Planetary ball mill

A planetary ball mill and ball mill technology, applied in cleaning hollow objects, cleaning methods and utensils, grain processing, etc., can solve the problems that grinding balls and agglomerated materials cannot be ground and affect the effect of ball milling, so as to reduce grinding Effect, effect of preventing accumulation of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

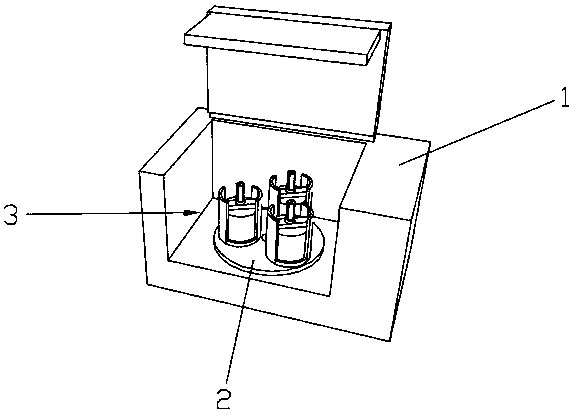

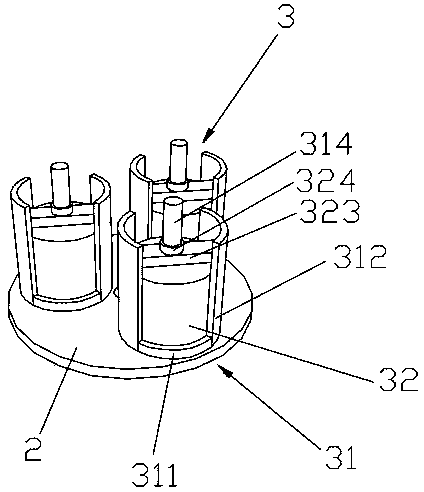

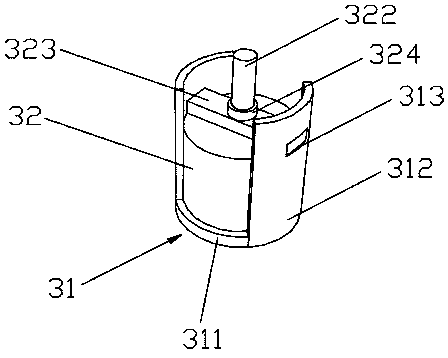

[0022] Such as Figure 1-7 As shown, a planetary ball mill of the present invention includes a ball mill body 1, a turntable 2 is arranged on the ball mill body 1, and a plurality of ball mill jars 3 are arranged on the turntable 2, and the ball mill jar 3 includes a jar seat 31 and a jar body 32, and the jar seat 31 includes a tank base plate 311, which is arranged on the turntable 2. The tank base plate 311 is a ring-shaped structure with an opening on the top surface, and a tank side plate 312 is arranged opposite to the top surface opening of the tank base plate 311. The tank side plate 312 is an arc-shaped plate structure, and one end of the tank side plate 312 is fixedly arranged on the top opening of the tank base plate 311, and the other end of the tank side plate 312 is also provided with a clamping gap 313, and the tank base plate 311 An externall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com