Aquatic feed mixing, processing and granulating device for micropterus salmoides

A technology of aquatic feed and granulation equipment, which is applied in the direction of feed, mixer, raw material extrusion granulation, etc. It can solve the problems of low automation, affecting pellet quality, cumbersome operation, etc., achieve high automation, ensure pellet quality, The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

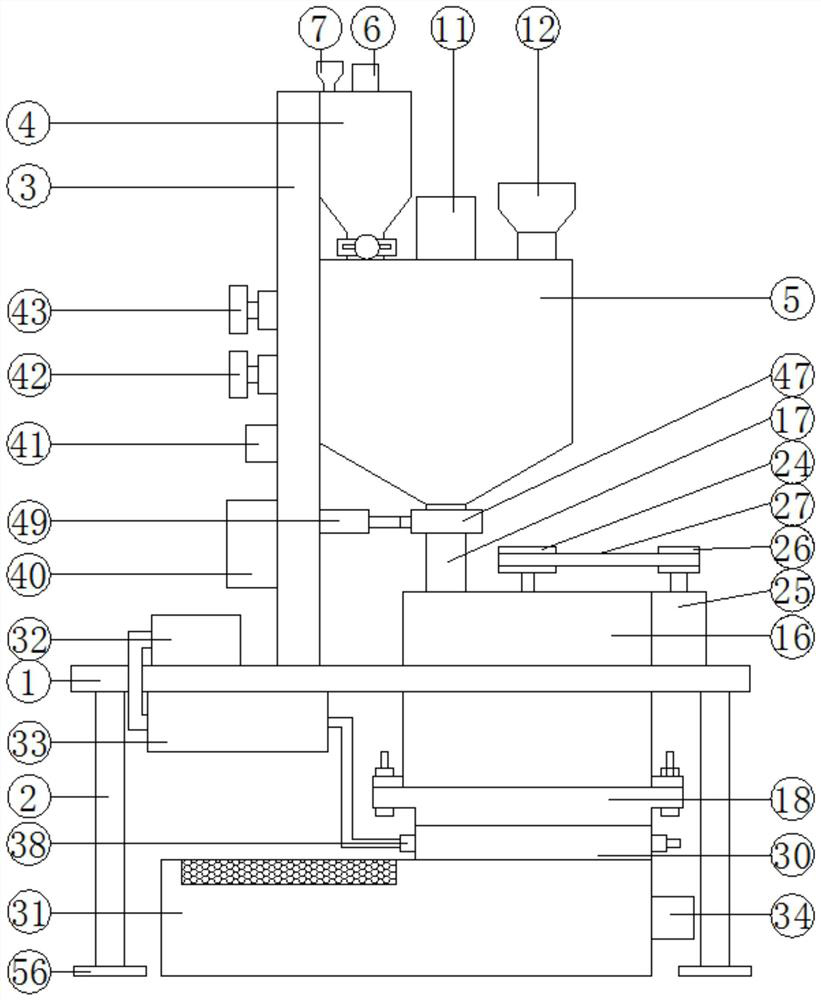

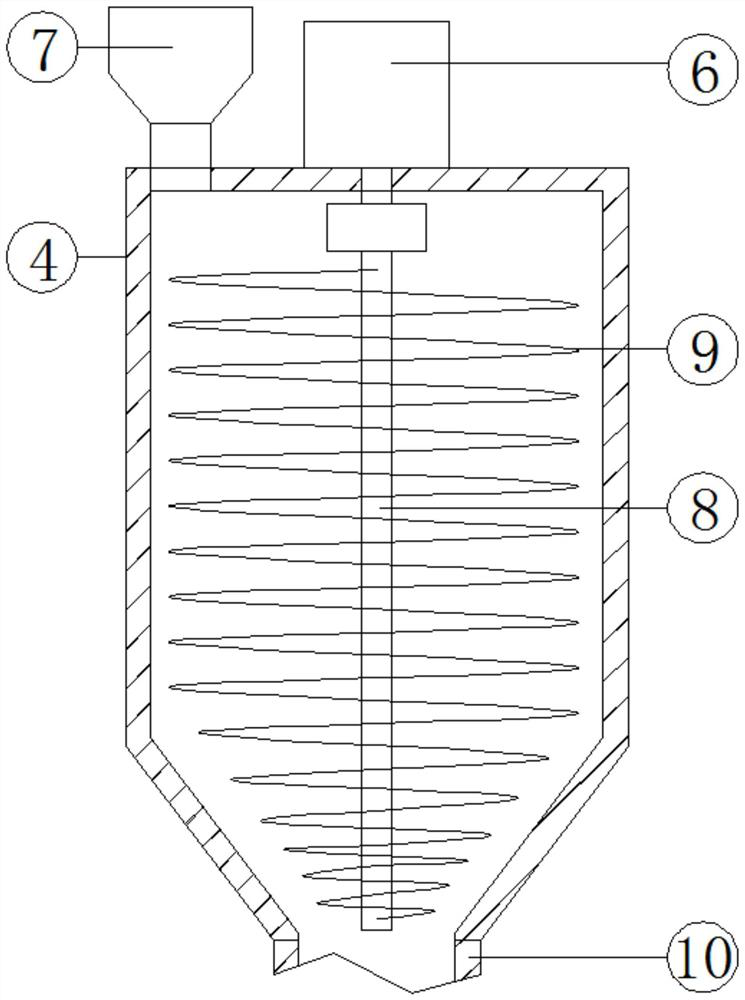

[0039] See Figure 1-9 , According to an embodiment of the present invention, a California bass aquatic feed mixing processing and pelletizing device, including a workbench 1, four corners of the workbench 1 are fixed with support columns 2 below, the workbench 1 is fixed A support plate 3 is provided. The upper side of the support plate 3 is fixed with a crushing drum 4 and a mixing drum 5 in turn from top to bottom. The crushing drum 4 is fixed with a first motor 6 and a first feeding port 7, The rotating shaft of the first motor 6 extends into the crushing drum 4 and is fixedly provided with a first transmission shaft 8. The outer wall of the first transmission shaft 8 is fixedly provided with a spiral crushing blade 9, and the crushing drum 4 and the A first feeding pipe 10 is fixed between the mixing cylinders 5, a first electric valve device is arranged in the middle of the first feeding pipe 10, and a second motor 11 and a second feeding port are fixed on the crushing cyl...

Embodiment 2

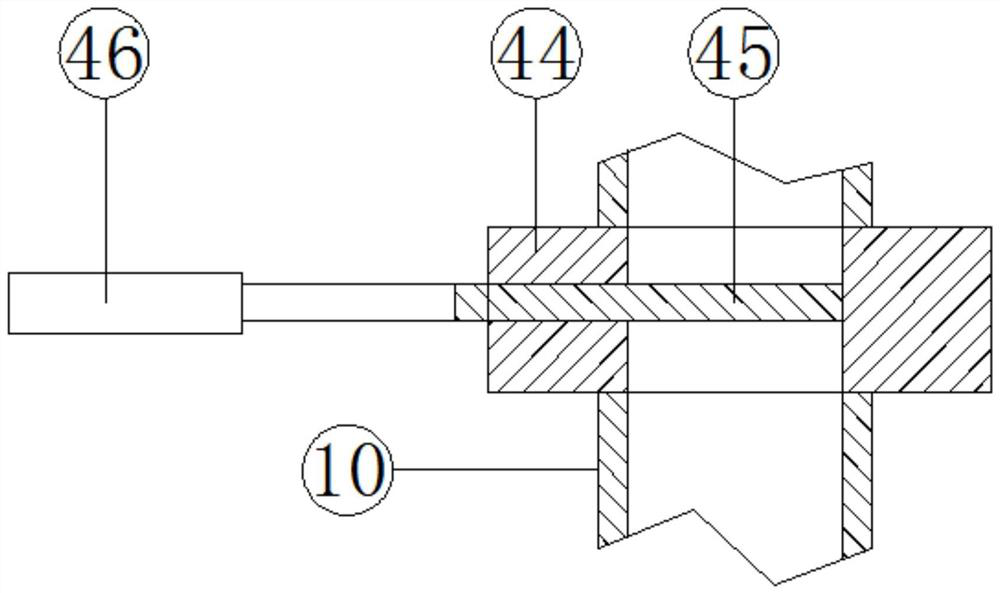

[0042] See Figure 2-3 For the first motor 6, the rotating shaft of the first motor 6 is fixedly connected to the first transmission shaft 8 through a first coupling; for the first electric valve device, the first electric valve device It includes a first valve body 44, the first valve body 44 is fixed in the middle of the first feeding pipe 10, the middle of the first valve body 44 is provided with a first sliding cavity, and a sliding cavity is provided in the first sliding cavity. There is a first sliding plate 45, the outer wall of the first sliding plate 45 is fixed with a first electric telescopic rod 46, the first electric telescopic rod 46 is fixed on the crushing drum 4, the first electric telescopic rod 46 and the The PLC controller 40 is electrically connected.

[0043] Through the above-mentioned solution of the present invention, the first coupling can fixedly connect the rotating shaft of the first motor 6 and the first transmission shaft 8, and can drive the first ...

Embodiment 3

[0045] See Figure 4-5 For the second motor 11, the rotating shaft of the second motor 11 and the second transmission shaft 13 are fixedly connected by a second coupling; for the second electric valve device, the second electric valve device Including a second valve body 47, the second valve body 47 is fixed in the middle of the second feed pipe 17, a second sliding cavity is opened in the middle of the second valve body 47, and a sliding cavity is provided in the second sliding cavity. There is a second sliding plate 48. The outer wall of the second sliding plate 48 is fixedly provided with a second electric telescopic rod 49, and one end of the second electric telescopic rod 49 away from the second sliding plate 48 is fixedly connected to the support plate 3. The second electric telescopic rod 49 is electrically connected with the PLC controller 40.

[0046] Through the above-mentioned solution of the present invention, the second coupling can fixedly connect the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com