Preparation method of nanoscale high-boron-content composite acid magnesium detergent

A compound acid and nano-scale technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of large particle size, high sulfur content, high product viscosity, etc., achieve good anti-wear performance and colloidal stability, sulfur The effect of low content and high boron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

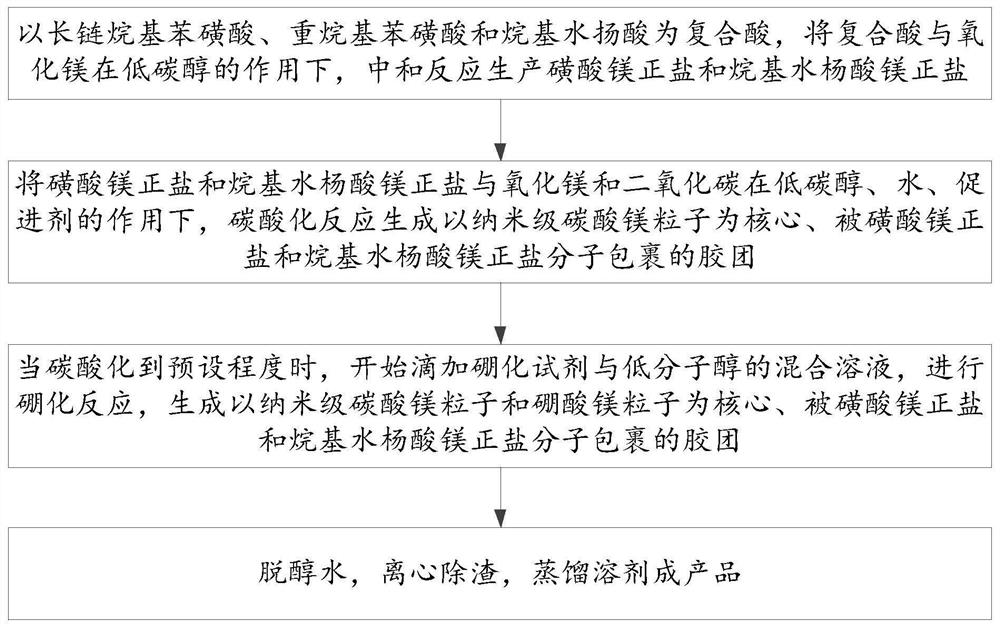

[0043] like figure 1 As shown, the present invention provides a method for preparing a nano-high boron content composite flaky flare, including:

[0044] Step 1, with a long chain alkylbenzenesulfonic acid, an alkylbenzenesulfonic acid and an alkyl aqueous acid, and the magnesium acid magnesium acid is produced by neutralization with magnesium oxide at low alcohol. Salt and alkyl salicylate is produced;

[0045] Specifically include:

[0046] As a further improvement in the present invention, step 1, specifically includes:

[0047] In four flasks equipped with a stirrer, reflow condensation, thermocouple thermometers, an organic solvent, long chain alkylbenzene sulfonic acid, hemylbenzene sulfonic acid, alkyl aqueous acid, base oil, low carbonol , Small molecular acid, fatty acids, magnesium oxide, warming stirring, neutralizing reaction to produce sulfonate osulfonate and alkyl salicylate.

[0048]Further, the active content of the long chain alkylbenzenesulfonic acid is 85% to 9...

example 1

[0070] Example 1: Preparation of High Boron Content Compound Acids Magnesium Cleantic MG-B1

[0071] To 500 ml of four flask, 100 g of xylene # solvent, 20 g of long chain alkylbenzenesulfonic acid, 10 g of hemantanesulfonic acid, 10 g alkyl hydrotlic acid, 50 g 150 Sn, 15 g of methanol, 4.0 g of fourteen acid, 3.0 GCC and 8.0 g of magnesium oxide, warmed to 40 to 60 ° C. After completion, 15 g of methanol was added, 5.0 g of polyisobutylene di diapone, stirred for 30 min, control 40-60 ° C; then 2 g of ethylenediamine, 4 g of magnesium oxide and 5 g of water, at 40 to 60 ° C, at 45 ml / min The gas is accented from carbon dioxide, vents to 2L, one free base 45mgkoh / g; maintain temperature unchanged, add 1 g of ethylenediamine, 6 g of magnesium oxide and 5g water, then venting to 5.5 L, secondary free base 120 mgkoh / g, Stop ventilation. 50 g of boric acid and 60 g n-butanol were configured, and the boric acid solution was started, and the dropwise addition time was 90 min, and...

example 2

[0072] Example 2: Preparation of High Boron Content Composite Based Cake MG-B2

[0073] To 500 ml of four flask, 100 g of xylene # solvent, 20 g of long chain alkylbenzenesulfonic acid, 10 g of hemantanesulfonic acid, 10 g alkyl hydrotlic acid, 50 g 150 Sn, 15 g of methanol, 4.0 g of fourteen acid, 3.0 GCC and 8.0 g of magnesium oxide, warmed to 40 to 60 ° C. After completion, 15 g of methanol was added, 5.0 g of polyisobutylene di diapone, stirred for 30 min, control 40-60 ° C; then 2 g of ethylenediamine, 4 g of magnesium oxide and 5 g of water, at 40 to 60 ° C, at 45 ml / min The gas is accented from carbon dioxide, ventilates to 2L, one free base 45mgkoh / g; maintain temperature unchanged, 1 g of ethylenediamine, 6 g magnesium oxide and 5g water, then ventilated to 6.5 L, secondary free base 80 mgkoh / g, Stop ventilation. 30 g of boric acid and 40 g n-butanol were configured, and the boronic acid solution was started, and the dropwise time was 60 min, and the reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com