Drilling rod with axial deep groove wear-resistant joint for well drilling

A deep groove, axial technology, applied in the direction of drill pipe, drilling equipment, drill pipe, etc., can solve the problems of increasing mud circulation loss along the way, not solving fundamental problems, increasing circulating pump pressure, etc., to reduce the labor force of workers Labor intensity, reduce the labor intensity of workers, and promote the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

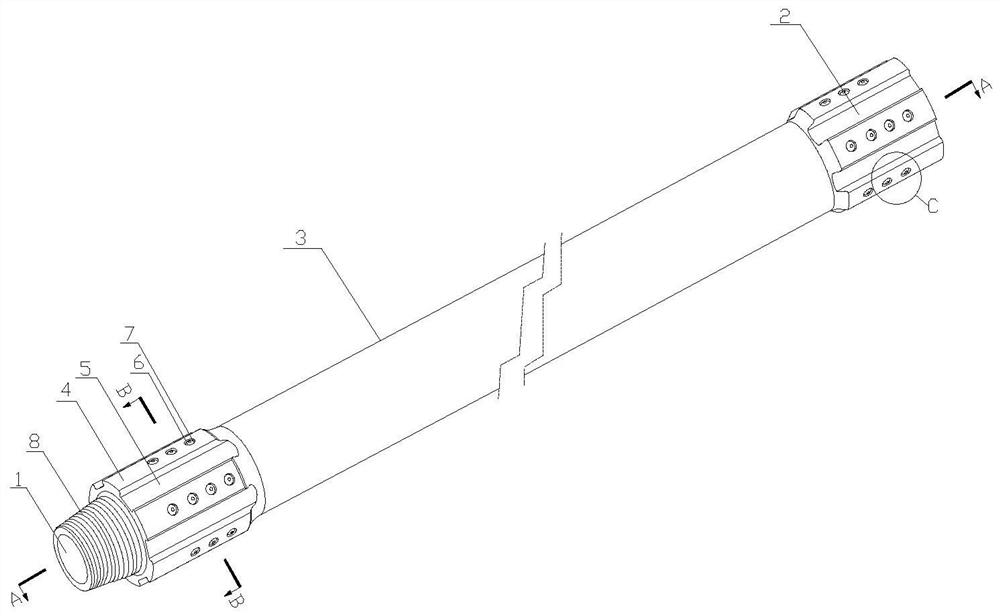

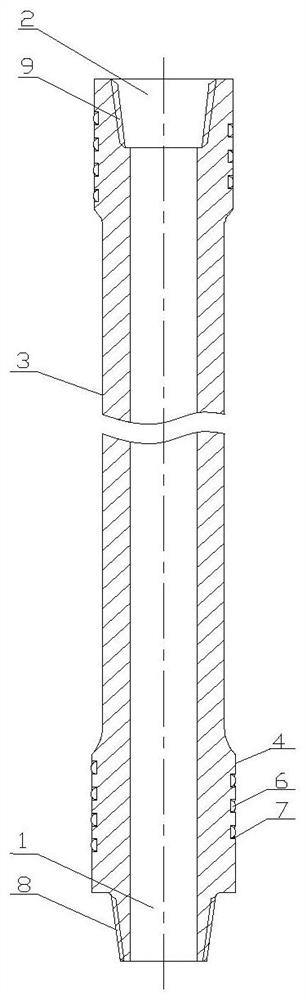

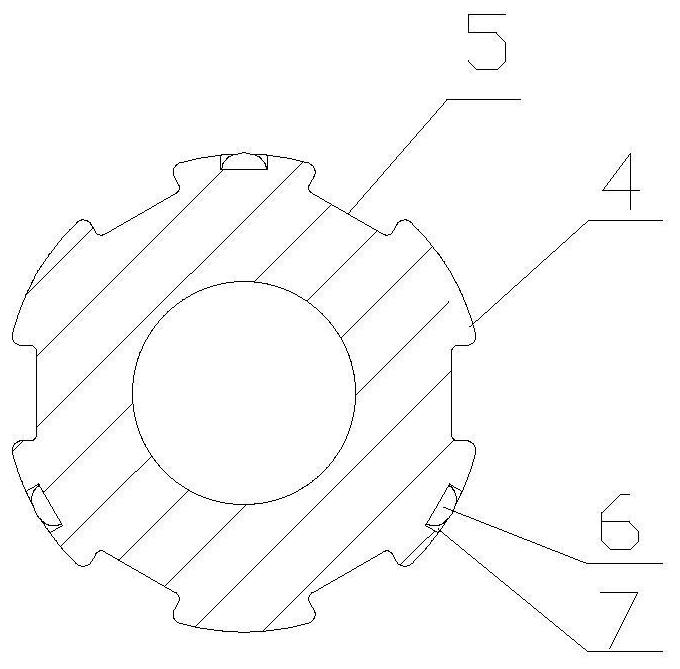

[0017] A drill pipe for drilling with axial deep groove wear-resistant joints, including a rod body 3, and the axial ends of the rod body 3 are respectively provided with a male joint 1 and a female joint 2 with a diameter larger than the rod body 3 (consistent with the national standard for drill pipes) , the bottom of the male joint 1 is provided with a male joint connecting part 8 with an external thread, and the inside of the female joint 2 is provided with an internal thread 9 matching with the male joint connecting part 8, and the male joint 1 and the female joint 2 have a plurality of Joint unscrewing slots 5 extending along its axial direction, joint anti-wear ribs 4 are formed between two adjacent joint unscrew slots 5, and joint anti-wear ribs 4 are provided with wear-resistant materials or provided with multiple Convex crown installation blind hole 7, smooth and wear-resistant convex crown 6 is fixedly connected in the convex ball installation blind hole 7, the highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com