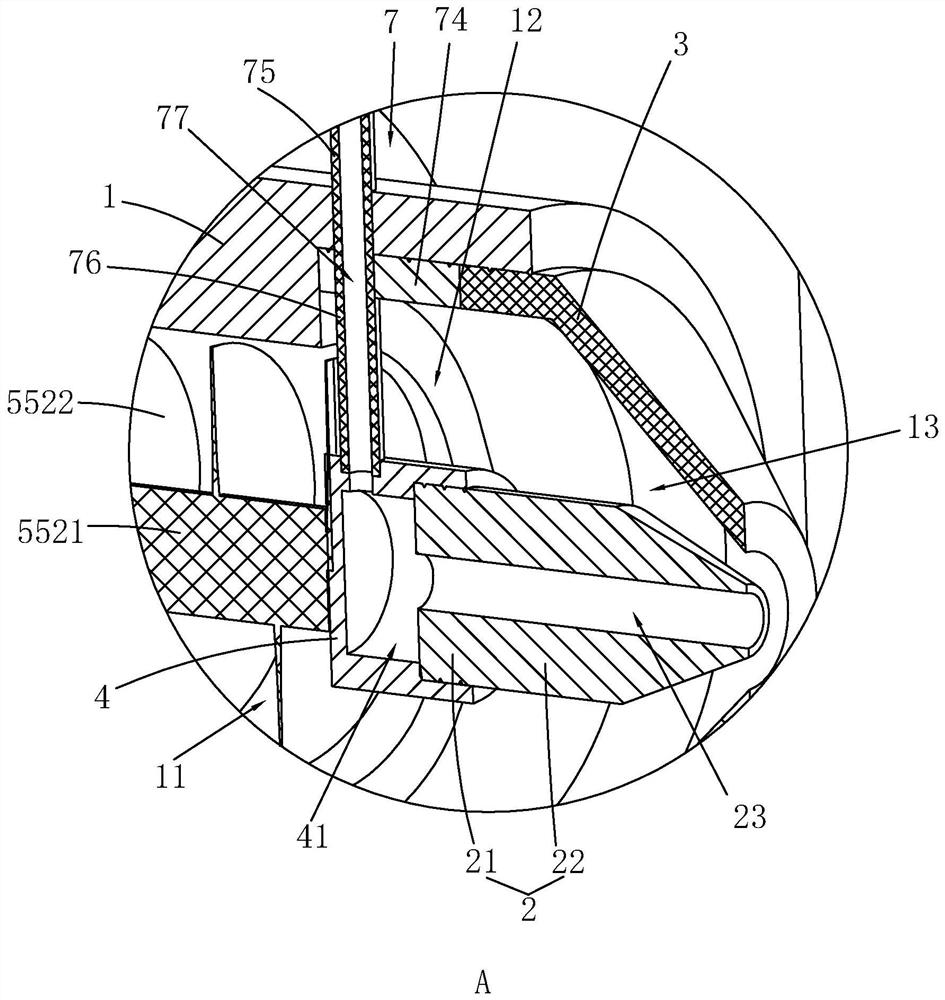

[0036] The following is attached Figure 1-3 The application is described in further detail.

[0037] The embodiment of the present application discloses a rubber hose extruding device and method. refer to figure 1 and figure 2, The rubber hose extrusion device includes a fuselage 1, a core 2, a die 3, an installation collar 4, an extrusion mechanism 5 for extruding materials, a heating mechanism 6 for heating materials, and a cooling mechanism for cooling the rubber hose And the connection mechanism 7 for connecting the core 2 and the installation collar 4; the heating mechanism 6, the extrusion mechanism 5, the connection mechanism 7 and the cooling mechanism are all located on the fuselage 1; the core 2, the die 3 and the installation collar 4 are set close to the discharge port of the fuselage 1, the die 3 and the installation collar 4 are coaxially arranged, a transition cavity 12 for the material to pass is arranged between the core 2 and the installation collar 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com