Liquid paint pumping apparatus

A pumping equipment and liquid technology, which is applied in the field of pumping liquid paint equipment, can solve problems such as ball wear and leakage, and achieve the effects of reduced wear, reduced noise, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

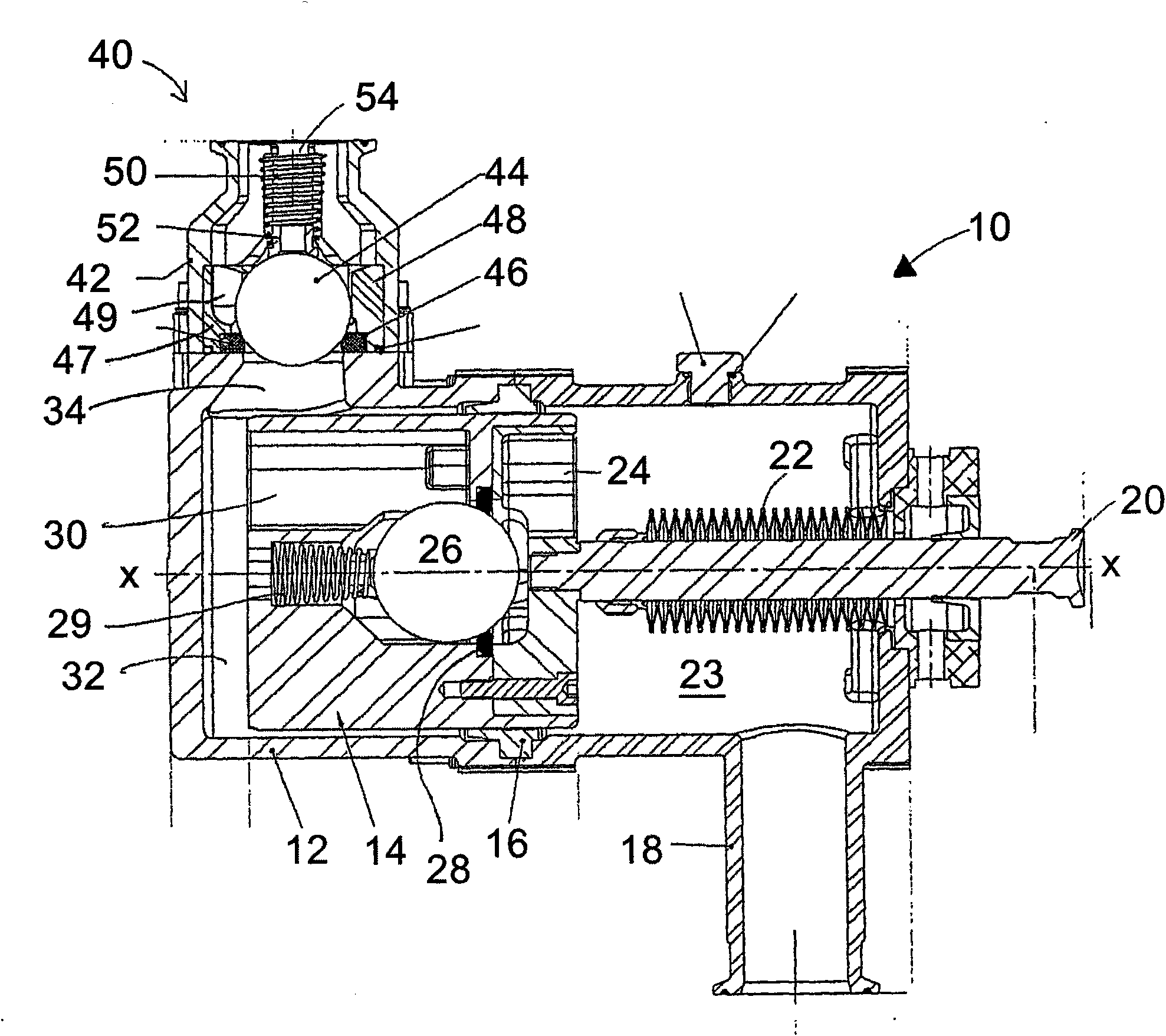

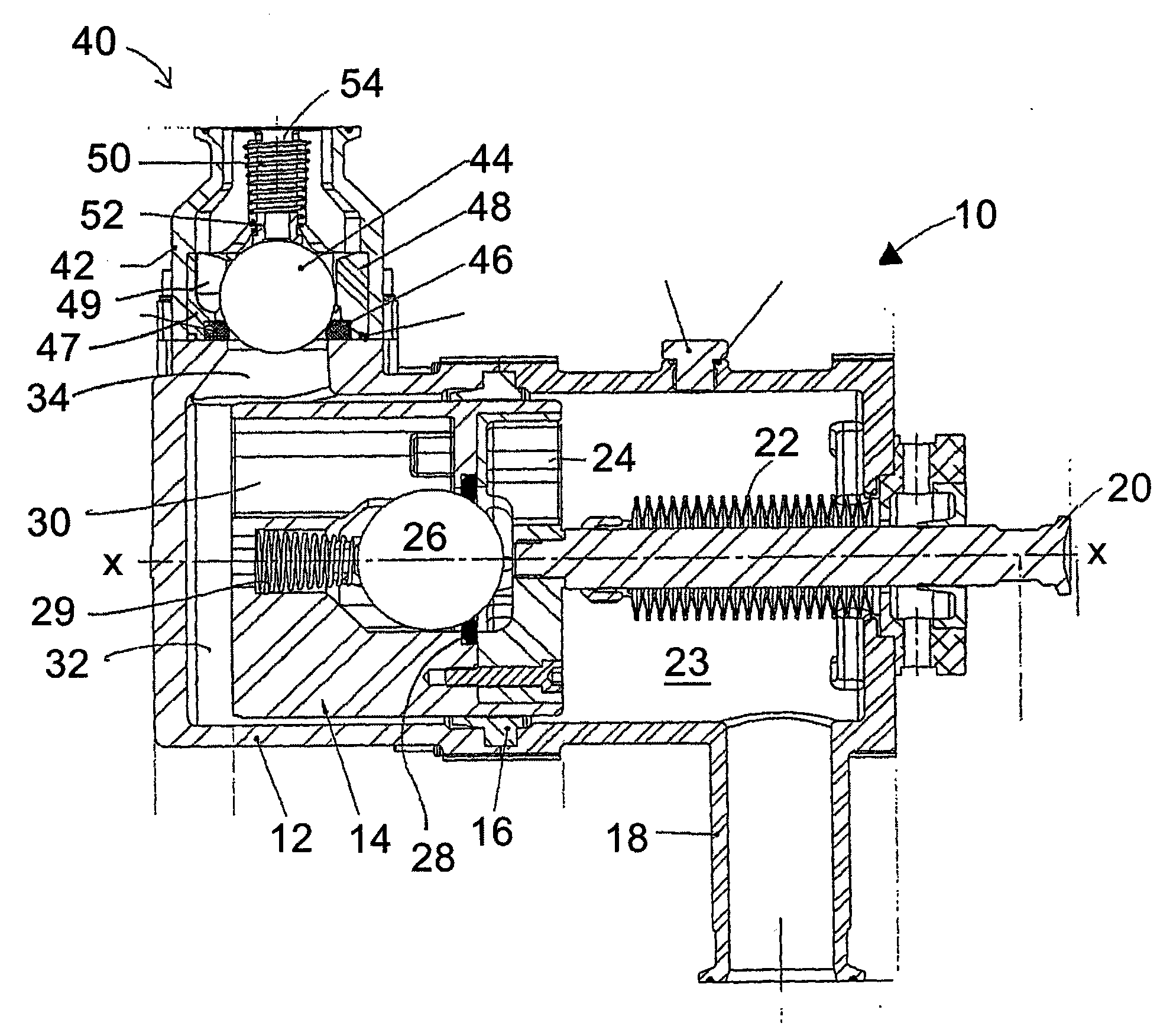

[0025] refer to figure 1 , The paint pumping device 10 includes a cylinder liner 12 in which a piston 14 is installed for reciprocating movement along the axis X-X. Annular seal ring 16 forms a seal between cylinder liner 12 and piston 14 . The cylinder liner is provided with an inlet port 18 for connection to a liquid paint supply. Piston 14 is connected to shaft 20, which is driven in a reciprocating manner by drive means (not shown). A bellows seal 22 forms a seal with the cylinder 12 about the shaft 20 .

[0026] An inlet check valve arrangement is located in the structure of the piston 14 which includes a ball member 26 which is biased towards a contact seat 28 by a helical compression spring. Inlet check valve device (in figure 1 In the position shown in ) a seal is provided between the inlet side channel 24 and the outlet side channel 30 . Inlet side passage through to figure 1 A space 23 to the right of the middle piston 14 is in fluid communication with the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com