Wear-resisting weak-abrasiveness bionic tool joint

A drill pipe joint and abrasive technology, applied in the field of bionic coupling, can solve the problems of increased wear of the upper part of the drill pipe joint and the inner wall of the casing, the life cannot meet the drilling speed increase, and increase the loss of mud along the way, so as to reduce the occurrence of downhole accidents Probability, prolonging the life of drill pipe, improving the effect of drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

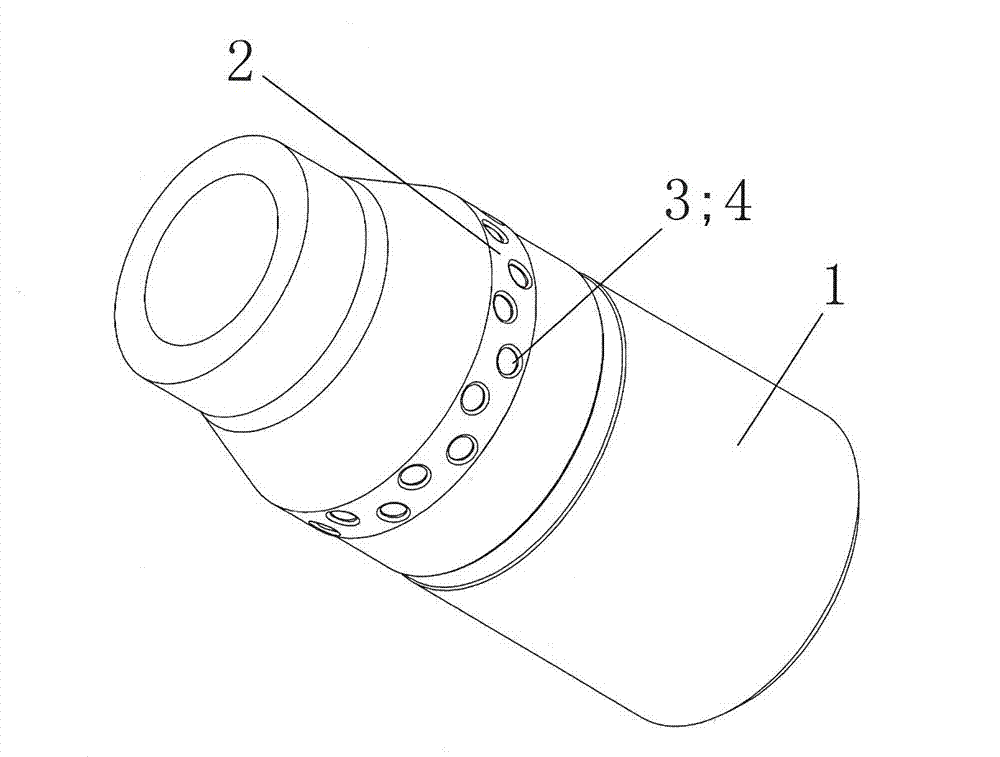

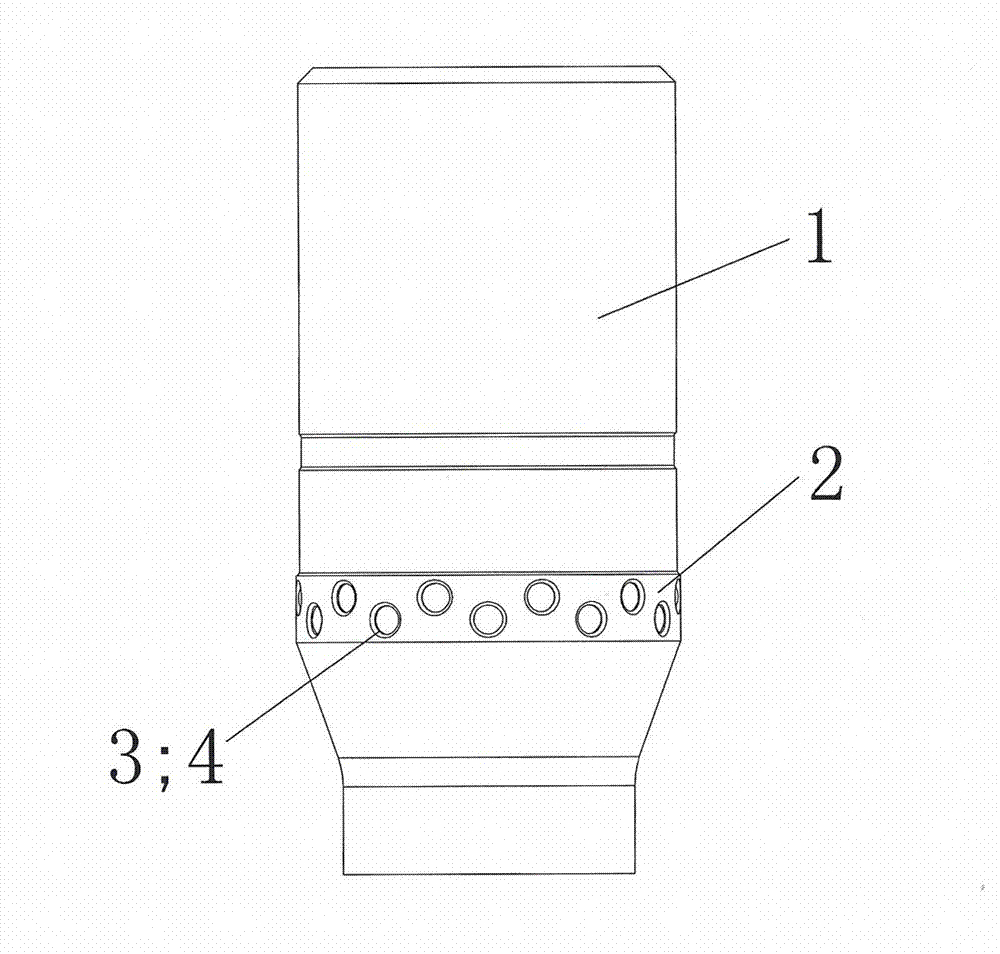

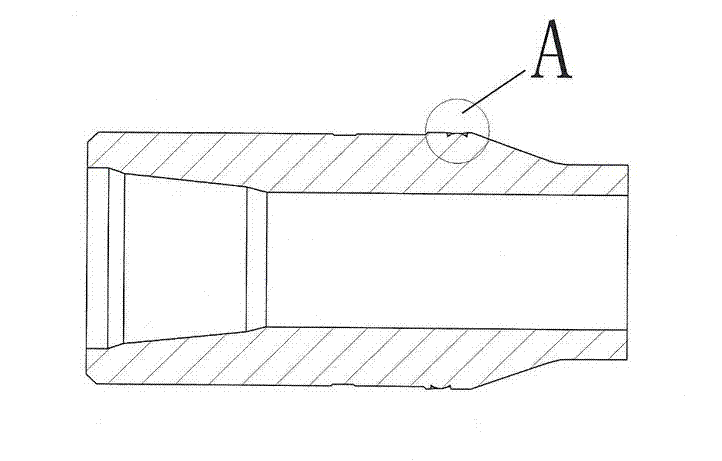

[0015] see figure 1 , figure 2 , image 3 and Figure 4 As shown, in this embodiment, several regularly arranged concave non-smooth structural units 3 are arranged on the bionic wear-resistant belt 2 of the drill pipe joint 1, and each concave non-smooth structural unit 3 is provided with a convex hull type non-smooth structural unit 3. The structural unit 5, the depth of the concave non-smooth structural unit 3 is equal to the entire height of the convex hull non-smooth structural unit 5, the aperture of the concave non-smooth structural unit 3 is 0.001~0.1 mm smaller than the diameter of the convex hull non-smooth structural unit 5, and the concave The top of the pit non-smooth structure unit 3 is a concave pit edge surface arc transition 4, which is combined with the low friction coefficient and high wear-resistant convex hull non-smooth structure unit 5 through interference fit to form a wear-resistant non-smooth structure surface. The top surface of the combined conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com