Evaluation testing device for anti-sand screen tube blockage characteristic in exploitation process of natural gas hydrate and method thereof

An experimental device and sand control screen technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems that affect test results, do not conform to actual conditions, lack of permeability of sand retaining media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

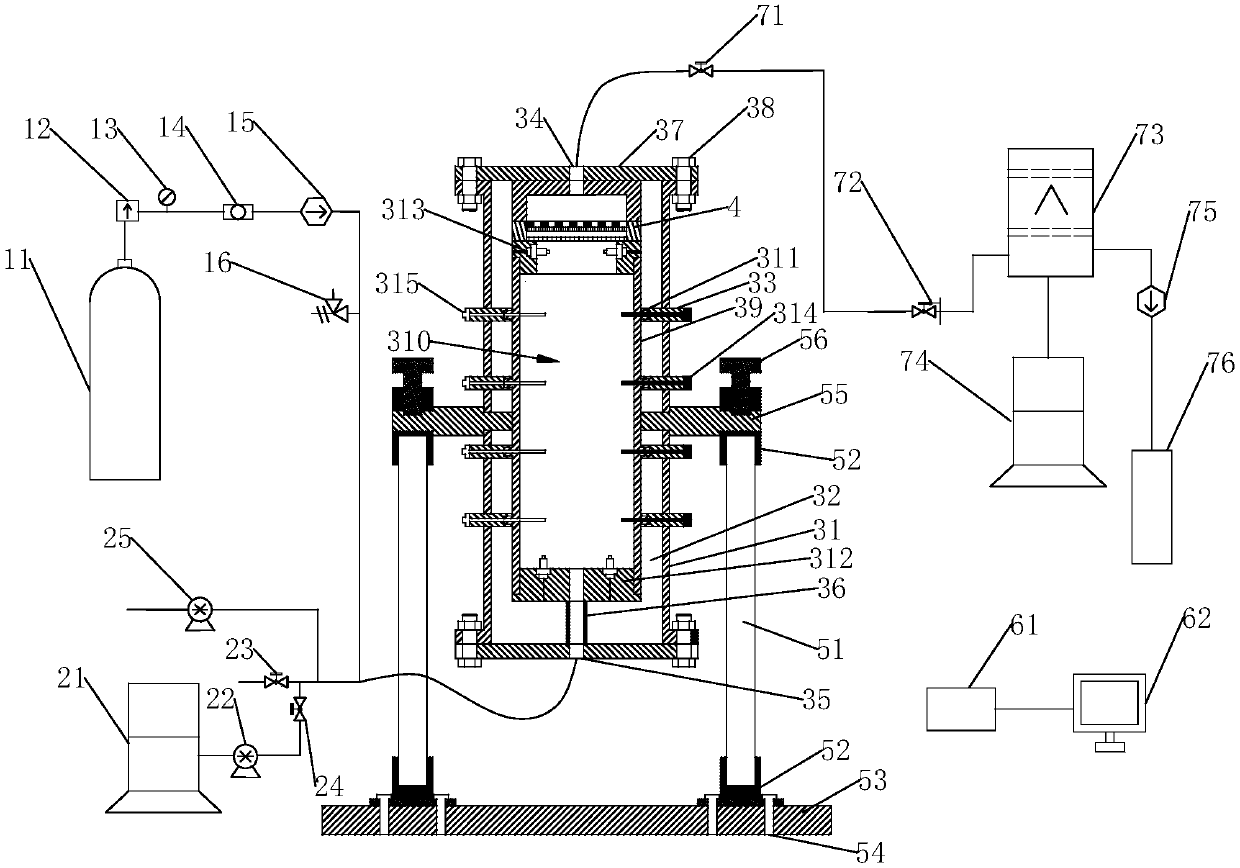

[0037] The invention provides an experimental device for simulating sand production in the process of natural gas hydrate exploitation, which can study the influencing factors of sand production in the process of natural gas hydrate exploitation in unconsolidated sandstone formations by means of physical experiments, and can analyze the sand production before and after the process of hydrate exploitation. The changes in formation characteristics and the clogging of screen pipes are scientifically evaluated to provide a reference for solving the sand production problem in the process of on-site natural gas hydrate production.

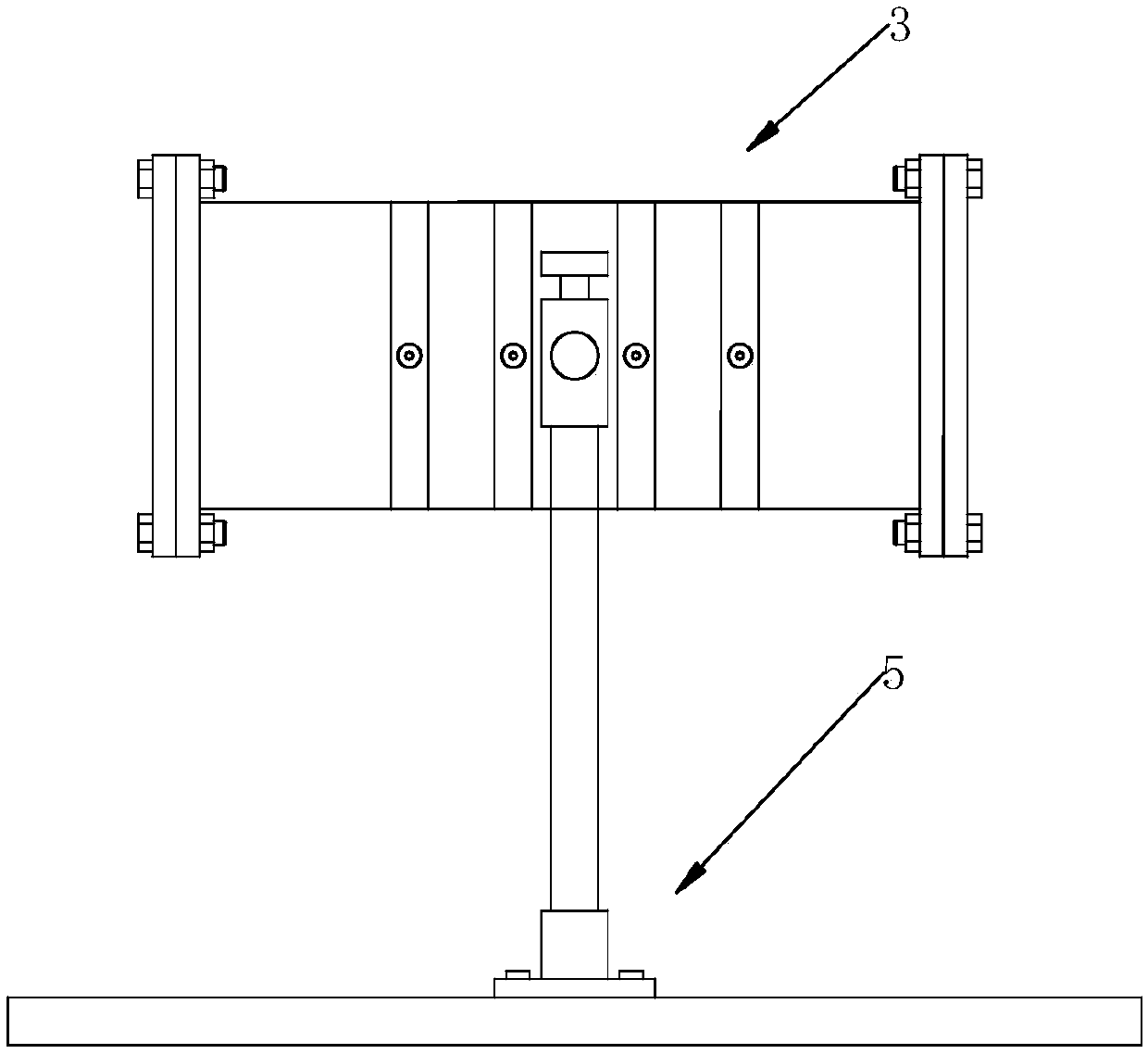

[0038] As shown in the figure, an experimental device for evaluating the clogging characteristics of sand control screens during natural gas hydrate exploitation includes an experimental device body 3, a support base 5, a liquid supply system, a gas supply system, and a fluid export and collection system.

[0039] The experimental device body 3 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com