Mixing material separation and dust-reduction device and application thereof

A dust suppression device and a technology for mixing materials, which are used in combination devices, separation methods, dispersed particle separation, etc., can solve the problems of short service life, low separation efficiency, poor dust suppression effect, etc., and reduce erosion and abrasion. The effect of reducing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

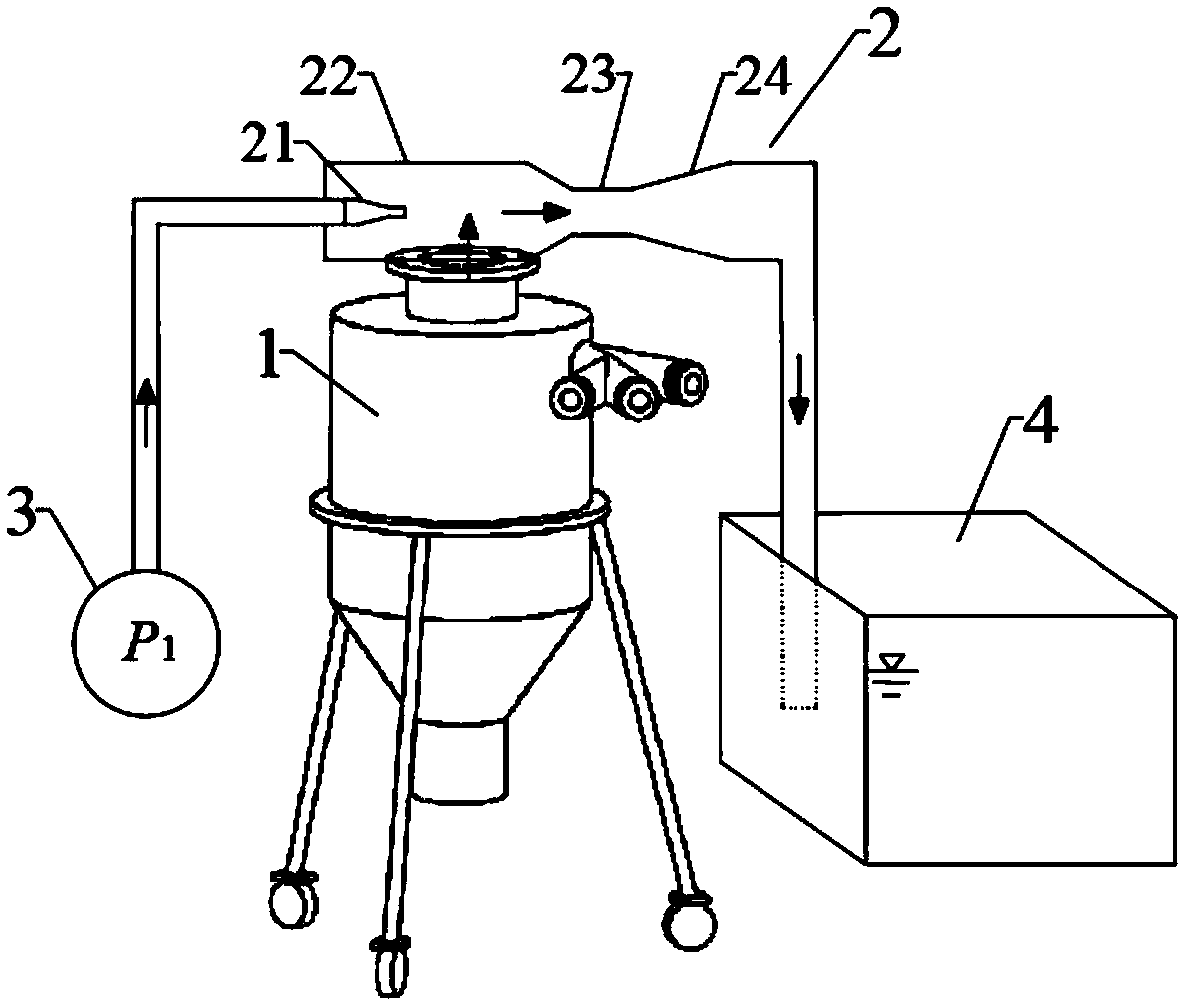

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In the embodiment of the present invention, such as Figure 1~6 As shown, a mixed material separation and dust reduction device is provided, which includes a multi-channel bionic cyclone 1 and an ejector 2, wherein the multi-channel bionic cyclone 1 is used to separate the mixed material, and the ejector 2 is The separation of the mixed material provides auxiliary power, and at the same time, the ejector 2 can discharge the secondary rising mixed airflow (dust to be treated) into the water storage liquid level in the dust reduction box through the pipeline, so as to realize dust reduction treatment.

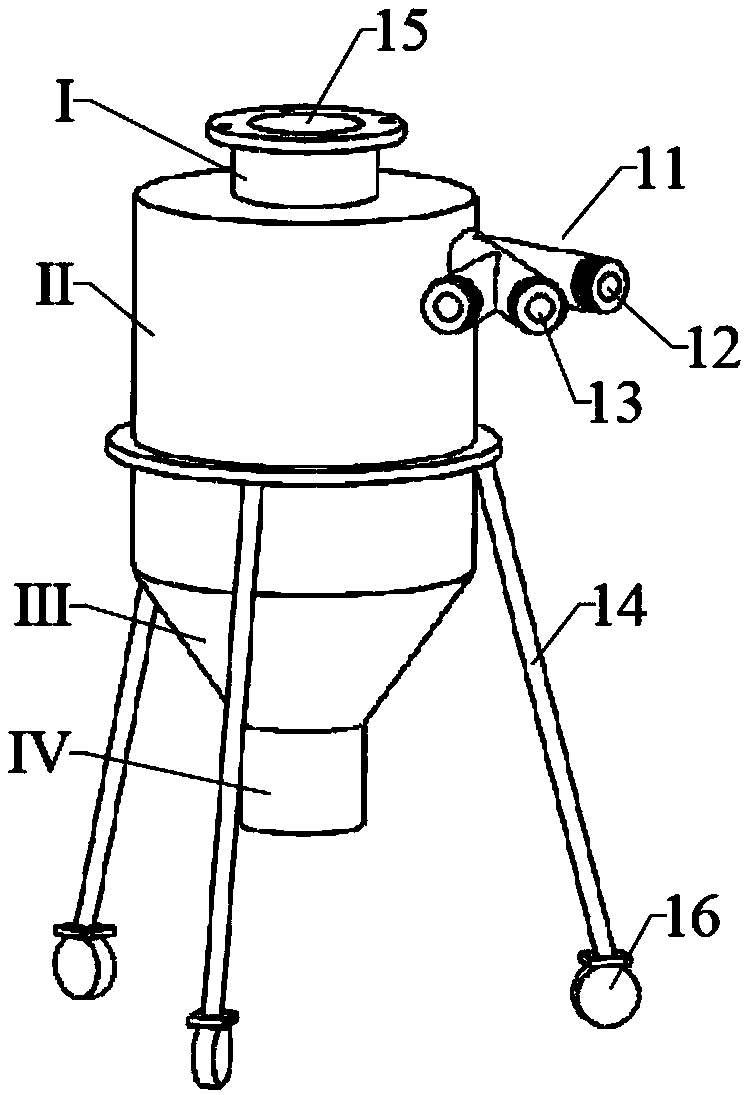

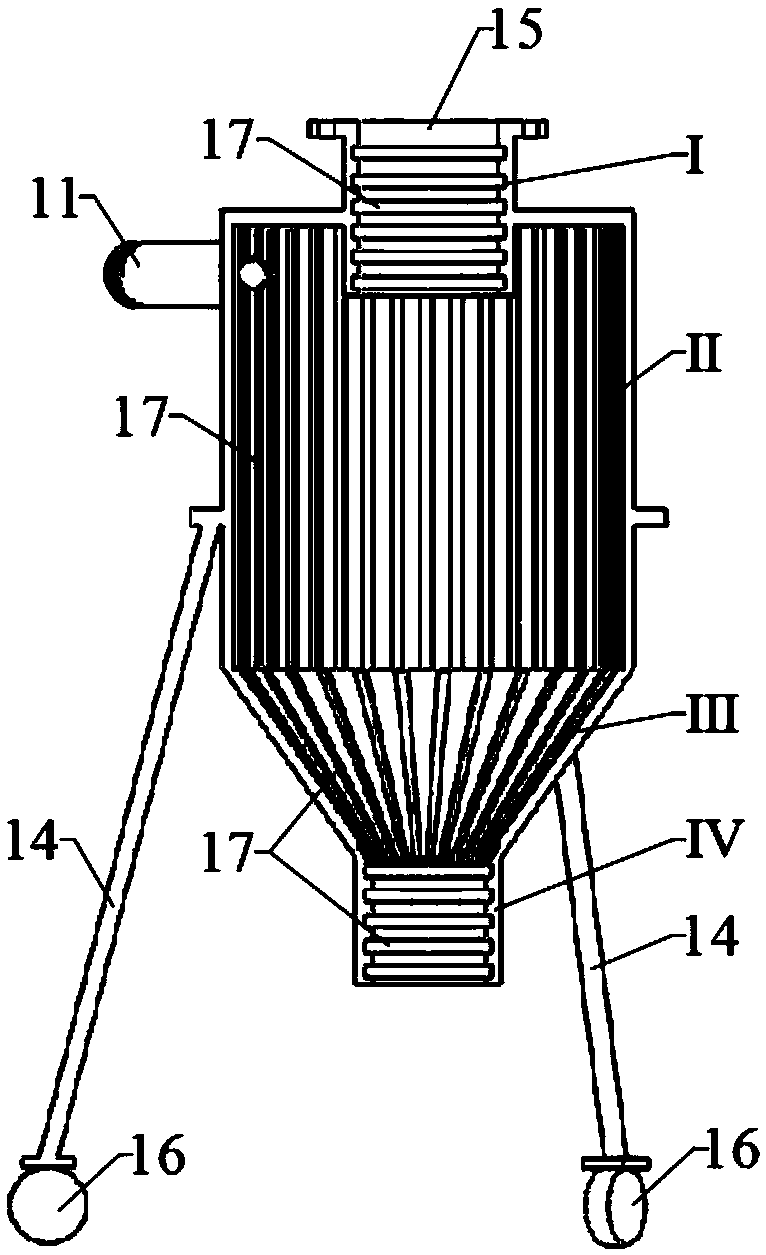

[0039] The multi-channel biomimetic cyclone 1 includes an overflow pipe I, a cyclone chamber II, a shrinking hopper III and a sample discharge pipe IV. Among them, the swirl chamber II is a cylinder with the upper end capped, but a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com