Method for processing cavity surface of casting mold

A processing method and cavity technology, which can be used in casting and molding equipment, molds, mold components, etc., can solve problems such as reducing mold release, sticking, and angular shapes of concave and convex parts, reducing contact area, reducing Contact area, the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

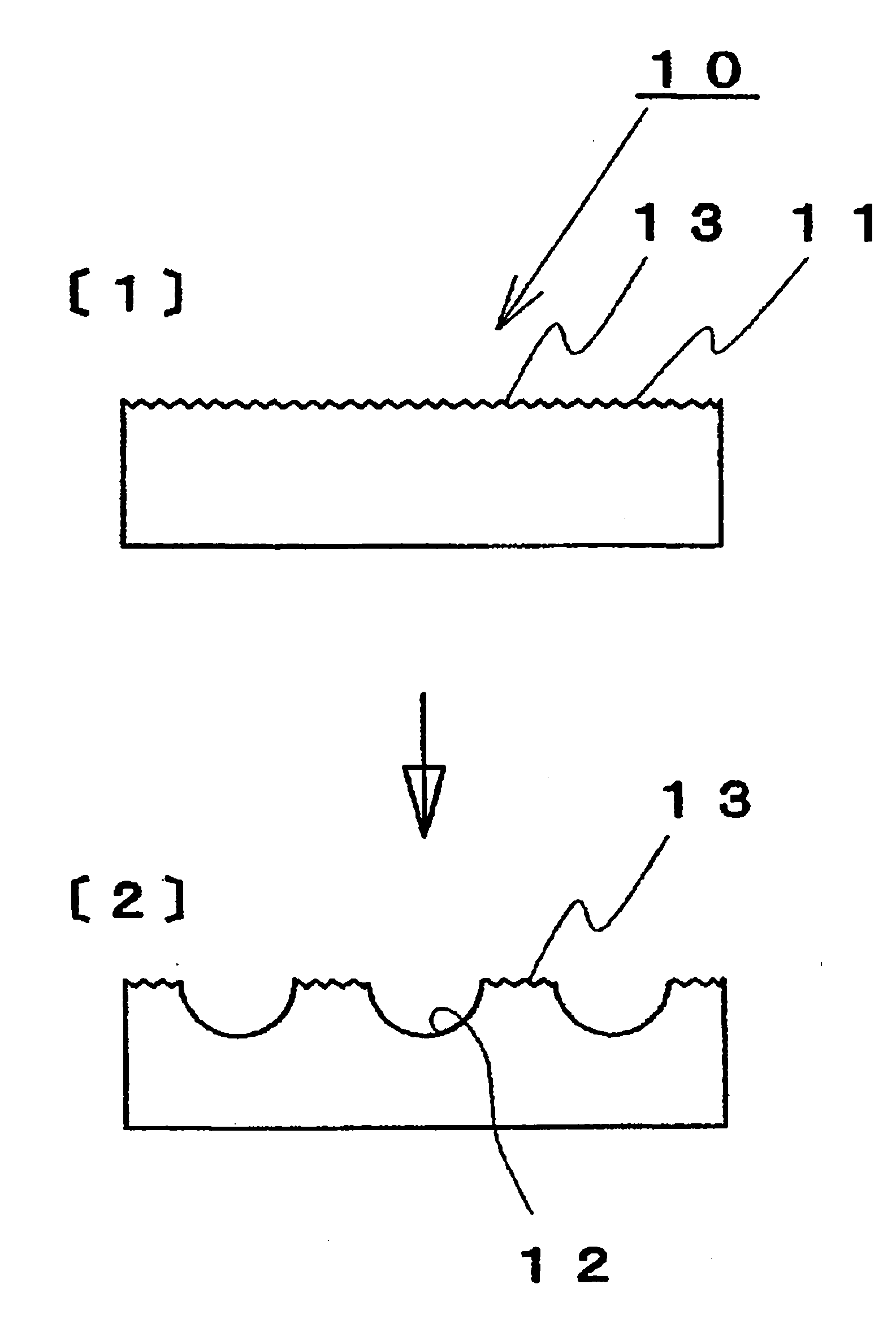

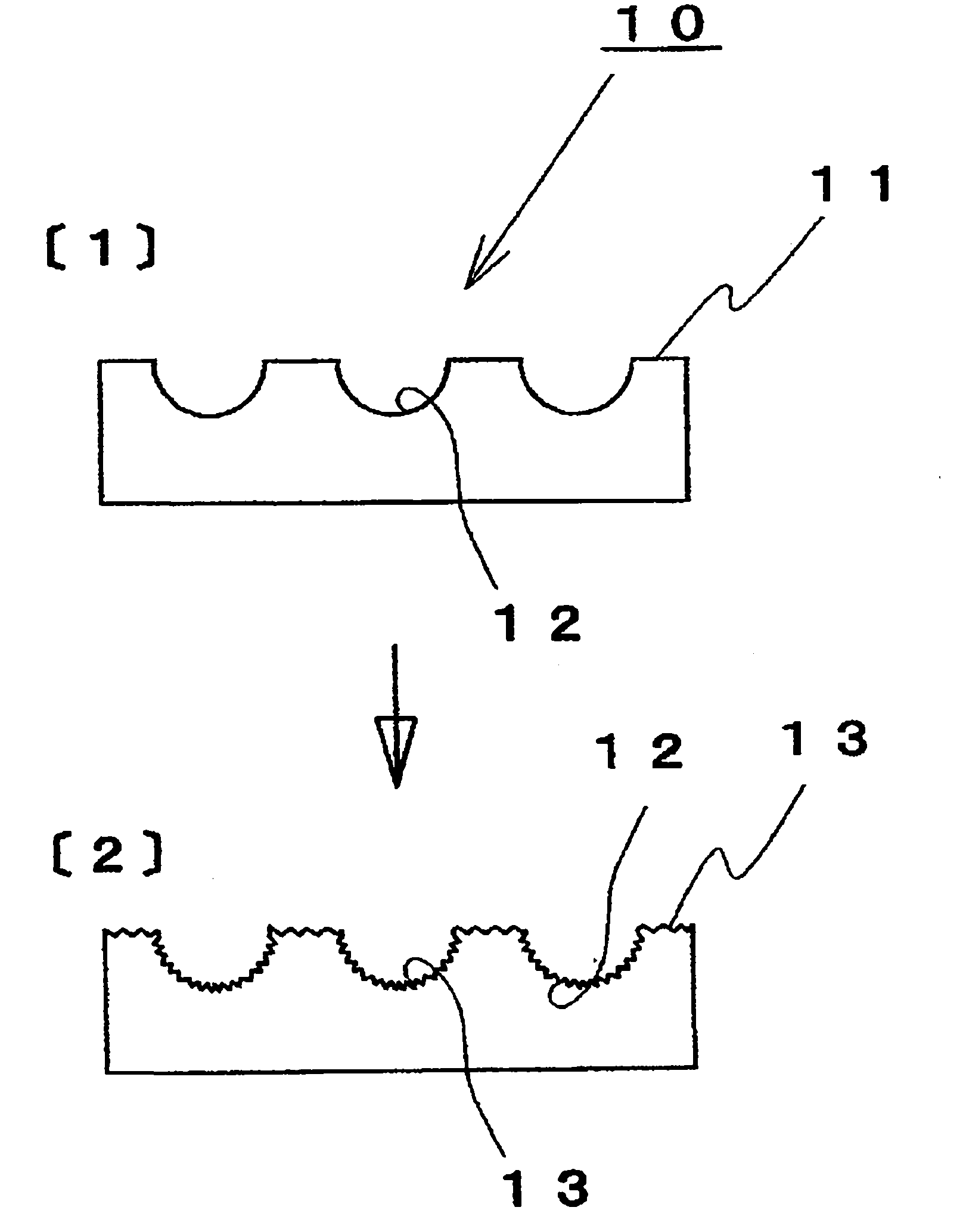

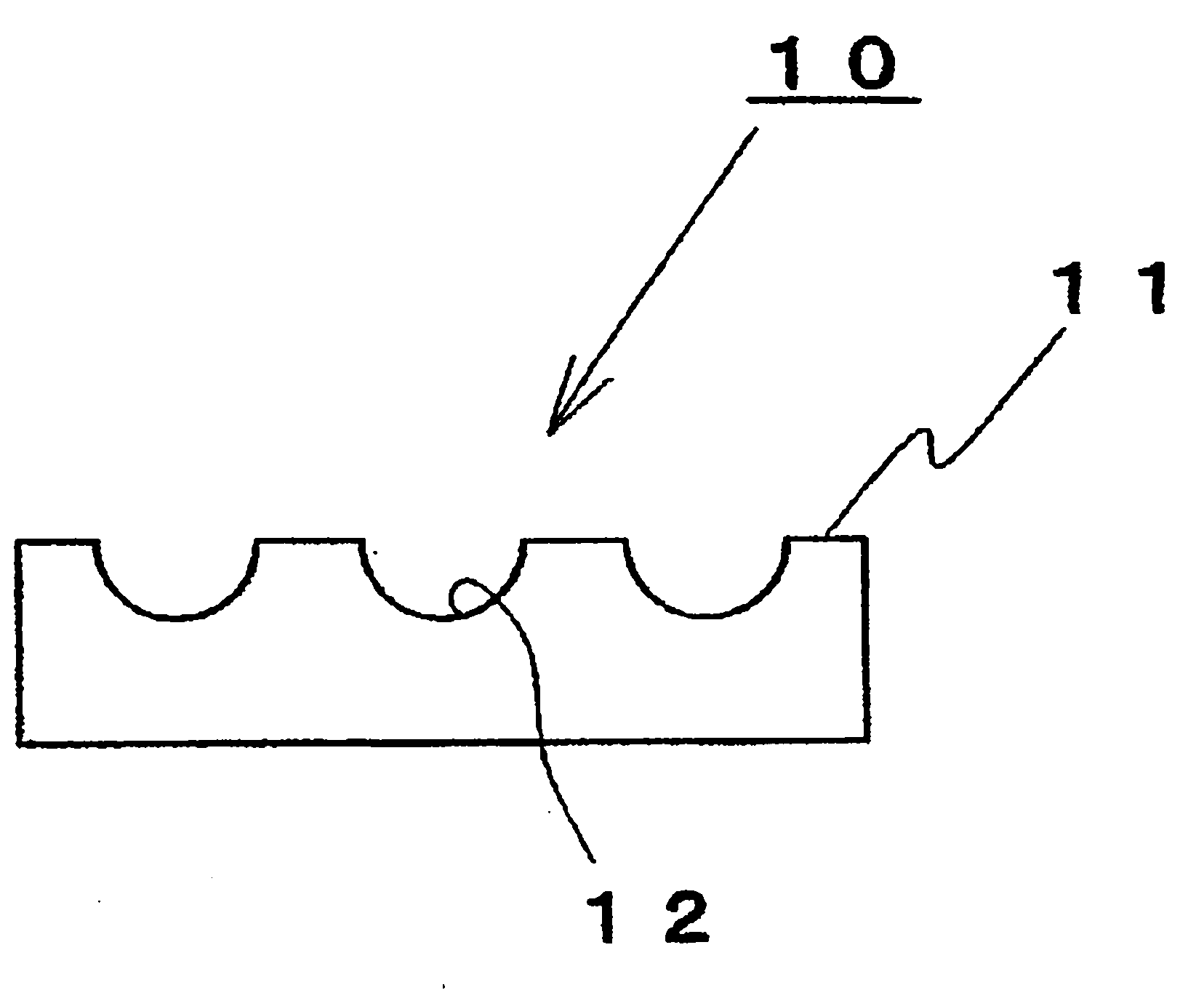

[0044] Embodiment is the example that utilizes processing method (a) to implement, Figure 4 (1)-(3) show the form of the surface texture of the surface (cavity surface 11) of the test piece used as a mold material before processing and after each spray processing process. Hereinafter, this embodiment will be described in detail using the above-mentioned drawings. However, the present invention is not limited to the following embodiments.

[0045] Figure 4 (1) shows the surface properties of a test piece of alloy tool steel SKD61 used as the mold material used in this example. Formed processing marks. The hardness of the test piece was Hv470-500, and the surface roughness was Ra0.07 (≈Rz0.6μm).

[0046] Figure 4 (2) Indicates "amorphous" spherical amorphous particles with a hardness of Hv900 and a particle size of 50 μm TM (AM-50 manufactured by Shinto Kogyo Co., Ltd.) was used as the second blasting material in the blasting process B, and the surface properties of the...

Embodiment 2

[0052] In this example, a thin plate material was cast using a die-casting die, and the fluidity was compared with a cavity surface produced by a conventional wrinkling method. In order to eliminate the influence of the deviation of casting conditions, a mold with symmetrical cavity shape was prepared, and the conventional wrinkle processing was performed on the left half of the cavity surface, and the spray processing of the present invention was carried out on the right half of the cavity surface, and compared liquidity. The fluidity was evaluated by comparing the density of the left half and the right half of the casting. In the case of poor fluidity, the density decreases due to phenomena such as poor filling or entrapment of air bubbles.

[0053] Pouring molten metal, using aluminum alloy (ADC12: density 2.72g / cm 3 ) is poured into the cavity at a melting temperature of 700°C and a mold temperature of 300°C. Density measurement was performed after the casting was remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com