A process method for adjusting the thickness of iron-based amorphous alloy strip

An iron-based amorphous alloy and iron-based alloy technology, applied in the field of metal functional material preparation, can solve the problems of low saturation magnetic induction intensity of amorphous alloys, reduced Fe content, lack of effective technical methods for regulating the thickness of amorphous alloy strips, etc. Achieve the effect of low cost, easy implementation, and improvement of preparation efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

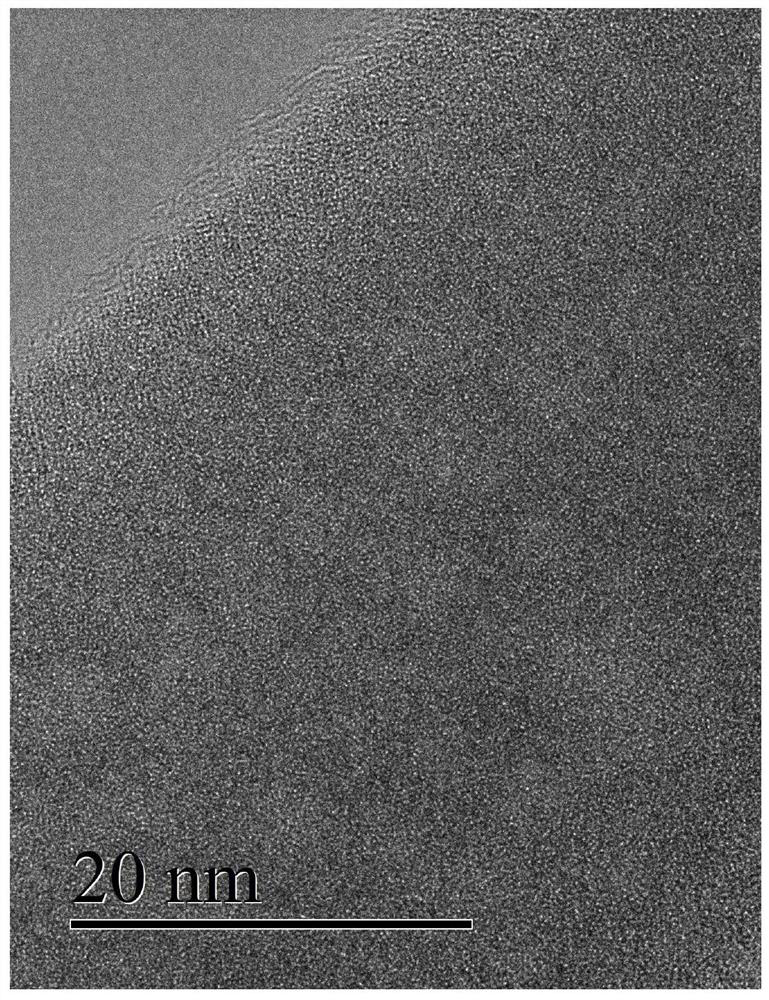

[0031] With finished Fe 76 PCSi 6 B 16 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the specific operation steps are as follows:

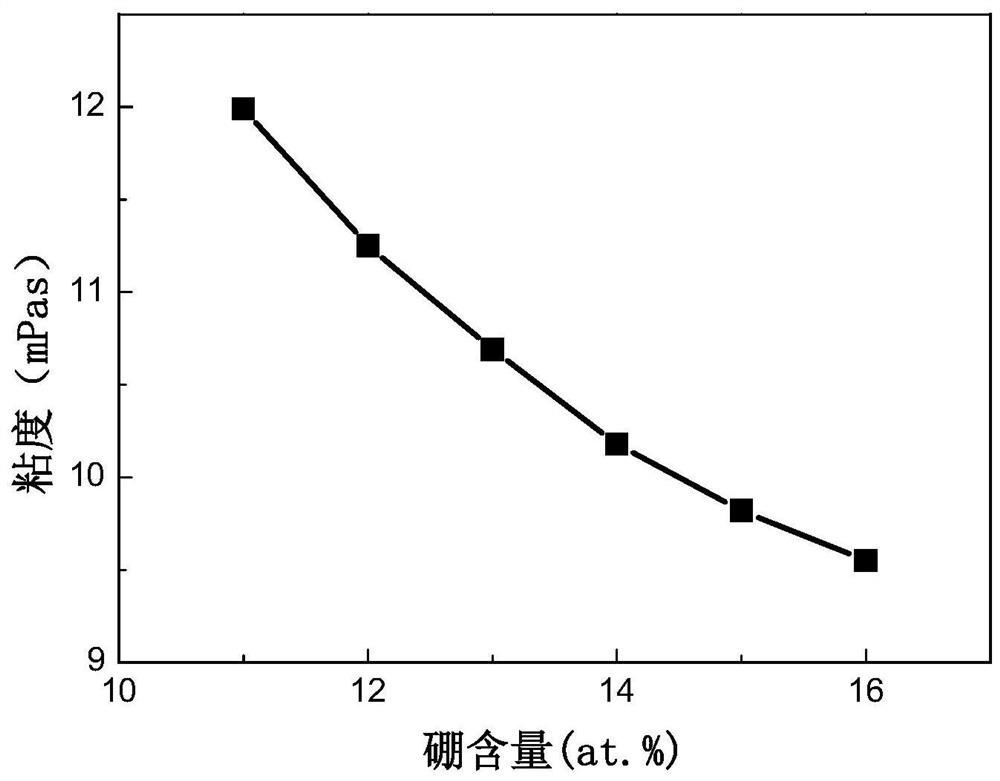

[0032] Step S1, establish the relationship between alloy melt viscosity and alloy composition: (1) Prepare a series of different non-metal element components Fe by changing the ratio of non-metal elements Si and B with different coordination numbers in the iron-based amorphous alloy 76 PCSi 22-X B X alloy melts, where the value of X ranges from 11 to 16; then the viscosity of these alloy melts is measured at 1300°C with a high-temperature viscosity measuring instrument (product of GBX Company, model: Viscodrop 2000), and the viscosity of the alloy melts varies with The characteristics of the composition changes of different Si and B nonmetallic elements;

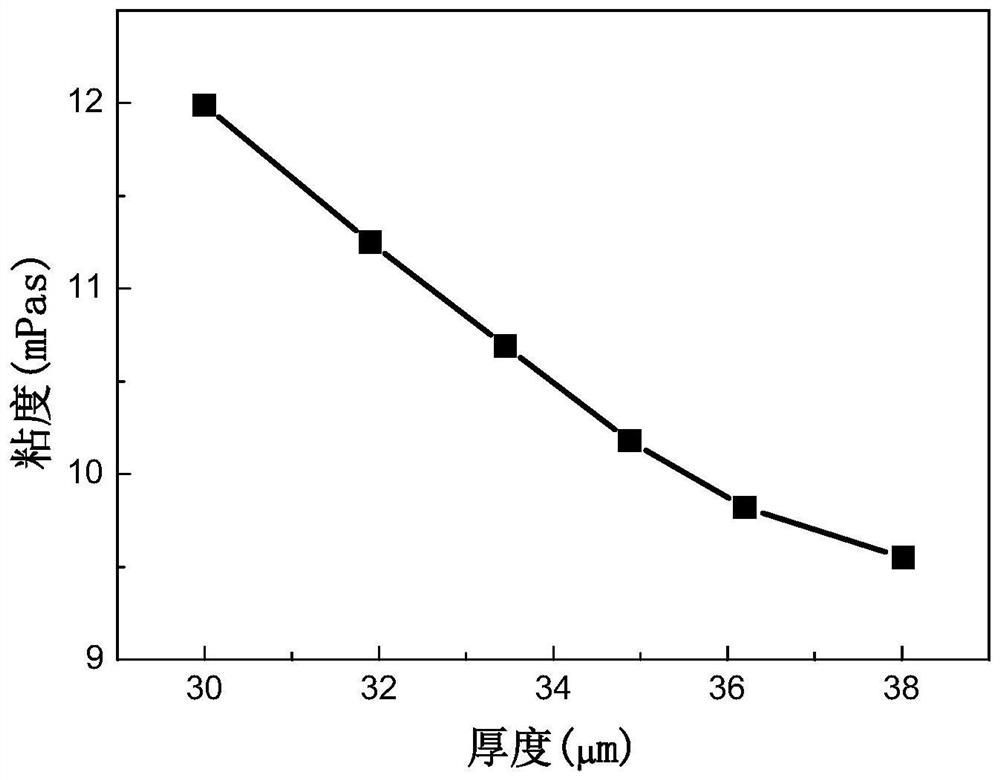

[0033] Step S2, establishing the relationship between the critical thickness of the amorphous alloy strip and the viscosity of the alloy ...

Embodiment 2

[0036] With finished Fe 76 PCSi 11 B 11 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the specific operation steps are as follows:

[0037] Step S1, establish the relationship between alloy melt viscosity and alloy composition: (1) Prepare a series of different non-metal element components Fe by changing the ratio of non-metal elements Si and B with different coordination numbers in the iron-based amorphous alloy 76 PCSi 22-X B X alloy melts, where the value of X ranges from 11 to 16; then the viscosity of these alloy melts is measured at 1300°C with a high-temperature viscosity measuring instrument (product of GBX Company, model: Viscodrop 2000), and the viscosity of the alloy melts varies with The characteristics of the composition changes of different Si and B nonmetallic elements;

[0038] Step S2, establishing the relationship between the critical thickness of the amorphous alloy strip and the viscosity of the alloy...

Embodiment 3

[0041] With finished Fe 76 PCSi 9 B 13 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the specific operation steps are as follows:

[0042] Step S1, establish the relationship between alloy melt viscosity and alloy composition: (1) Prepare a series of different non-metal element components Fe by changing the ratio of non-metal elements Si and B with different coordination numbers in the iron-based amorphous alloy 76 PCSi 22-X B X alloy melts, where the value of X ranges from 11 to 16; then the viscosity of these alloy melts is measured at 1300°C with a high-temperature viscosity measuring instrument (product of GBX Company, model: Viscodrop 2000), and the viscosity of the alloy melts varies with The characteristics of the composition changes of different Si and B nonmetallic elements;

[0043]Step S2, establishing the relationship between the critical thickness of the amorphous alloy strip and the viscosity of the alloy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com