Patents

Literature

55results about How to "Reduce abrasiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

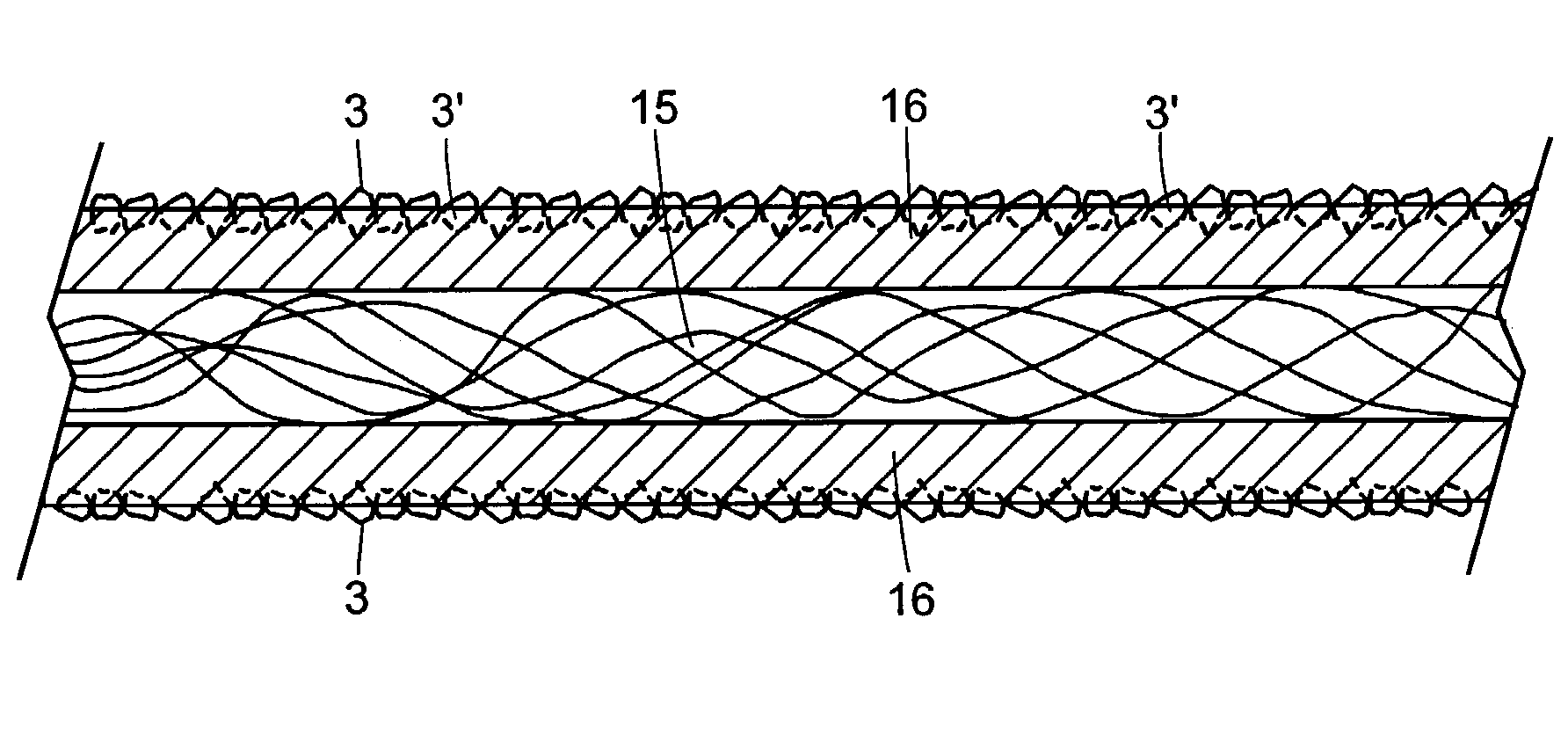

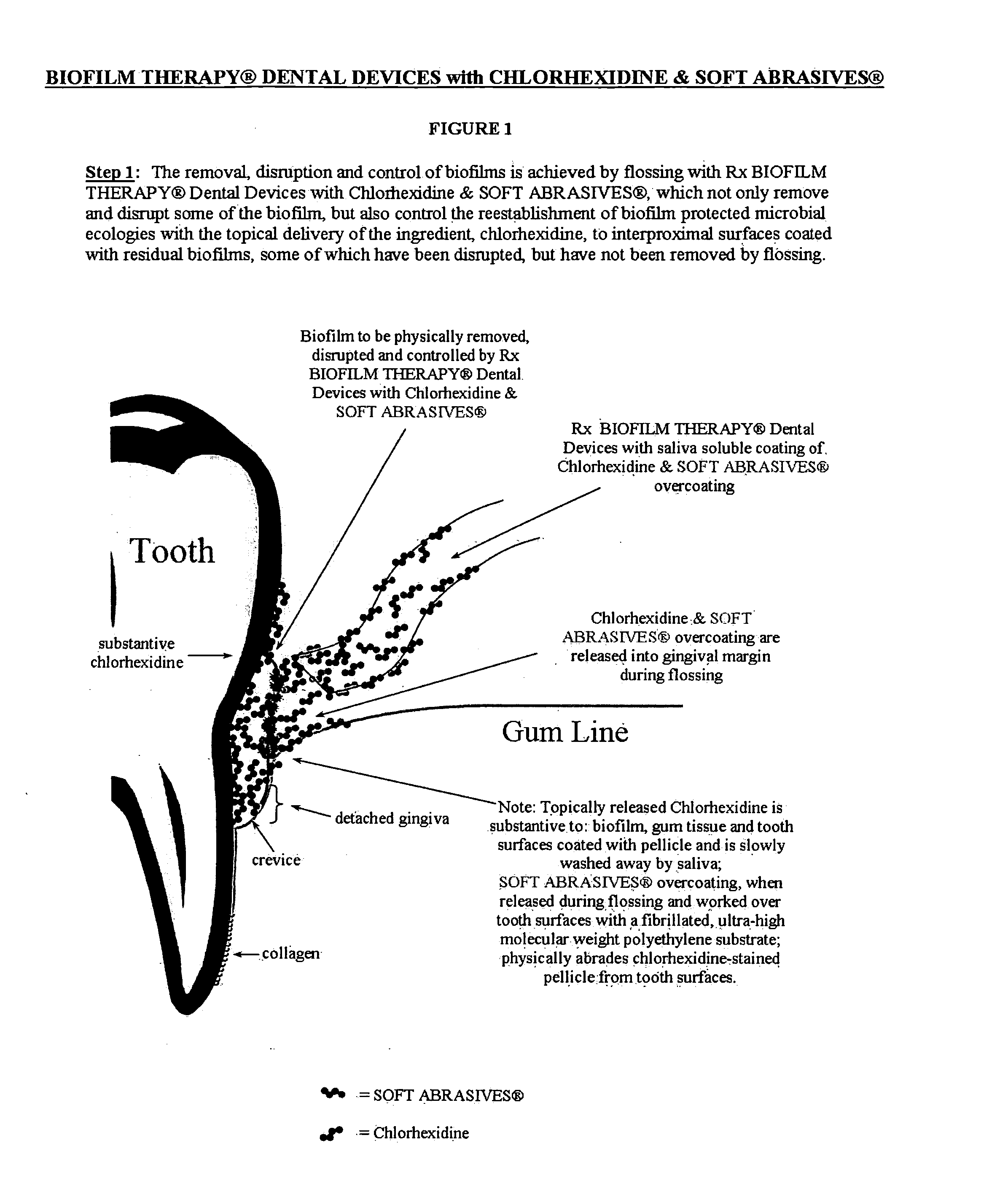

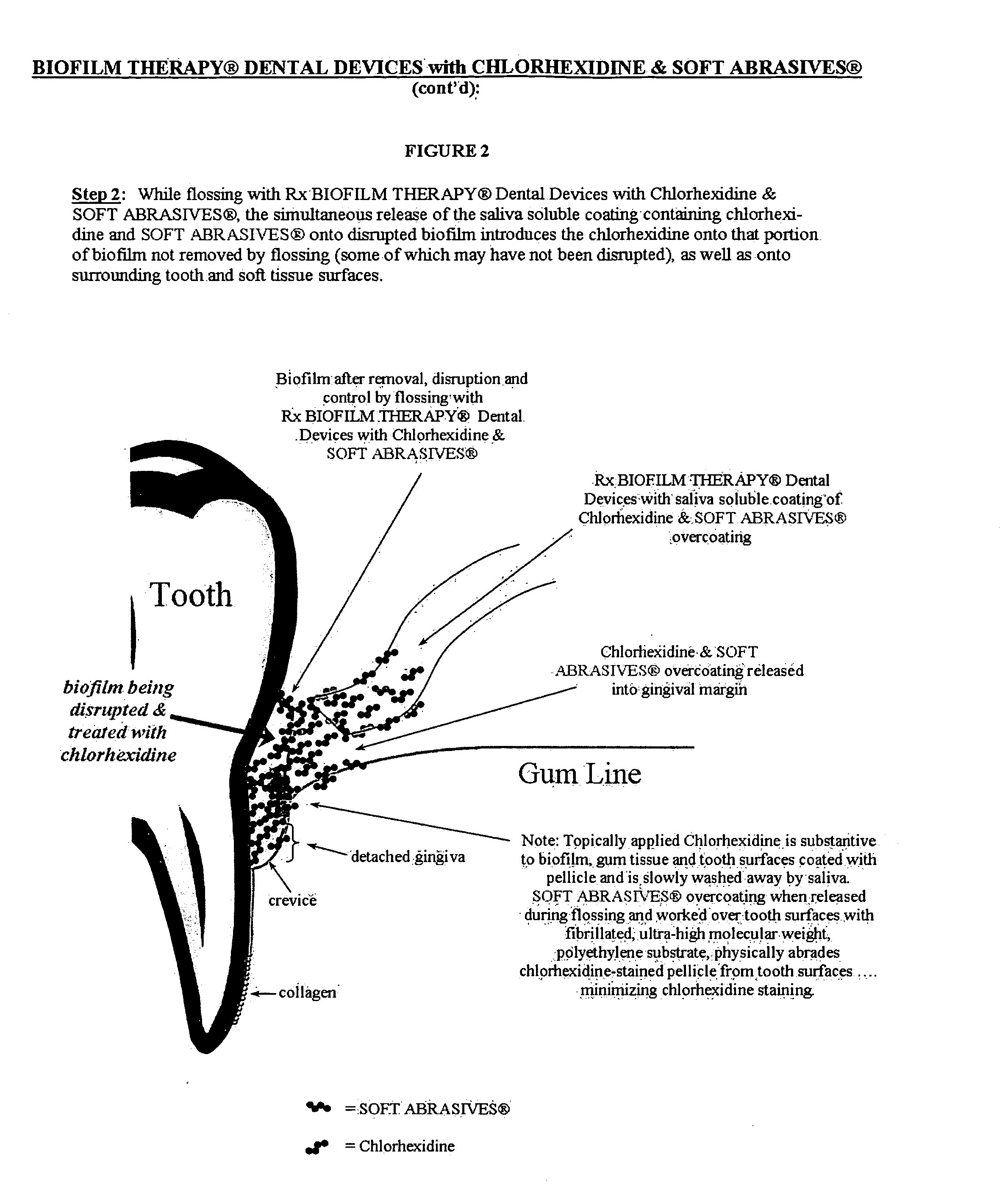

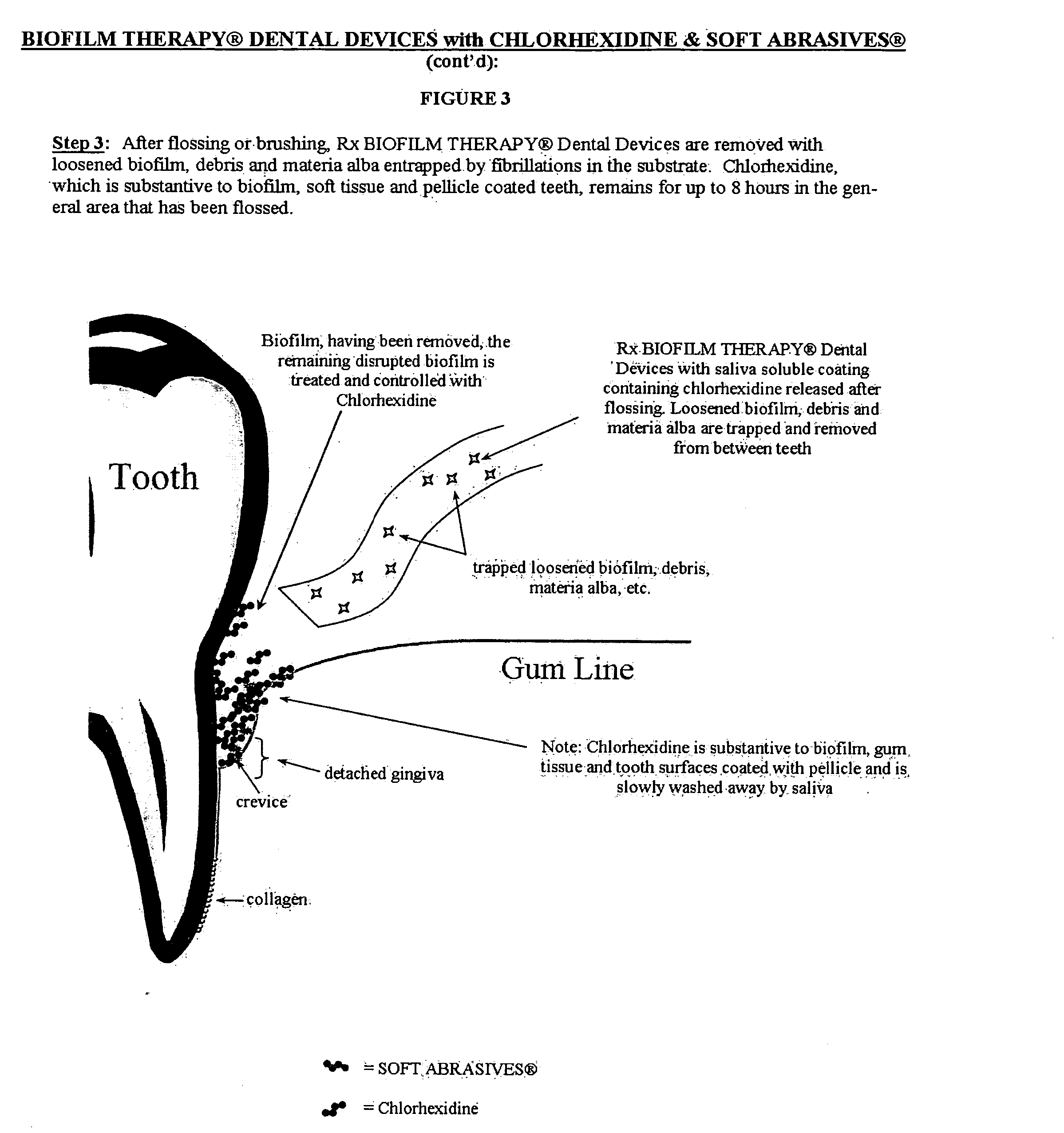

Coated multifilament dental devices overcoated with imbedded particulate

Disclosed are coated multifilament dental devices overcoated with biofilm-responsive, imbedded, particulate abrasives.

Owner:WHITEHILL ORAL TECH

Sialagogue coatings for interproximal devices

InactiveUS20060177384A1Increase blood flowIncreasing and prolonging saliva flowCosmetic preparationsToilet preparationsWaxEmulsion

Owner:WHITEHILL ORAL TECH

Red herbal dentifrice

InactiveUS20070116652A1Mild abrasivityReduce abrasivenessCosmetic preparationsToilet preparationsDental enamelOral health

A dentifrice composition of the invention can be applied to teeth and / or gums by any conventional A dentifrice composition comprises (a) calcium carbonate having properties of particle size and angularity effective to provide mild abrasivity to dental enamel; (b) red iron oxide of low abrasivity in an effective amount on which to impart red color to the composition; and (c) a herbal component comprising at least one botanical or extract thereof, in a total herbal component amount effective to promote oral health.

Owner:COLGATE PALMOLIVE CO

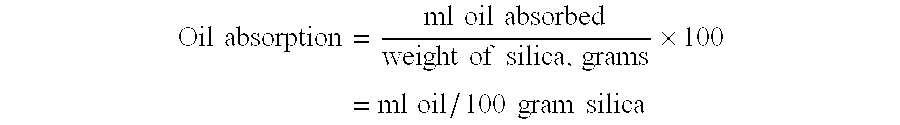

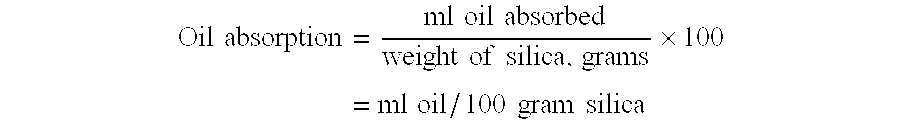

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

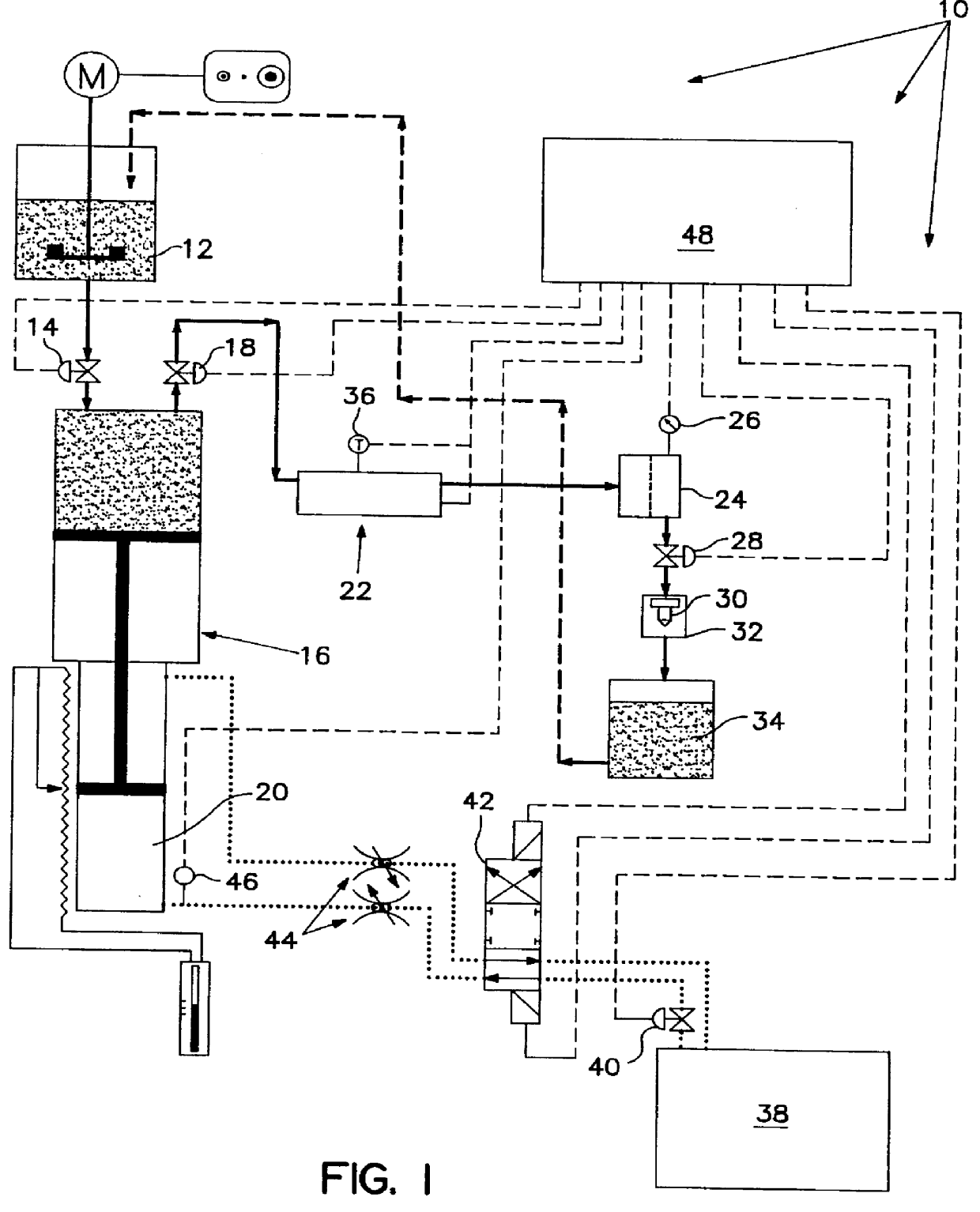

Abrasive liquid slurry for polishing and radiusing a microhole

InactiveUS6132482AImprove economyImprove efficiencyEdge grinding machinesPigmenting treatmentViscosityStreamflow

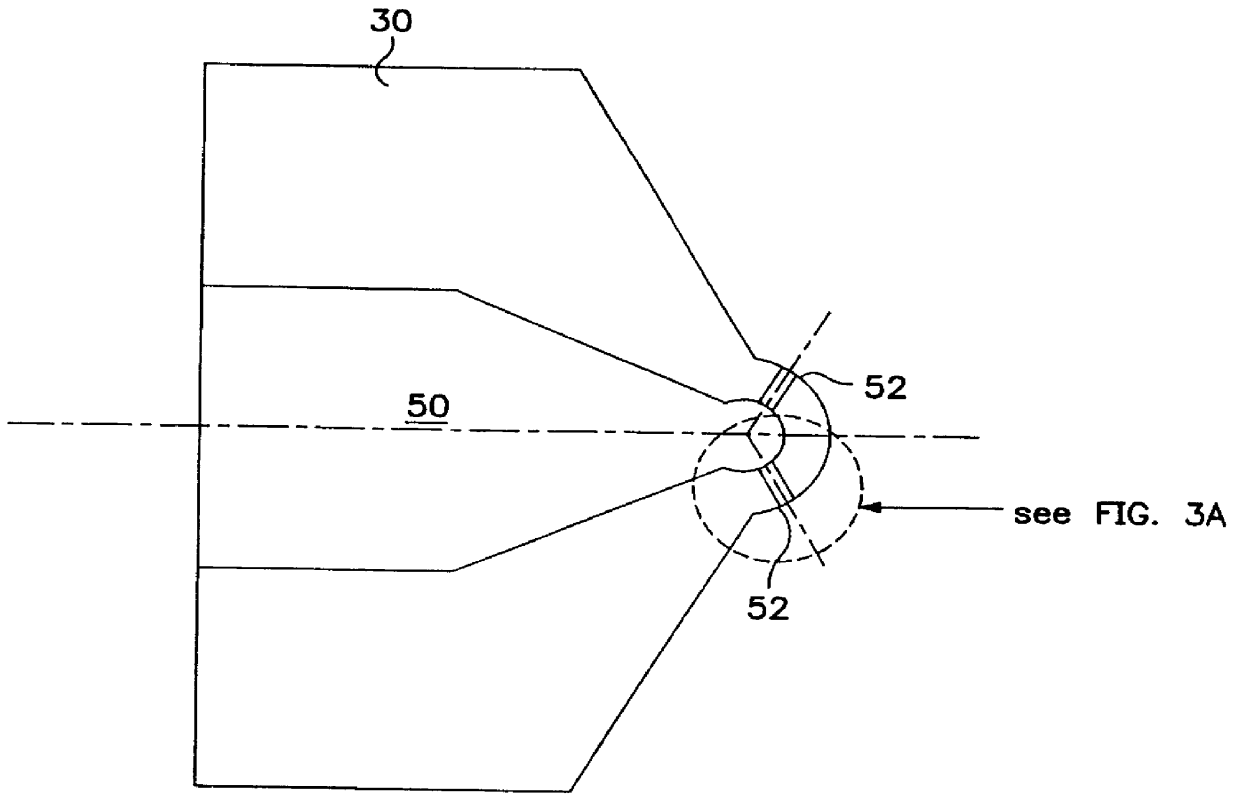

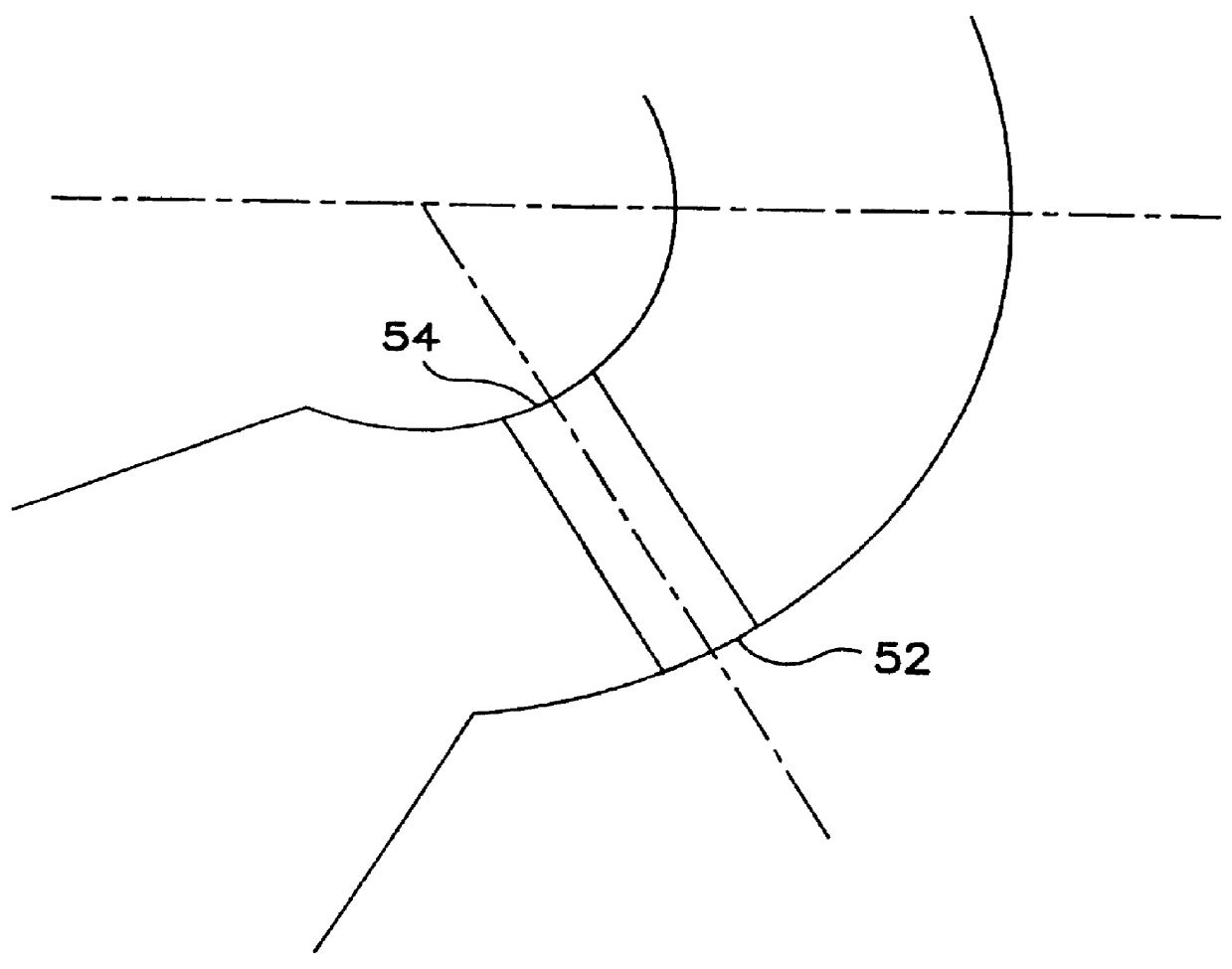

A system and method for radiusing and sizing microholes in diesel fuel injectors. A liquid abrasive slurry with rheological properties is used. As the slurry approaches and flows through the microhole, it is at first at a lower viscosity. Subsequently, the slurry is characterized by a high viscosity which enables the use of a flow meter in the slurry flow path which directly and accurately monitors slurry flow rate and mass flow in real time. This allows for the individual slurry processing of nozzles to their specified flow rate in a continuous process.

Owner:EXTRUDE HONE CORP

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS7270803B1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Production and/or recovery of products from waste sludge

InactiveUS20120328497A1Increase valueReduce abrasivenessCalcium/strontium/barium carbonatesAluminium compoundsIonCarbon dioxide

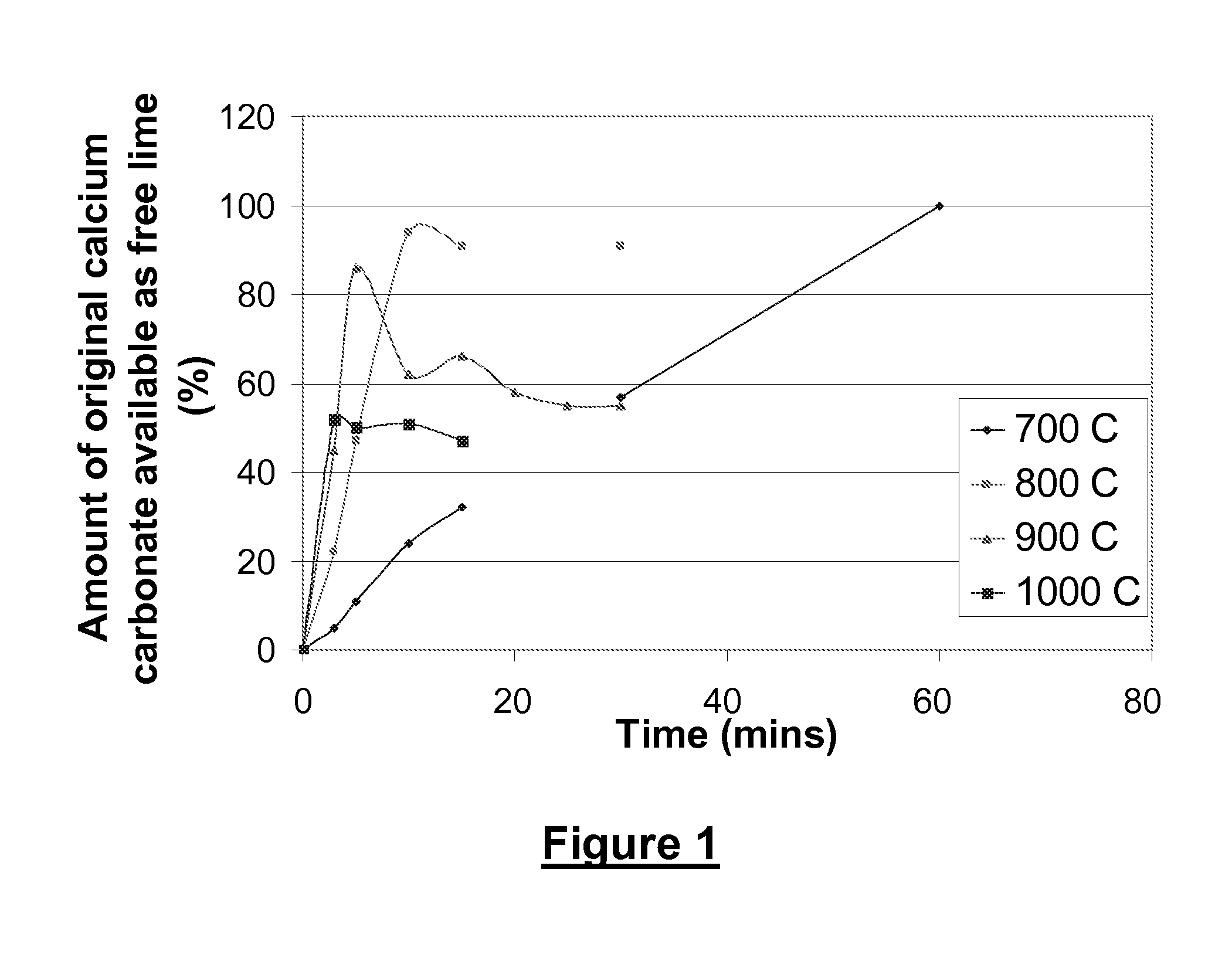

A method of producing calcium carbonate from a waste sludge containing calcium carbonate and at least one silicate mineral. The method comprises the steps of:(i) incinerating the sludge to an ash in which at least 60% of the calcium carbonate present in the sludge is converted to free calcium oxide which is unreacted with the silicate mineral(s),(ii) optionally slaking the ash to convert at least a portion of the free calcium oxide therein to calcium hydroxide,(iii) treating either the ash from step (i) or the slaked ash from step (ii) with an aqueous solution of a polyhydroxy compound to provide a solution of dissolved calcium hydroxide,(iv) separating insoluble material from the solution of calcium ions obtained in step (iii),(v) dispersing carbon dioxide through the solution obtained from step (iv) so as to produce calcium carbonate, and(vi) separating the calcium carbonate produced in step (v).

Owner:CALCITECH SYNTHETIC MINERALS

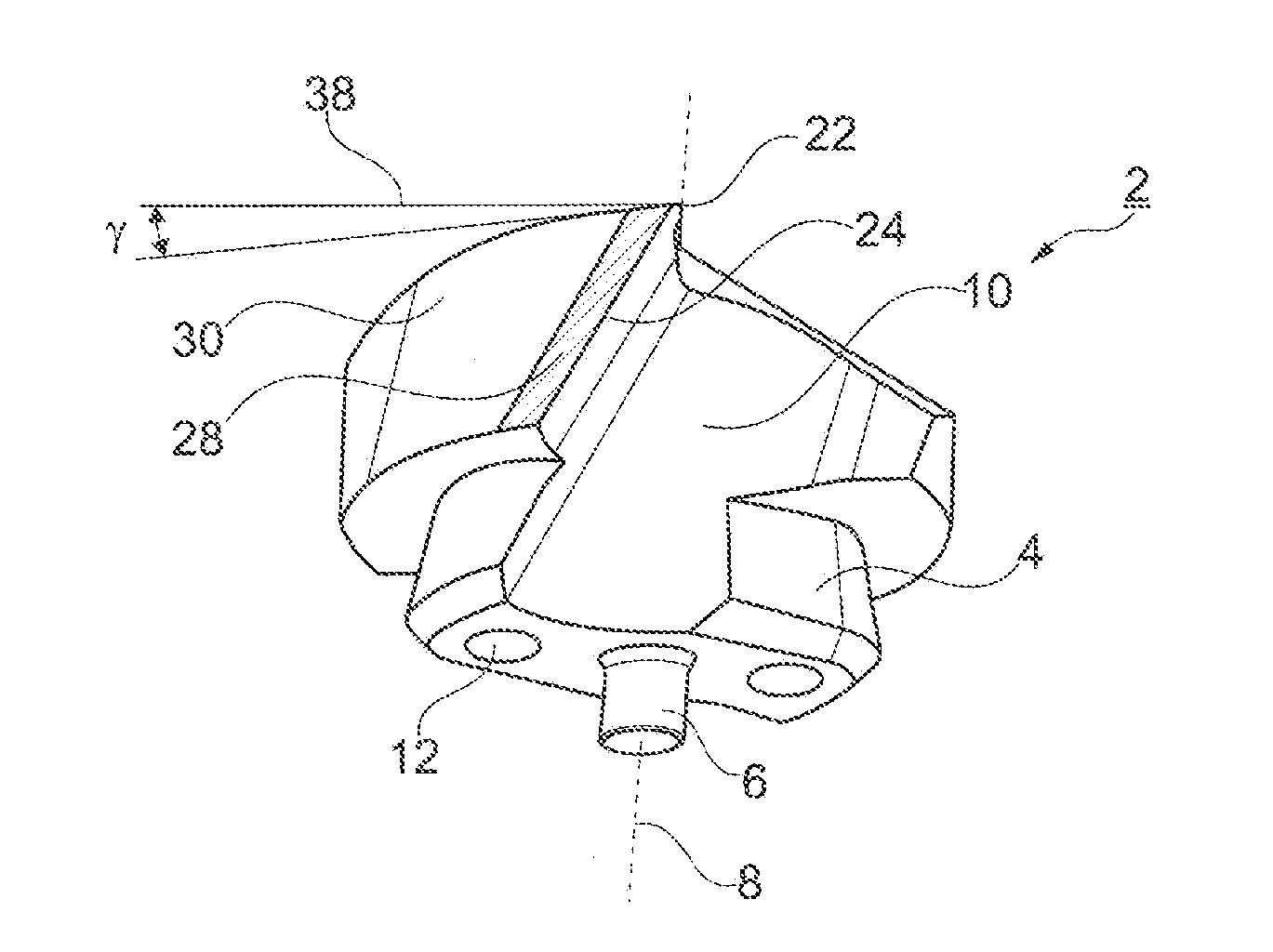

Rotary tool and method for manufacturing

ActiveUS20160263663A1Improve propertiesImprove wear characteristicsWorkpiecesTurning toolsEngineeringMechanical engineering

A rotary tool, in particular drilling tool, extends along a longitudinal axis and has an end surface; a brad point; and at least one major cutting edge extending outward up to an edge corner. A first free surface segment adjoins the major cutting edge, and a second free surface segment in turn adjoins said first free surface segment. To keep the stress, in particular the wear, low in the region of the end surface, the first free surface segment has a lower average abrasiveness than the second free surface segment.

Owner:KENNAMETAL INC

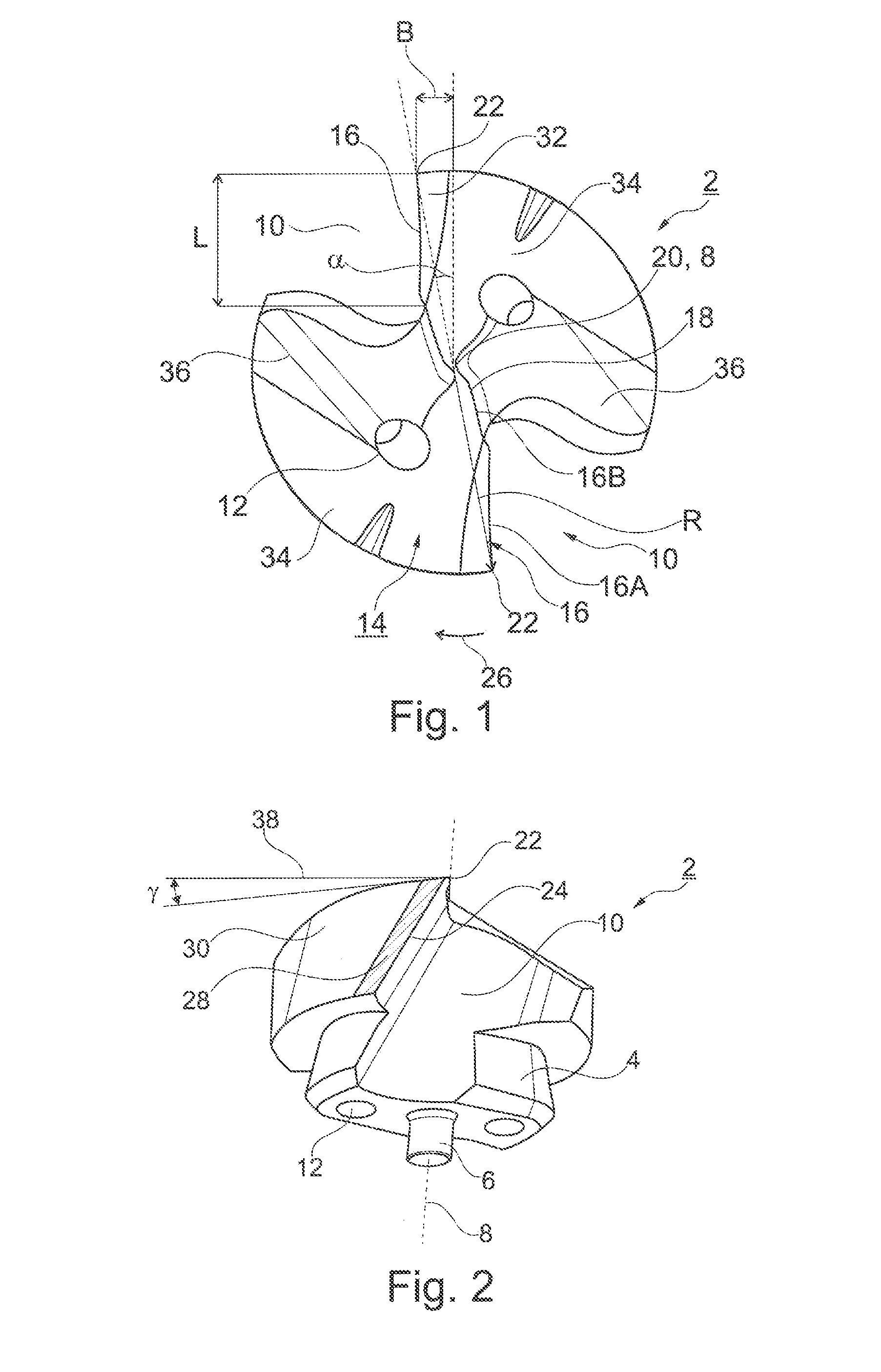

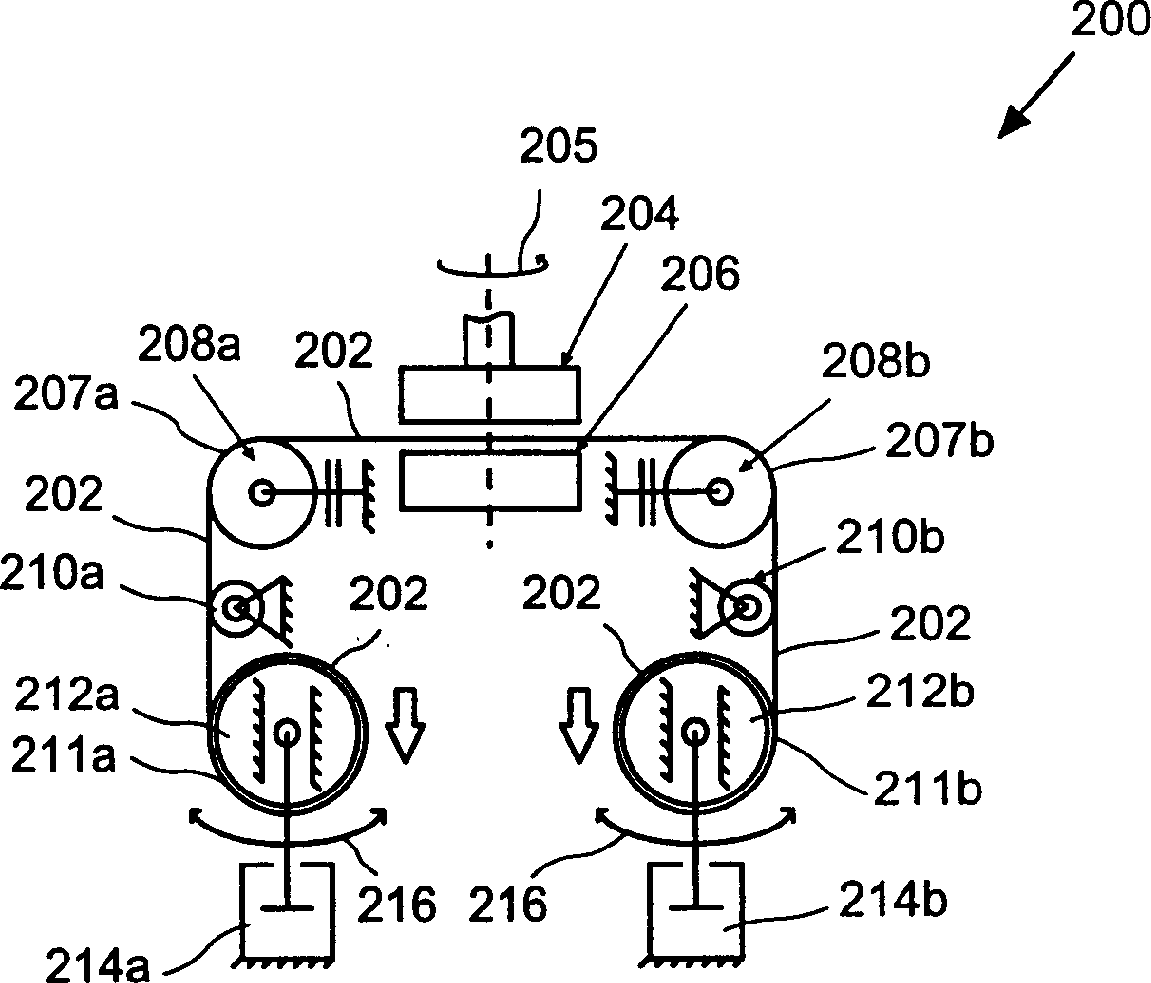

Oscillating fixed abrasive CMP system and methods for implementing the same

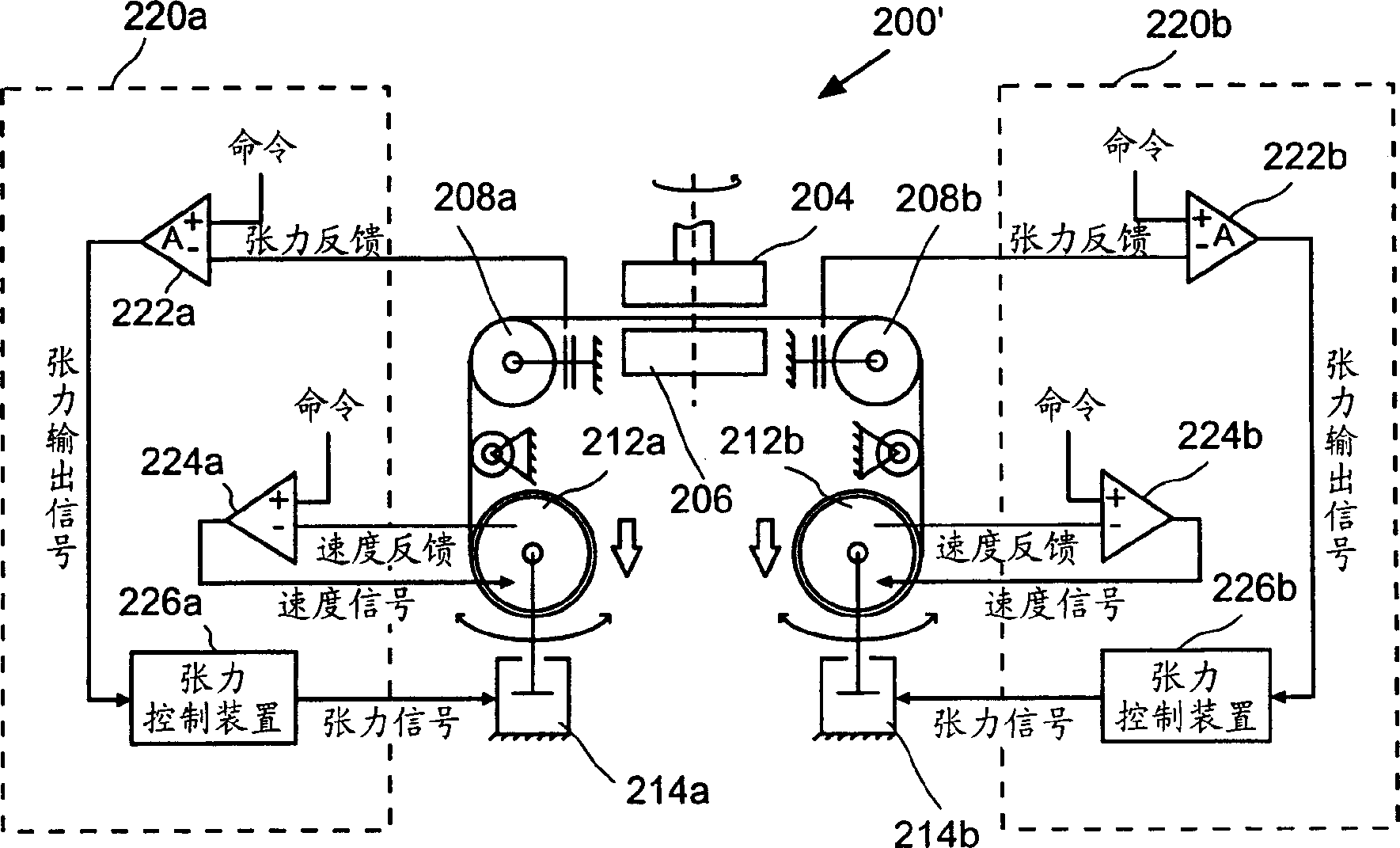

InactiveCN1438931ALess labor and in a very short offline timeShort offline timeBelt grinding machinesSemiconductor/solid-state device manufacturingEngineeringWeb handling

A chemical mechanical polishing (CMP) apparatus is provided. A first roller is situated at a first point and a second roller situated at a second point, such that the first point is separate from the second point. A polishing pad strip is also included and has a first end secured to the first roller and a second end secured to the second roller in a web handling arrangement. The polishing pad strip is configured to provide a surface onto which a substrate to be polished is lowered. Preferably, the polishing pad strip is a fixed abrasive pad and is configured to receive chemicals or DI water so as to facilitate a removal of material from a surface of the substrate.

Owner:LAM RES CORP

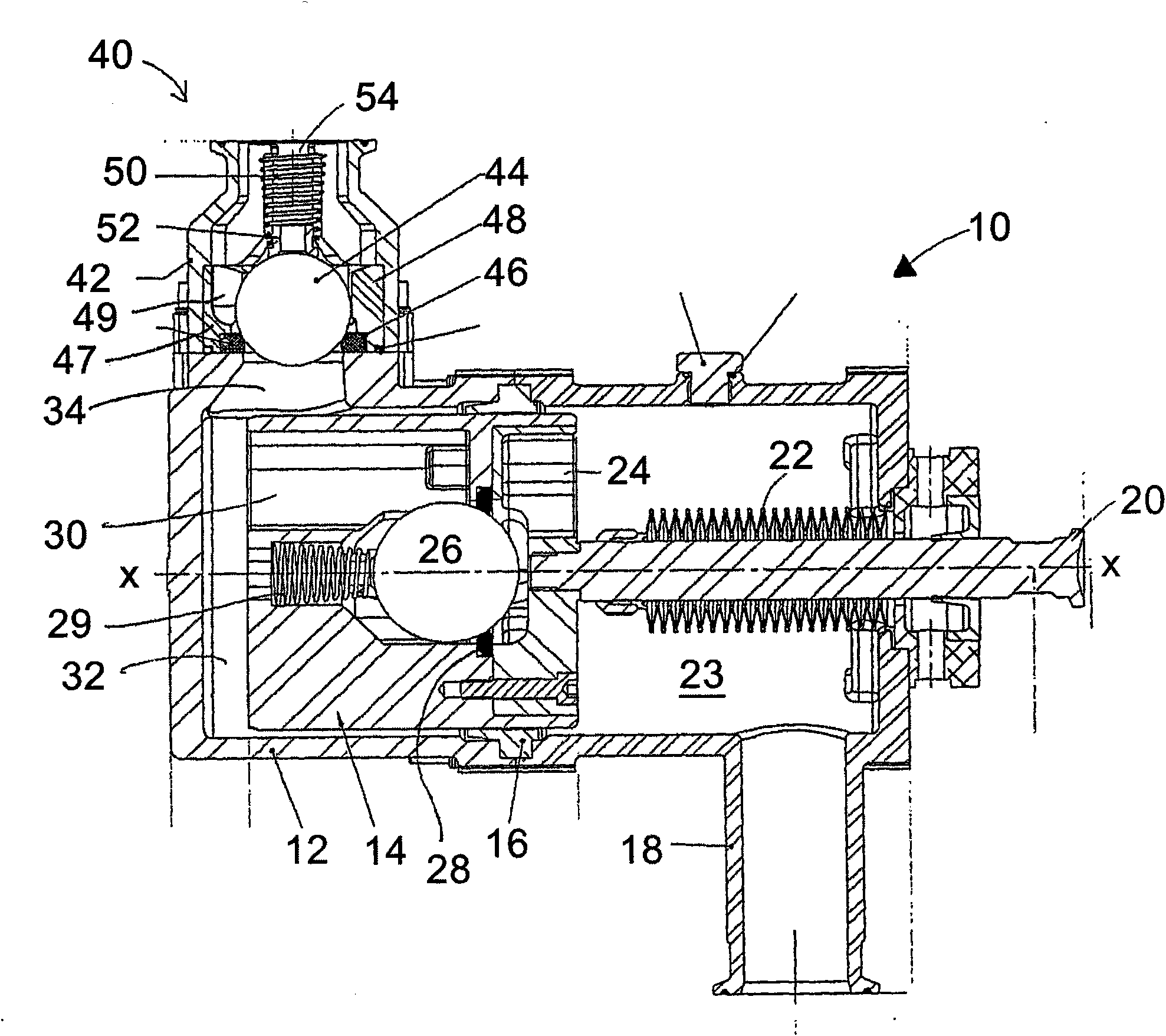

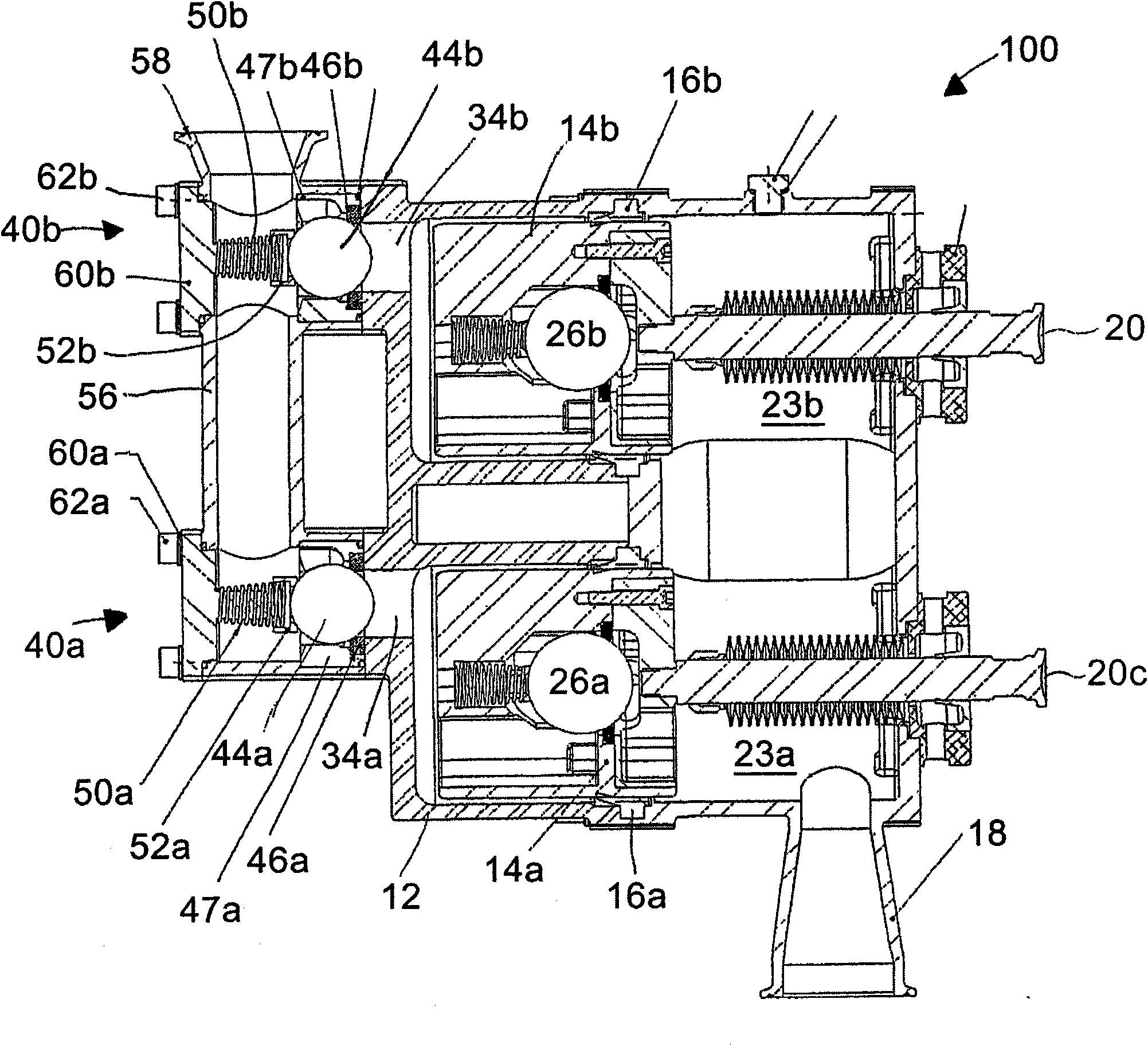

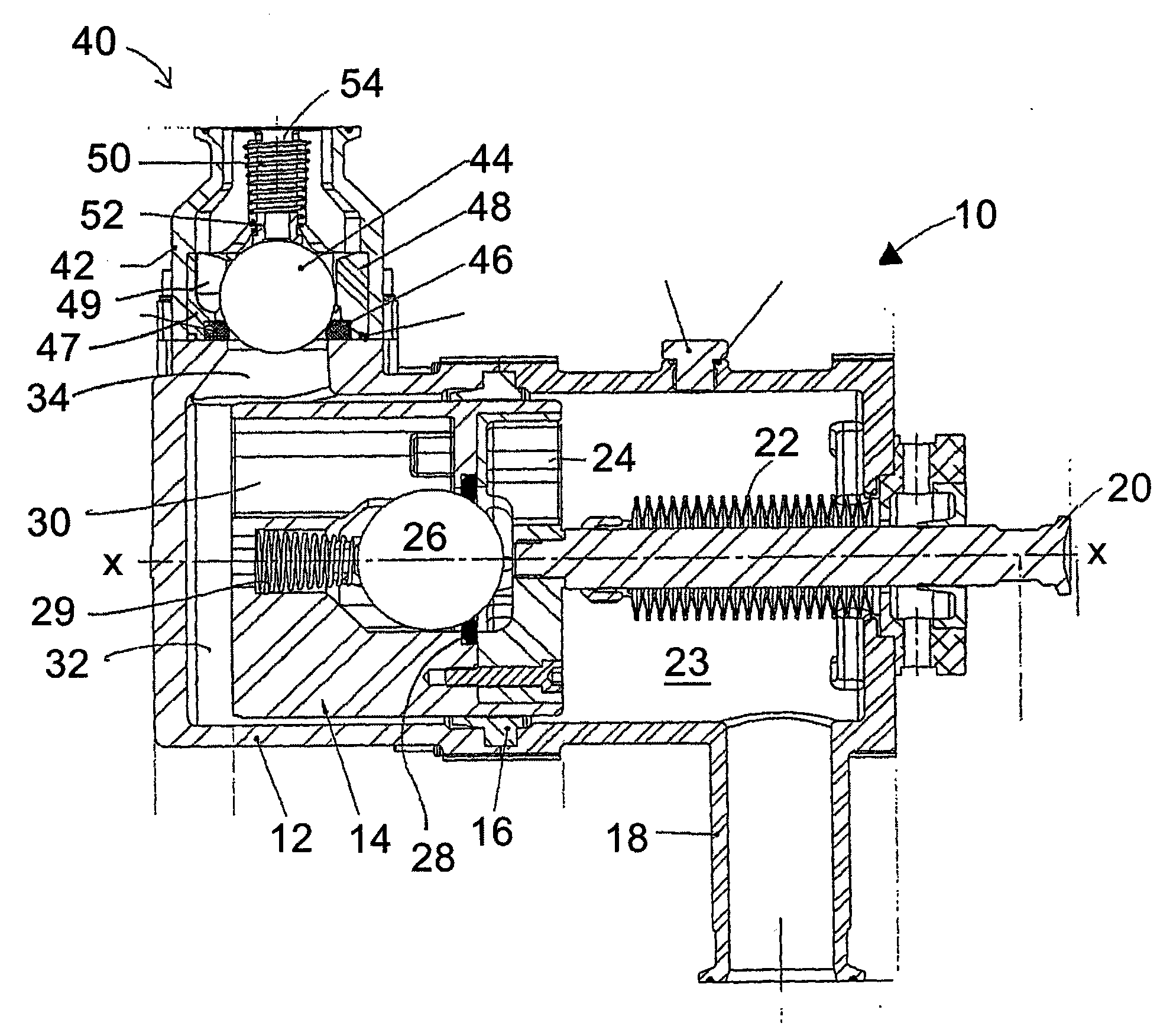

Liquid paint pumping apparatus

ActiveCN101796300AReduce abrasionReduce abrasivenessPositive displacement pump componentsCheck valvesCheck valvePiston

The invention relates to a liquid paint pumping apparatus comprising a piston reciprocable in a cylinder to pump liquid paint during a substantially horizontal pumping stroke of the piston and to charge the cylinder with paint during a reverse stroke of the piston. The apparatus further comprises a check valve disposed within the piston, the check valve comprising: a ball member, a seat, a spring urging the ball member into engagement with the seat, and a plastics cage guiding movement of the ball towards and away from the seat. The seat receives the ball member so as to form a seal to prevent flow of liquid paint between the ball and the seat during the pumping stroke of the piston, and the ball member moves away from the seat during the reverse stroke of the piston.

Owner:FINISHING BRANDS UK

Coating composition for a paper and paper coated therewith

InactiveUS20040067356A1Ink scuff may be considerably reducedGood print glossPigmenting treatmentNatural cellulose pulp/paperPigmentCoated paper

Coating composition comprising mineral pigment, for creating a matt or silk coated paper with decreased ink scuff tendency. The coating composition also comprises organic particles, which particles in an amount of 0.5-9.5 weight-% calculated on said mineral pigment, exhibit a particle size of more than 2 mum and at the most 50 mum. The invention also relates to a paper which is coated with said coating composition.

Owner:STORA ENSO AB

Coating composition for a paper and paper coated therewith

InactiveUS6833025B2Ink scuff may be considerably reducedGood print glossPigmenting treatmentNatural cellulose pulp/paperMaterials sciencePigment

Coating composition comprising mineral pigment, for creating a matt or silk coated paper with decreased ink scuff tendency. The coating composition also comprises organic particles, which particles in an amount of 0.5-9.5 weight-% calculated on said mineral pigment, exhibit a particle size of more than 2 mum and at the most 50 mum. The invention also relates to a paper which is coated with said coating composition.

Owner:STORA ENSO AB

Water based magnetic ink character recognition ink jet ink based on dispersion of functionalized nanoparticulate magnetic ferrite

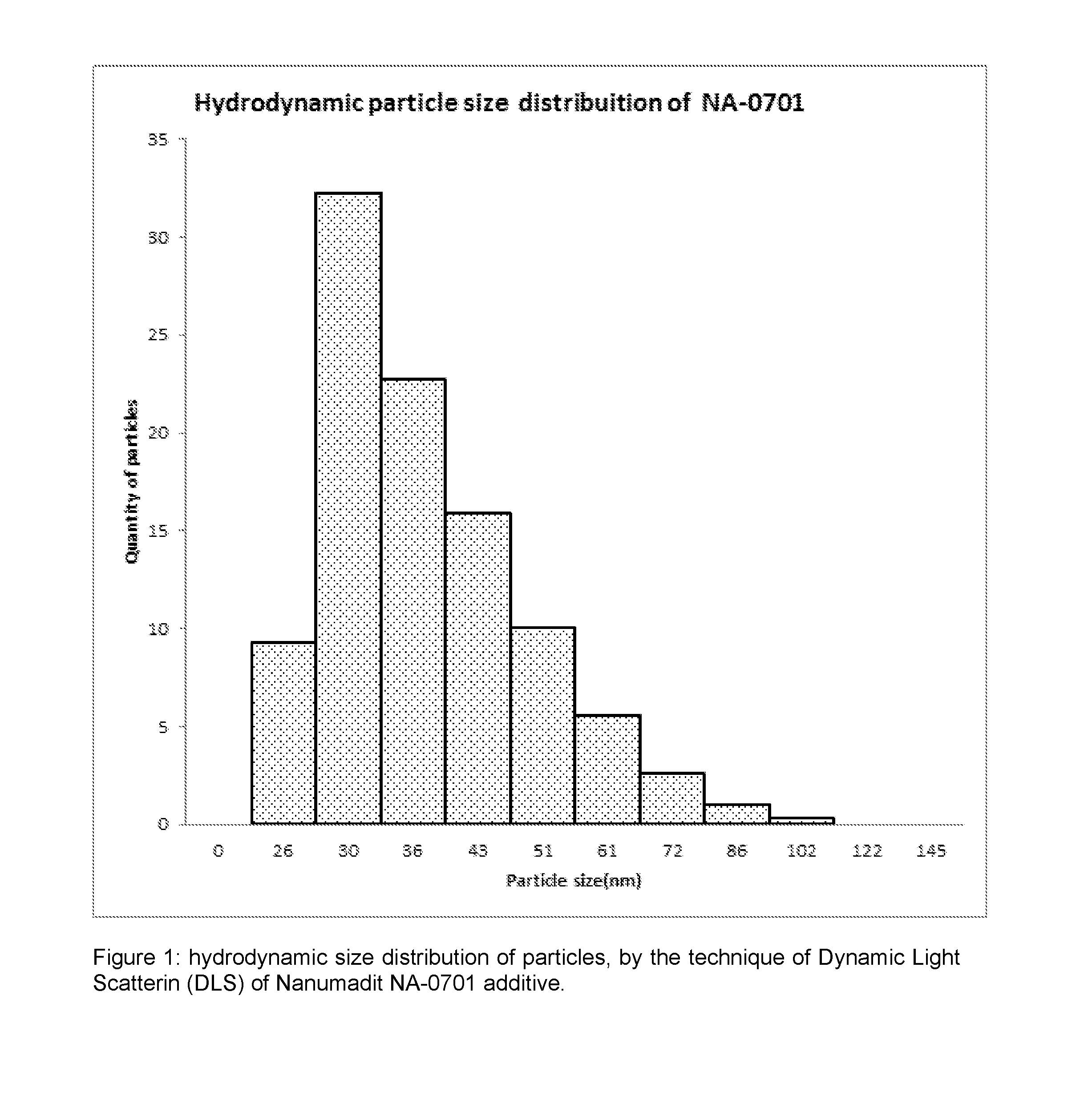

InactiveUS20160208120A1Improve performanceUnique dispersionMagnetic liquidsInksWater basedMagnetite Nanoparticles

The present invention describes a method to obtain magnetic aqueous ink composition for MICR (Magnetic Ink Character Recognition) ink jet printing comprising an aqueous dispersion of functionalized magnetic nanoparticles, humectant agents, solvents, biocide and water. It also allows obtaining stable inks for long periods with extremely high concentrations of magnetic nanoparticles with loading between 15% and 40% by mass and magnetic signals varying from 80 to 200%. Through the use and special combination of humectant agents, the present inventions increase the print head protection, by decreasing abrasiveness and increasing fluidity. The resulting ink has superior printing quality and increased service life of the printing system.

Owner:NANUM NANOTECNOLOGIA SA

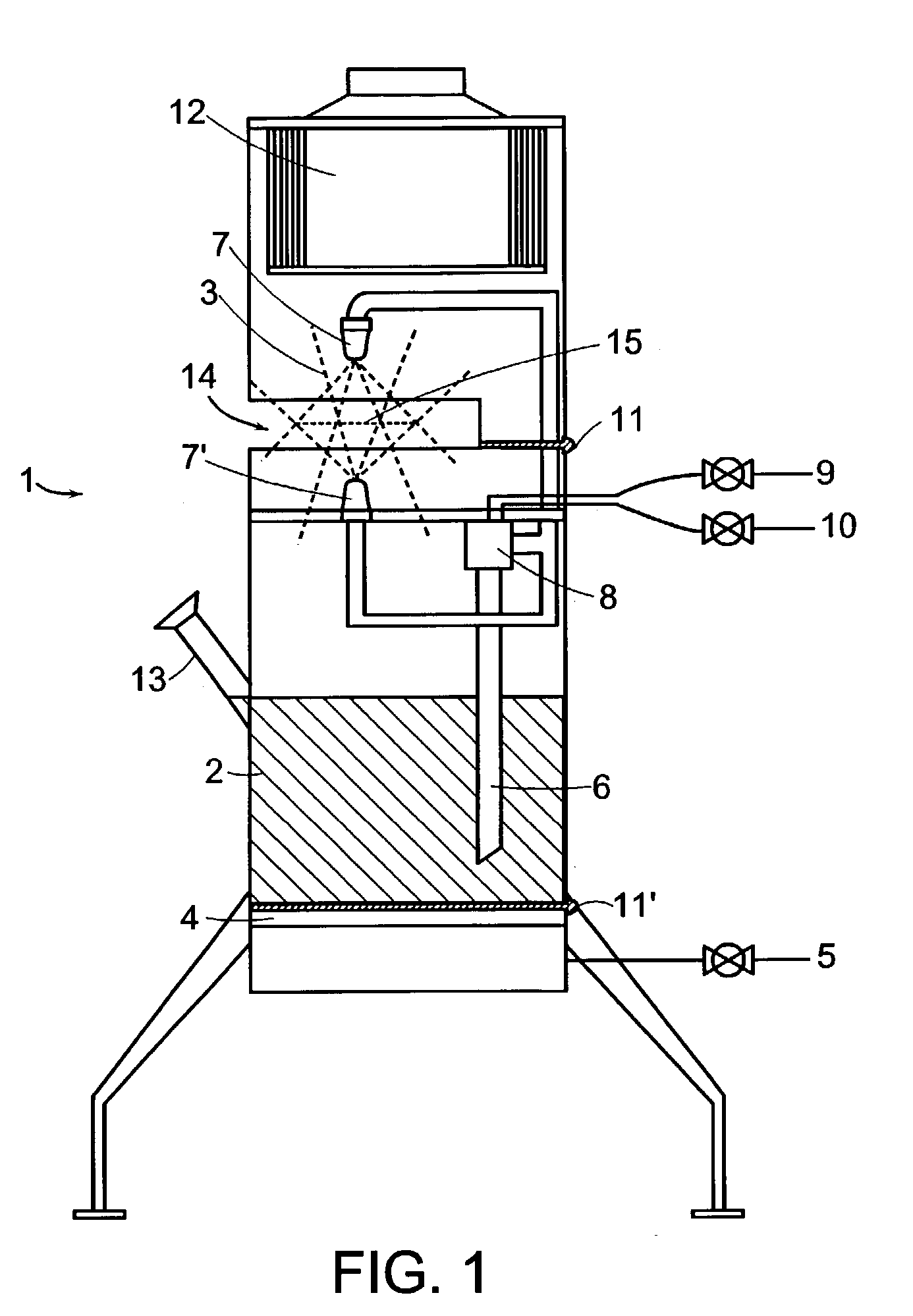

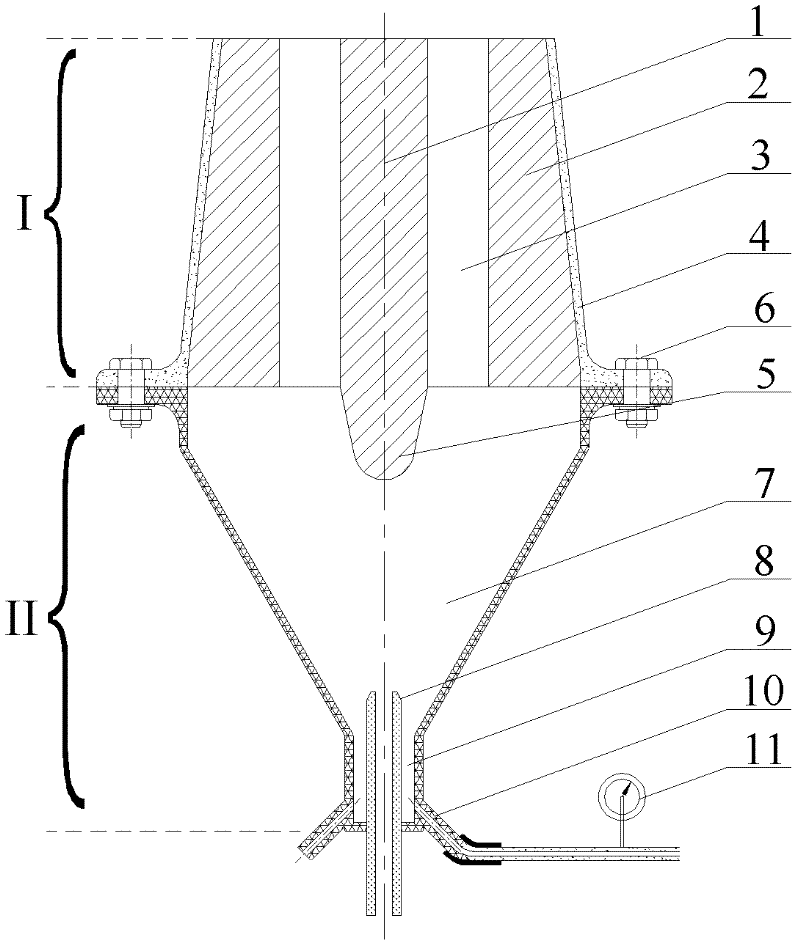

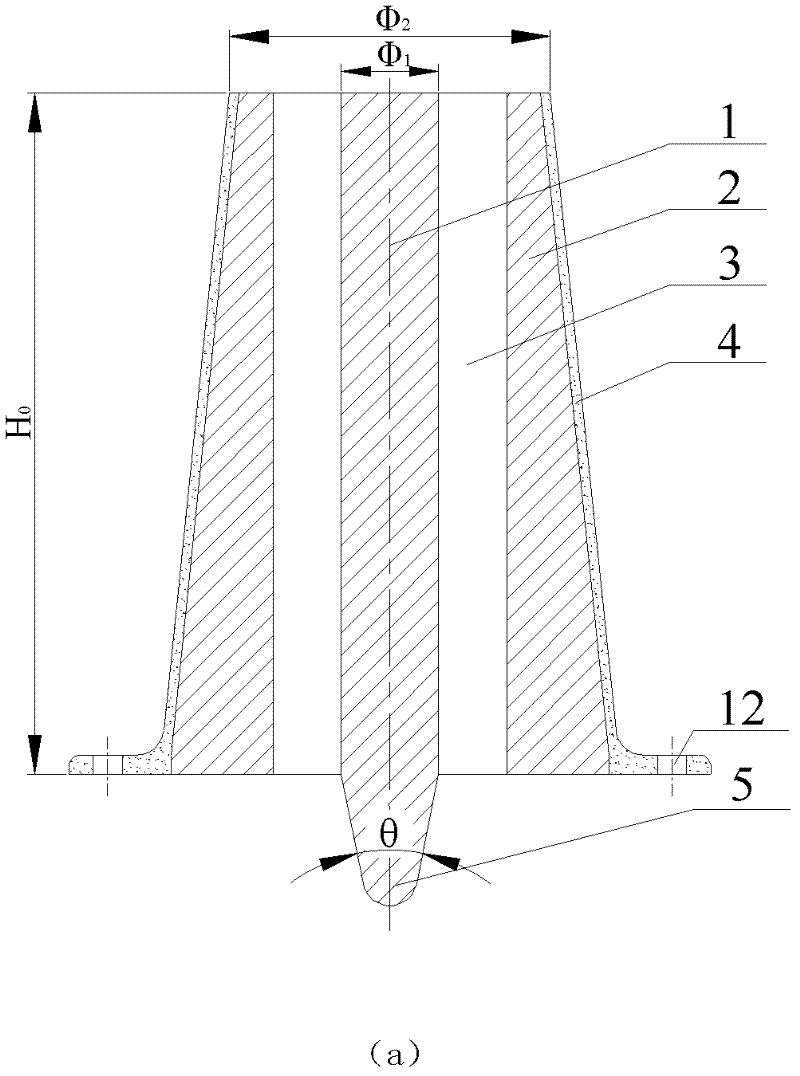

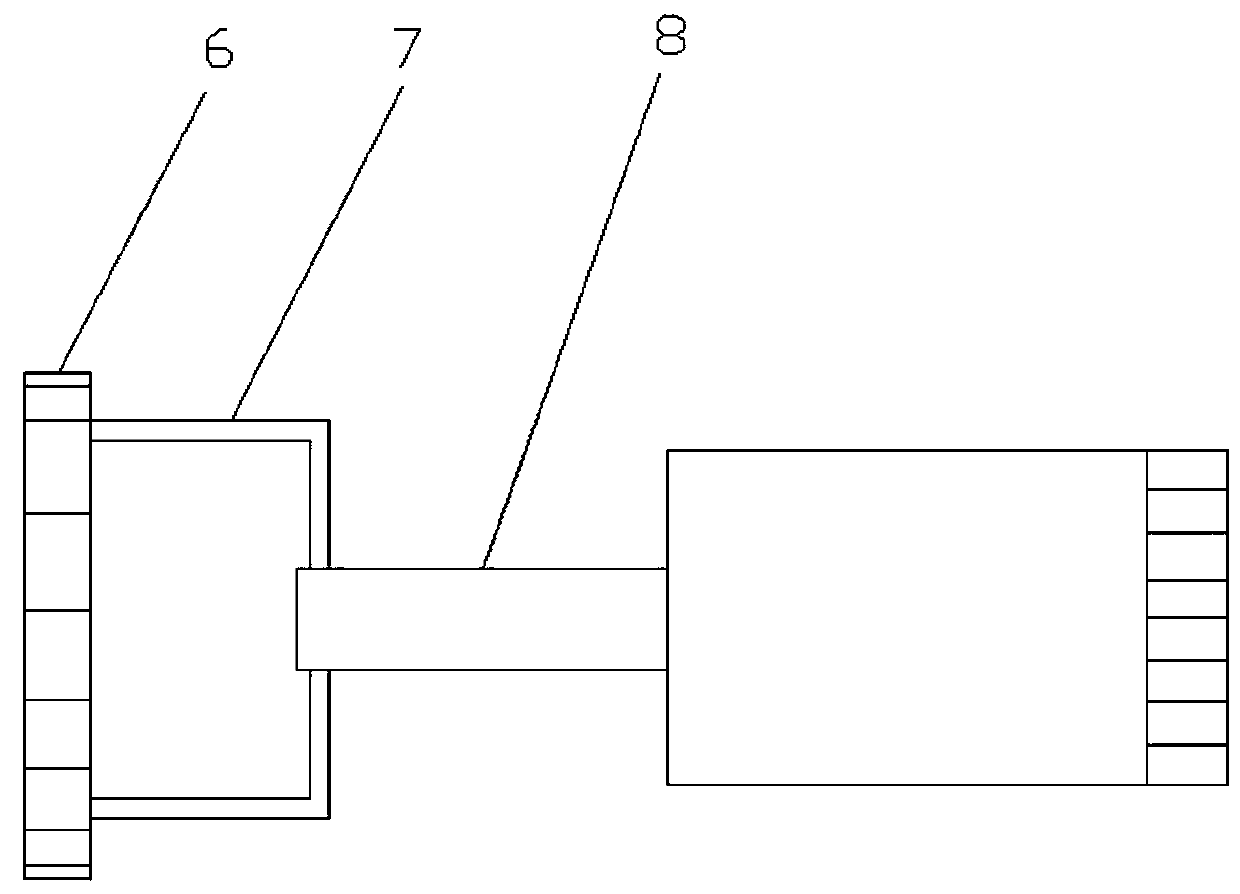

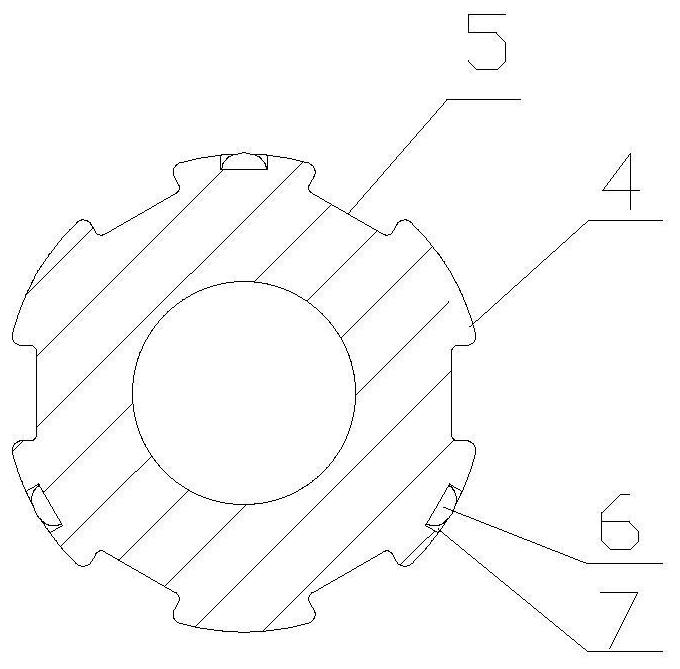

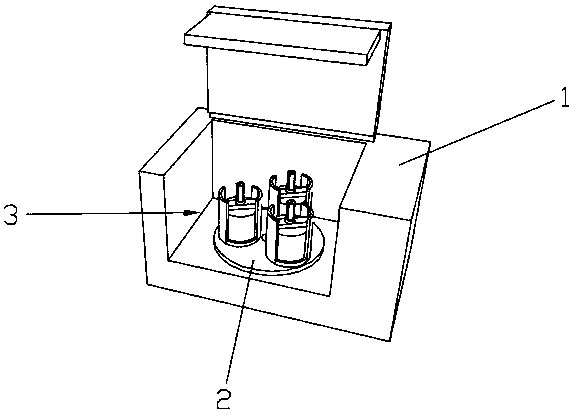

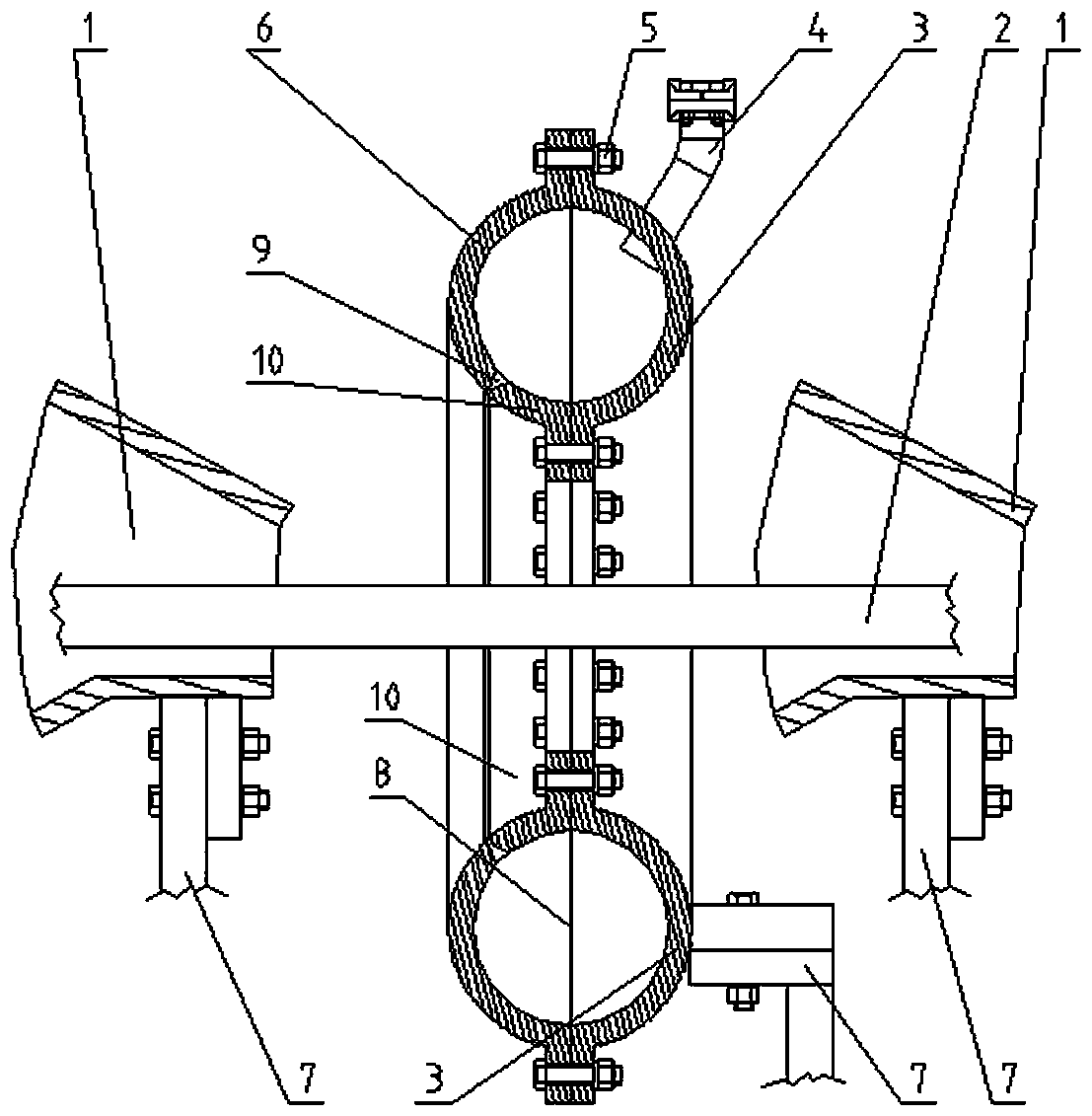

A device for blowing and spraying powder at the bottom of a ladle in a cyclone-protected gas storage chamber

The invention discloses a ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber, and belongs to the technical field of steel smelting. The ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber comprises a slit-type powder injection component I and the whirlwind-type flow-smoothing gas storage chamber II.A fire-resistant material is filled into the slit-type powder injection component. Multiple slits are distributed uniformly in the fire-resistant material. A middle axle plane which passes through ends which belong to the slits and are close to an axle center, and a vertical plane where the slits are arranged form an included angle gamma. The bottom of the whirlwind-type flow-smoothing gas storage chamber is connected with a whirlwind-type accelerating chamber. A low end of the whirlwind-type accelerating chamber is provided with a whirlwind-type gas flow conveying pipes. The whirlwind-type gas flow conveying pipes are arranged at both sides of a power-gas flow conveying pipe and form respectively beta angles with the power-gas flow conveying pipe. The ladle bottom blowing power injectiondevice with the whirlwind-type flow-smoothing gas storage chamber can reduce obviously a degree of powder-gas flow pulsation, accumulation of falling powder, and resistance to a powder-gas flow when the powder-gas flow is fed into the slits, can improve obviously a uniform flow conveying rate of the powder-gas flow in the slits. The ladle bottom blowing power injection device with the whirlwind-type flow-smoothing gas storage chamber has the advantages of stable blowing, small pulsation, low corrosion on fire-resistant materials, safe and reliable characteristics, feasibility for continuous and stable blowing and long service life of fire-resistant materials.

Owner:NORTHEASTERN UNIV LIAONING

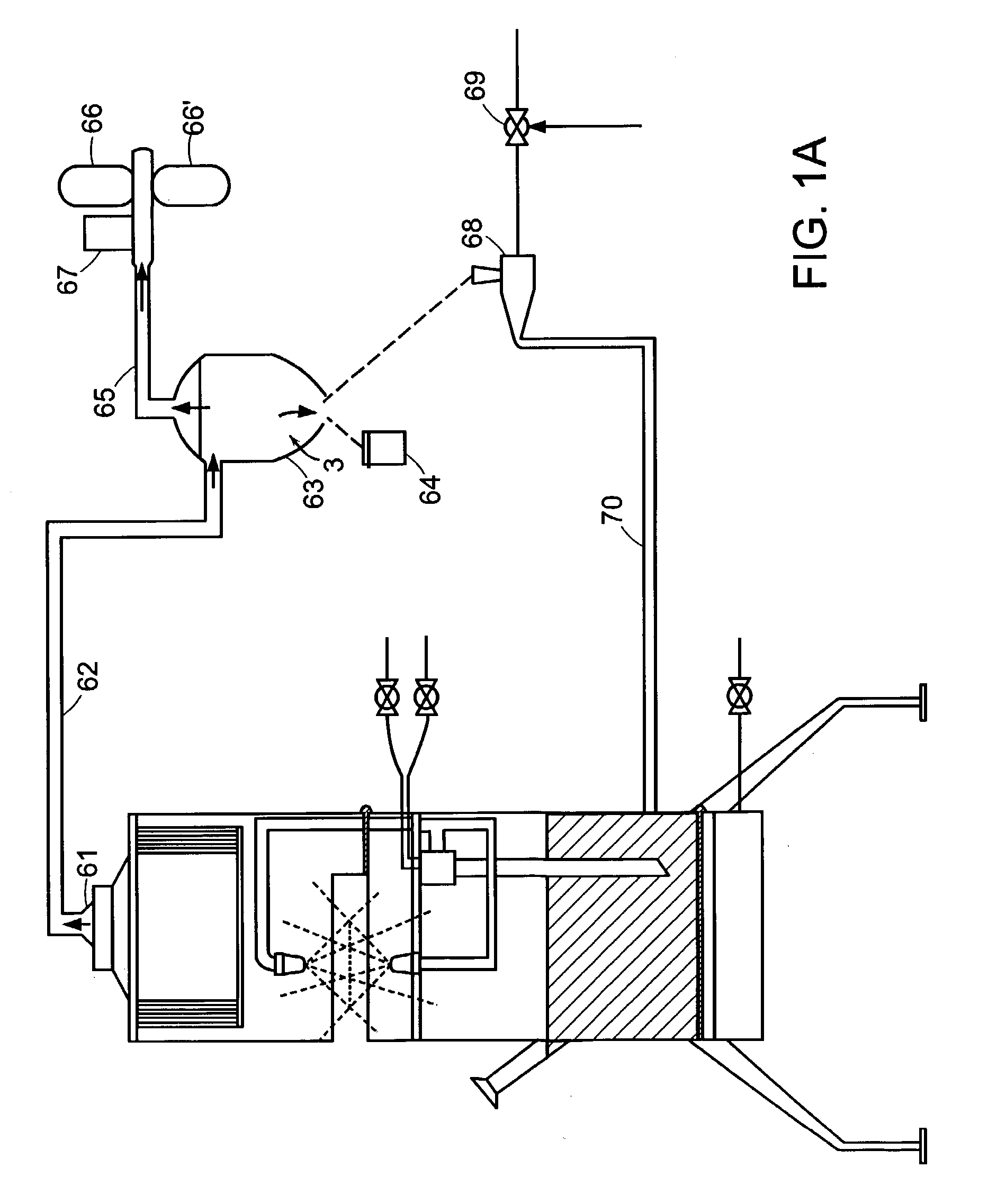

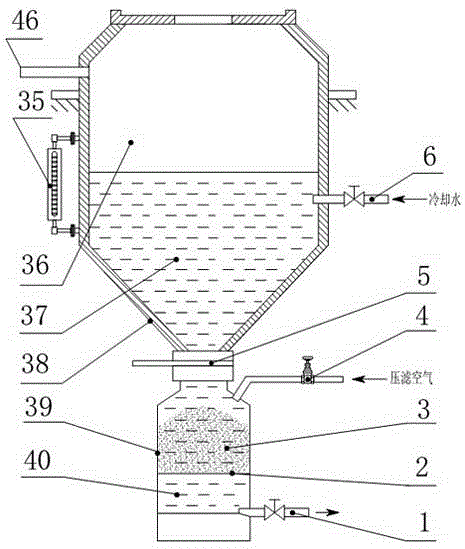

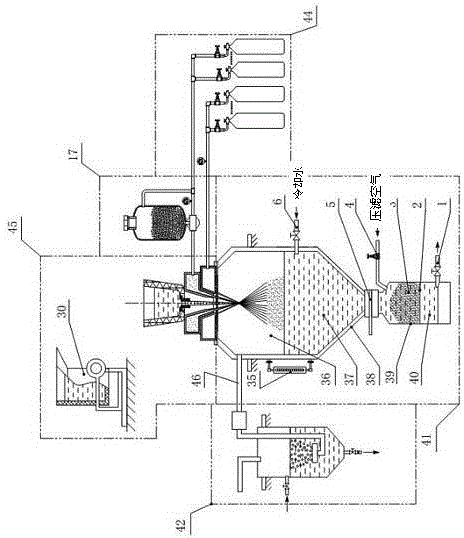

Water-cooling fast-condensing method and device for preparing powder-mixed atomized water-cooling fast-condensing magnetic abrasives

The invention provides a water-cooling fast-condensing device of preparation equipment for free-falling powder-mixed atomized water-cooling fast-condensing magnetic abrasives. The water-cooling fast-condensing device comprises a water drain valve (1), a filter screen (2), magnetic abrasives (3), a filter-pressing air valve (4), a gate valve (5), a cold water valve (6), a water level gauge (35), an atomizing water-cooling chamber (36), cooling water (37), an atomizing water-cooling chamber shell (38), a magnetic abrasive tank (39), filtering water (40) and an atomizing cavity exhaust pipe (46). According to the device, the flying distance of molten-state liquid drops containing hard abrasives is controlled by adjusting the level of the cooling water, so that condensing time is controlled, and the distribution depth of hard abrasive particles in a magnetic abrasive metal base body is controlled; the hard abrasive particles are distributed in the shallow surface layer of the magnetic abrasive metal base body and tightly combined with the metal base body, so that the high-performance magnetic abrasives are obtained. The invention also provides a method for preparing the free-falling powder-mixed atomized water-cooling fast-condensing magnetic abrasives. The reliable device is provided for controlling the depth distribution of the hard abrasives in the magnetic abrasive metal base body and preparing the high-performance magnetic abrasives.

Owner:SHANDONG UNIV OF TECH

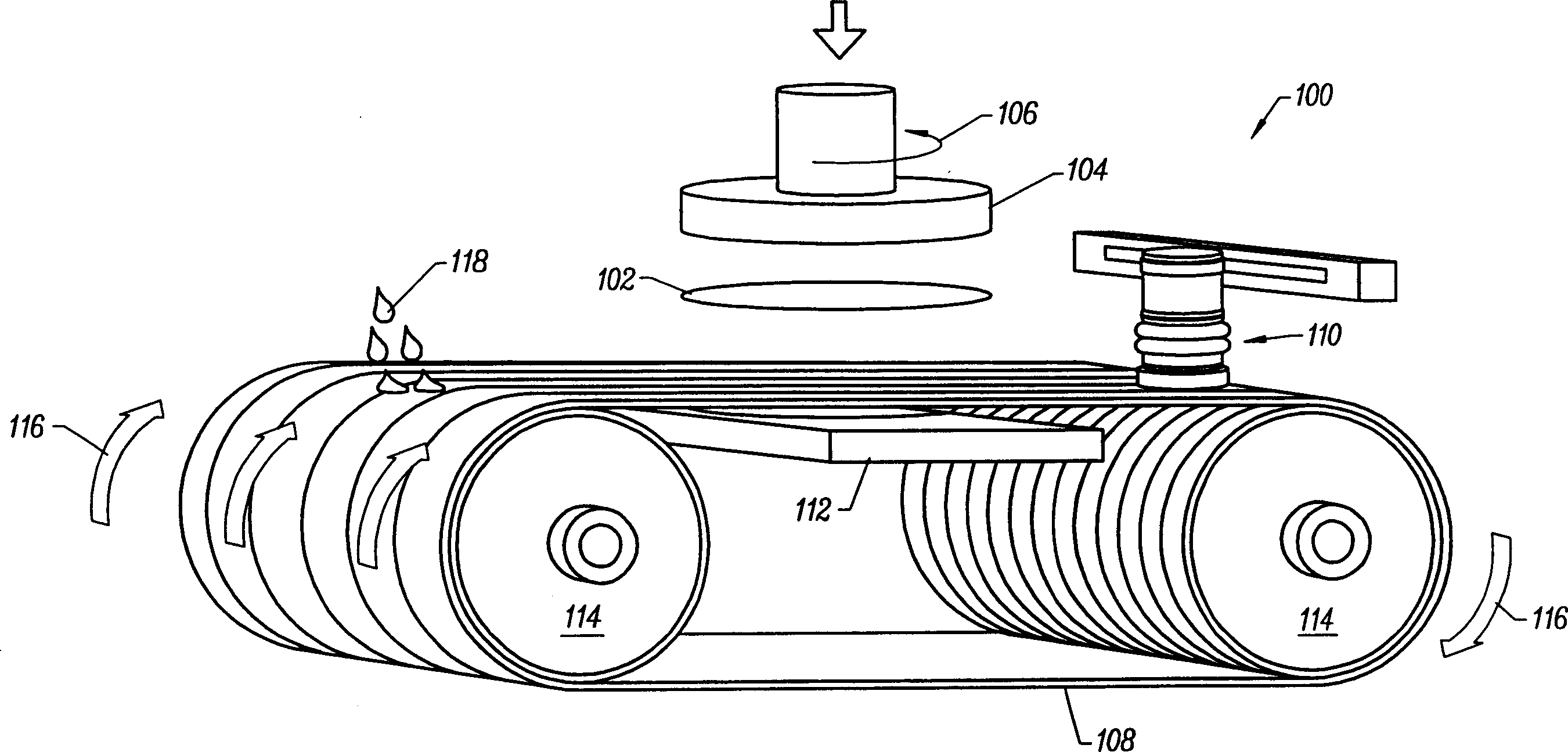

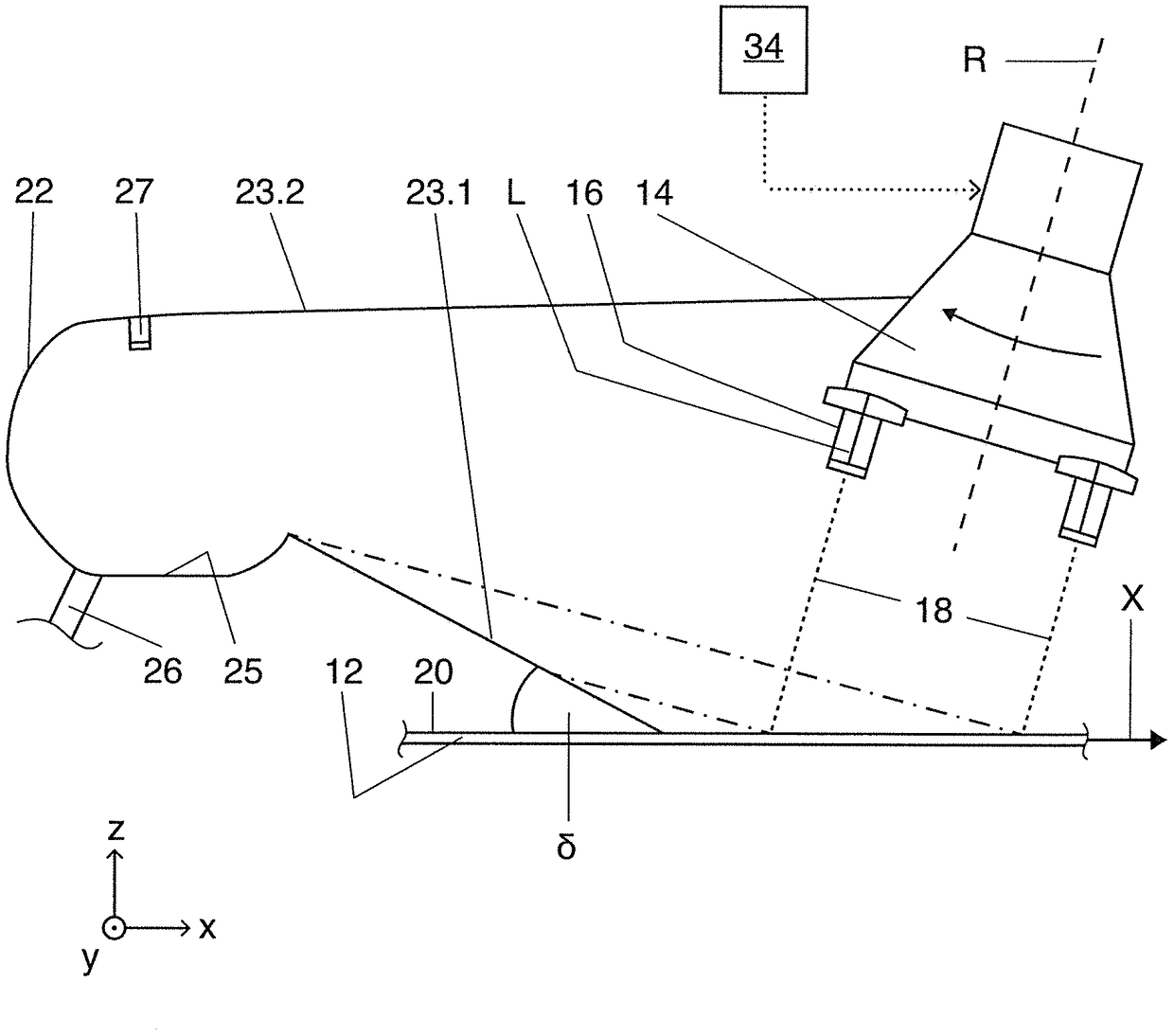

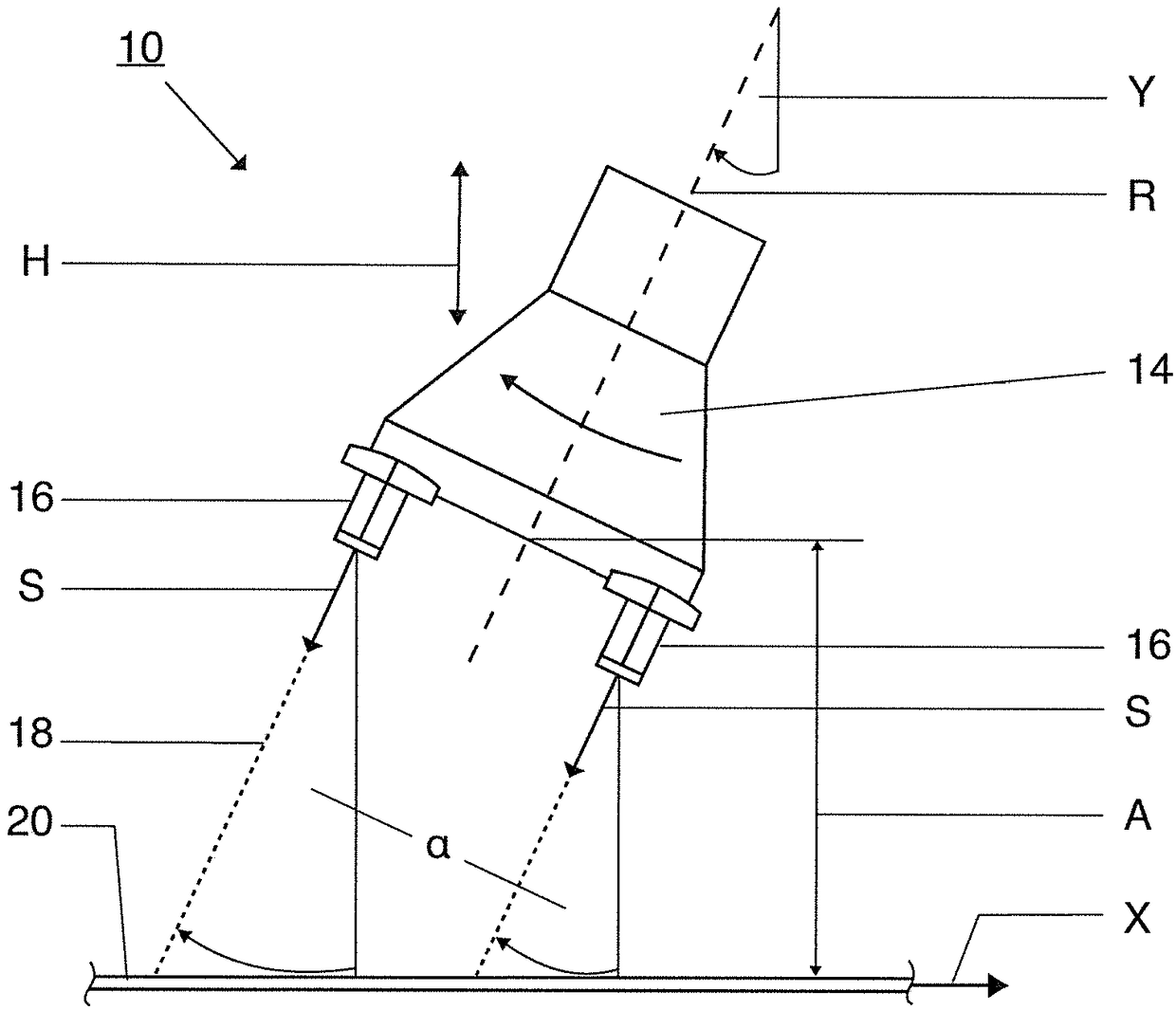

Device and method for descaling a workpiece in motion

ActiveCN108778543ASufficient to remove scale massSave running mediumMovable spraying apparatusWork treatment devicesRotational axisJet flow

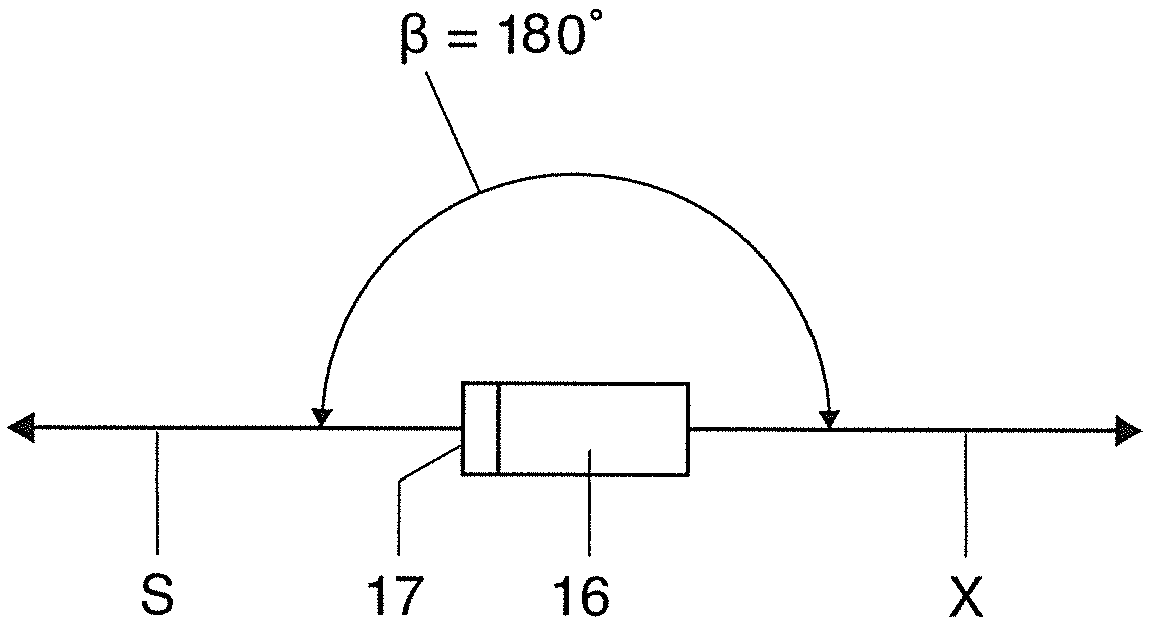

The invention relates to a device and a method for descaling a workpiece that is in motion relative to the device in a movement direction (X). The device (10) comprises a rotor head (14) which can rotate about an axis of rotation (R) that is tilted, at an angle (Gamma), at an incline with respect to an orthogonal line to a surface (20) of the workpiece (12). The device also comprises a plurality of jet nozzles (16) mounted on the rotor head (14), wherein a liquid (18), particularly water, can be emitted from the jet nozzles (16) onto the workpiece (12) at an angle of incidence (ALPHA) at an incline to the surface (20) of said workpiece (12). The jet nozzles (16) are mounted rigidly on the rotor head (14) such that, when said rotor head (14) rotates about its axis of rotation (R), the spraydirection (S) of the liquid (18) emitted from the jet nozzles (16) is directed counter relative to a projection into a plane parallel to the surface (20) of the workpiece (12), i.e. at a spray angle(Beta) of approximately 180 DEG to the movement direction (X) of the workpiece (12).

Owner:SMS GRP GMBH

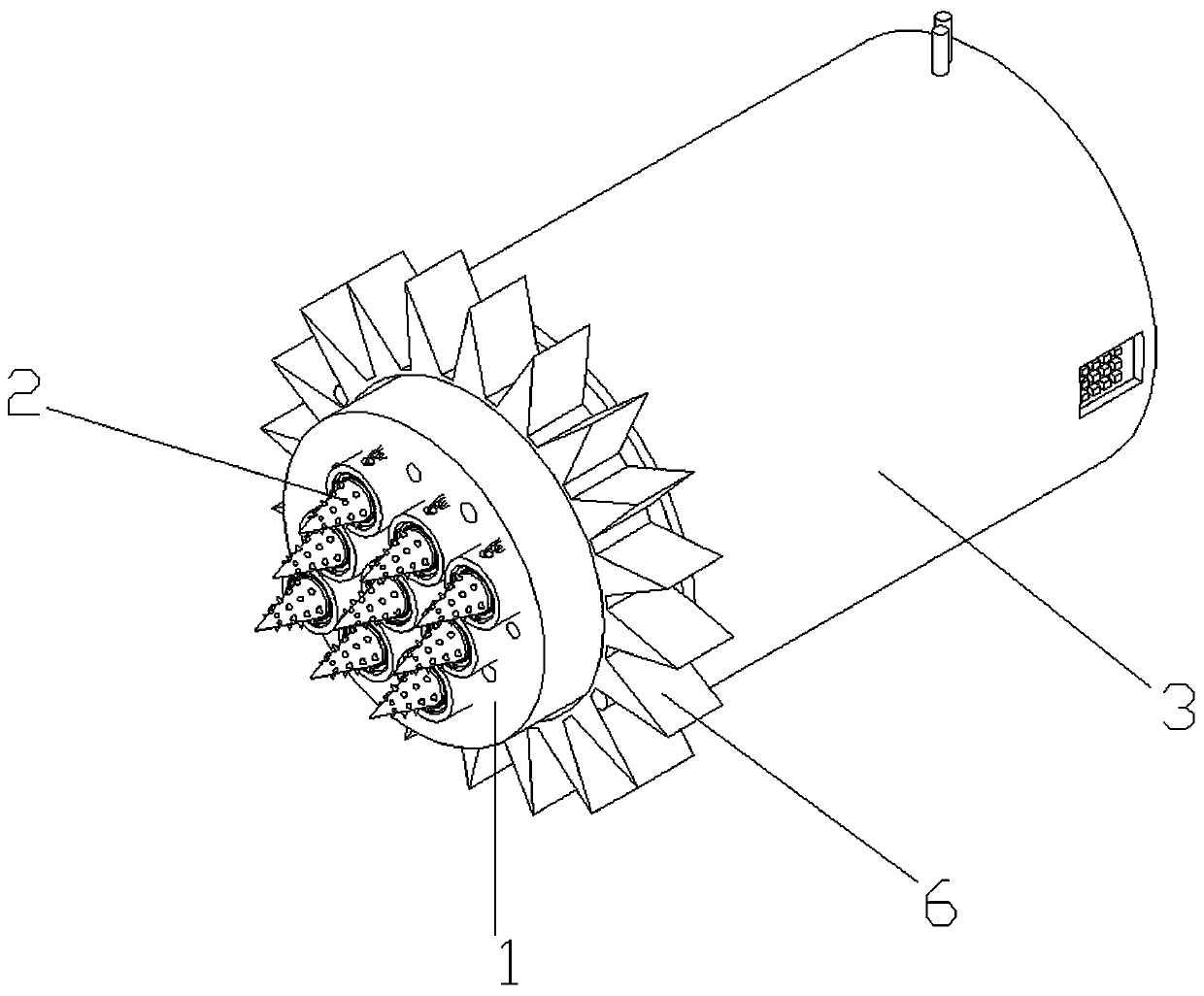

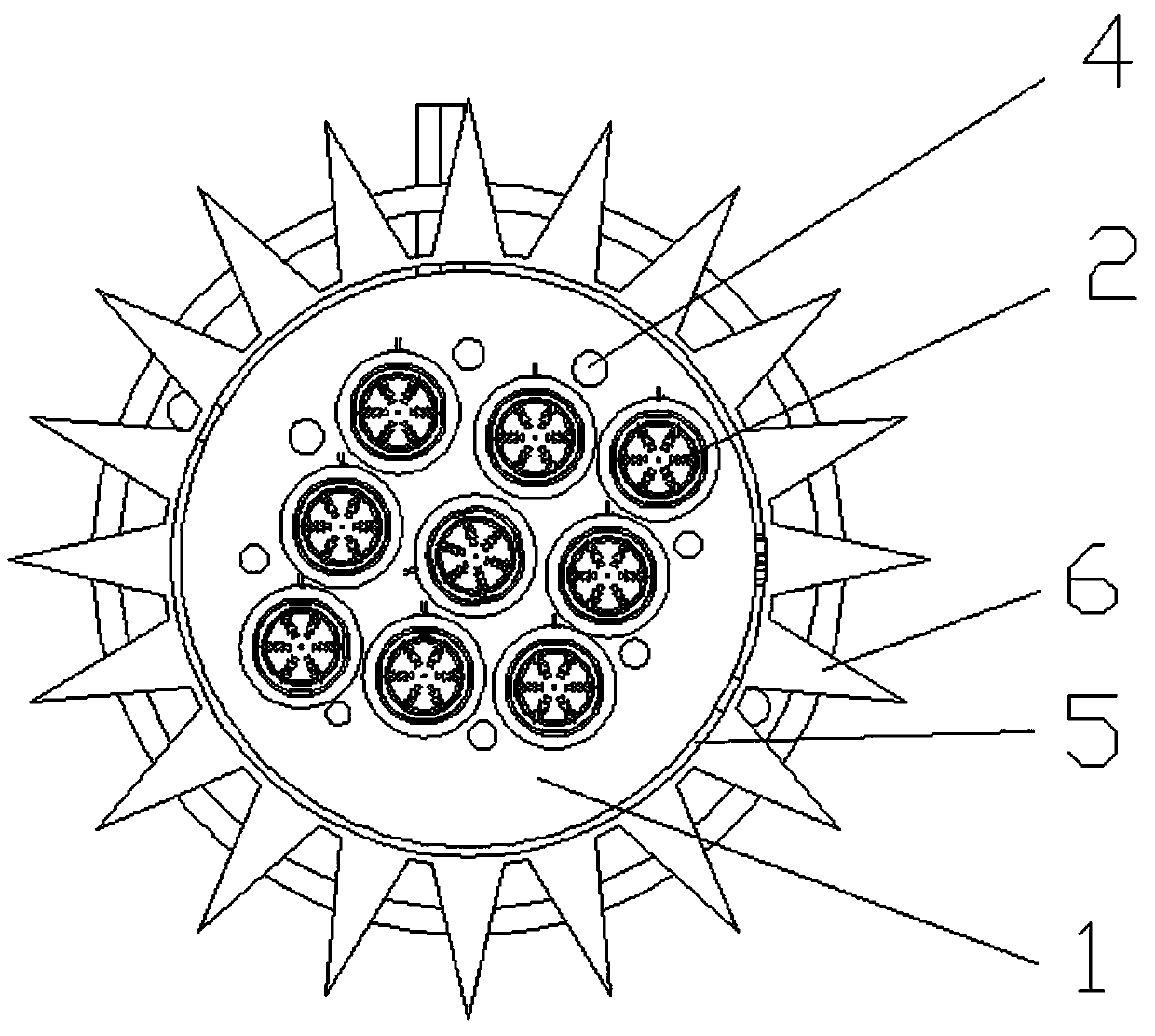

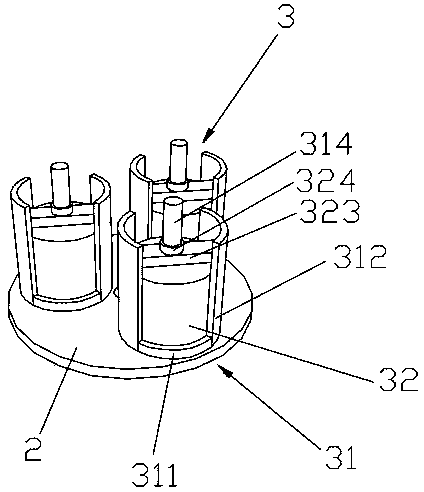

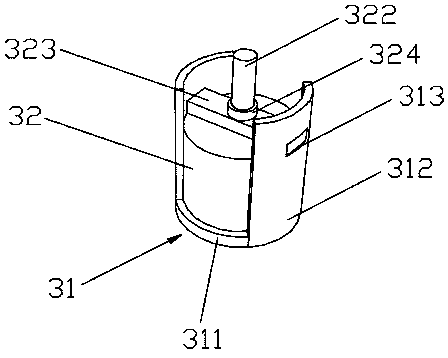

Electromagnetic impulsive rock breaking and drilling device and application method

The invention discloses an electromagnetic impulsive rock breaking and drilling device and an application method. The device comprises a mounting disc. A plurality of drill bit mechanisms are arrangedon one side of the mounting disc, the other side of the mounting disc is fixedly connected to the end part of a shield, and each drill bit mechanism comprises a mounting barrel fixedly arranged in the mounting disc, and a self-rotating drill bit capable of moving front and back is arranged in the mounting barrel. In addition, the invention discloses the application method corresponding to the device. The device solves the problem that an existing rock breaking technique is insufficient in safety, pollutes the environment and is low in efficiency, and meanwhile, achieves impulsive rock breaking and rotary drilling functions.

Owner:CHINA THREE GORGES UNIV

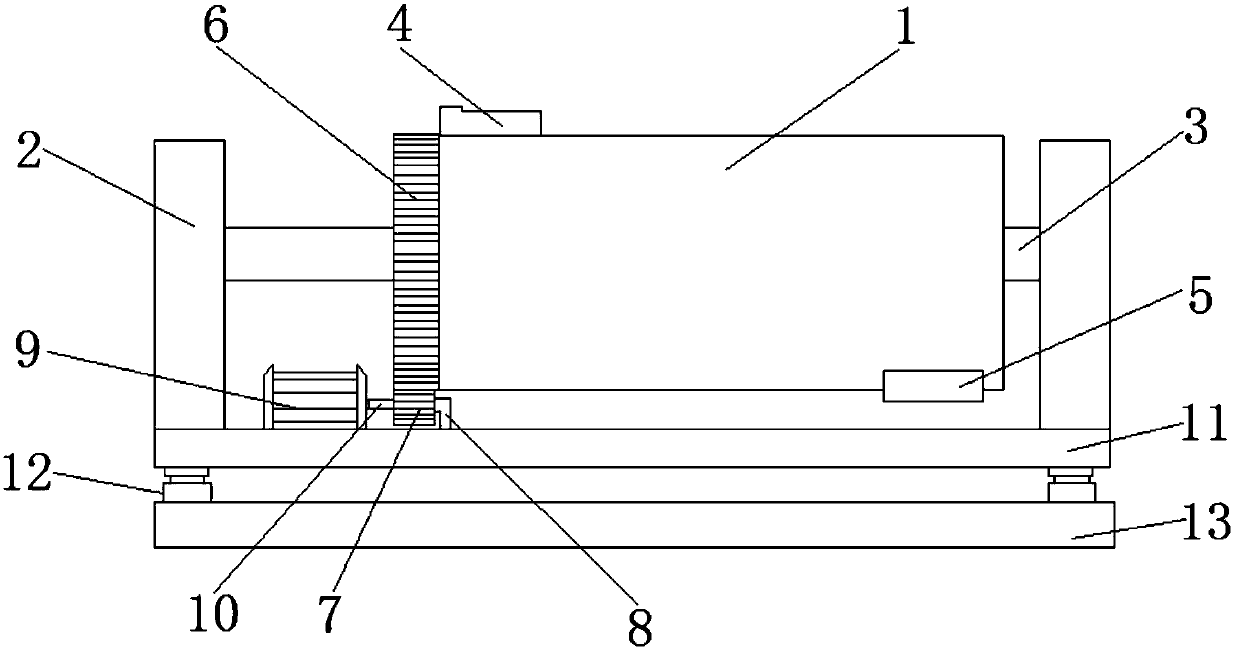

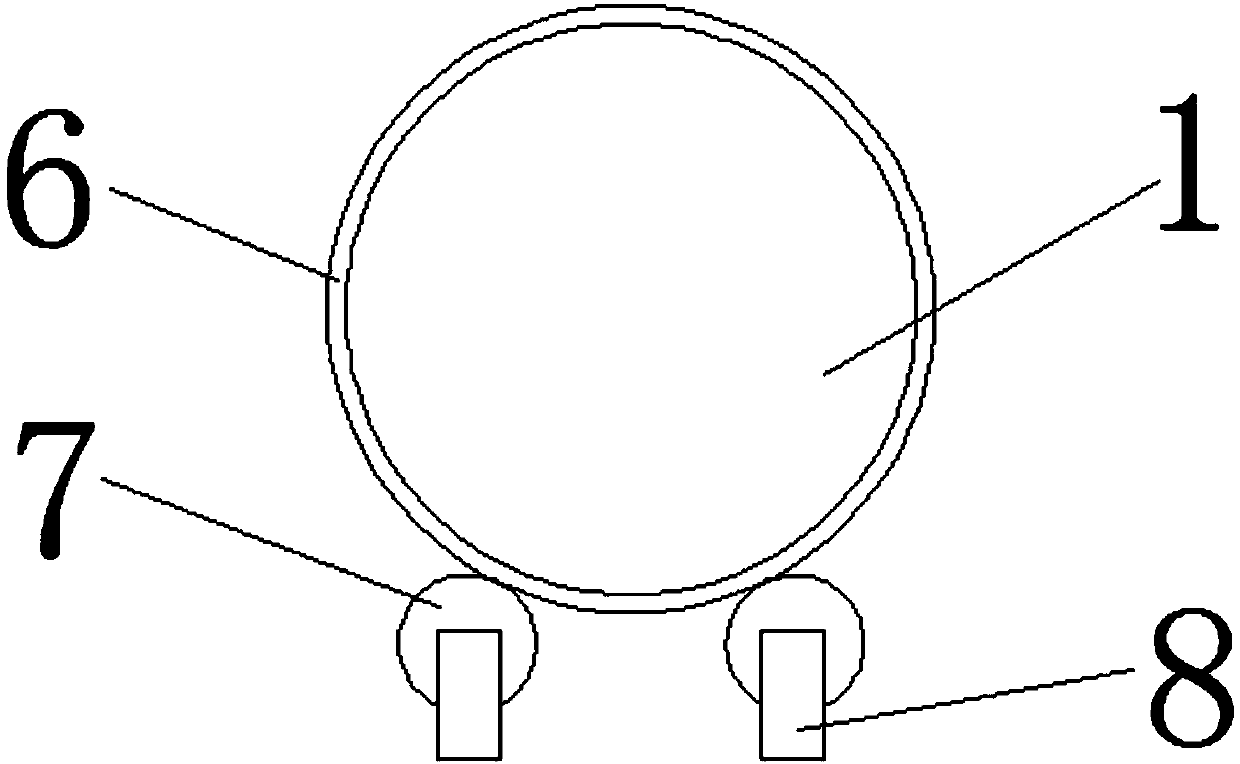

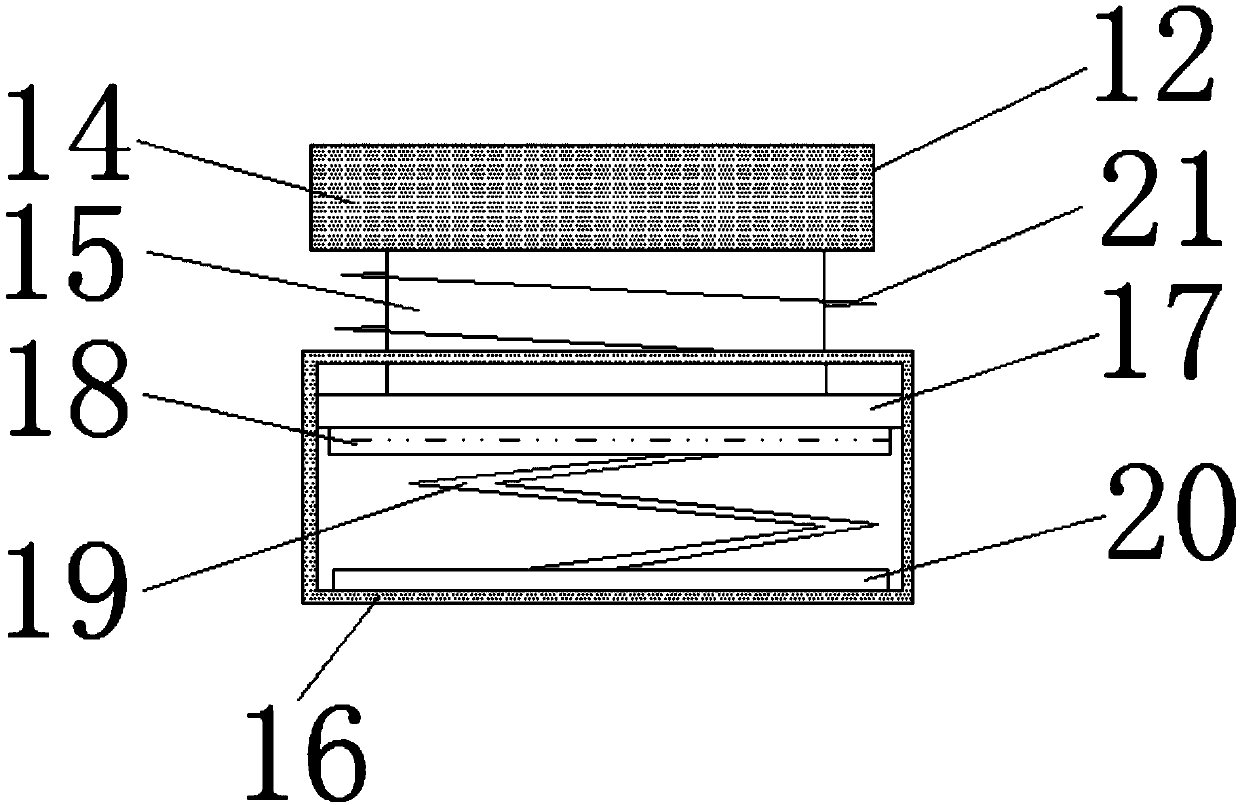

Ball mill with good stability

InactiveCN107649253AImprove stabilityImprove the smooth operation of workNon-rotating vibration suppressionGrain treatmentsFatigue damageEngineering

The invention provides a ball mill with better stability and relates to the technical field of ball mills. The ball mill with better stability includes a ball mill body, the ball mill body is movably installed between two brackets on both sides of the ball mill body through a rotating shaft, the bracket is welded to the top of the bottom plate, the bottom of the bottom plate is welded to the top of the buffer, and the buffer The bottom of the part is welded to the top of the base, the top of the ball mill body is fixedly installed with a feeder, and the bottom of the ball mill body is fixedly installed with a discharge port. The ball mill with better stability is equipped with buffer parts. The elastic properties of the buffer parts weaken the vibration generated when the ball mill is working, weaken the additional dynamic load generated during the operation of the main body and the torque transmitted by the linkage shaft, etc., and improve the performance of the ball mill. Stable operation, reduce the periodic impact and grinding effect of the ball mill during operation, reduce fatigue damage such as impact and grinding, and improve the service life of the ball mill.

Owner:江门市新会区联垦农业经营有限公司

Aqueous surface treatment composition for paper and board

ActiveUS20190271115A1Improve surface qualityImprove suppression propertiesSpecial paperPaper coatingCardboardAmylosucrase activity

Embodiments disclosed herein provide enzymatic formulations comprising a polypeptide having amylase activity for producing a paper product. Also provided are aqueous surface treatment compositions for paper and board comprising degraded starch. Further provided are methods for producing paper and board using the aqueous surface treatment composition, and to corrugated boards produced from this paper.

Owner:BASF AG

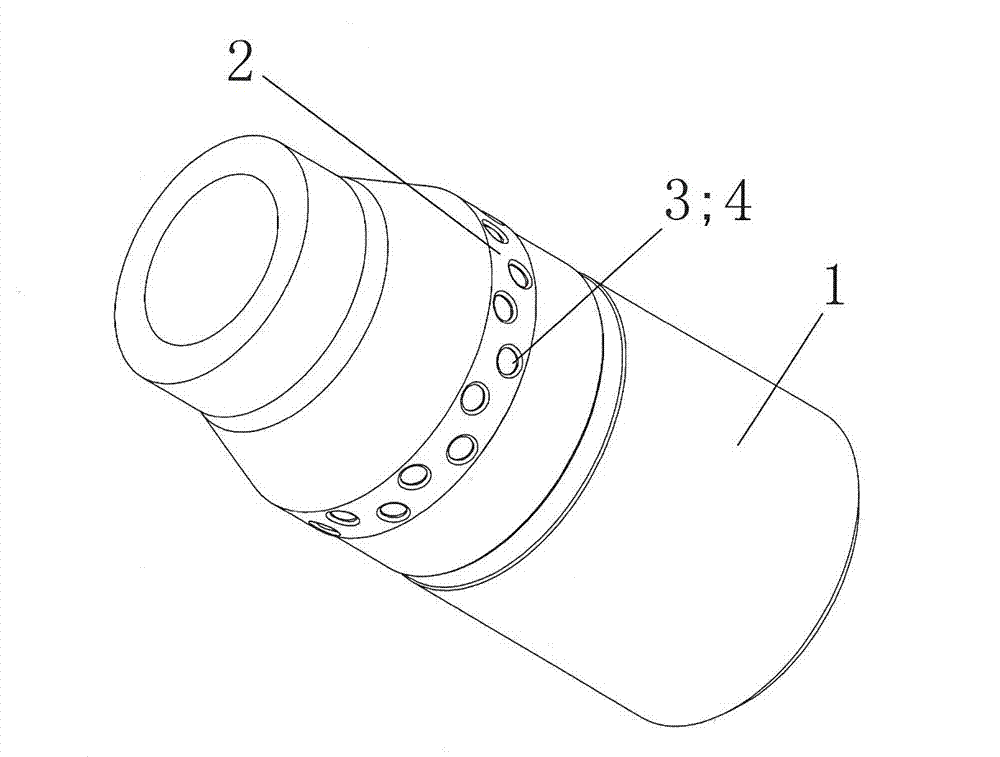

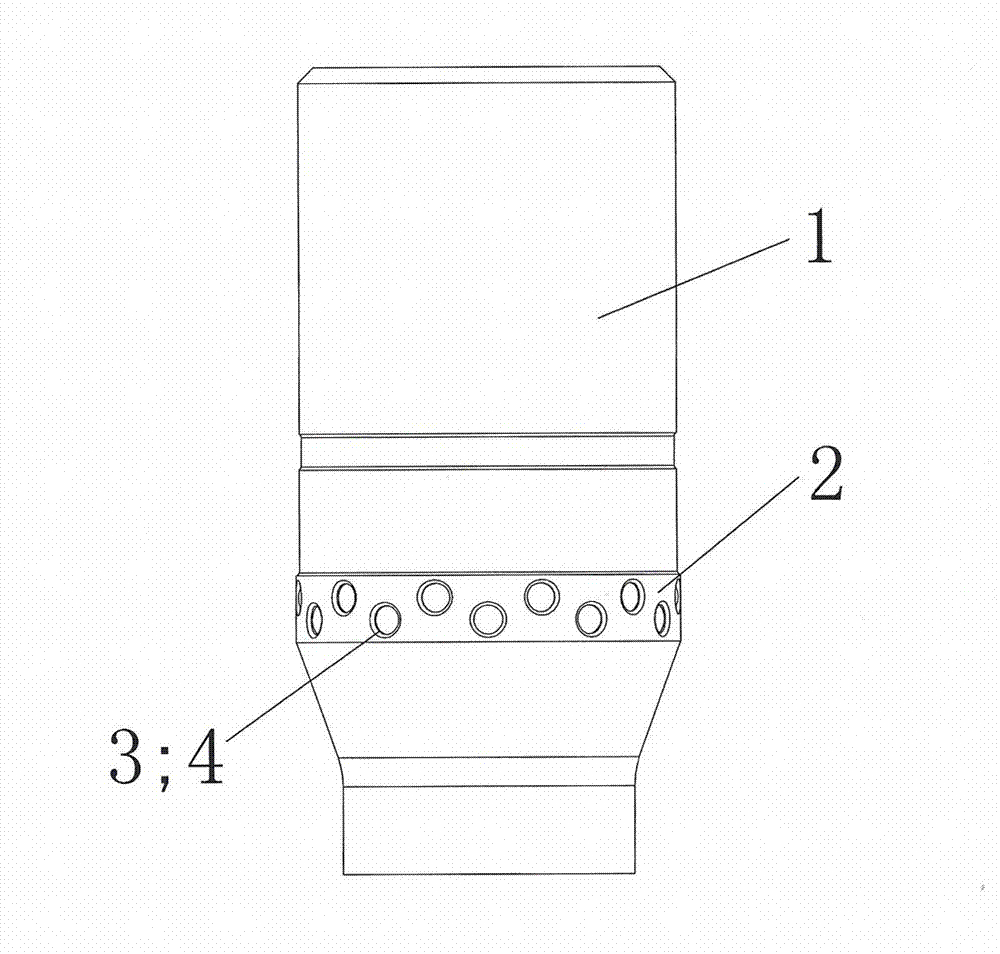

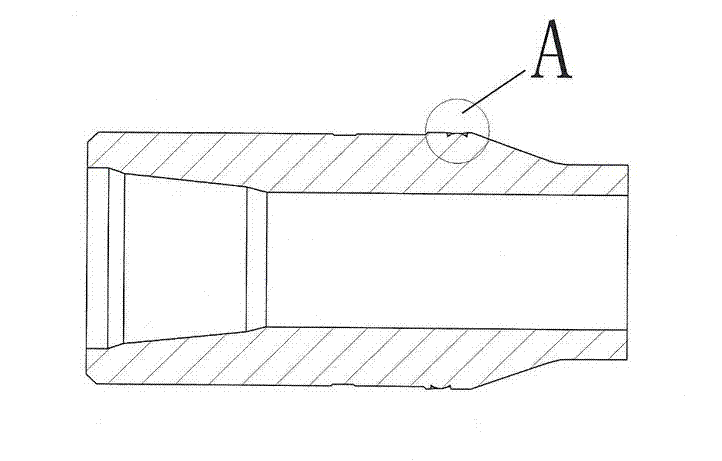

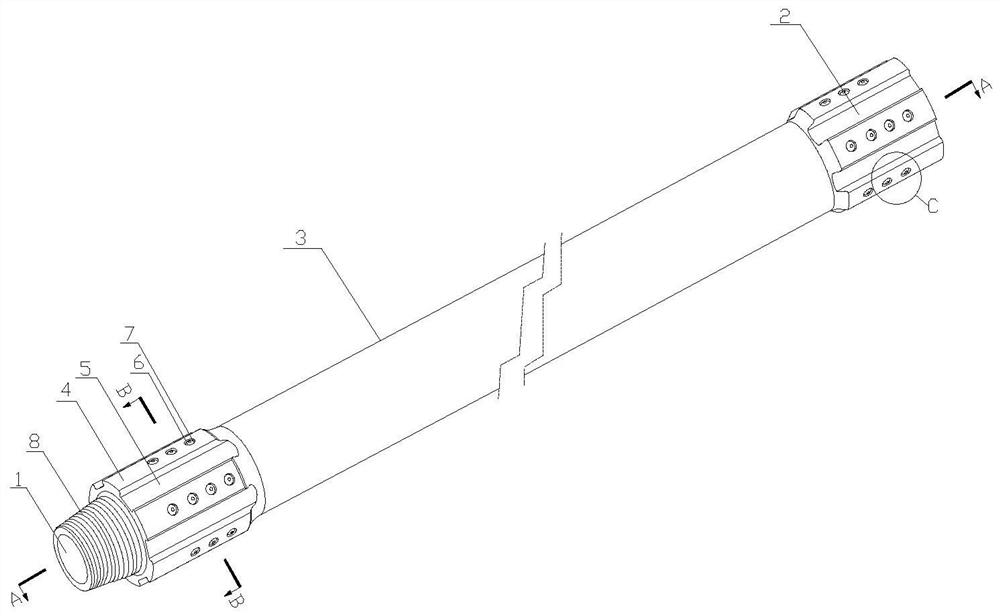

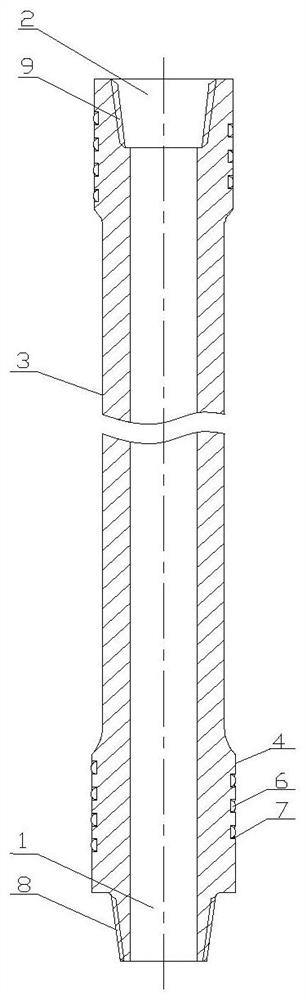

Wear-resisting weak-abrasiveness bionic tool joint

InactiveCN102828701AImprove wear resistanceReduce abrasivenessDrilling rodsDrilling casingsInterference fitWear resistance

The invention discloses a wear-resisting weak-abrasiveness bionic tool joint, which is characterized in that a plurality of pit unsmooth structure units which are regularly distributed are arranged on a bionic wear-resisting belt of the tool joint, each pit unsmooth structure unit is internally provided with a convex-hull-shaped unsmooth structure unit, the depth of the pit unsmooth structure unit is identical to the overall height of the convex-hull unsmooth structure unit, the aperture of each pit unsmooth structure unit is 0.001 to 0.1mm smaller than the diameter of the convex-hull unsmooth structure unit, the top of each pit unsmooth structure unit is in arc transition of a pit prismatic surface to be connected together with the low-friction-coefficient high-wear-resisting convex-hull unsmooth structure unit in an interference fit way to form a wear-resisting unsmooth structure surface, and the top surface of the combined convex-hull unsmooth structure unit is leveled to the surface of the tool joint. The wear-resisting weak-abrasiveness bionic tool joint has characteristics that the service life of a drill pipe is prolonged, the abrasion on a bushing is reduced, the anti-viscosity is strong, the wear resistance of the drill pipe is improved, and the like, and can effectively reduce the underground accident, improve the drilling quality and save the drilling cost.

Owner:JILIN UNIV

Drilling rod with axial deep groove wear-resistant joint for well drilling

ActiveCN112253002AExtended service lifeImprove work efficiencyDrilling rodsDrilling casingsWell drillingStructural engineering

The invention relates to the technical field of drilling in geological engineering, in particular to a drilling rod with an axial deep groove wear-resistant joint for well drilling. The drilling rod comprises a rod body, a male connector and a female connector are arranged at two ends of the rod body, and a plurality of connector unscrewing clamping grooves extending along the axial direction of the male connector and the female connector are distributed on the male connector and the female connector in the circumferential direction. A connector anti-abrasion flange is formed between every twoadjacent connector screwing and unscrewing clamping grooves and provided with wear-resistant materials or a plurality of convex spherical crown installation blind holes, the smooth wear-resistant convex spherical crowns are fixedly connected into the convex spherical crown installation blind holes, and the rod body, the male connector and the female connector are each of a through hollow structure. The drill rod can be continuously screwed or unscrewed without applying radial pressure in the tripping and drill rod screwing and unscrewing processes, no damage is caused to the surface of the connector, abrasion of the connector is only generated in a well and the wall of the well, and therefore the overall service life of the drill rod is prolonged, the probability of accidents such as drilling tools and jamming of the drill rod is reduced, and the safety of the drill rod is improved. Therefore, the working efficiency of drilling is improved and the drilling cost is saved.

Owner:JILIN UNIV

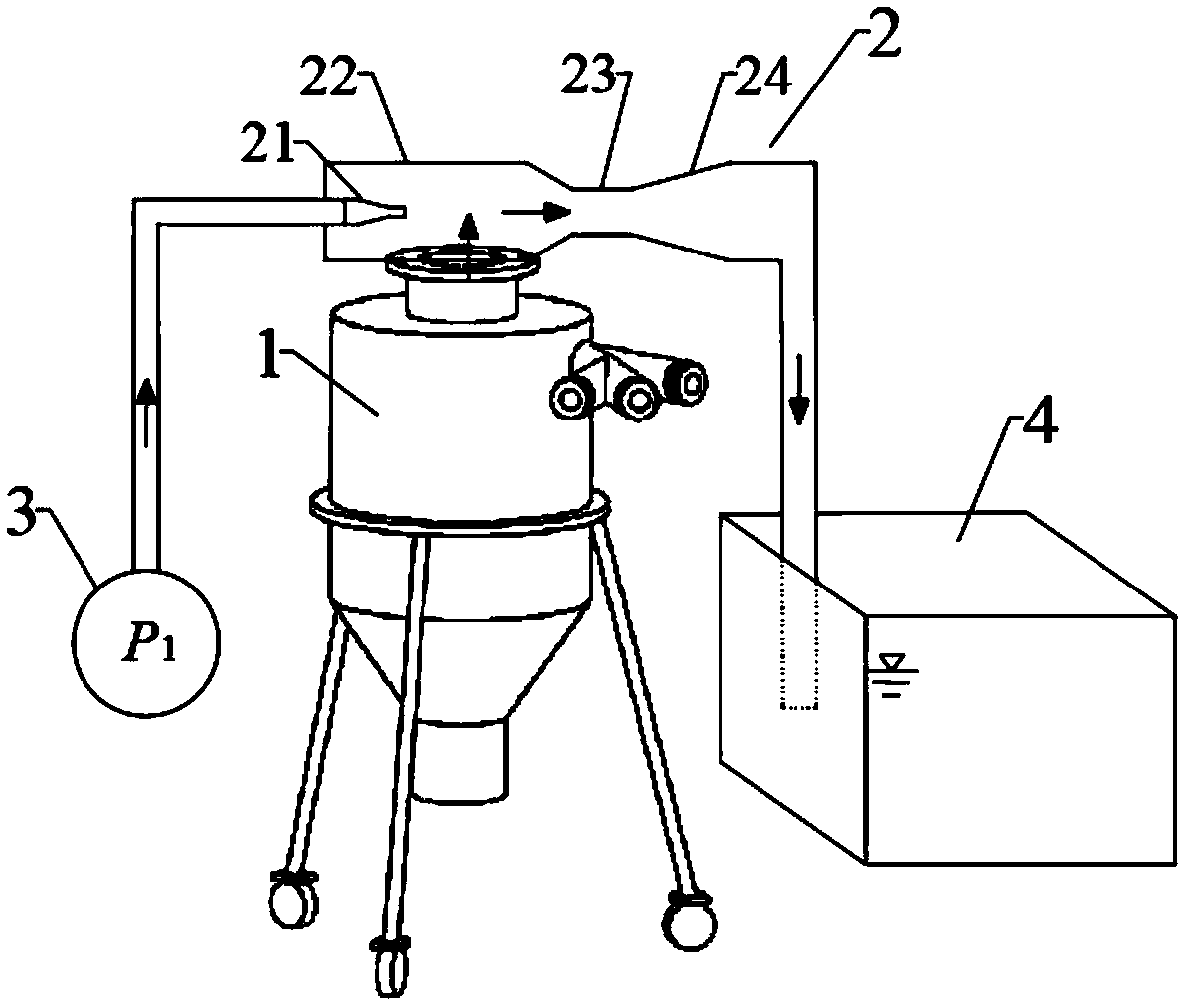

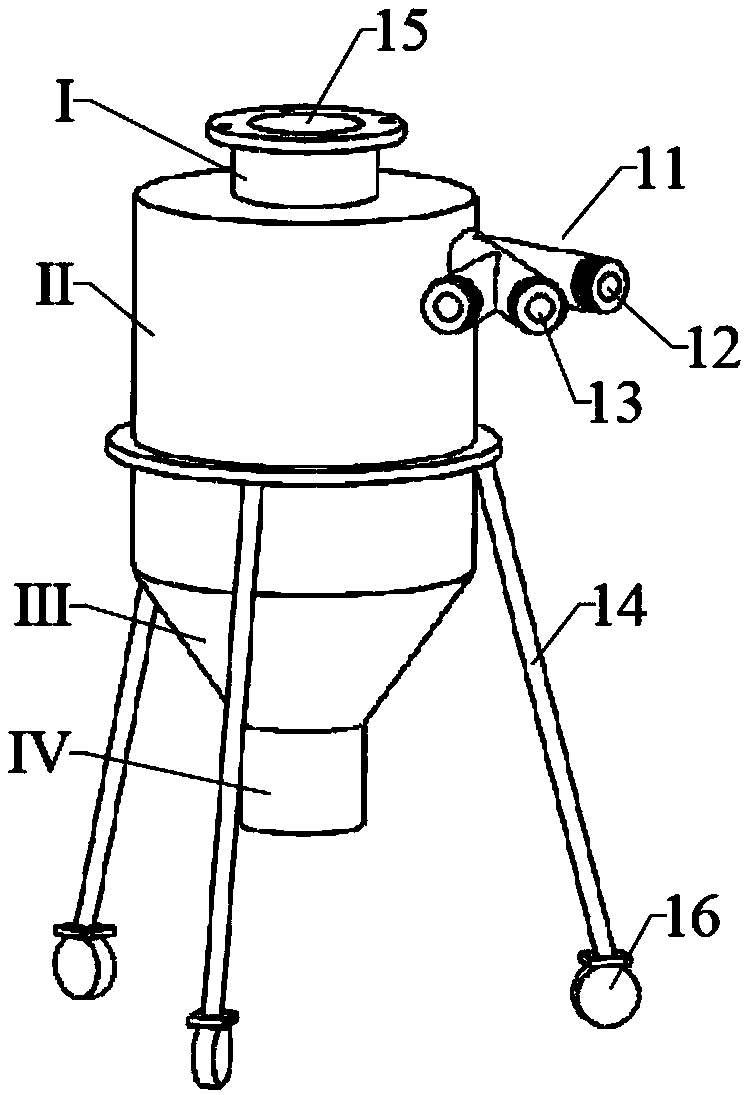

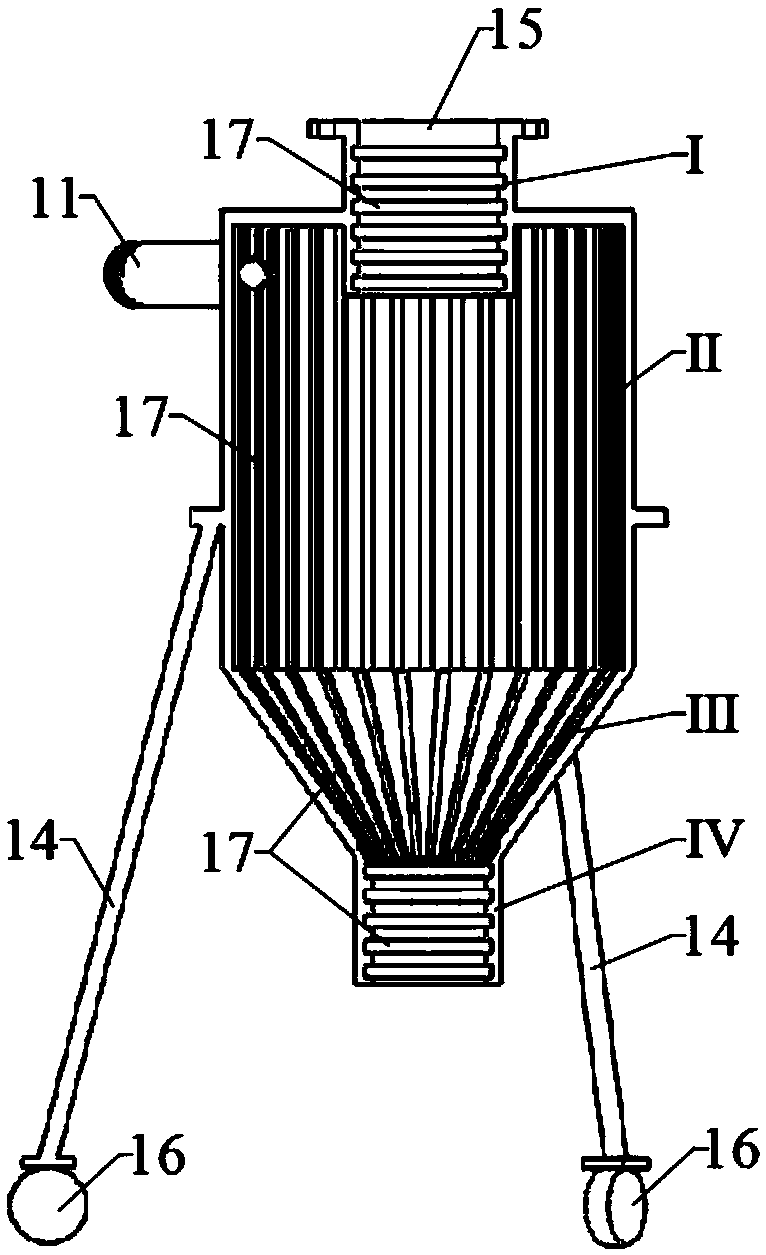

Mixing material separation and dust-reduction device and application thereof

The invention discloses a mixing material separation and dust-reduction device and application scenarios thereof. The device comprises a multi-channel bionic swirler and an ejector, wherein the multi-channel bionic swirler comprises an overflow tube, a swirl chamber, a shrinking hopper and a sample discharge tube, which are fixedly connected with each other from top to bottom; bionic non-smooth units are distributed on the inner wall surface of the multi-channel bionic swirler; an inlet channel is disposed at the upper end of a side wall of the swirl chamber; the ejector comprises a spray nozzle, a mixing chamber, a throat tube and a diffusion chamber; one end of the spray nozzle is connected with a high-pressure pump, and the other end of the spray nozzle stretches into the interior of the mixing chamber; the mixing chamber is connected with the overflow tube in a closing manner; two ends of the throat tube are respectively connected with the mixing chamber and the diffusion chamber in a closing manner; and the diffusion chamber is connected with a dust-reduction box through a pipeline. The device is mainly used in scenarios in which a large amount of dust is generated such as drilling, geotechnical engineering, grouting engineering, geological disaster control engineering, mining, tunnel piercing and the like, and is capable of solving the technical problems that the existingdevice is low in separation efficiency on mixing materials, unsatisfactory in dust-reduction effect, serious in abrasion, short in service life and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

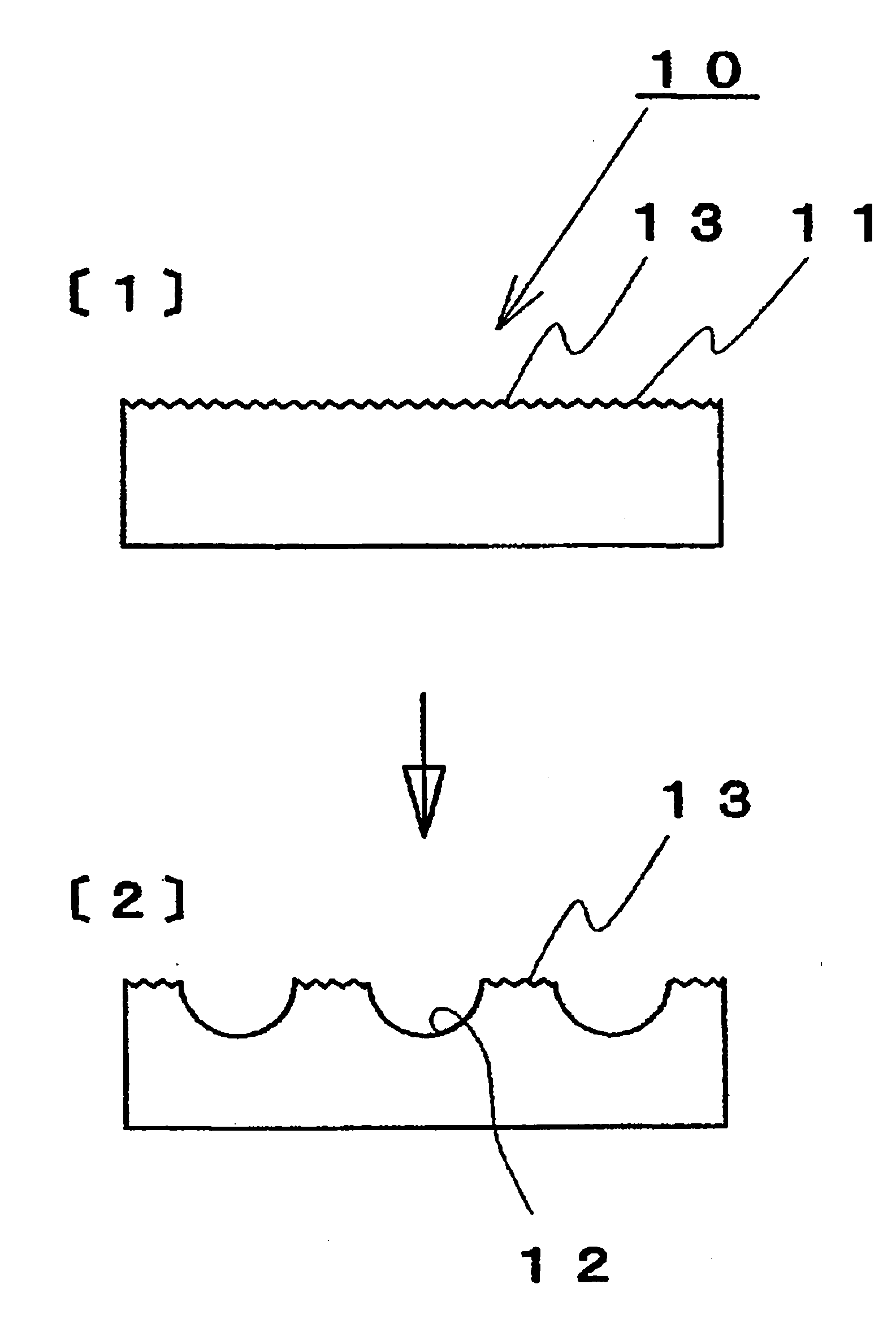

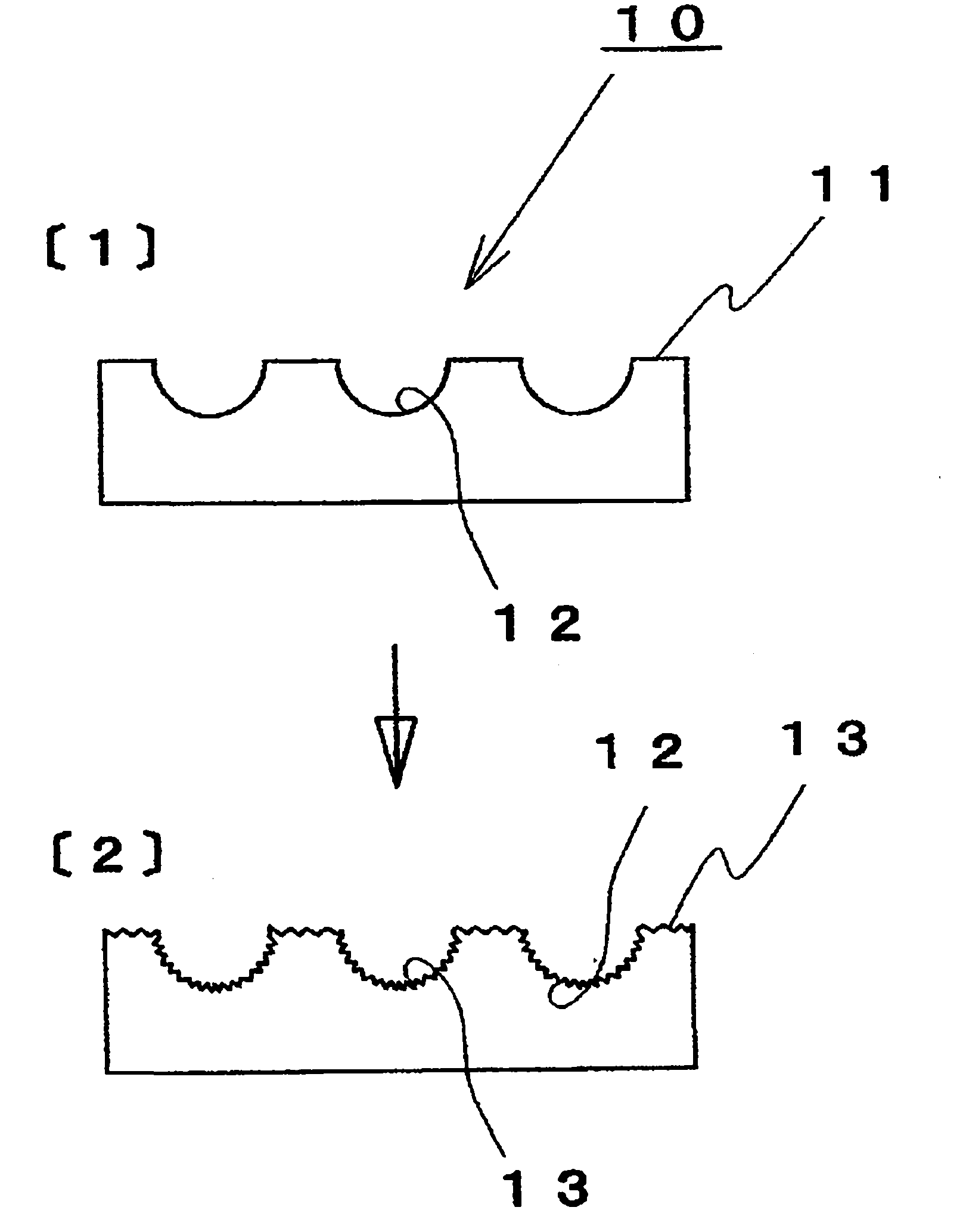

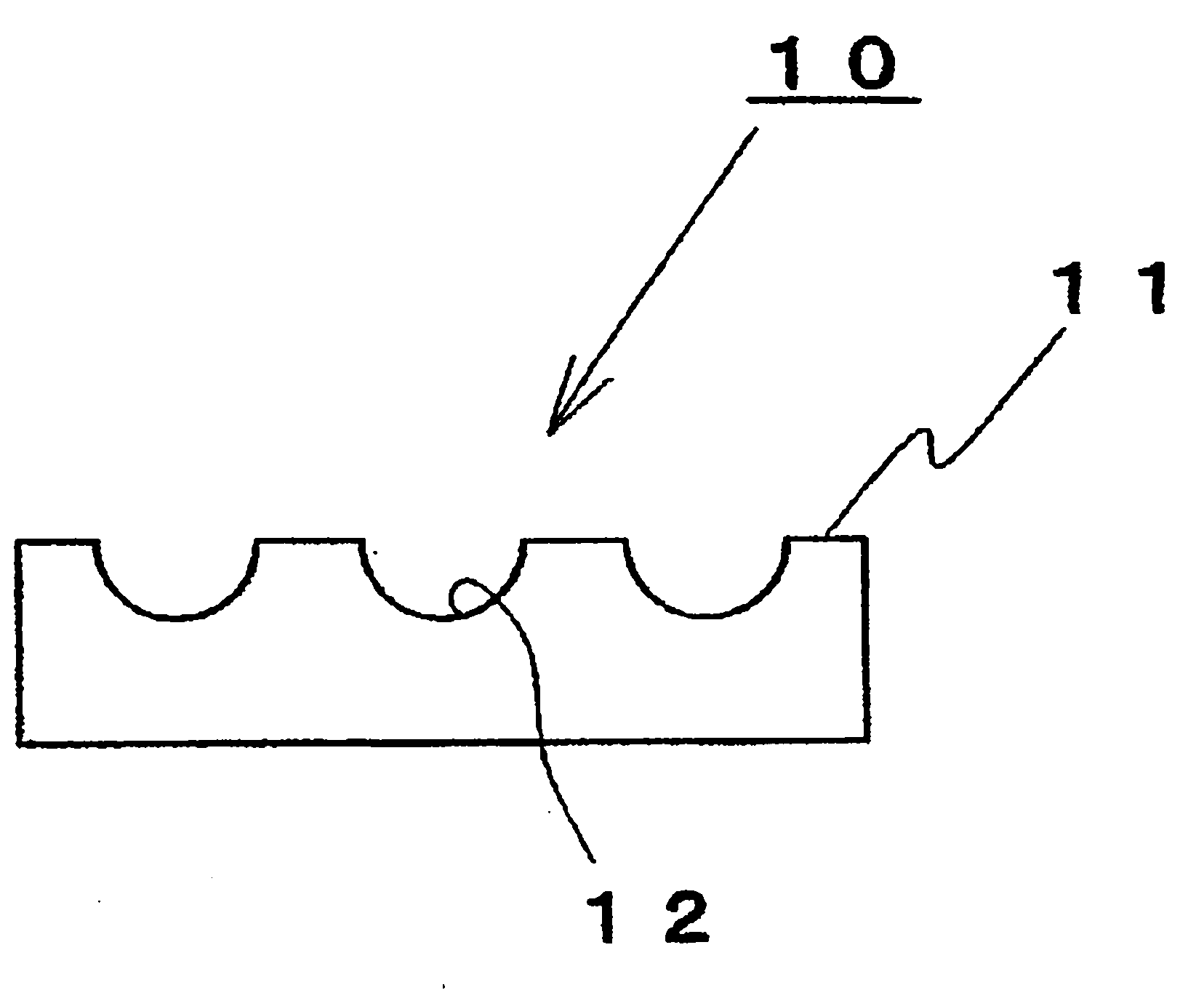

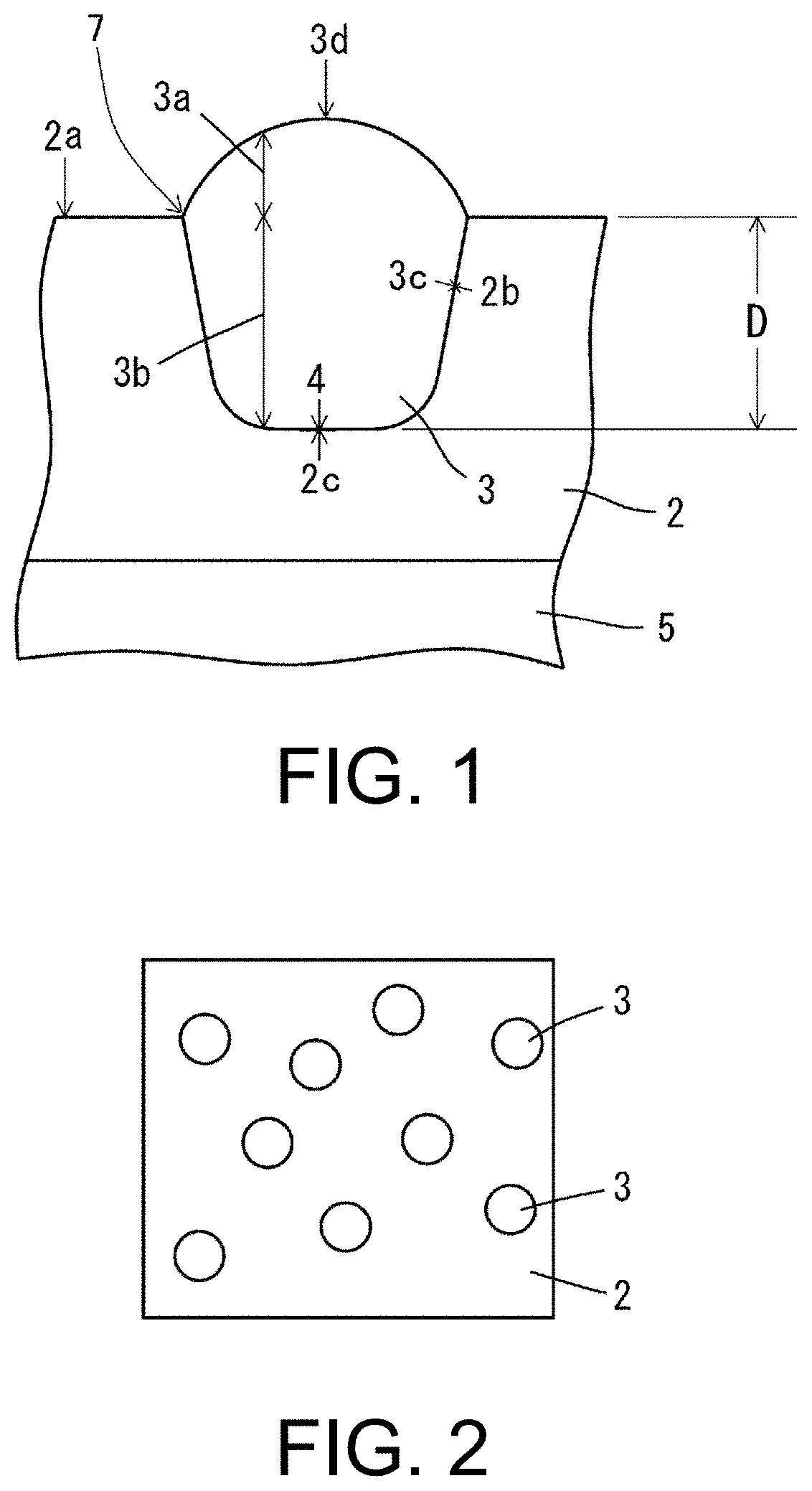

Method for processing cavity surface of casting mold

ActiveCN102159341AReduce contact areaEasy to demouldFoundry mouldsFoundry coresCasting moldMaterials science

Disclosed is a method for processing the cavity surface of a casting mold wherein the fluidity is good even if the shape of the cavity surface (casting product) is complicated, mold release performance is excellent, reprocessing is possible, and the life of the mold can be enhanced. A jet processing step (A) for forming hemi-spherical first dimples (12) in the cavity surface (11), and a jet processing step (B) for forming second dimples (13) more minute than the first dimples (12) are provided, a processing method (a) and a processing method (b) where either the jet processing step (A) or the jet processing step (B) is carried out preferentially, and a processing method (c) where only the first dimples (12) are formed by carrying out only the jet processing step (A) are provided.

Owner:SINTOKOGIO LTD

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS20070224132A1Excellent abrasionImprove rendering capabilitiesPigmenting treatmentCosmetic preparationsEngineeringSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Planetary ball mill

PendingCN110961201APrevent sample accumulationReduce grinding effectHollow article cleaningGrain treatmentsPhysicsBall mill

The invention provides a planetary ball mill, and particularly relates to the technical field of smashing equipment. The planetary ball mill comprises a ball mill body, a rotary disc is arranged on the ball mill body, and a plurality of ball milling pots are arranged on the rotary disc. Each ball milling pot comprises a pot base and a pot body, wherein the pot base comprises a pot base bottom plate arranged on the rotary disc, the pot base bottom plate is of a circular ring structure with an opening formed in the top surface, pot side plates are oppositely arranged on the opening in the top surface of the pot base bottom plate, each pot side plate is of an arc plate structure, one end of each pot side plate is fixedly arranged on the opening in the top surface of the pot base bottom plate,the other end of each pot side plate is provided with a plate clamping notch, an external thread rod is vertically arranged on the pot base bottom plate, one end of the external thread rod penetratesthrough the pot base bottom plate, and a scraping rod is arranged on the side wall of one end of the external thread rod. The planetary ball mill has the advantages that the situation that the grinding effect is reduced as specimens accumulate at the bottom of the pot body can be prevented, and in the specimen scraping process, pressure between scrapers and the inner wall of the pot body can be automatically adjusted, so that damage to the inner wall of the pot body is reduced.

Owner:安徽致磨新材料科技有限公司

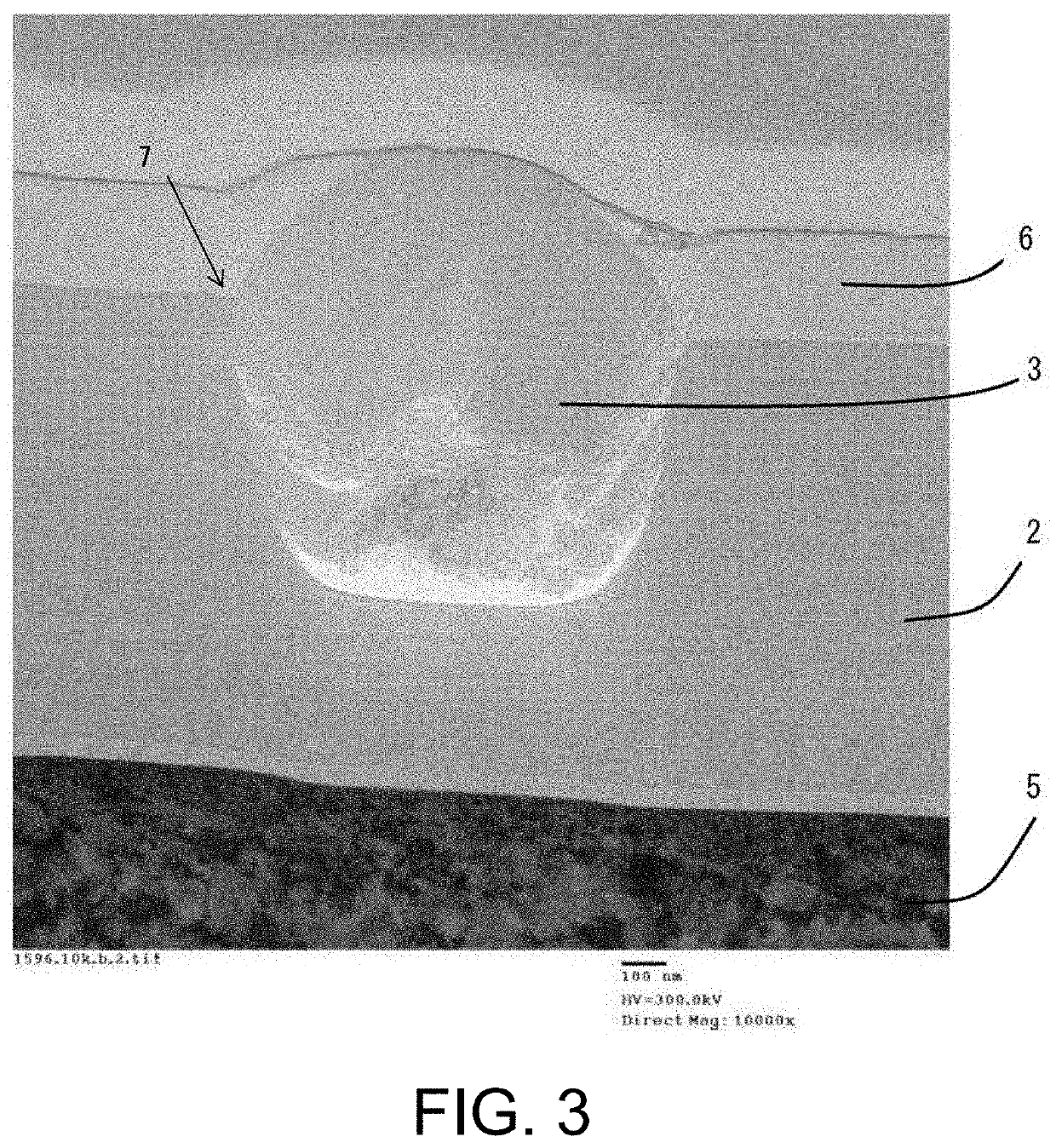

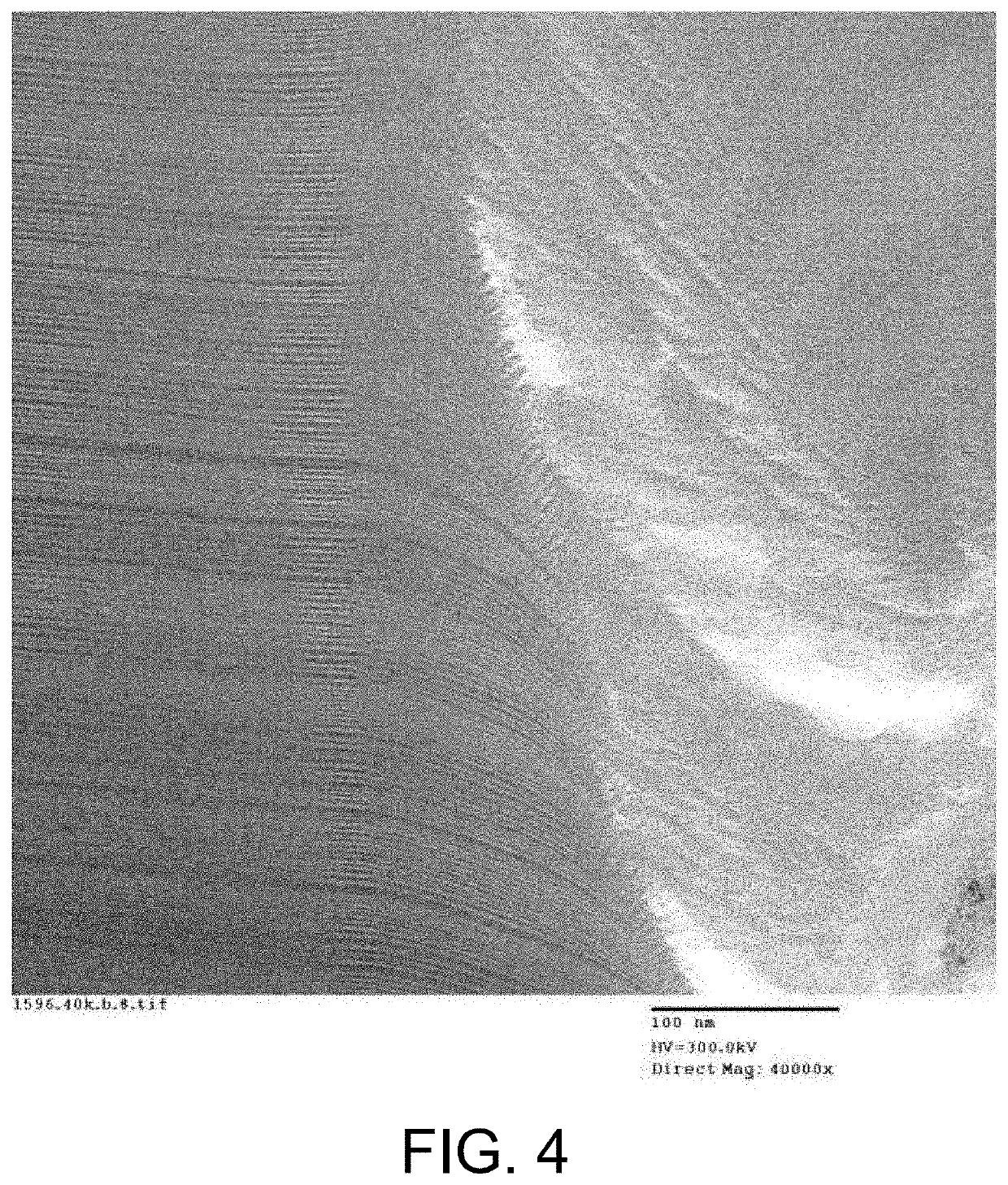

Hard carbon film, manufacturing method for same, and sliding member

PendingUS20210156021A1Improve wear resistanceReduce abrasivenessVacuum evaporation coatingSputtering coatingCarbon filmGraphite

A hard carbon film that forms a sliding surface of a sliding member, wherein the hard carbon film includes terminal atoms that bond to carbon atoms and has a plurality of protruding shaped parts, part of which protrude from the surface thereof, with the periphery of each of the plurality of protruding shaped parts being terminated by a terminal atom. A manufacturing method for the hard carbon film for producing the hard carbon film on a sliding surface of the sliding member using arc vapor deposition having graphite as the vaporization source, wherein a gas containing the terminal atoms that bond to carbon atoms is introduced, and the plurality of protruding shaped parts is grown on the surface of the hard carbon film while terminating the periphery of the plurality of protruding shaped parts by bonding of the terminal atoms to carbon atoms.

Owner:NIPPON ITF

Scale removal device for profile steel

PendingCN108421836AReduced abrasivenessIncrease rolling kilometersWork treatment devicesMetal rolling arrangementsIron oxideRing type

The invention discloses a scale removal device for profile steels, and is applied to the technical field of rolling of profiles. The scale removal device for profile steels mainly comprises a ring type header, a guide and guard box, a rolling piece and a connecting rack. A profile rolling production line is provided with the ring type header which can allow the rolling piece to pass through the inside of the ring type header, in a rolling process, the ring type header can obliquely spray high-pressure water to the upper surface of the rolling piece through an annular spraying opening in the upper portion of the ring type header, and iron oxide on the surface of the rolling piece in the peripheral 360-degree direction can be beaten and cleaned thoroughly by high-pressure water without deadzones. The scale removal device for the profile steel is simple in structure and easy to mount and manufacture, and can be mounted at different positions of the rolling production line according to actual rolling production requirements.

Owner:XINJIANG BAYI IRON & STEEL

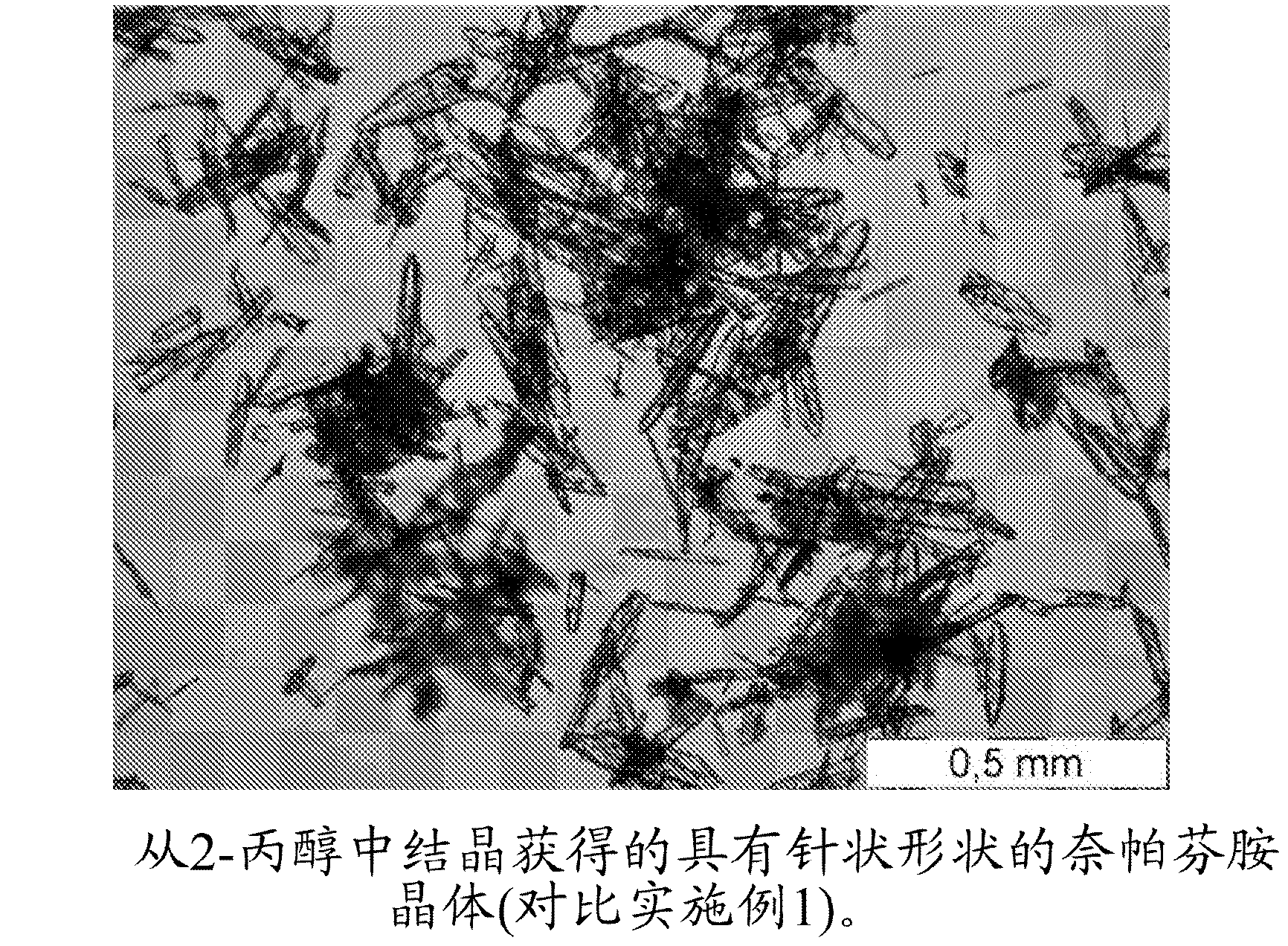

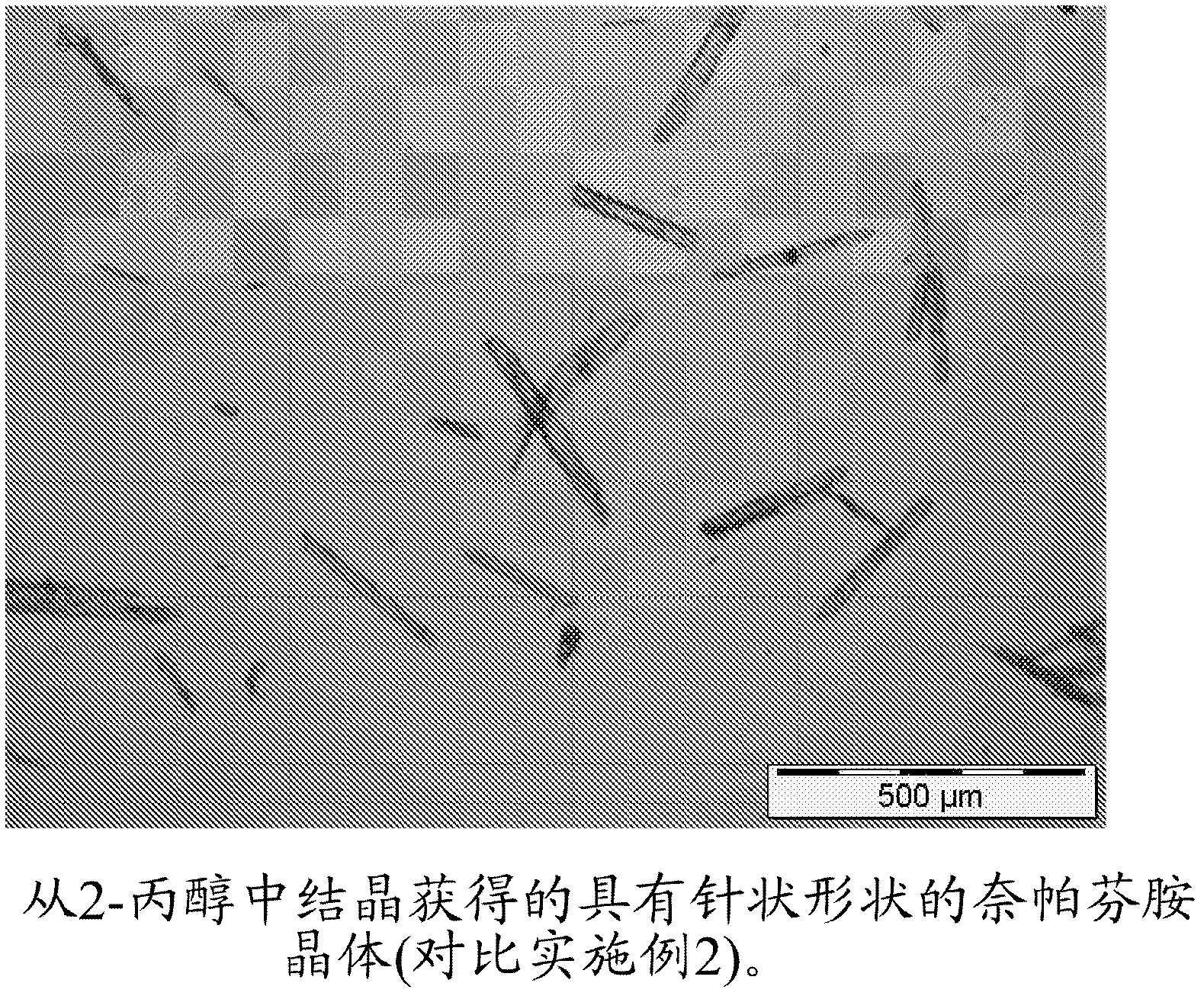

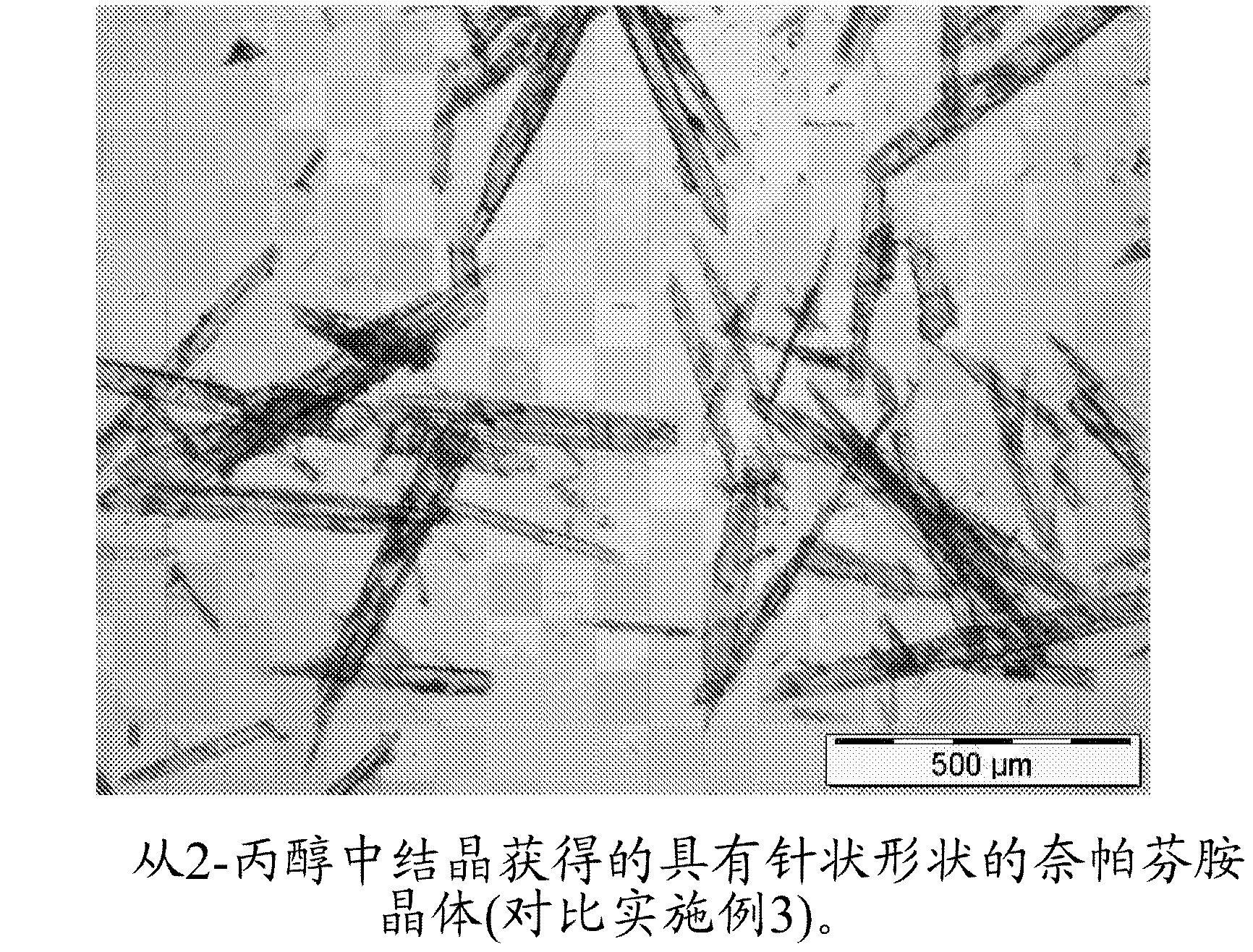

New crystals of a benzoylbenzeneacetamide derivative

InactiveCN102438979AUniform shapeImprove propertiesOrganic active ingredientsSenses disorderPhenacylCombinatorial chemistry

Owner:MEDICHEM

Oral care composition containing pumice and calcium carbonate

ActiveUS20160030330A1Enhance cleaning benefitHigh pcr/rda ratioCosmetic preparationsToilet preparationsCalcium carbonateCleaning teeth

Owner:COLGATE PALMOLIVE CO

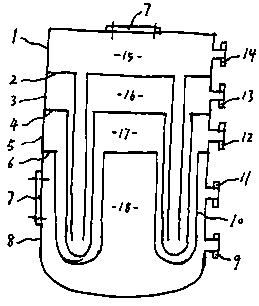

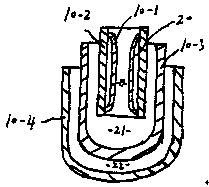

Steam generator for metal fast reactor

InactiveCN108758587ALow flow resistanceSmall pressure dropCorrosion preventionStationary tubular conduit assembliesNuclear engineeringSecondary side

The invention provides a steam generator for metal fast reactor. The steam generator comprises a container body and a heat exchanger arranged in the container body. The container body is provided witha primary side outlet, a primary side inlet, a secondary side outlet and a secondary side inlet from bottom to top, and at least a shell pass and a first pipe pass are formed in the container body. Ahigh-temperature medium enters the shell pass through the primary side inlet, and is exported from the primary side outlet after cooling. A low-temperature medium enters the first pipe pass through the secondary side inlet, and is exported from the secondary side outlet after heating. According to the steam generator for the metal fast reactor, the mode that the high-temperature medium flows through the shell pass and the low-temperature medium flows through the pipe pass is used, the velocity of the shell pass as well as the abrasion degree of the pipe wall of a heat exchange pipe and the container wall are reduced, the circulation ability is improved, and the reliability and safety of the steam generator are improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com