Colour forming device, manufacturing method thereof, electronic product and vehicle

A manufacturing method and color-generating technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high production cost and application limitations, and achieve the effects of low production cost, wide application, and rich and diverse color changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

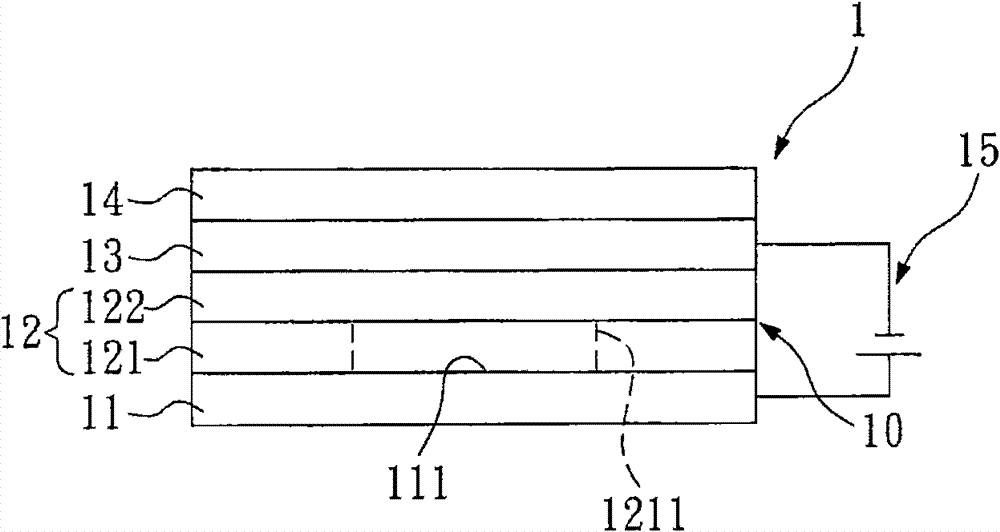

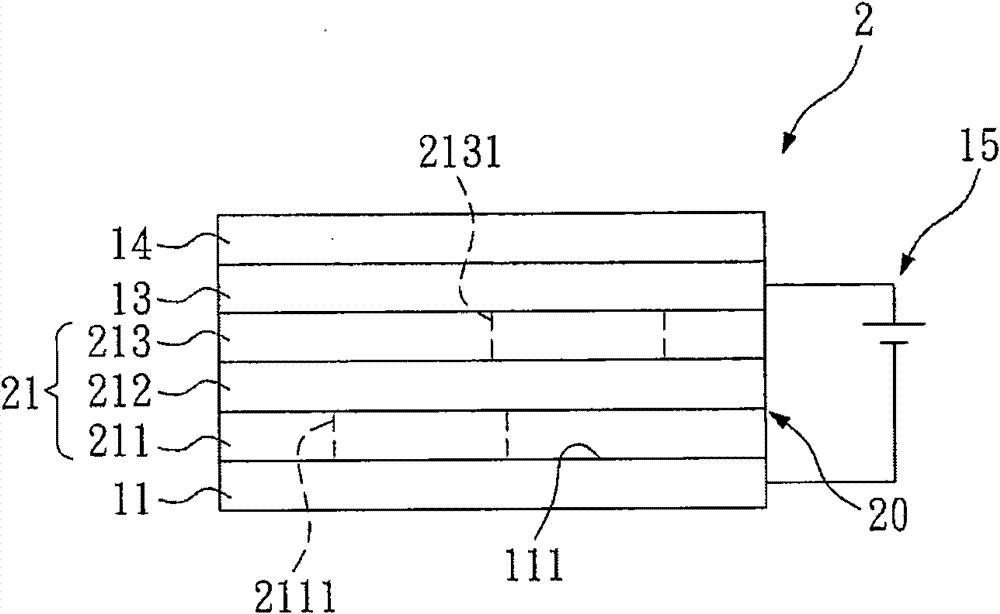

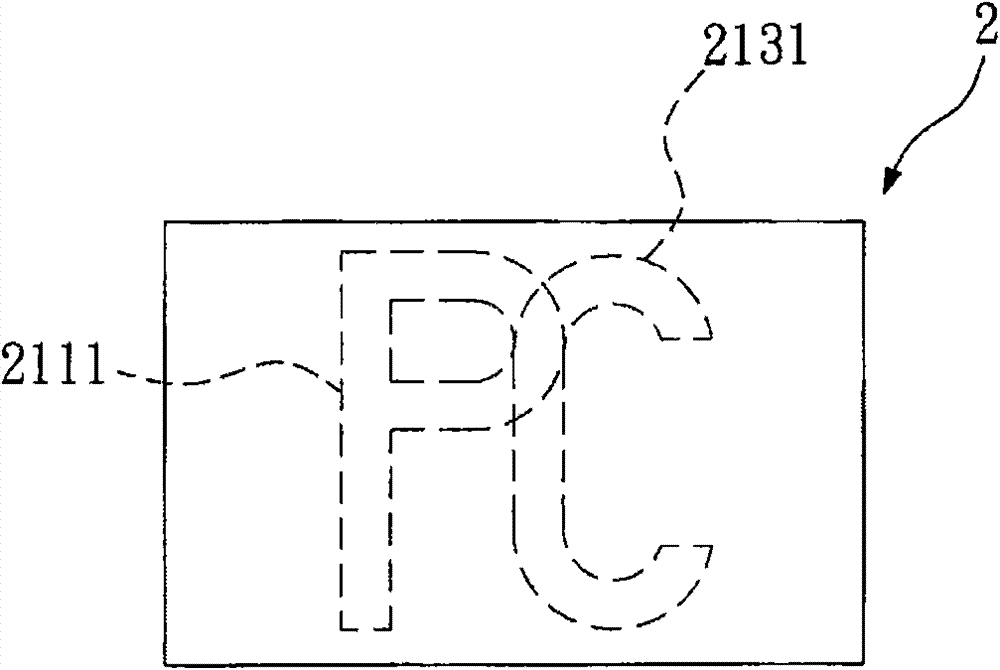

[0045] figure 1 A schematic diagram showing the first embodiment of the color generating device of the present invention. In this embodiment, the chromogenic device 1 includes a body 11, a chromogenic layer 10, a transparent conductive oxide thin film (TCO) 13, a transparent protective layer (such as a polymer layer) 14 and a power supply 15. The body 11 is an opaque conductor and has a surface 111 . The surface 111 of the body 11 has a set roughness (Ra), and the set roughness is preferably between 0.2 μ to 0.5 μ. Preferably, the body 11 is made of stainless steel. More preferably, the surface 111 is a polished mirror surface, which can further enhance the color and gloss performance of the color generating device 1 .

[0046] The chromogenic layer 10 includes at least one composite chromogenic layer 12 , and each composite chromogenic layer 12 includes a chromogenic oxide layer 121 and an ion storage layer 122 . The chromogenic layer 10 is disposed on the surface 111 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com