Water-cooling fast-condensing method and device for preparing powder-mixed atomized water-cooling fast-condensing magnetic abrasives

A magnetic abrasive and gas atomization technology, applied in the field of water-cooled quick-setting devices, can solve the problems of shortened service life, affecting the grinding ability of magnetic abrasives, affecting the quality of magnetic abrasive preparation, etc., and achieve the effect of improving grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

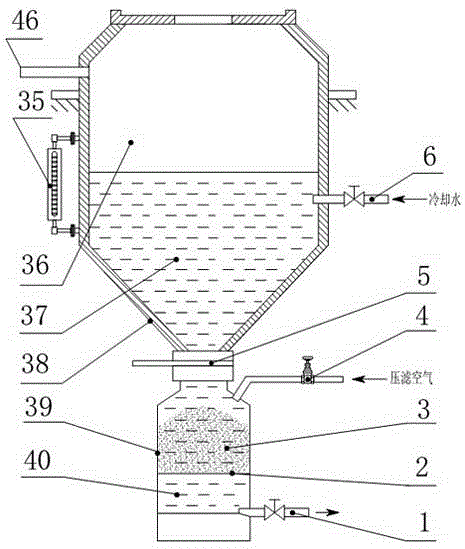

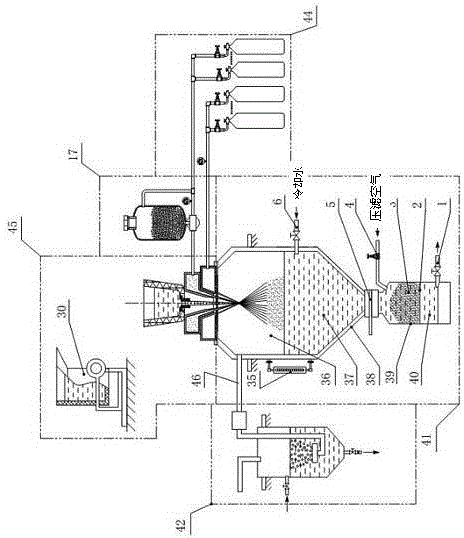

[0014] as attached figure 1 As shown, the magnetic abrasive preparation mixed powder gas atomization water-cooled quick-condensation device includes: water discharge valve (1), filter screen (2), magnetic abrasive material (3), pressure filter air valve (4), gate valve (5), cold water Valve (6), water level gauge (35), atomization water cooling chamber (36), cooling water (37), atomization water cooling chamber shell (38), magnetic abrasive tank (39), filtered water (40), atomization Cavity exhaust pipe (46);

[0015] The shell of the atomizing water cooling chamber (38) is a cylindrical tank as a whole, and its lower part is conical; the magnetic abrasive tank (39) is also a cylindrical tank as a whole, and its upper part is conical; A water level gauge (35) is installed on the side of 38) to measure the water level in the atomization water cooling ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com