Rapid compounding repair method of pavement

A composite repair and rapid technology, applied in the field of road repair, can solve the problems of easy aging and shedding, large differences in elastic modulus and thermal expansion coefficient, and achieve the effect of good fluidity, high strength and bonding strength, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A rapid composite repair method for pavement, comprising:

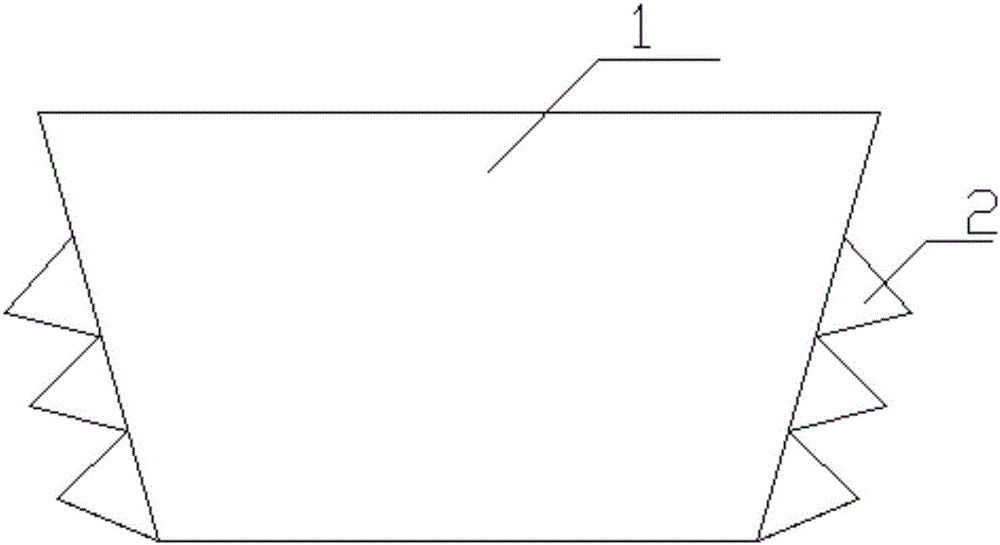

[0026] 1) Crushing the cracks or pits on the concrete pavement to form a pit 1 with a four-sided platform structure with a large upper part and a smaller one at the bottom, so that the previous cracks or pits are in the cracked pit 1 after treatment, and the size of the pit 1 is larger than Cracks or potholes will do. Preferably, when the treated road surface is a pit, the volume of the seam pit 1 is twice the volume of the pit; when the treated road surface is a crack, the side length of the upper surface of the seam pit 1 is 1.5 times the length of the longer side of the crack, The depth of pit 1 is 1.5 times the depth of the crack. One of the opposite sides of the bottom surface of the seam pit 1 is the same as the driving direction, and the angle between any side of the seam pit 1 and the bottom surface of the seam pit 1 is 110°, and the two sides of the seam pit 1 parallel to the driving direction are com...

Embodiment 2

[0033] A rapid composite repair method for pavement, comprising:

[0034] 1) Break the cracks on the concrete pavement to form a seam pit with a large and small four-sided platform structure. One of the opposite sides of the bottom of the seam pit is the same as the driving direction, and the side of any seam pit is the same as the bottom surface of the seam pit. The included angles are all 130°, and the two sides of the seam pit parallel to the driving direction are symmetrically dug from bottom to top with four sequentially connected grooves. The grooves have a regular triangular prism structure, and the grooves are triangular. The surface is perpendicular to the direction of travel. After completing the above operations, it is necessary to keep the seam pit clean and dry, so that the grouting material can be fully combined with the seam pit to be repaired to avoid the problem of falling off.

[0035]2) On the other two sides of the seam pit, there are at least two inserts ...

Embodiment 3

[0039] A grouting material, in parts by weight, the preparation method of which is as follows: 100 parts of cement, 19 parts of diatomite, 160 parts of the first rock sand, 0.4 parts of molasses retarder, 1.5 parts of water reducer, lithium chloride (Increased strength agent) 9 parts and 3 parts of coagulant accelerator are mixed evenly, according to the water-cement ratio 0.25:1, add water and stir in a forced mixer for 2 minutes. Wherein, the first rock sand is composed of arsenic sandstone, coal gangue, pyroclastic rock, light silicomanganese slag, bentonite, closed-cell perlite and pearl sand according to the quality of 25:19:20:10:6:6:7 Coordinated. The water reducer is made of melamine, zinc borate, propylene glycol alginate, polysilicic iron sulfate and corn starch in a mass ratio of 20:5:4:2:3, and the coagulant is a particle size less than 3um Calcium hydroxide particles. In this embodiment, the following raw materials can be within the set particle size range. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com