Ultrasonic transduction equipment for tapping processing and torsional tapping machine

A technology of ultrasonic energy conversion and tapping machine, applied in metal processing equipment, fluid using vibration, thread cutting machine, etc., can solve the problems of low processing accuracy, easy breakage of taps, low vibration frequency, etc., and achieve high-efficiency internal thread processing , Suitable for mass processing, high pass rate of middle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

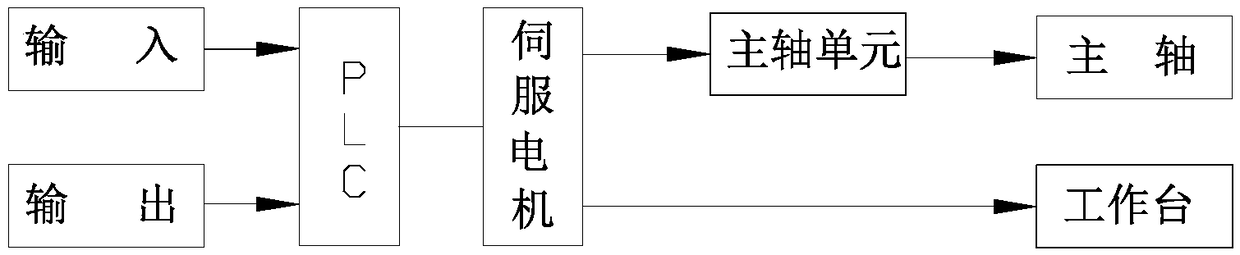

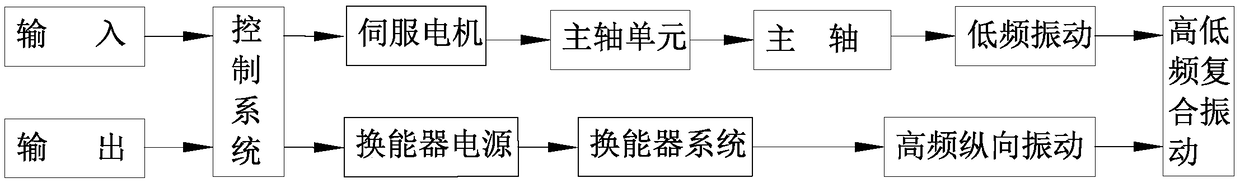

Method used

Image

Examples

Embodiment Construction

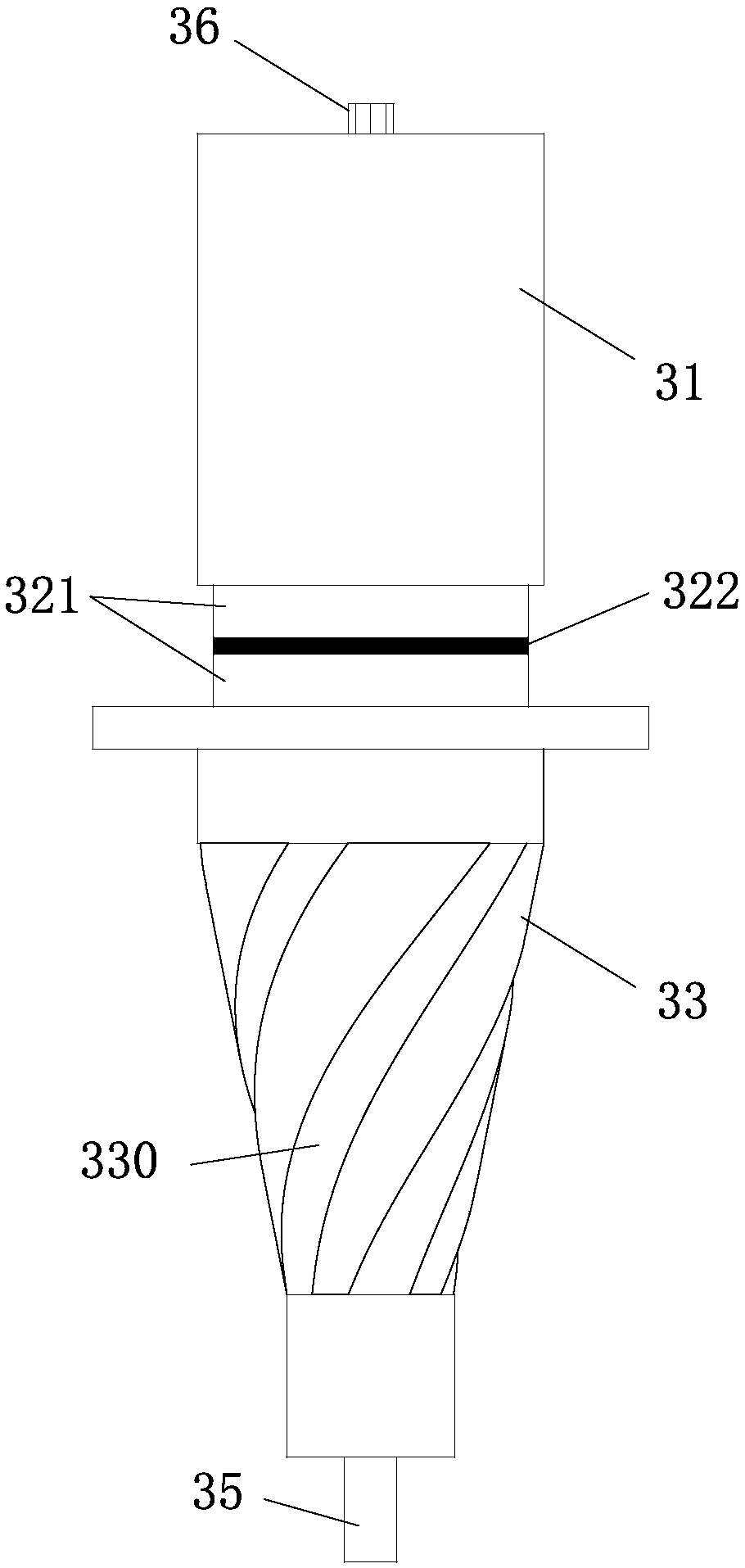

[0025] Such as Figure 3 to Figure 5 As shown, the ultrasonic transducer device 30 for tapping processing of the present invention includes an upper load block 31 (also referred to as a rear load block in the field of transducers) that weakens the transmission of longitudinal vibration energy and has a heat dissipation function, and strengthens the longitudinal vibration energy Transmission to the screw tap 35 and the lower load block 33 (also referred to as the front load block in the field of transducers) that produce torsional vibration transformation, between the upper load block 31 and the lower load block 33 that are arranged up and down, there is a device that can convert electric energy to generate The transducing element with the action of longitudinal vibration mechanical energy of ultrasonic frequency, when the longitudinal vibration generated by the transducing element propagates to the outer surface of the lower load block 33, the lower load block 33 processed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sound velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com