Easy-to-unwind self-adhesive protection film and preparation method thereof

A technology of self-adhesive protective film and protective film, which is applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc. Pollution, film stretching deformation and other problems, to achieve excellent water and oxygen barriers, to solve pollution or residue, and the effect of large property differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

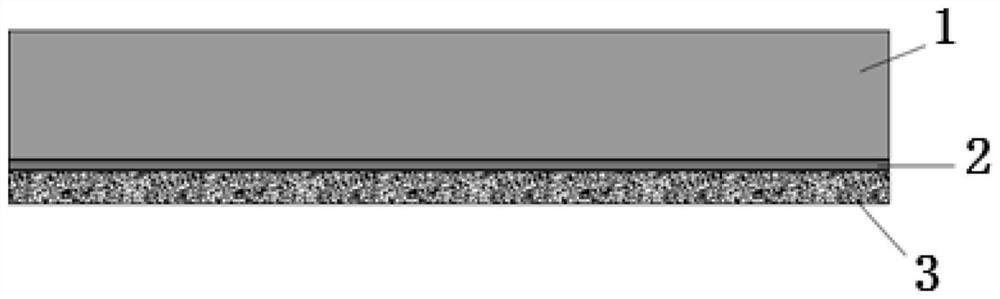

[0043] This embodiment provides an easy-to-unwind co-extrusion self-adhesive protective film, which is composed of the following three-layer structure in order, and the specific components are shown in Table 1.

[0044] Table 1:

[0045]

[0046]

[0047] The preparation method of present embodiment protective film is:

[0048] 1) The preparation of the modified polyolefin material is as follows: weigh the above-mentioned components according to the weight part, mix them evenly in a high-speed mixing pot, put them into a twin-screw extruder for melt extrusion and granulation, and obtain the modified polyolefin material for the support layer. and the working parameters of the twin-screw are: twin-screw length-to-diameter ratio of 28:1–65:1, screw diameter of 35mm, temperature of 130°C, screw speed of 500rpm / min; modified polyolefin The melt flow rate was 3.5 g / 10 min.

[0049] 2) The materials of each layer are mixed evenly and then added to the three-layer co-extrusion...

Embodiment 2

[0051] This embodiment provides an easy-to-unwind co-extruded self-adhesive protective film, which is composed of the following three-layer structures in order, as shown in Table 2 below:

[0052] Table 2:

[0053]

[0054]

[0055] The preparation method of present embodiment protective film is:

[0056] 1) The preparation of the modified polyolefin material is as follows: weigh the above-mentioned components according to the weight part, mix them evenly in a high-speed mixing pot, put them into a twin-screw extruder for melt extrusion and granulation, and obtain the modified polyolefin material for the support layer. and the working parameters of the twin-screw are: twin-screw length-to-diameter ratio of 28:1–65:1, screw diameter of 65mm, temperature of 180°C, screw speed of 300rpm / min; modified polyolefin The melt flow rate was 12.8 g / 10 min.

[0057] 2) The materials of each layer are mixed evenly and then added to the three-layer co-extrusion blown film equipment....

Embodiment 3

[0059] This embodiment provides an easy-to-unwind co-extruded self-adhesive protective film, which is composed of the following three-layer structures in order, as shown in Table 3 below:

[0060] table 3:

[0061]

[0062] The preparation method of present embodiment protective film is:

[0063] 1) The preparation of the modified polyolefin material is as follows: weigh the above-mentioned components according to the weight part, mix them evenly in a high-speed mixing pot, put them into a twin-screw extruder for melt extrusion and granulation, and obtain the modified polyolefin material for the support layer. and the working parameters of the twin-screw are: the aspect ratio of the twin-screw is 28:1-65:1, the screw diameter is 75mm, the temperature is 250°C, and the screw speed is 300rpm / min; the melt flow rate is 10g / 10min.

[0064] 2) Stir the materials of each layer evenly and add them to the three-layer co-extrusion blown film equipment. The thickness ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com