Process of making PVC mosaic floor

A manufacturing method and technology for floor mats, applied in the field of floor mat manufacturing, can solve the problems of poor pattern color effect, dull visual effect, easy decolorization of floor mats, etc., and achieve the effects of good decorative effect, rich patterns and strong stereoscopic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

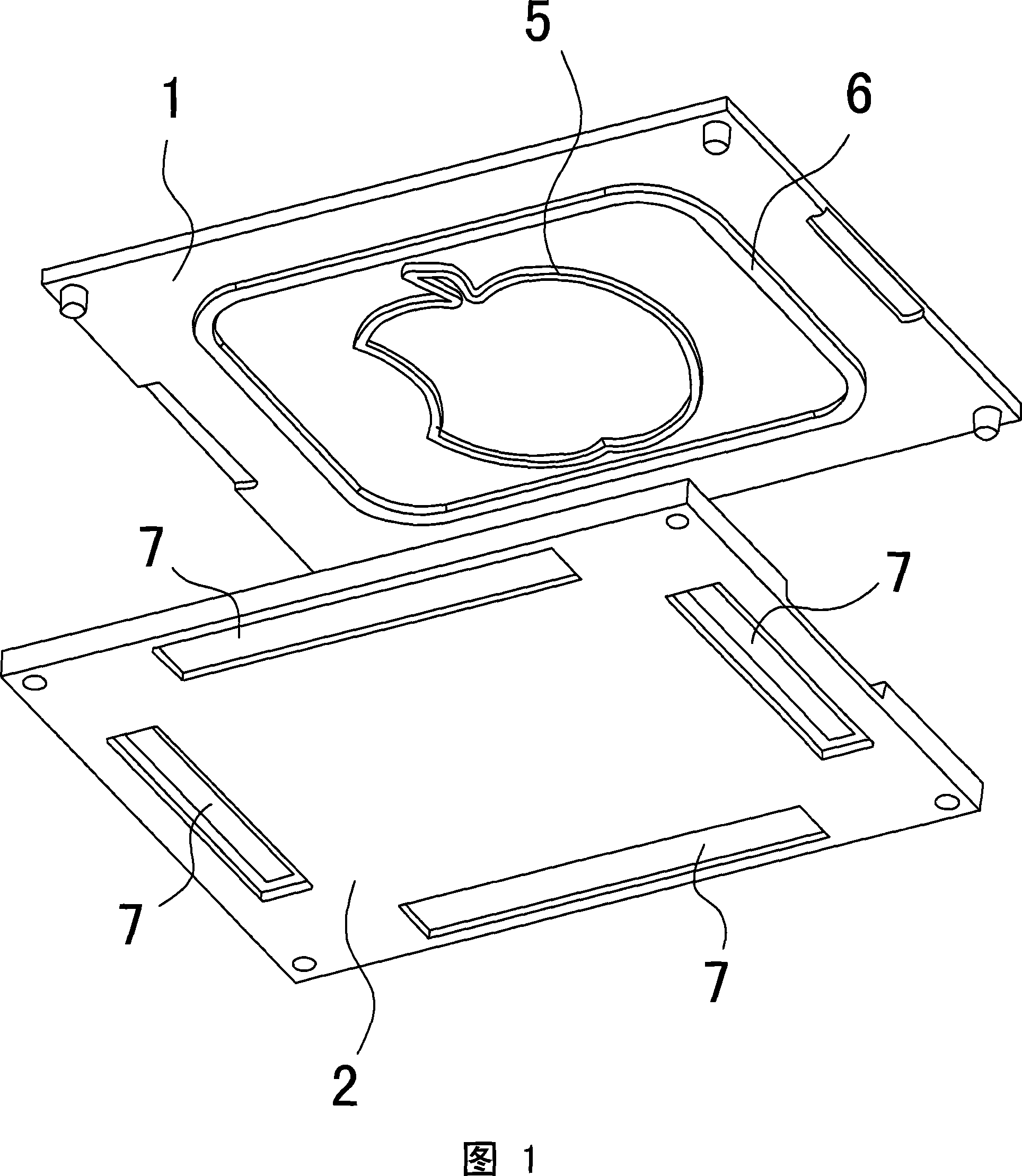

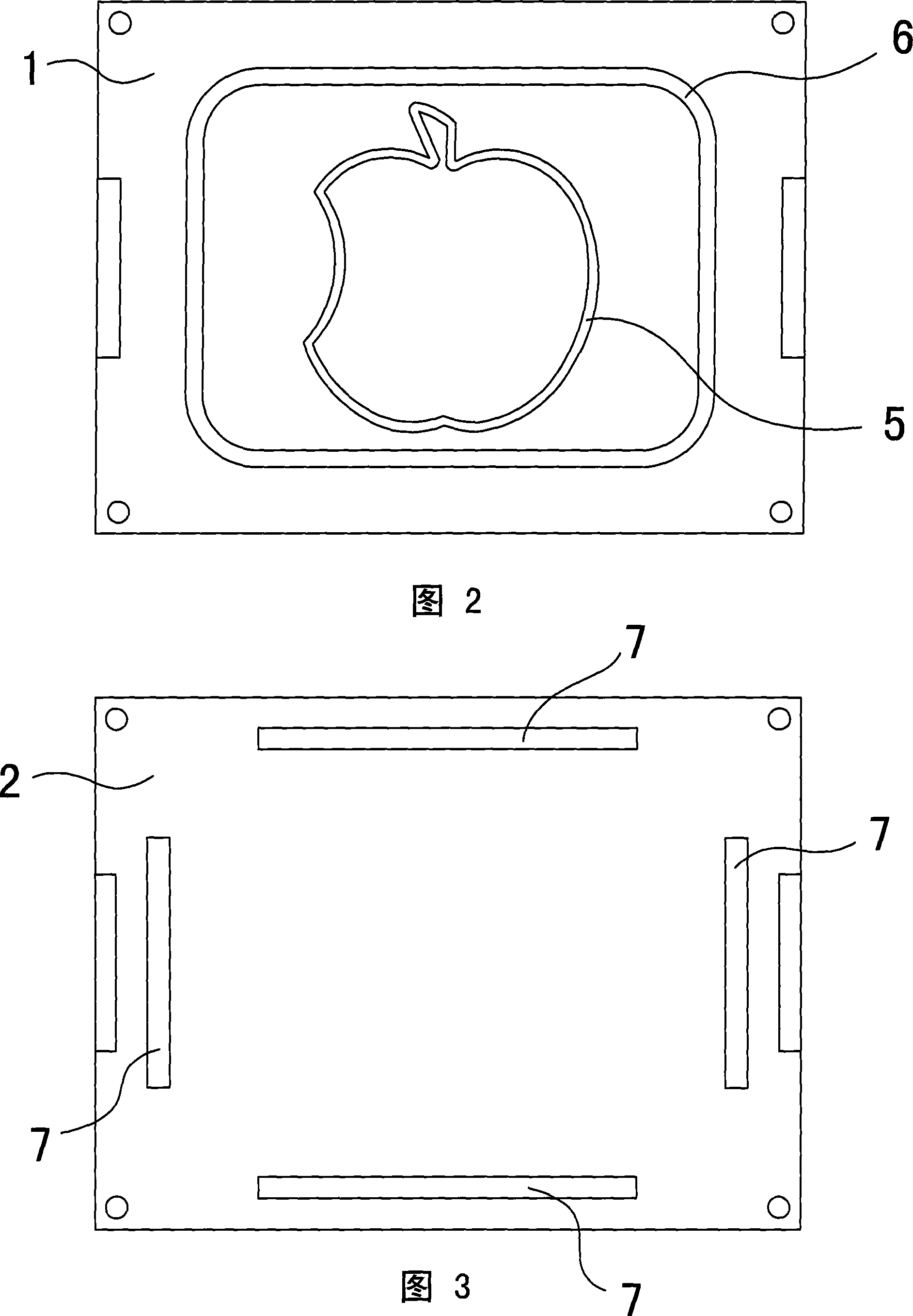

[0041] Embodiment 1: A manufacturing method of a PVC jigsaw puzzle floor mat, as shown in Figure 4, with two different natural colors of PVC winding layers 3 as objects, wherein 8 represents color A, and 9 represents color B, according to the following process route Carry out: PVC winding layer→knife die stamping and cutting→exchange jigsaw puzzle→configure the bottom layer→ultrasonic pressure welding seam→hot melt bonding→post-processing. The specific steps and content are as follows:

[0042] (1), Die stamping and cutting

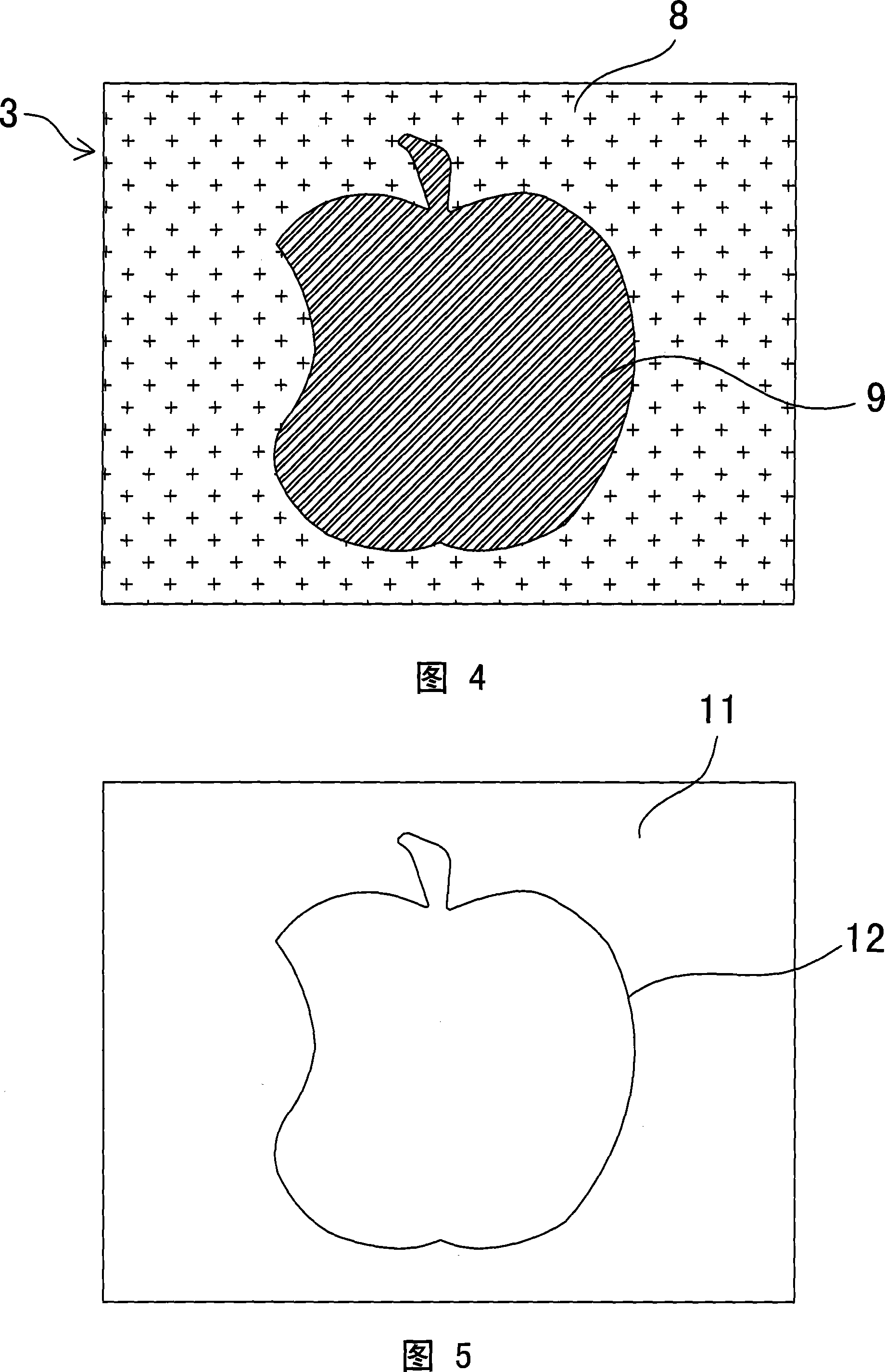

[0043] Place the PVC winding layers 3 of two different natural colors of A color 8 and B color 9 respectively on the worktable, punch and cut them with a knife template 11 (shown in Figure 5 ) with the same pattern, and divide it into solid pattern parts and Cutout pattern part. Stamping can adopt hydraulic cutting machine to carry out overall one-time cutting, and the pressure and stroke of stamping can be determined according to the thickness and stre...

Embodiment 2

[0054] Embodiment 2: A manufacturing method of a PVC jigsaw puzzle floor mat, as shown in FIGS. Means A color, 9 means B color, 10 means C color. In this embodiment, the whole apple is divided into a picture of the apple itself represented by B color 9 and an apple handle picture represented by C color 10 . Using a knife template 11 with the same pattern (see FIG. 8 ) to stamp and cut the PVC winding layers 3 of three different natural colors, then exchange the three solid patterns with each other, and flatly assemble them into the hollow patterns of different natural colors. Make a pattern. Others are the same as the first embodiment, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com