Production method and processing mold of PVC co-extrusion stone plastic profiled material

A technology for processing molds and production methods, applied to the production method of PVC co-extruded stone-plastic profiles and the field of processing molds, can solve the problem of poor surface friendliness of pure stone-plastic materials, high hardness and short service life of pure stone-plastic materials, etc. problems, to achieve the effect of enhanced surface friendliness, enhanced surface strength, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The production method of PVC co-extruded stone-plastic profiles, the process steps are as follows:

[0038] (1) Add PVC stone plastic to the mixer according to the formula ratio, heat up to 110 degrees by material self-friction, then cool to 40 degrees by condenser and then add to the main hopper;

[0039] (2) Add the PVC material to the mixer according to the formula ratio, heat up the material to 110 degrees by self-friction, then cool it to 40 degrees by the condenser and then add it to the auxiliary hopper;

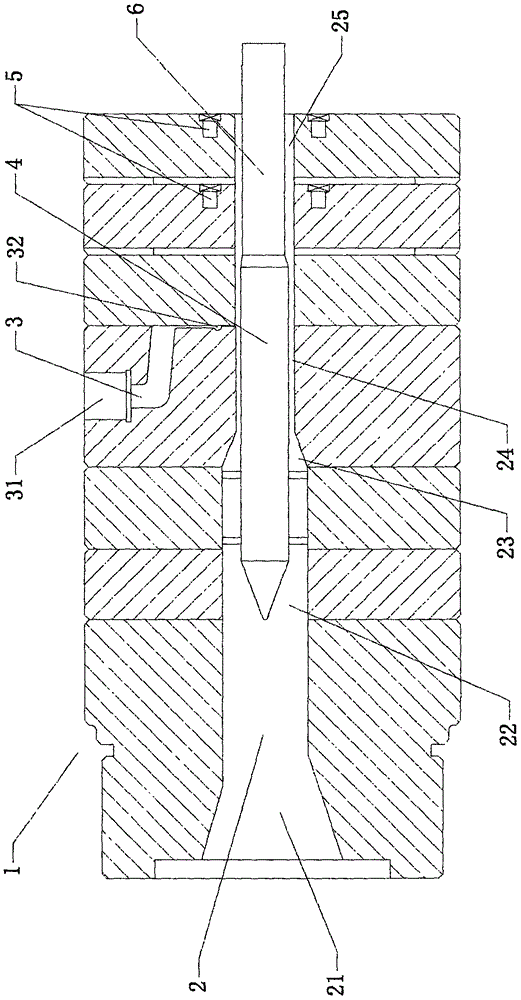

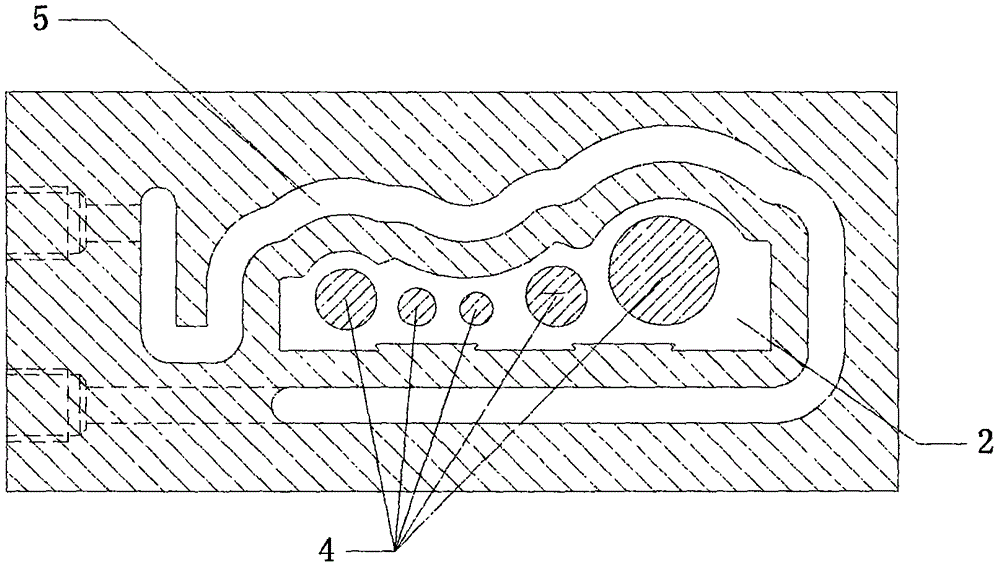

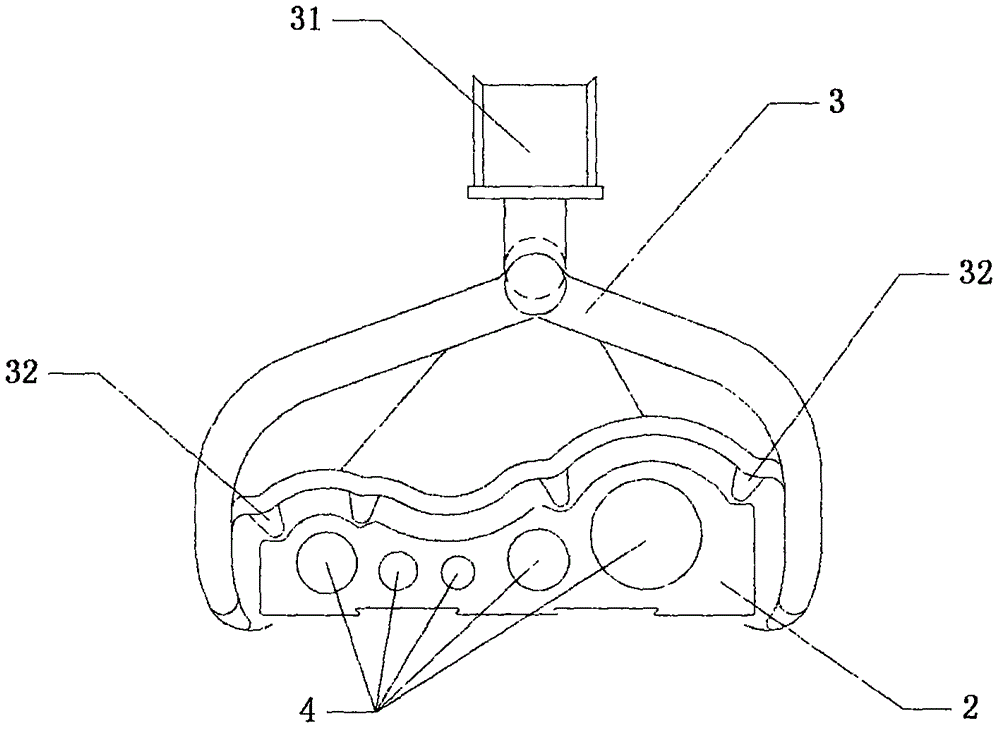

[0040] (3) PVC stone plastic is extruded by an extruder and pressed into the PVC stone plastic feed port of the processing mold to realize compaction, melting, mixing and homogenization, and form a core in the processing mold. At the same time, the PVC material is also extruded Extrude into the PVC material inlet of the processing mold, and coat the outer layer of the formed core; the screw temperature of the extruder is 85 degrees, and the extrusion pressure i...

Embodiment 2

[0050] The production method of PVC co-extruded stone-plastic profiles, the process steps are as follows:

[0051] (1) Add PVC stone plastic to the mixer according to the formula ratio, heat up to 120 degrees by material self-friction, then cool to 45 degrees by condenser and then add to the main hopper;

[0052] (2) Add the PVC material to the mixer according to the formula ratio, heat up the material to 120 degrees by self-friction, then cool it to 45 degrees by the condenser and then add it to the auxiliary hopper;

[0053] (3) PVC stone plastic is extruded by an extruder and pressed into the PVC stone plastic feed port of the processing mold to realize compaction, melting, mixing and homogenization, and form a core in the processing mold. At the same time, the PVC material is also extruded Extrude into the PVC material inlet of the processing mold, and coat the outer layer of the formed core; the screw temperature of the extruder is 90 degrees, and the extrusion pressure is ...

Embodiment 3

[0063] The production method of PVC co-extruded stone-plastic profiles, the process steps are as follows:

[0064] (1) Add PVC stone plastic to the mixer according to the formula ratio, heat up to 130 degrees through material self-friction, and then add it to the main hopper after being cooled to 50 degrees by the condenser;

[0065] (2) Add the PVC material into the mixer according to the formula ratio, heat up to 130 degrees through material self-friction, and then add the auxiliary hopper after being cooled to 50 degrees by the condenser;

[0066] (3) PVC stone plastic is extruded by an extruder and pressed into the PVC stone plastic feed port of the processing mold to realize compaction, melting, mixing and homogenization, and form a core in the processing mold. At the same time, the PVC material is also extruded Extrude into the PVC material inlet of the processing mold, and coat the outer layer of the formed core; the screw temperature of the extruder is 95 degrees, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com