Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

A technology of metal composite materials and high-speed trains, applied to brake parts, friction linings, mechanical equipment, etc., can solve the problems of short life, high wear rate, poor thermal stability, etc., and achieve good wear resistance and heat resistance Recession ability, convenient engineering preparation, and the effect of improving macroscopic uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

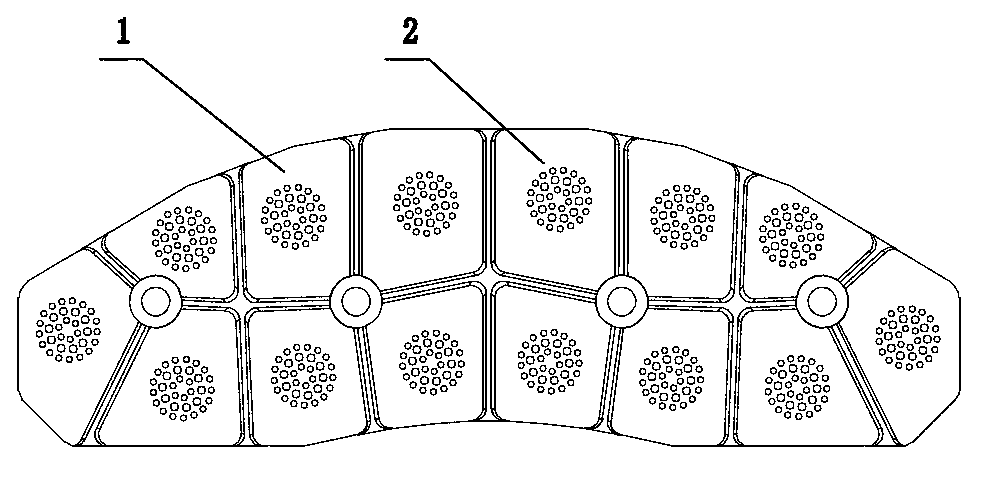

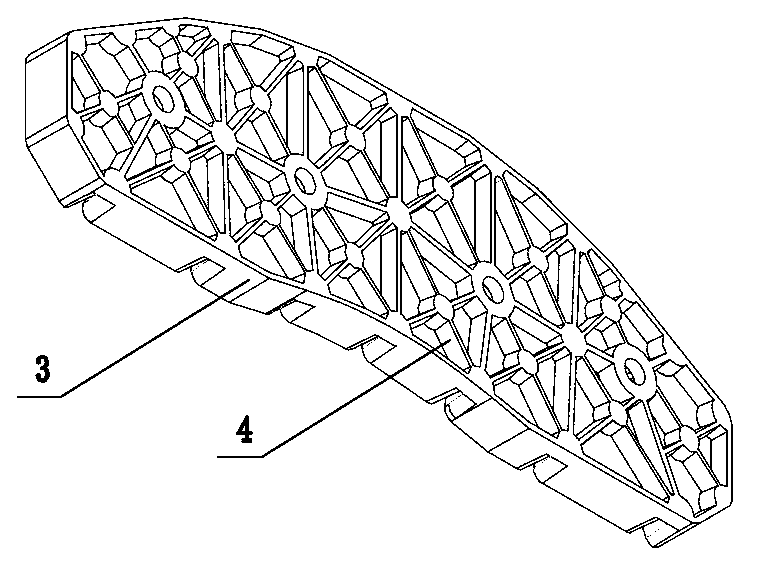

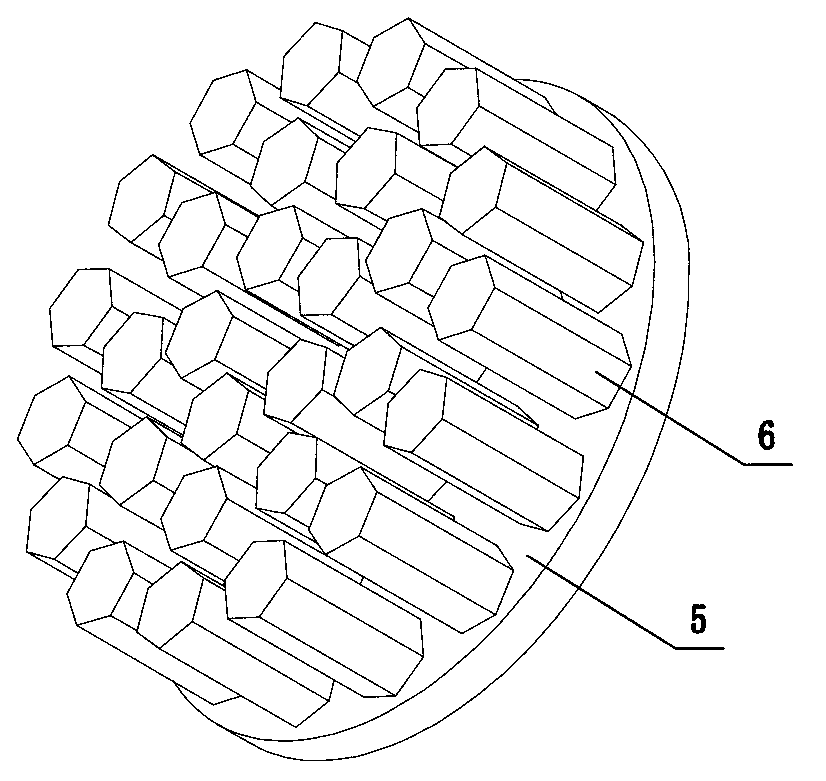

[0036] Example 1: Preparation method of columnar array conjoined SiC ceramic block reinforced copper-based composite brake sheet

[0037] Step 1: Preparation of SiC ceramic blocks in a columnar array: According to the requirements, obtain a circular SiC ceramic column 6 with a cross section of 3 and a rectangle with a longitudinal section of 4×10, with a column spacing of 3 mm, along the x-axis and In the y-axis equidistant array mode, the thickness of the ceramic substrate 5 is 2.5 mm. According to the shrinkage rate of silicon carbide sintering is 17~20%, a suitable gypsum female mold is prepared, and the silicon carbide slurry prepared according to a certain proportion is placed in the female mold, and the conjoined ceramic element is obtained by grouting. Blank. Dry the conjoined ceramic green body, modify the shape, polish, and adopt a pressureless sintering process at 1950-2100 ℃, and keep it warm for 30-60 minutes to obtain a ceramic block.

[0038] Step 2: Surface tr...

Embodiment 2

[0043] Embodiment 2: columnar array conjoined B 4 Preparation method of C ceramic block reinforced copper-based composite material brake sheet

[0044] Step 1: Cylindrical Array Conjoint B 4 Preparation of C ceramic block: According to the requirements, obtain a hexagonal cross-section with a side length of 3 mm and a height of 12 mm. 4 C Ceramic pillars 6, the distance between pillars is 4 mm, arrayed at equal intervals along the x-axis and y-axis, the thickness of the ceramic substrate 5 is 2 mm, according to B 4 C The shrinkage rate during sintering is 18~22%, and a suitable steel mold is prepared. B will be prepared according to a certain proportion and granulated 4 C powder is put into the female mold, and the green body is taken out after forming with a pressure of 100 ~ 200 MPa, put into a soft mold cover and then formed by isostatic pressing at a pressure of 150 ~ 250 MPa to obtain a conjoined ceramic green body? The bulk ceramic green body is dried, trimmed, polis...

Embodiment 3

[0050] Example 3: Columnar array conjoined TiB 2 Preparation method of ceramic block reinforced iron-based composite brake pad

[0051] The difference from Example 1 is that TiB 2 The cross section of the ceramic block is an ellipse with different length-to-diameter ratios and a rectangle with a longitudinal section of 3×12. The column spacing is 3 mm. The ceramic substrate 5 has a thickness of 3 mm. Casting 20Cr steel in TiB with column array conjoined by negative pressure-electromagnetic field co-casting method 2 In the preheated film-coated sand mold casting cavity of the ceramic block, the ceramic array and steel are combined into one body to obtain the gate plate. Negative pressure-electromagnetic field combined casting improves the fluidity and filling ability of the melt, refines the grains, and greatly reduces the defects of castings. After precision machining and quenching + annealing heat treatment, the strength of the aluminum base reaches 375 MPa.

[0052] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com