Preparation method of boronized ashless dispersant

An ashless dispersant and boronization technology, which can be used in additives, petroleum industry, lubricating compositions, etc., and can solve the problems of low boron content and poor storage stability of boronized ashless dispersants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

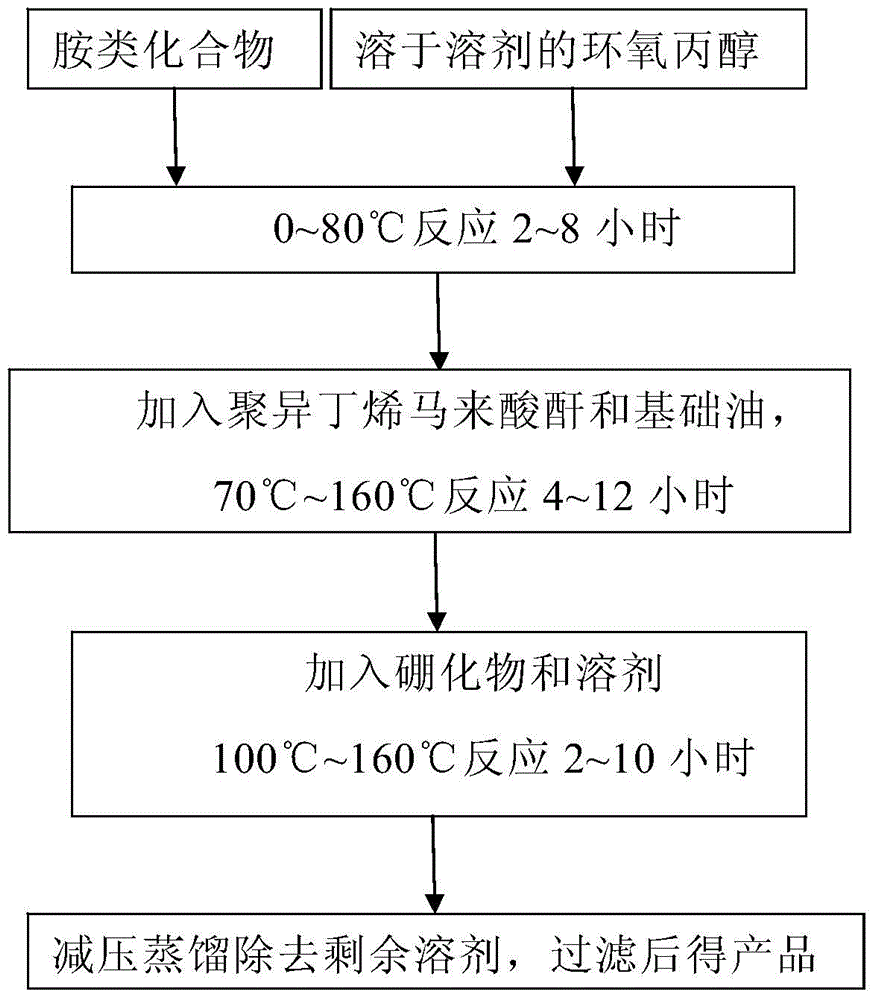

Method used

Image

Examples

Embodiment 1

[0071] Add 26 parts of tetraethylenepentamine to the reaction bottle, keep the temperature at 10°C, dissolve 10 parts of glycidyl alcohol in 40 parts of ethanol, and add it dropwise to the reaction bottle. After reacting for 5 hours, add 300 parts of 1300 polyisobutylene maleic anhydride, 90 parts of base oil, heat up to 140°C for 6 hours, cool down to 60°C, add 32 parts of boric acid, 32 parts of butanol, react at 110°C for 6 hours, distill off the solvent under reduced pressure, filter Finally, a boronated ashless dispersant is obtained.

Embodiment 2

[0073] Add 26 parts of polyene polyamine to the reaction flask, keep the temperature at 10°C, dissolve 10 parts of glycidyl alcohol in 40 parts of ethanol, and add it dropwise to the reaction flask. After reacting for 5 hours, add 300 parts of 1300 polyisobutylene maleic anhydride, 90 parts of base oil, heat up to 140°C for 6 hours, cool down to 60°C, add 32 parts of boric acid, 32 parts of butanol, react at 110°C for 6 hours, distill off the solvent under reduced pressure, filter Finally, a boronated ashless dispersant is obtained.

Embodiment 3

[0075] Add 26 parts of tetraethylenepentamine to the reaction bottle, keep the temperature at 10°C, dissolve 10 parts of glycidyl alcohol in 40 parts of ethanol, and add it dropwise to the reaction bottle. After reacting for 5 hours, add 300 parts of 1300 polyisobutylene maleic anhydride, 90 parts of base oil, heat up to 140 ° C for 6 hours, cool down to 60 ° C, add 110 parts of tributyl borate, 50 parts of butanol, react at 110 ° C for 6 hours, and remove by vacuum distillation Solvent, filtered to obtain boronated ashless dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com