Oscillating fixed abrasive CMP system and methods for implementing the same

A chemical machinery and grinding method technology, applied in the direction of grinding machine tools, grinding devices, machine tools suitable for grinding workpiece planes, etc., can solve the problems of reducing output, time-consuming and laborious updating of grinding pads, etc., to achieve less maintenance costs and less output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

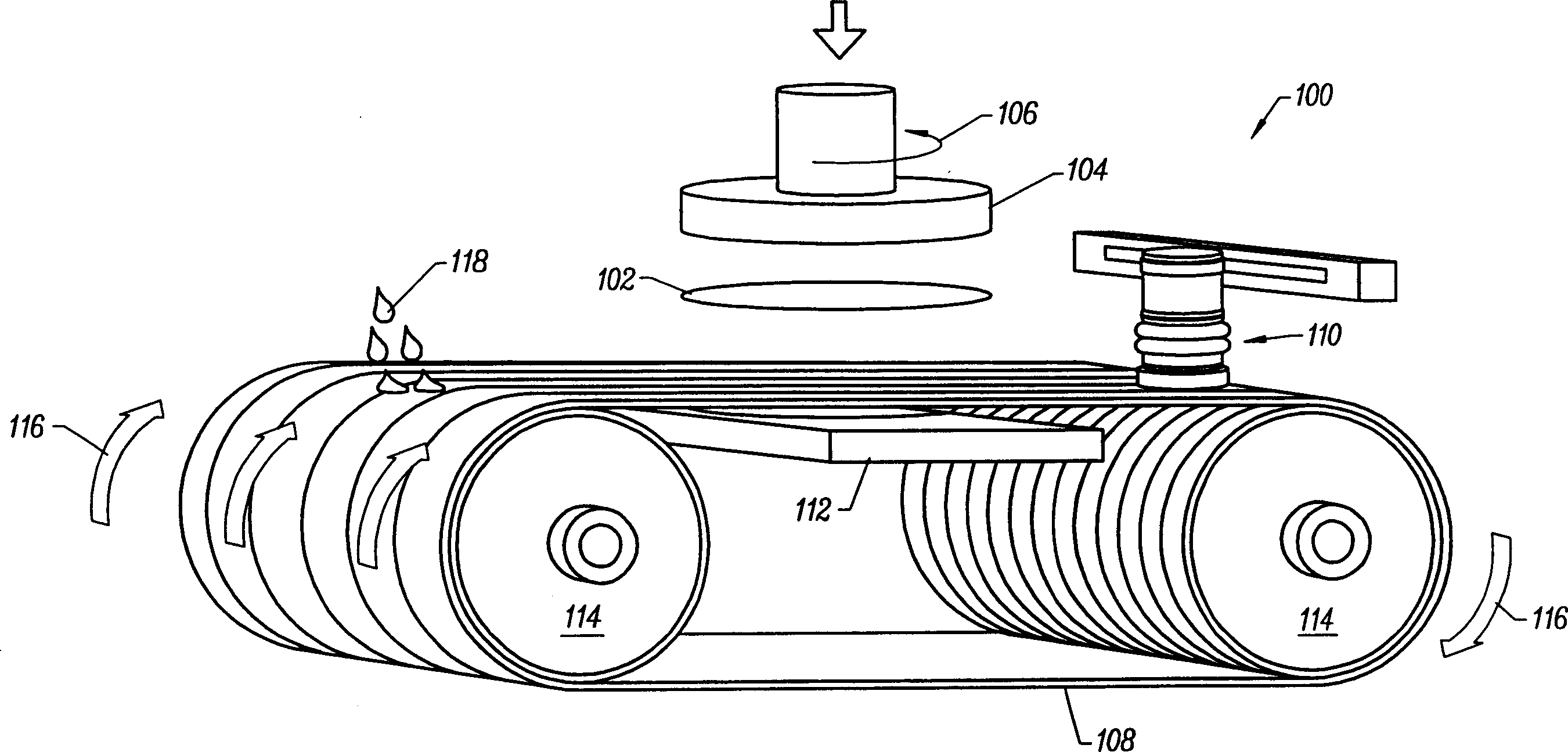

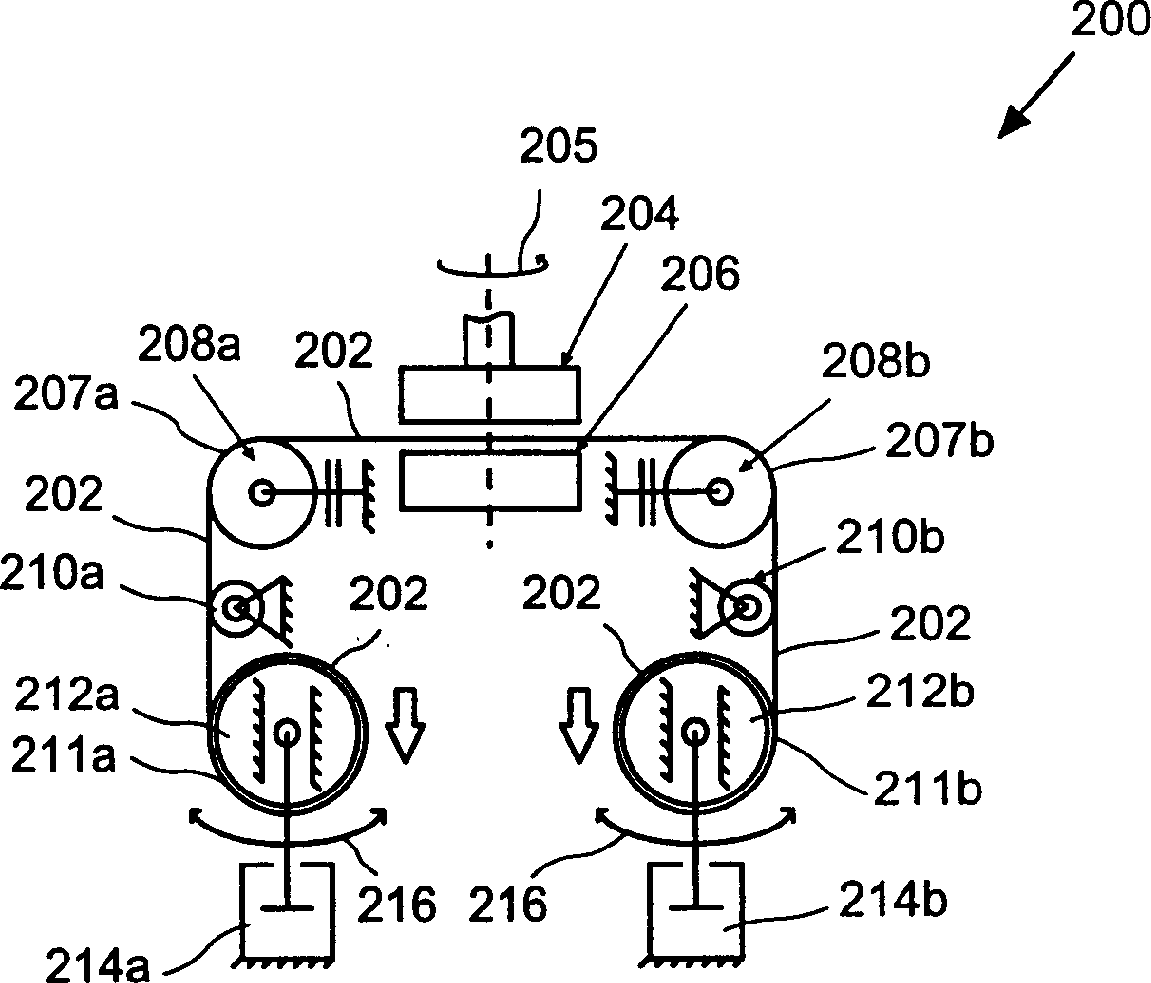

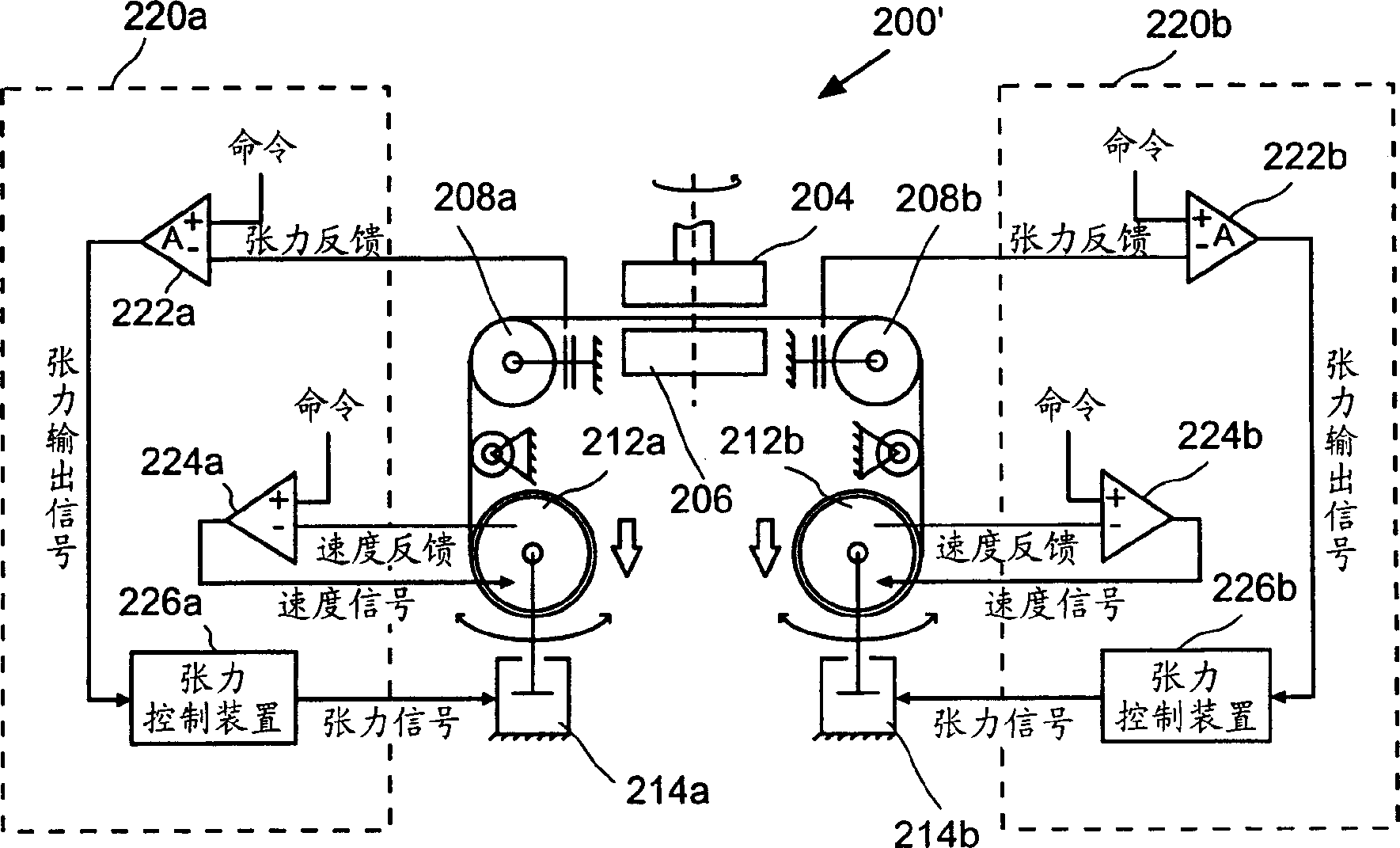

[0027] The following will describe an invention for a chemical mechanical polishing system that enables efficient polishing of layer surfaces of wafers. The chemical mechanical polishing system preferably achieves a polishing pad that requires less maintenance and can be repaired more effectively after it loses its polishing effect. In each preferred embodiment of the present invention, the grinding pad is a grinding pad with fixed grinding materials. And the grinding pad of this fixed grinding material is then preferably arranged as the grinding pad belt that is connected between the feeding cylinder and the recovery cylinder. This configuration is referred to herein as a spool operating configuration. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It is understood, however, that one skilled in the art may practice the present invention without some or all of these specific details...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com