Preparation method of room-temperature regenerated phenolic resin and recycling technology and application thereof

A phenolic resin, room temperature technology is applied in the field of preparation of renewable phenolic resin at room temperature, which can solve the problems of high recovery cost, inability to realize re-solidification and recycling of resin recovery products, and difficulty in PR recovery, and achieves the effect of promoting heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

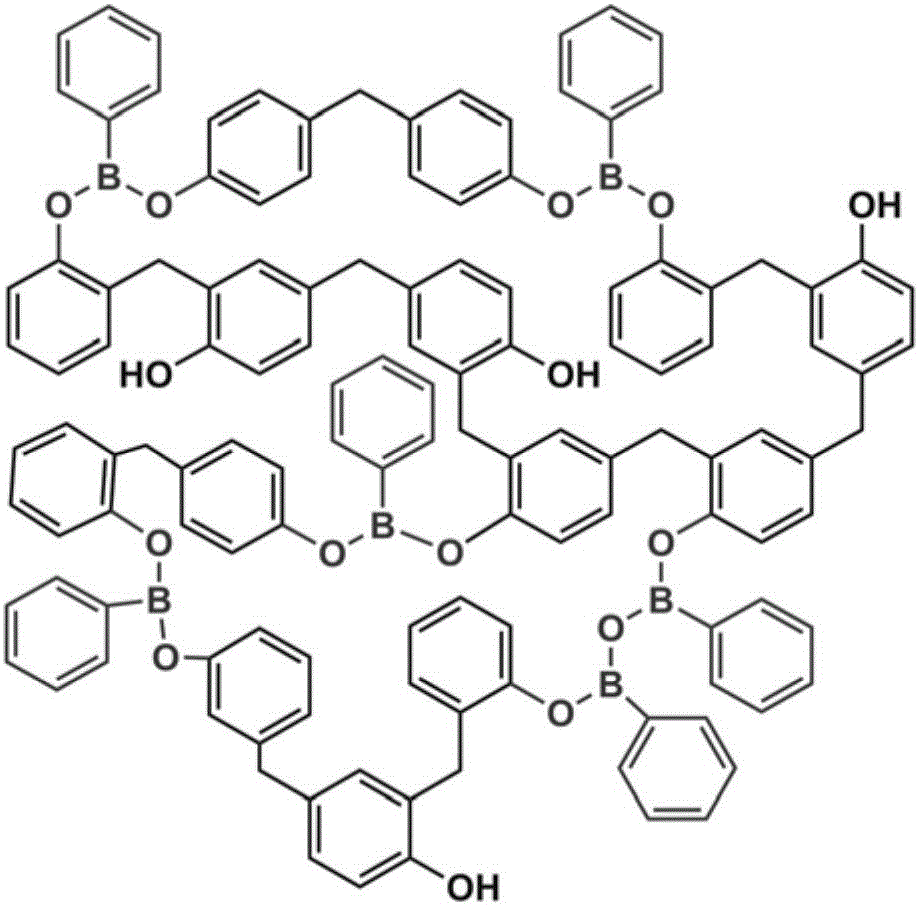

[0035] A new type of boron-containing thermoplastic phenolic resin was obtained by melting and blending 20g of high-ortho thermoplastic phenolic resin and 11g of phenylboronic acid at 70°C; using a staged heating program of 130°C / 3h+190°C / 5h in a tubular The novel boron-containing thermoplastic phenolic resin is cured under a nitrogen atmosphere in a furnace to obtain a cured resin.

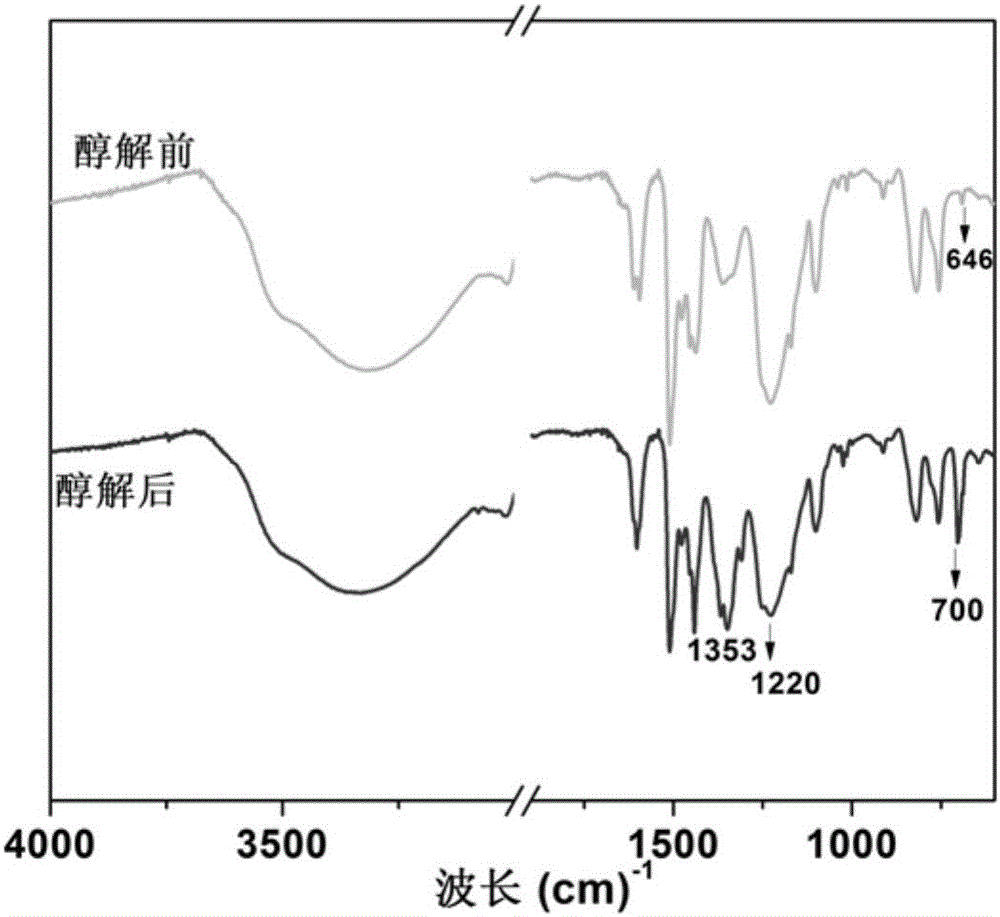

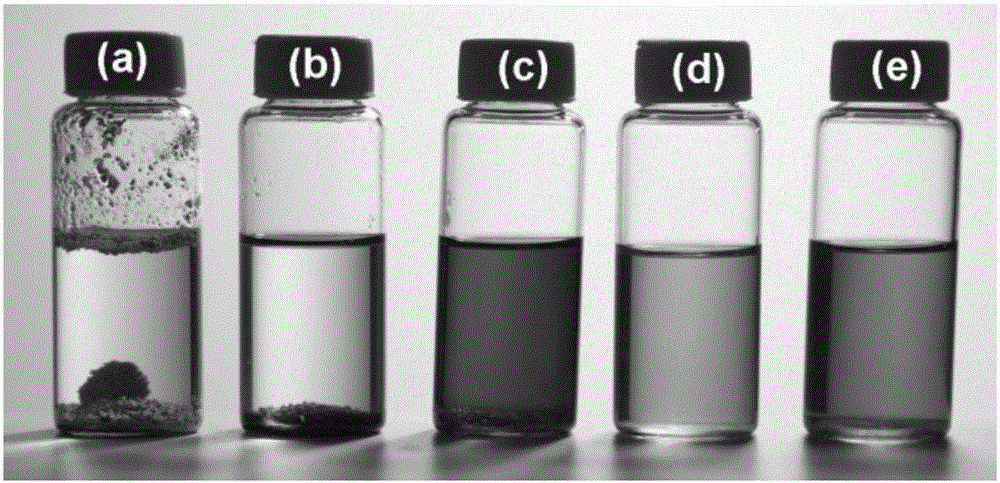

[0036] At room temperature, dissolve 10 g of cured resin in 50 mL of a mixed solvent of ethanol and water (the mass ratio of ethanol and water is 3:1), let it stand for 30 min, and place it in a vacuum oven at 90 °C (vacuum degree is 0.09 MPa), After drying for 5 hours to remove the solvent, the regenerated phenolic resin at room temperature can be obtained.

[0037] Under magnetic stirring, 20g of high-ortho thermoplastic phenolic resin and 4g of naphthylboronic acid were dissolved in ethanol to obtain a new boron-containing thermoplastic phenolic resin ethanol solution, and the boron-containing...

Embodiment 2

[0045] 30g of bisphenol A type thermoplastic phenolic resin and 6g of diphenylboronic acid were blended by heating at 60°C to obtain a new type of boron-containing thermoplastic phenolic resin; a staged heating program of 140°C / 4h+195°C / 6h was used in vacuum The novel boron-containing thermoplastic phenolic resin is cured in a nitrogen atmosphere in an oven to obtain a cured boron-containing thermoplastic phenolic resin.

[0046] At room temperature, dissolve 10g of boron-containing thermoplastic phenolic resin in 50mL of ethanol, let it stand for 50min, and dry it in a vacuum oven (vacuum degree: 0.09MPa) at 80°C for 2.0h to remove the solvent to obtain a regenerated phenolic resin .

[0047] Under magnetic stirring, dissolve 30g of high-ortho thermoplastic phenolic resin and 6g of diphenylboronic acid in ethanol to obtain a new boron-containing thermoplastic phenolic resin ethanol solution, which is prepared by compounding the boron-containing thermoplastic phenolic resin et...

Embodiment 3

[0050] A mixture of 25g of ordinary thermoplastic phenolic resin and 4.6g of biphenylboronic acid and dihydroxyphenylboronic acid was blended at 100°C to obtain a new boron-containing thermoplastic phenolic resin; using 125°C / 4h+160°C / 2h+200°C / The new boron-containing thermoplastic phenolic resin was cured in a tube furnace nitrogen atmosphere with a staged temperature rise program of 4 hours to obtain a cured resin.

[0051] At room temperature, dissolve 10 g of cured resin in 50 mL of a mixed solvent of ethanol and water (mass ratio: 2:1), let it stand for 35 min, and then dry it in a vacuum oven at 80 °C (vacuum degree: 0.09 MPa) for 2 h to remove Solvent, you can get regenerated phenolic resin.

[0052] Under magnetic stirring, a mixture of 25 g of ordinary thermoplastic phenolic resin and 4.6 g of biphenylboronic acid and dihydroxyphenylboronic acid was dissolved in ethanol to obtain a new boron-containing thermoplastic phenolic resin ethanol solution for the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com