Patents

Literature

56results about How to "Good resistance to heat decay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

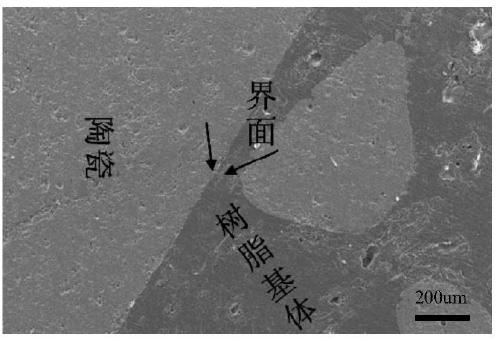

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

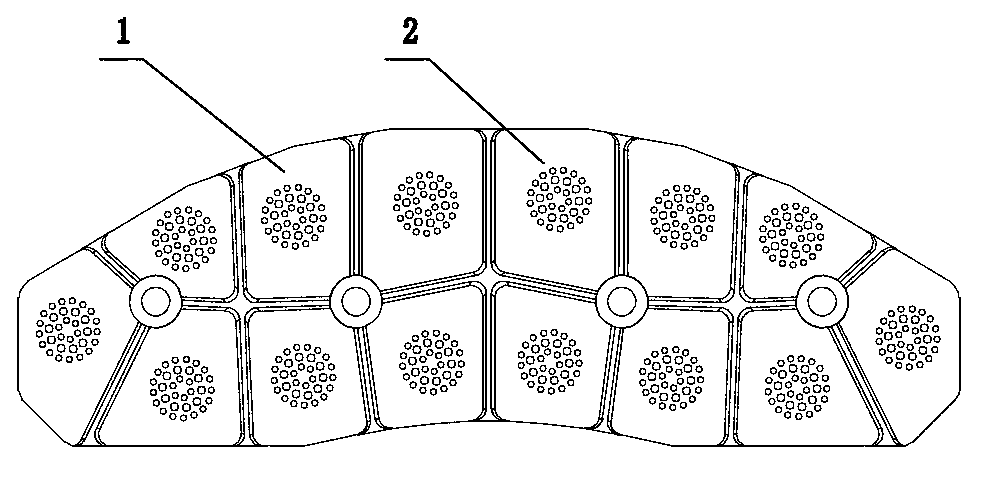

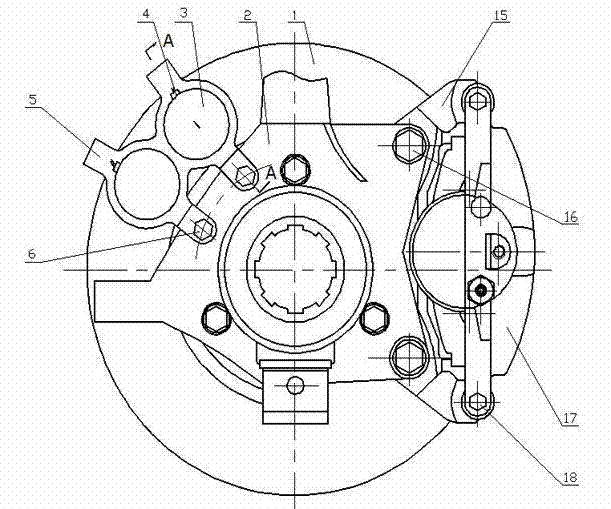

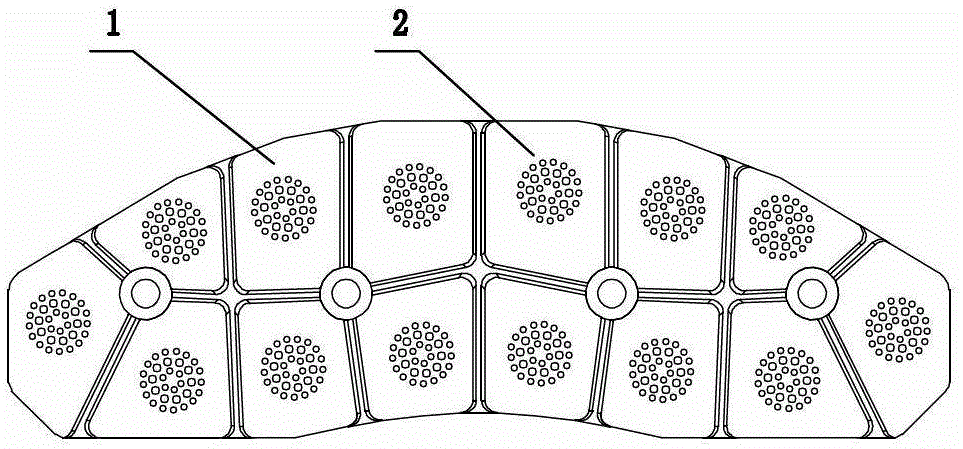

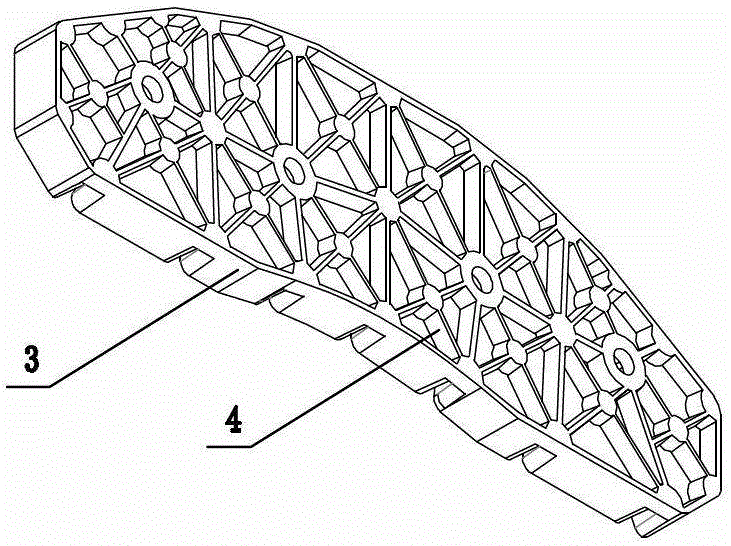

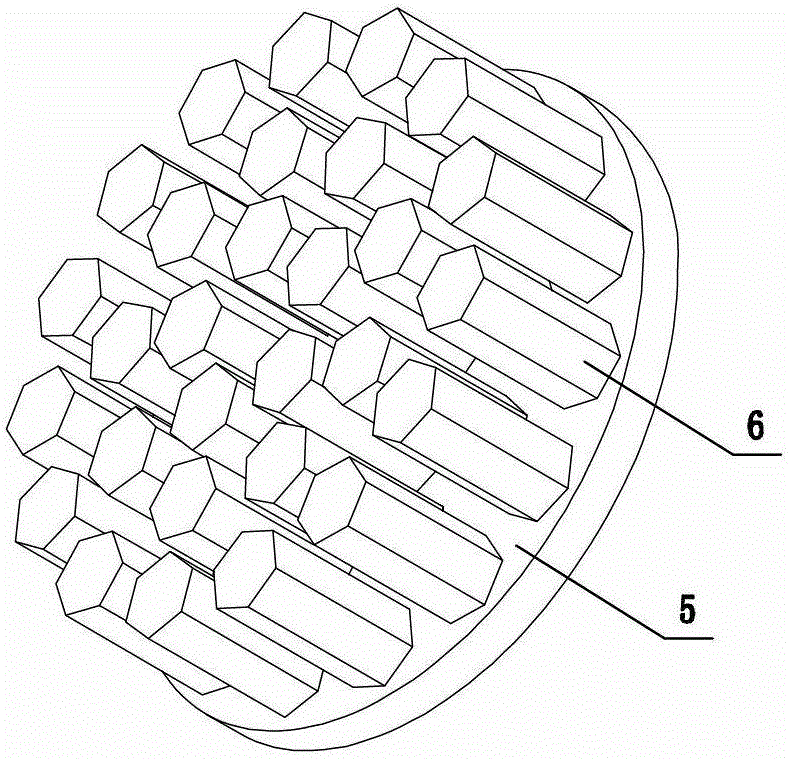

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

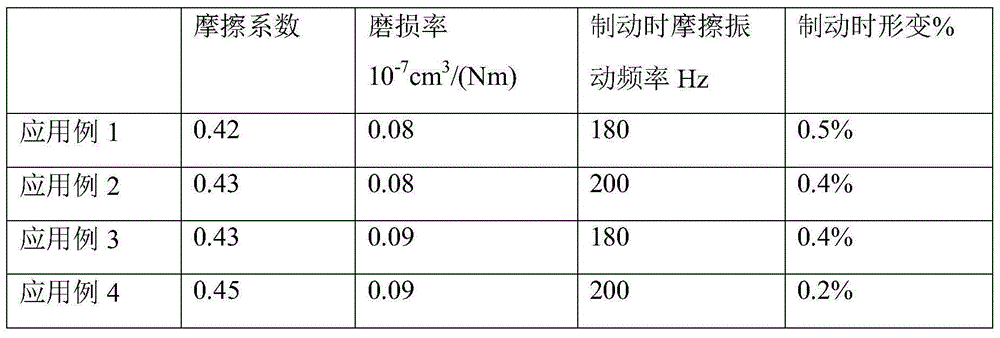

Low-noise heat-fade-resistant resin-base friction material

InactiveCN104109342AStable coefficient of frictionReduce noiseOther chemical processesLow noisePolymer science

The invention discloses a l-noise heat-fade-resistant resin-base friction material which is prepared from the following components in percentage by mass: 10-15% of nano aluminum oxide modified phenol aldehyde resin, 3-6% of aramid fiber pulp, 12-18% of mineral fiber, 5-7% of graphite, 3-5% of antimony trisulfide, 5-7% of coke, 0.5-1.5% of aluminum oxide, 3-5% of ferric oxide, 5-7% of cashew oil friction powder, 3-9% of expanded vermiculite, 2-6% of kieselguhr, 3-9% of nitrile-butadiene rubber and the balance of barium sulfate. The material has the advantages of appropriate and stable friction factor, favorable heat fade resistance, low abrasion ratio, low braking noise, high plastic deformation resistance, high shock resistance and the like, and conforms to the operating requirements.

Owner:YANCHENG INST OF TECH

Cross-country friction material composition for disc friction blocks and preparation method

The invention relates to a cross-country friction material composition for air discs, and the cross-country friction material composition for air discs is characterized by being composed of the following raw materials in parts by weight: 20-52 parts of reinforced fibers, 4-16 parts of an adhesive and 23-86 parts of a friction performance modifier. The cross-country friction material composition for air discs is prepared by the steps of weighing the reinforced fiber, the adhesive and the friction performance modifier by weight to prepare a molding compound, paving a base-layer material formed by weighed fiber material and adhesive on a mold, paving weighed friction material on the base layer to carry out thermocompression, and finally carrying out thermosetting. The cross-country friction material composition for air discs is used for the air disc brakes in complicated road conditions, particularly the cold highland area and wading road conditions, so that a friction material which has good heat recession resistance, high wading restoration performance, temperature alternation repeated impact resistance and stable friction performance is provided.

Owner:CHINA FIRST AUTOMOBILE

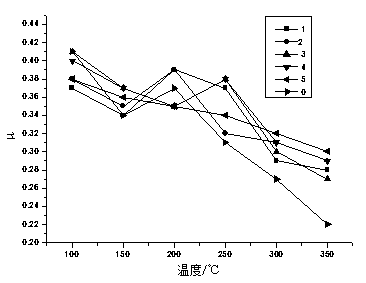

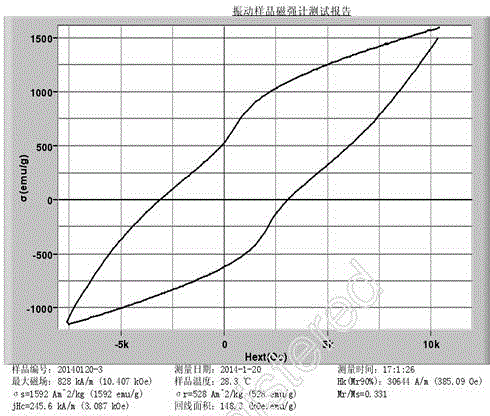

Formula and preparation method of mine hoist soft-magnetism brake shoe material

ActiveCN103937452AStable friction and wearEasy to prepareOther chemical processesFiberAdditive ingredient

The invention discloses a formula and preparation method of a mine hoist soft-magnetism brake shoe material. The material formula consists of the following ingredients in parts by weight: 10-20 parts of organic binder, 15-50 parts of reinforcing fibers, 10-50 parts of friction performance modifier, 3-10 parts of filler and 5-30 parts of soft magnetic material. The preparation method comprises the steps of crushing, mixing, carrying out hot-press forming, carrying out heat treatment and the like. The material formula has the beneficial effects that a mine hoist soft-magnetism brake shoe shows stable friction and wear properties and good heat resistance and is better adaptable to extreme braking conditions, such as high speed and heavy load; due to the added soft magnetic material, the coefficient of friction of the hoist brake shoe is increased, and the wear rate of the hoist brake shoe is reduced, so that the brake shoe has relatively high magnetic conductivity and magnetic induction intensity, and the most basic material conditions are provided for magnetic field control during braking friction. The preparation method of the mine hoist soft-magnetism brake shoe is relatively simple and does not need beforehand magnetizing, and a friction behavior can be regulated and controlled through adjusting the size of magnetism by an external magnetic field during braking.

Owner:CHINA UNIV OF MINING & TECH

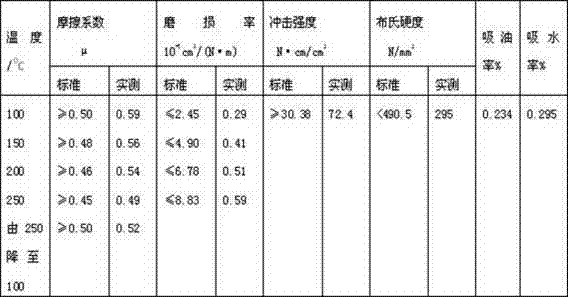

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

High-speed low-load basalt fiber-reinforced frictional material with moderate frictional coefficient and preparation method thereof

ActiveCN105733506AProtection Mechanical PropertiesImprove wear resistanceOther chemical processesFriction liningLow loadFrictional coefficient

The invention provides a high-speed low-load basalt fiber-reinforced frictional material with moderate frictional coefficient and a preparation method thereof. The high-speed low-load basalt fiber-reinforced frictional material comprises the following components in percentage by mass: 5-9% of basalt fibers, 15% of steel fibers, 4-10% of mineral fibers, 10% of acrylonitrile-butadiene rubber phenolic resin, 10% of barium sulfate, 8% of iron ore, 3% of alumina, 6.25% of white mica, 5% of vermiculite, 14% of petroleum coke, 3.75% of frictional powder and 12% of graphite. The preparation method comprises the following steps of: preparing raw materials, carrying out manual stirring, carrying out mechanical stirring, carrying out secondary manual stirring, carrying out secondary mechanical stirring, and carrying out hot press moulding and curing, so that the basalt fiber-reinforced frictional material is obtained. Excellent properties of the basalt fibers are utilized, expensive aramid fibers are replaced by cheap fibers, the high-speed low-load basalt fiber-reinforced frictional material has the advantages of stable frictional coefficient in high temperature working environment, relatively low wear rate and good heat fading resistance, the wear resistance and pressure-bearing capacity of the material are improved, the cost is reduced, the hardness is moderate, and requirements of the frictional material can be better met.

Owner:GUANGXI UNIV FOR NATITIES

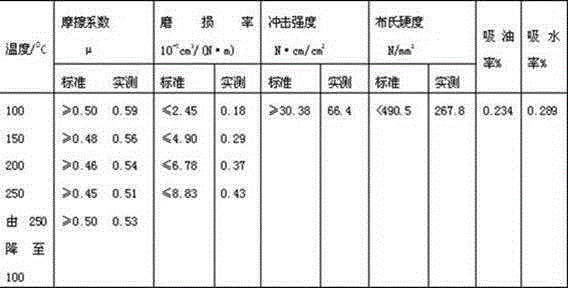

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Non-asbestos micro-metal mineral fiber disk type brake block for automobile

InactiveCN104533998ASensitive brakesBrake pads require sensitive brakingOther chemical processesFriction liningAcrylonitrileStearic acid

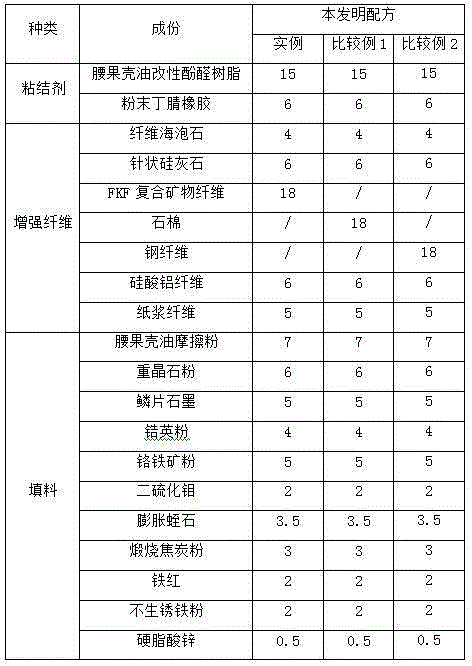

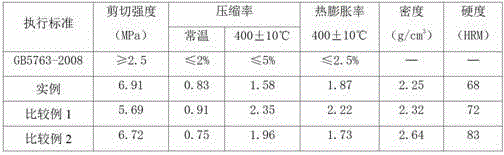

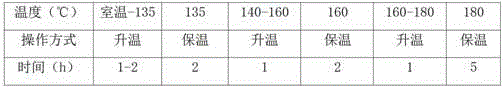

The invention discloses a non-asbestos micro-metal mineral fiber disk type brake block for an automobile. The non-asbestos micro-metal mineral fiber disk type brake block comprises, by weight, 10-20% of cashew nut shell oil modified phenolic resin, 3-8% of powder butadiene-acrylonitrile rubber, 3-8% of fibrous sepiolite, 5-10% of needle-like wollastonite, 15-20% of FKF composite mineral fiber, 5-10% of alumina silicate fiber, 2-6% of paper pulp fiber, 5-10% of cashew nut shell oil friction powder, 5-13% of blanc fixe, 3-15% of crystalline flake graphite, 1-10% of zircon powder, 0.1-0.7% of zinc stearate, 4-7% of chromite ore fines, 1-3% of molybdenum disulfide, 3-6% of expanded vermiculite, 1-5% of calcined coke powder, 1-5% of iron oxide red and 1-6% of rustless iron powder. The production process comprises the steps that the components are pre-mixed and mixed through an automatic mixer, the amount of finally-formed materials is weighted according to the required specification of the disk type brake block, a cold blanket is formed after cooling forming, hot press forming and heat processing are carried out, and the finished product is manufactured through fine machining. The non-asbestos micro-metal mineral fiber automobile disk type brake block has the advantages of being stable in friction abrasion performance, good in mechanical property, excellent in heat recession resisting performance and long in service life.

Owner:福建冠良汽车配件工业有限公司

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

Permanent magnet braking and frictional braking combined brake and braking method

InactiveCN102155508BReduce heatReduce wearBrake actuating mechanismsActuatorsMagnetAutomotive engineering

The invention discloses a permanent magnet braking and frictional braking combined brake for automobile braking or deceleration and a braking method. The brake comprises a permanent magnet braking device and a frictional braking device, wherein the permanent magnet braking device comprises a magnetic conductive plate, a magnetic conductive ring, a magnetic conductive sleeve and a permanent magnet and is symmetrically distributed at both sides of a brake disk; the magnetic conductive sleeve is internally provided with the permanent magnet which reciprocates along the axial direction of the magnetic conductive sleeve; one end of the permanent magnet close to the braking disk is sheathed with the magnetic conductive ring in a clearance way, and the magnetic conductive ring is fixedly connected with the magnetic conductive sleeve; the outer side of the magnetic conductive ring is provided with the magnetic conductive plate which is fixedly connected with the permanent magnet; during emergency braking, the permanent magnet braking device and the frictional braking device jointly take effect; during non-emergency braking or long slope braking, if a vehicle speed is higher than 30km / h, only the permanent magnet braking device brakes; if the vehicle speed is lower than 30km / h, only the frictional braking device brakes; and the permanent magnet braking and frictional braking combined brake has good heat-fading resistance, reduces the frictional braking abrasion, prolongs the service life of the brake and reduces the noise of the whole brake.

Owner:JIANGSU UNIV

Method of preparing automobile brake pad by adopting basalt fiber

ActiveCN106949179AStable performanceExtended service lifeOther chemical processesFriction liningWollastoniteBasalt fiber

The invention relates to a method of preparing an automobile brake pad by adopting basalt fiber. The method comprises the following steps: butadiene nitrile rubber modified phenolic resin, surface modified basalt superfine fiber, acicular wollastonite fiber and carbon fiber are added to a material mixing machine and are mixed; then crystalline flake graphite, artificial graphite particles, chromite powder, feldspar powder, dolomite powder, fluorite powder, calcium carbonate powder, mica, nano ZnO, butadiene nitrile rubber and wollastonite are sequentially added to the material mixing machine and mix is carried out; a mixture is placed in a brake pad mould, and hot pressing and demoulding are carried out; a hot pressed material after the demoulding is subjected to grading heat treatment; and a discharged brake pad is subjected to follow-up treatment and packing. The automobile brake pad prepared by the method has a stable friction coefficient and a low wear rate, and further has high heat resistance and heat-aging resistance.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

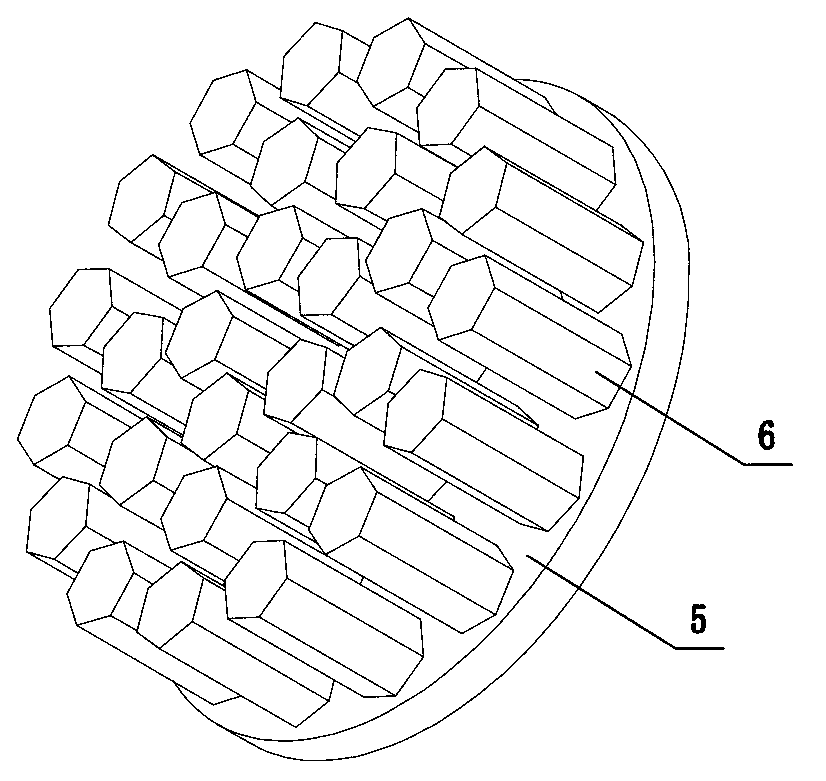

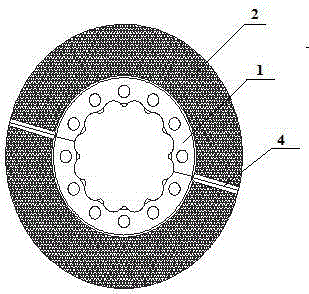

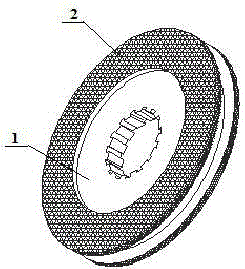

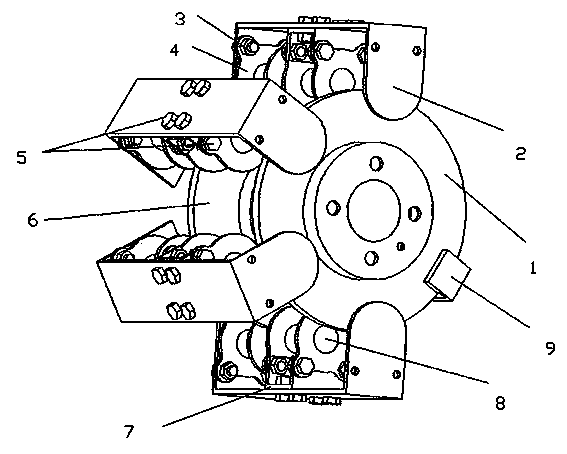

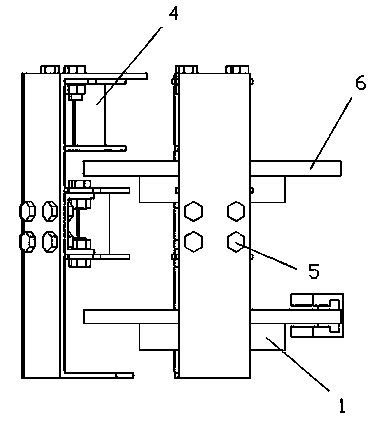

Foamed ceramic reinforced light metal composite friction clutch disc and brake disc

PendingCN106499741AHigh hardnessImprove wear resistanceBraking discsFriction clutchesSurface layerHardness

The invention relates to a foamed ceramic reinforced light metal composite friction clutch disc and brake disc. The brake disc comprises a metal base body, the metal base body is provided with one or two friction surface layers, and the friction surface layers are foamed ceramic reinforced light metal composite friction surface layers. According to the brake disc, the characteristics that industrial ceramic is high in hardness, high in wear resistance and resistant to high temperature are given full play to, the characteristics that light metal is light in weight, high in strength and good in toughness are given full play to, the industrial ceramic is made into foamed ceramic with the topological geometric structure through the proper technology, and then the foamed ceramic is combined with the light metal to be made into the novel friction clutch disc and brake disc with the characteristics of the foamed ceramic and the light metal. The clutch disc and brake disc can meet the friction engagement and brake requirements of moving machinery equipment such as airplanes, rail transit vehicles, road traffic vehicles and ships.

Owner:房殊

Boron and linseed oil double-modification phenolic resin-based friction resistance composite material and preparation method thereof

The invention provides a boron and linseed oil double-modification phenolic resin-based friction resistance composite material and a preparation method thereof, and relates to the field of friction resistance composite materials. According to the preparation method, the phenolic resin is toughened and modified by using the linseed oil which has a rich source. The method for preparing the phenolic resin-based friction resistance composite material comprises the following steps: mixing boron modified phenolic resin prepolymer with relatively mature production process technology and self-made linseed oil modified phenolic resin prepolymer; adding a reinforcement material such as glass fiber and other components into the mixture; forming the boron and linseed oil double-modification phenolic resin by heating; and performing binary modification of toughness and heat resistance on the boron and linseed oil double-modification phenolic resin to obtain a phenolic resin-based friction resistance composite material. Compared with a tung oil and cashew nut shell oil toughened and modified phenolic resin-based friction resistance composite material, the boron and linseed oil double-modification phenolic resin-based friction resistance composite material has the advantages of rich material resource, comparatively simple purification process, and stable performance of the obtained products. Compared with a rubber and thermoplastic resin toughened and modified phenolic resin-based friction resistance composite material, the boron and linseed oil double-modification phenolic resin-based friction resistance composite material has the advantages of high heat resistance and friction-wear performance of the products, and no off-odor generated during the use of the friction resistance material.

Owner:JIANGSU UNIV

Resin-matrix friction material for tailings of high silicon iron

InactiveCN101818046AImprove thermal stabilityGood resistance to heat decayOther chemical processesResin matrixAlkali feldspar

The invention provides a resin-matrix friction material for tailings of high silicon iron, which comprises the following components by weight percentage: 10-14% of tailings of high silicon iron, 10-30% of phenolic resin, 10-30% of butadiene styrene rubber, 0.1-5% of zinc stearate, 1-15% of carbon black, 10-30% of barium sulfate and 5-20% of feldspar powder, and the sum of weight percentage contents of the components is 100%. The resin-matrix friction material has the advantage of heat fading resistance, wherein the weight percentage content of the tailings of high silicon iron achieves 40%, and the the material cost of the resin-matrix friction material is reduced to a great extent.

Owner:YANCHENG INST OF TECH

Preparation method of potassium titanate and application of potassium titanate in friction material

ActiveCN105152203ALow priceImprove friction performanceAlkali titanatesOther chemical processesRoom temperatureWear resistance

The invention discloses a preparation method of potassium titanate. According to the preparation method, potassium carbonate and titanium dioxide are mixed for 15-20 minutes, uniformly stirred and transferred to a push slab kiln; firstly, the mixture is heated in the kiln from the room temperature, heated to 300 DEG C-320 DEG C in two hours, then heated again to 700 DEG C-720 DEG C in 6 hours, kept at the temperature for 8 hours, then heated to 900 DEG C-920 DEG C in 4 hours and kept at the temperature for 4 hours; then the mixture is cooled to the normal temperature, taken out and roughly smashed firstly, and the diameters of particles are controlled to be smaller than 1 cm; the roughly smashed material is subjected to ball milling for 10-20 hours, a product is subjected to heat treatment at the temperature of 700 DEG C-800 DEG C for one hour after ball milling, and potassium titanate is obtained. The potassium titanate prepared with the method has stable friction performance after being used in the friction material and has good abrasion performance, speed characteristic and heat recession resistance and better capability of reducing brake noise.

Owner:句容亿格纳米材料厂

Linseed oil modified phenol formaldehyde resin for friction material and its preparation method

A flax oil modified phenolic resin for friction material is prepared through proportionally mixing phenol with methylphenylsulfonic acid, stirring, adding flax oil, heating, reacting, cooling while stirring, heating while adding formaldehyde, stirring, adding ammonia water, slow heating until yellow turbid presents, cooling to 50 deg.C, vacuum dewatering until it become transparent, adding absolute alcohole, stirring while dissolving, and cooling, It has high thermal stability.

Owner:JIANGSU UNIV

Mine hoist hard magnetic brake shoe material formula and producing thereof

ActiveCN104099063AStable friction and wearIncrease coefficient of frictionOther chemical processesFiberRemanence

The invention discloses a mine hoist hard magnetic brake shoe material formula and a producing method thereof, the mine hoist hard magnetic brake shoe material comprises the following components in parts by weight: 10 to 20 parts of an organic binder, 15 to 50 parts of a reinforcing fiber, 15 to 45 parts of a friction performance regulator, 3 to 10 parts of a filler and 5 to 40 parts of a hard magnetic material. The producing method comprises crushing, mixing, hot pressing forming, magnetizing, heat treatment and surface processing technology and the like. The beneficial effects are that: a mine hoist hard magnetic brake shoe shows stable friction and wear properties and good heat resistance, and is better adapted to high speed and heavy load extreme braking working conditions; the added hard magnetic material increases the friction coefficient and reduces wear rate of the mine hoist brake shoe, the magnetized brake shoe has higher remanent magnetization and provides most basic material conditions for the magnetic field control of the braking friction process. The magnetized mine hoist hard magnetic brake shoe can maintain magnetism for a long term, the friction behavior can be influenced and adjusted in the braking process without an applied magnetic field.

Owner:CHINA UNIV OF MINING & TECH

Method for manufacturing IMC (Intermetallic Compound) silicon nitride ceramic-based composite brake pad

The invention relates to a method for manufacturing an IMC (Intermetallic Compound) silicon nitride ceramic-based composite brake pad. The method comprises the following steps of: carrying out mechanical alloying on an Fe3Al / Si3N4 composite material, then grinding to 1200 meshes, then mixing the Fe3Al / Si3N4 composite material, graphite powder and Al2O3 powder, and carrying out vacuum hotpressing and sintering in a die to obtain an Fe3Al / Si3N4-based composite brake pad raw material; and machining the brake pad raw material into a corresponding brake pad, and manufacturing the Fe3Al / Si3N4-basedcomposite brake pad through high-temperature pressing and laminating. The method for manufacturing the IMC silicon nitride ceramic-based composite brake pad, disclosed by the invention, has the advantages of low manufacturing cost, simple process, lower mating plate friction loss and capability of keeping a favorable braking effect still after continuously braking for a long time.

Owner:TAIYUAN UNIV OF TECH

Friction material for electric vehicle brake piece

InactiveCN106015399AImprove mechanical propertiesGood adhesionOther chemical processesBraking membersEpoxyCarbon fibers

The invention discloses a friction material for an electric vehicle brake piece. The friction material comprises, by weight, 30 parts of carbon fibers, 15 parts of aramid fibers, 50 parts of nitrile rubber buna, 30 parts of butadiene styrene rubber, 20 parts of carbon black, 12 parts of compound mineral fibers, 3 parts of sulphur, 4 parts of vermiculite, 7 parts of epoxy resin, 15 parts of barium sulfate, 8 parts of graphite, 1 part of an accelerant, 4 parts of a stabilizing agent and 2 parts of water. The friction material has the beneficial effects of being high in wear resistance and pressure resistance, stable in friction coefficient, low in fading rate, free of noise and the like.

Owner:JIANGSU PAVEL ELECTRIC TECH CO LTD

High heat load tolerant frictional material

InactiveCN105602523AStable coefficient of frictionReduce wear rateOther chemical processesUltrasound attenuationFiber

The invention discloses a high heat load tolerant frictional material. The frictional material is prepared from the following components in parts by weight: 15-35 parts of resin, 15-30 parts of composite fibers, 5-20 parts of polyimide, 5-15 parts of barium sulfate, 1-2 parts of wollastonite and 1-2 parts of aluminum oxide. The frictional material can bear a high heat load and is stable in frictional coefficient in a high-temperature environment and relatively low in wear rate, thereby having excellent heat attenuation resistance.

Owner:FOSHAN WASEDA INFORMATION CONSULTATION CO LTD

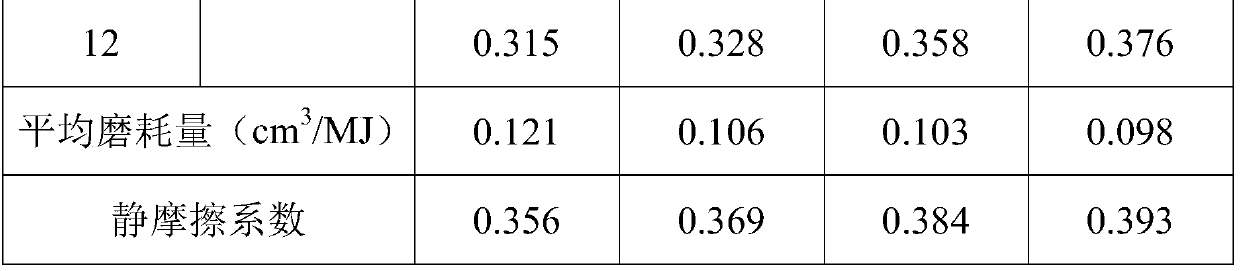

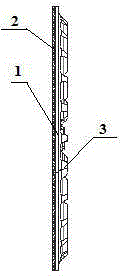

Silicon carbide foam ceramic/aluminum alloy composite material brake disc and preparation method thereof

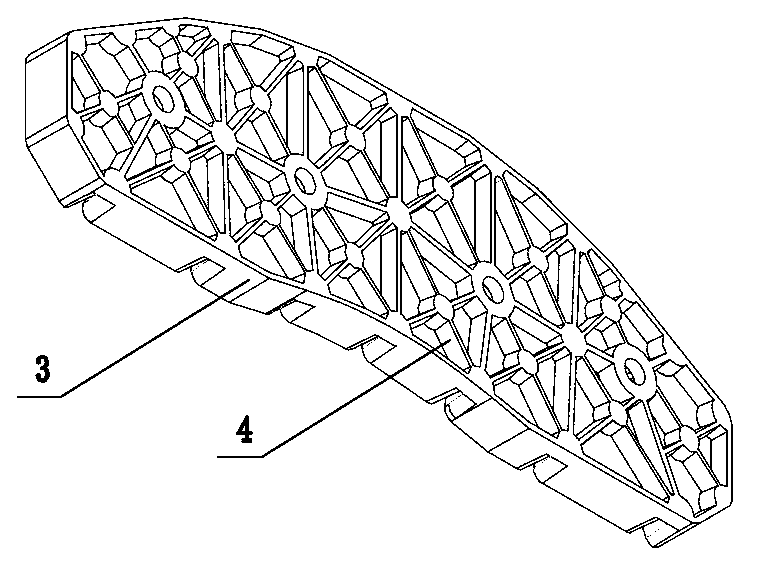

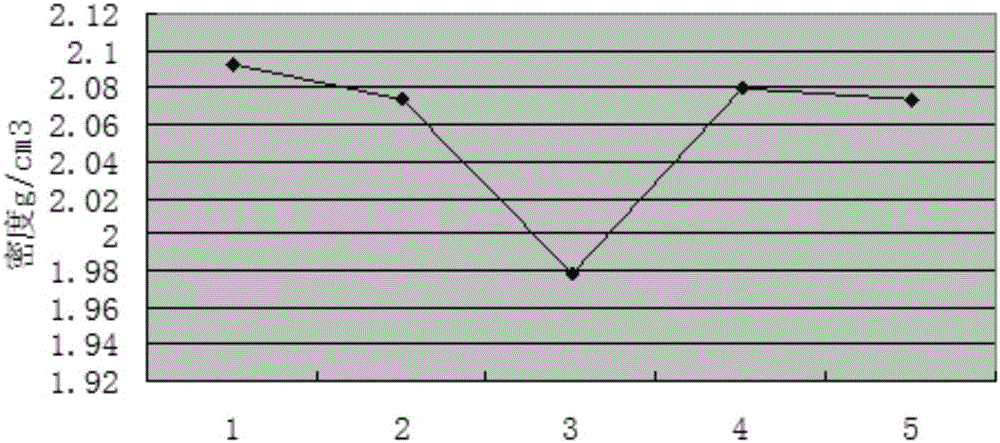

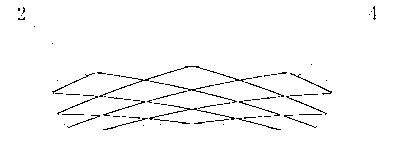

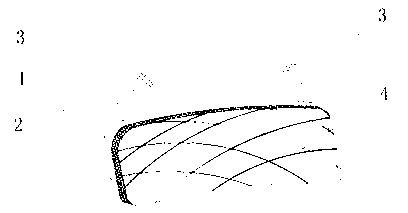

ActiveCN104235237BReduce weightImprove feeding capacityBraking membersFriction liningCeramic compositeAlloy composite

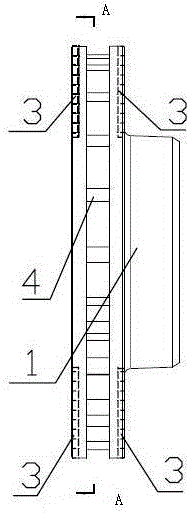

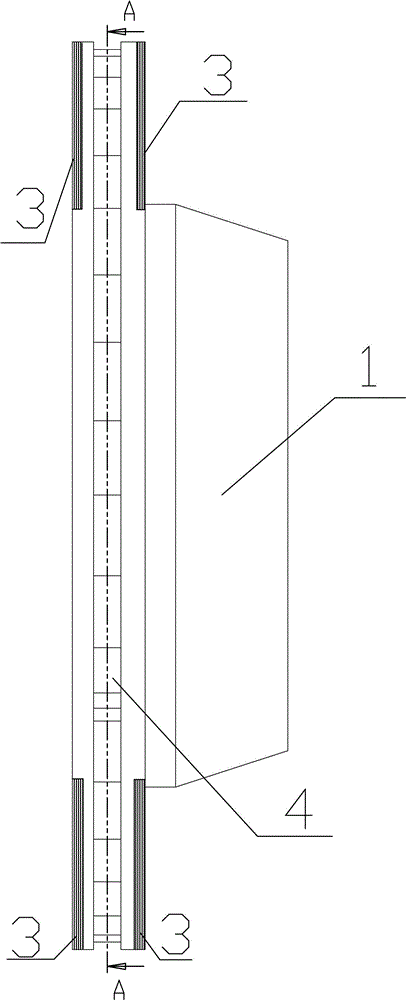

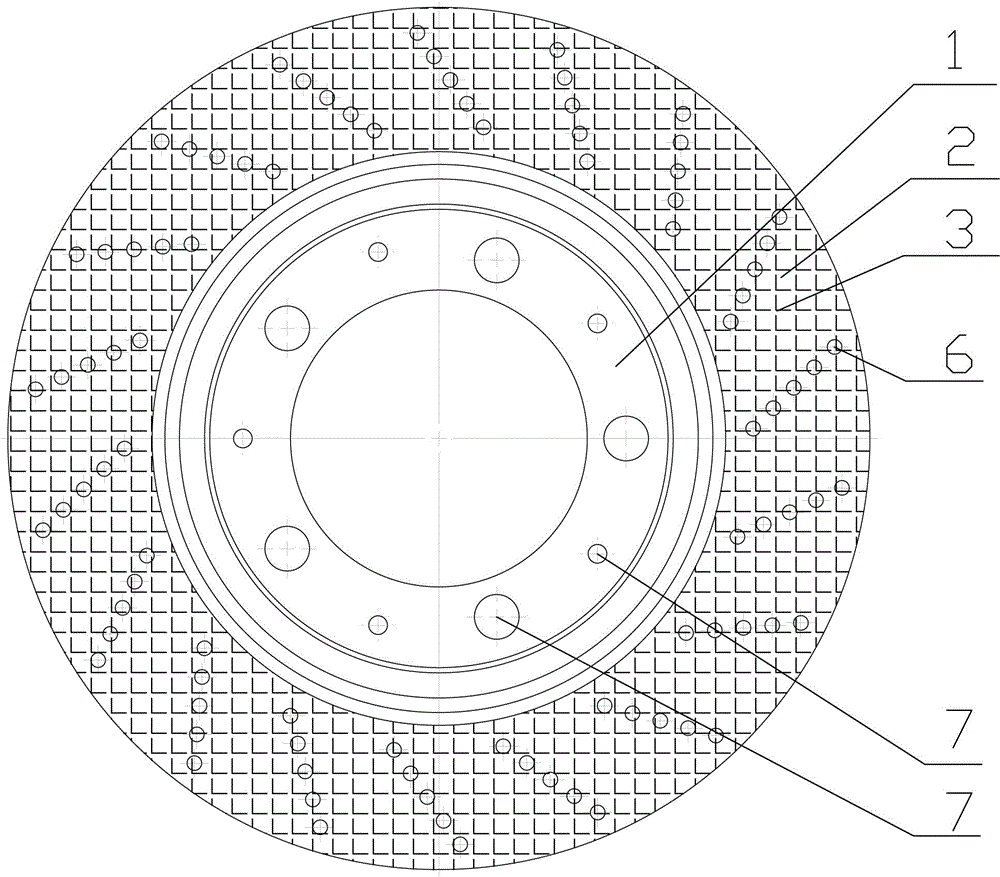

A friction disc of metal / continuous-structure phase ceramic composite material and a method for manufacturing same are provided. The friction disc comprises a metal disc body (1) and a friction layer of metal / continuous-structure phase ceramic composite material arranged on one side or symmetrically arranged on both sides of the disc body. The metal disc body (1) is a metal backboard mechanically connected with the friction layer (3); or the metal disc body can be made of the same material as the composite material in the friction layer (3), and integrally cast with the friction layer; or the metal disc body can be made of the same material as the metal material in the friction layer (3) and integrally cast with the friction layer; or the metal disc body can be made of the same material as the metal material in the friction layer (3) and integrally cast with the friction layer, the disc body having reinforcing ribs. The friction disc of composite material can significantly reduce the weight of clutch plates and friction braking plates, and also has excellent friction and wear performance. It can not only carry out safe and effective friction clutch and brake operation for various kinds of rotating machinery, but also achieve the purpose of reducing cost, light weight and energy saving.

Owner:SHIJIAZHUANG DONGDA HUITONG NEW MATERIAL CO LTD

Caron fiber reinforced friction plate

InactiveCN104533997AHigh strengthIncrease elasticityOther chemical processesFriction liningFiberWorking life

The invention discloses a carbon fiber reinforced friction plate, and belongs to the technical field of brake friction plates. Carbon fibers are used as reinforcing fibers to form a carbon fiber composite material; a carbon fiber composite friction resistance material takes carbon fibers (CF) as reinforcing fibers, takes novel phenolic resin (XYLOK) as a binder, and is supplemented with various performance regulators and fillers; each component of the carbon fiber composite friction resistance material is uniformly mixed and dried, and molded and pressed into the carbon fiber composite material brake friction plate through hot mould pressing. The carbon fiber reinforced friction plate has the advantage the carbon fiber reinforced friction plate is relatively high in friction coefficient, goof in heat fading resistance, long in working life and relatively environment-friendly.

Owner:来安县隆华摩擦材料有限公司

Composite friction material which is based on carbon component with controllable size and dimension and preparation method of composite friction material

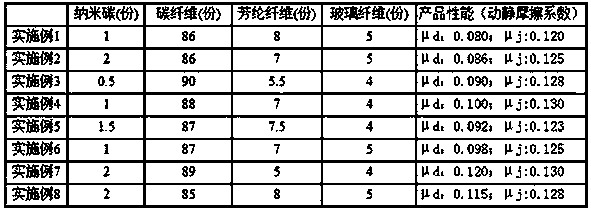

InactiveCN108822798AImprove friction and wearImprove heat resistanceOther chemical processesFriction liningPorosityGlass fiber

The invention relates to a composite friction material which is based on a carbon component with controllable size and dimension and a preparation method of the composite friction material. The composite friction material comprises a steel core plate layer, wherein a carbon paper-based friction layer is arranged on the surface of the steel core plate layer, and the friction material adopts 2.5D multi-dimensional carbon fiber to achieve controllable size and dimension; the preparation method comprises the specific steps: proportioning the carbon component; preparing a preform on a 2.5D multi-dimensional braiding machine; and preparing the composite friction material. The composite friction material is prepared from the following raw materials of: in parts by weight, 0.5-2 parts of nanocarbon, 85-90 parts of carbon fiber, 5-8 parts of aramid fiber and 4-5 parts of glass fiber. The nanocarbon is dispersed more uniformly in a matrix by utilizing the nanocarbon and carbon fiber, so that thecomposite friction material which is based on the carbon component with controllable size and dimension and has light weight, high specific strength, high friction coefficient, small wear rate and low porosity, a uniform and compact friction material and better heat fading resistance is prepared, the service life of the product is prolonged, and phenomena of fiber shedding is reduced; the preparation method of the composite friction material is provided.

Owner:杭州萧山红旗摩擦材料有限公司

Friction and electromagnetism integrated brake with double disk structure

ActiveCN102691737BRealize shuntIncreased braking safetyBrake actuating mechanismsActuatorsBrake torqueEngineering

The invention discloses a friction and electromagnetism integrated brake witha double disk structure for carrying out brake and deceleration on car. The brake comprises a first brake disk and a second brake disk. A brake clip is arranged on the first brake disk, and an electromagnetism brake device is arranged on the second brake disk. The electromagnetism brake device comprises several sets of excitation coils. Each set of the excitation coils comprises two coil windings and two iron cores. The coil winding is wound on the iron core. The two coil windings and the two iron cores are symmetrically distributed on both sides of the second brake disk. An aluminum support is arranged in the middle of the two coil windings. The friction and electromagnetism integrated brake with the double disks distributes brake torque of an electromagnetism brake anda friction brake through precise control, realizes brake heat shunt, avoids brake heat failure, and improves safety performance of vehicle brake.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Multidimensional nano-carbon reinforced friction material and preparation method thereof

ActiveCN112096764AReduce porosityReduce sheddingOther chemical processesFriction liningFiberCarbon fibers

The invention relates to a multidimensional nano-carbon reinforced friction material and a preparation method thereof, and belongs to the technical field of composite friction materials. The multidimensional nano-carbon reinforced friction material comprises a multidimensional nano-carbon reinforced friction material core plate layer which adopts a substrate made of a heat-resistant carbon fiber 65Mn reinforced material; and multidimensional nano-carbon lining layers are arranged at the upper end and the lower end of the substrate. The preparation method of the multidimensional nano-carbon reinforced friction material comprises the following steps: step one, weaving a fiber cloth; step two, curling and forming the fiber cloth, impregnating the fiber cloth in resin, drying, curing and cooling; step three, taking a steel plate, punching and forming, carrying out hot leveling, carrying out heat treatment, washing and drying, then taking the dried steel plate as a steel core plate layer ofa bottom layer; step four, carrying out ball-milling and alloying of nano-carbon and copper powder; and step five, pressing and embedding the copper powder containing nano-carbon into gaps of the nano-carbon lining layers on two end surfaces of a formed friction plate by using a pressing machine. The multidimensional nano-carbon reinforced friction material has the characteristics of light weight, high specific strength, high friction coefficient, low wear rate, low product porosity, uniformity, compactness and better heat fading resistance; the service life of the product is prolonged; and the fiber shedding phenomenon is reduced.

Owner:杭州萧山红旗摩擦材料有限公司

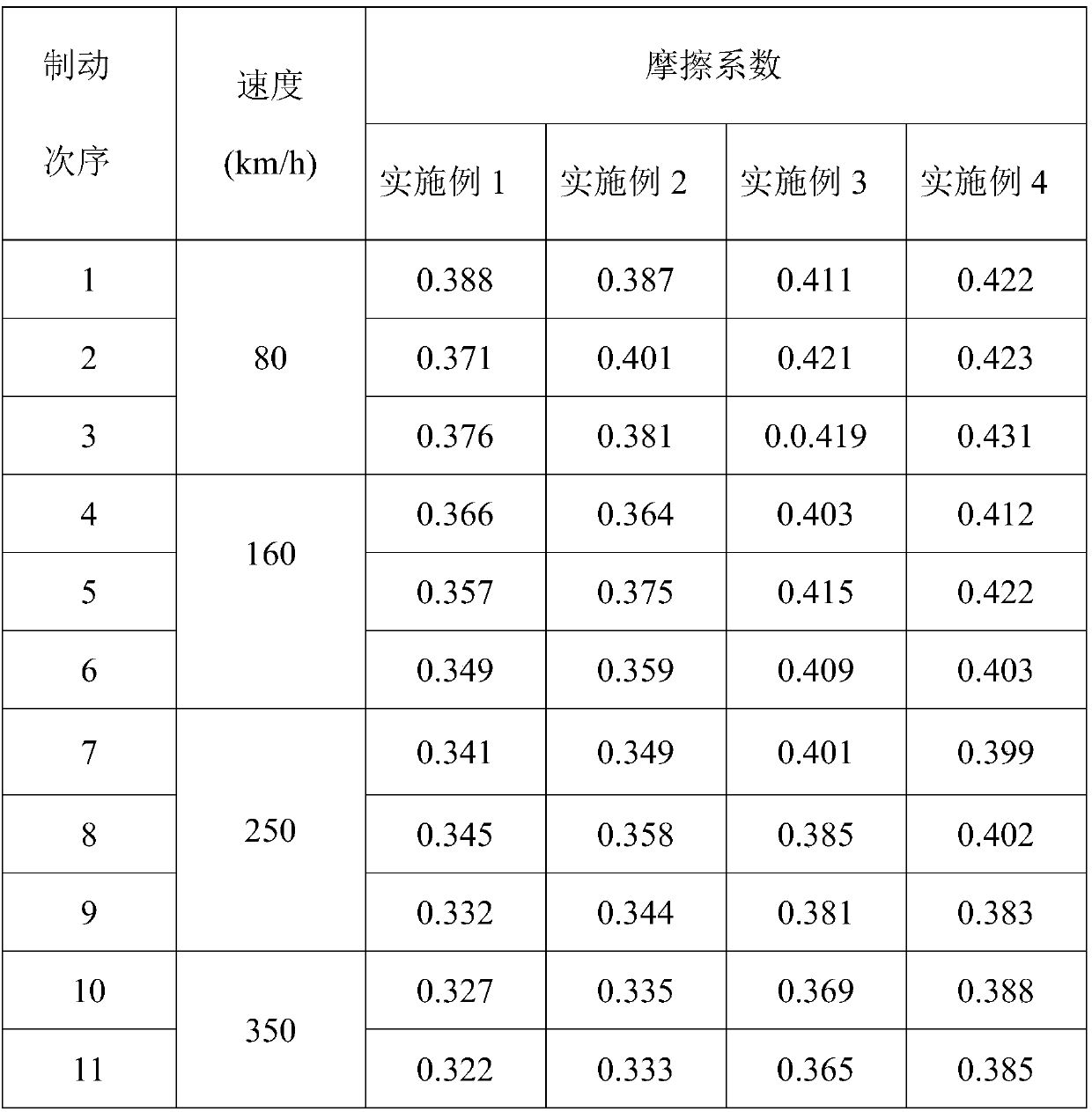

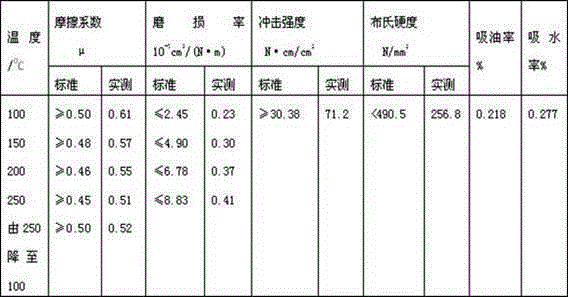

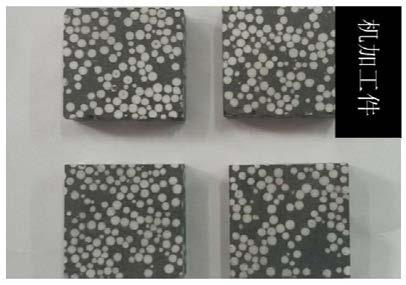

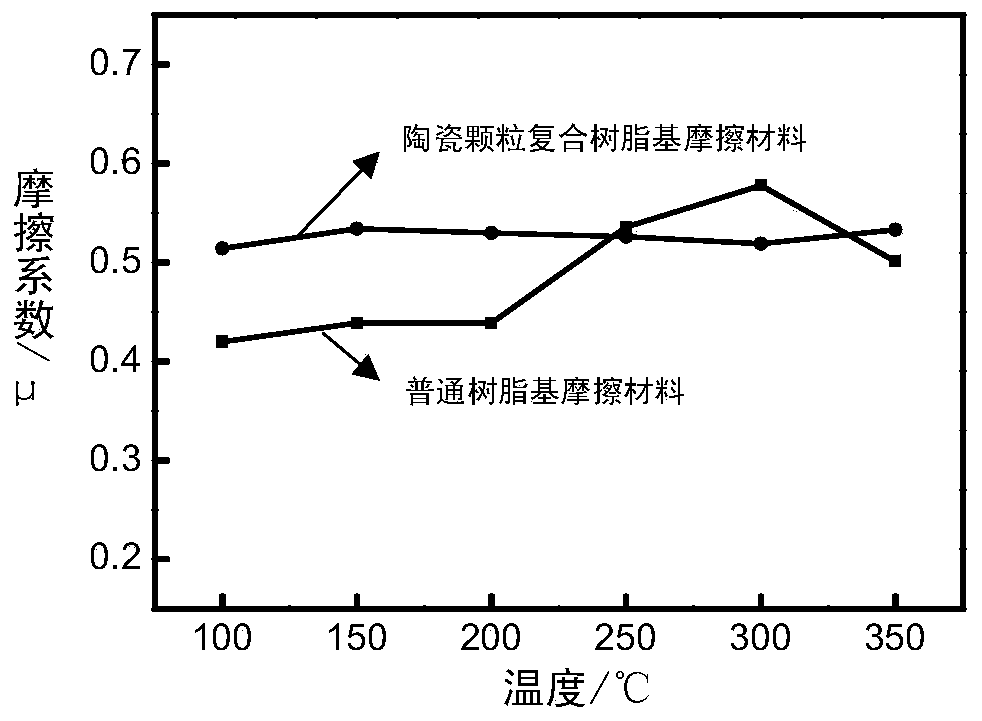

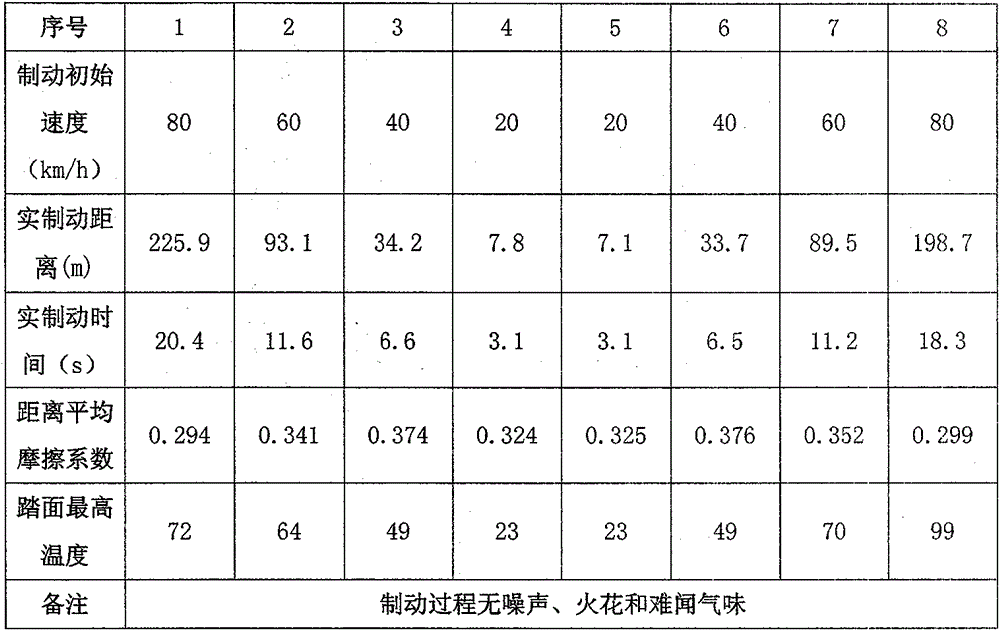

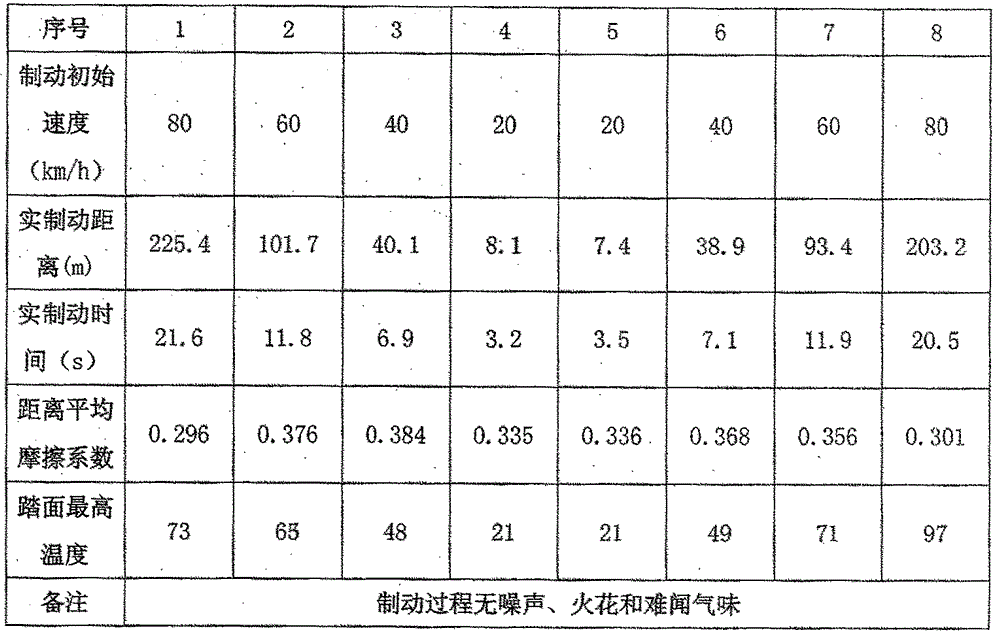

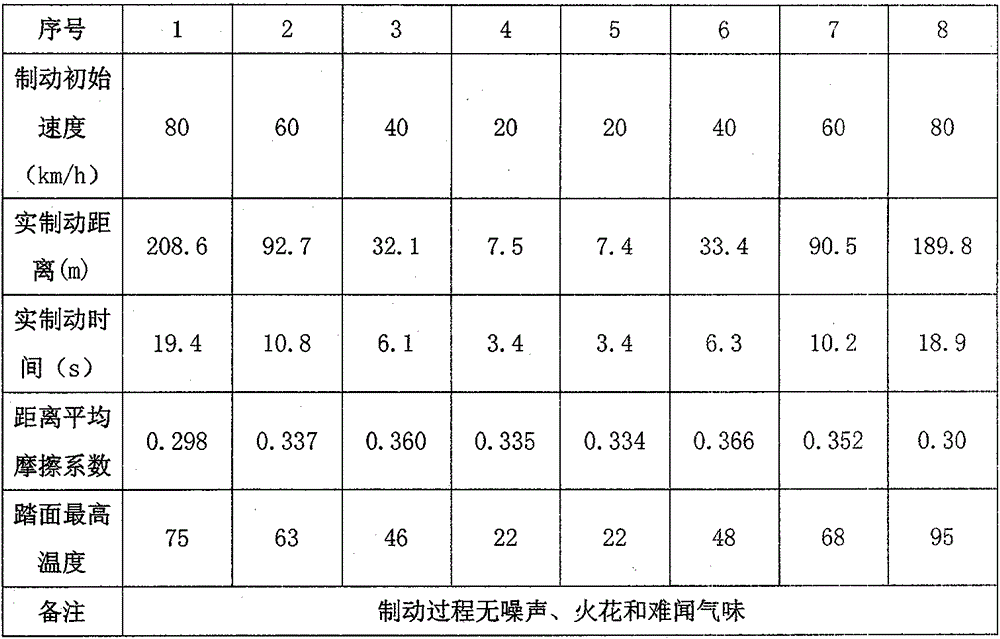

Ceramic Particle Composite Resin-Based Thermal Decay Resistance Friction Material and Preparation Method

ActiveCN106928649BImprove machinabilityImprove bindingOther chemical processesFriction liningHeat resistanceThermal decay

The invention provides a novel ceramic particle composite resin-based heat-resistance recession friction material comprising a resin-based friction material base body and ceramic particles; the resin-based friction material base body comprises the following components: a binder, an enhancing component, a friction modifier and filler; the particle diameters of the ceramic particles are 1.0-5.0mm. The invention also provides a preparation method of the novel ceramic particle composite resin-based heat-resistance recession friction material. The method comprises the following steps: uniformly missing the components of resin-based friction material powder at a ratio, adding the ceramic particles, uniformly mixing, performing hot press molding, and performing thermal treatment to obtain the novel ceramic particle composite resin-based heat-resistance recession friction material. The novel ceramic particle composite resin-based heat-resistance recession friction material prepared by using the method has very good machinability, good heat recession resistance, a stable friction factor, relatively low attrition and dual abrasion, and the like.

Owner:DALIAN UNIV OF TECH

Synthetic brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893BImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

Owner:GUANGXI UNIV FOR NATITIES

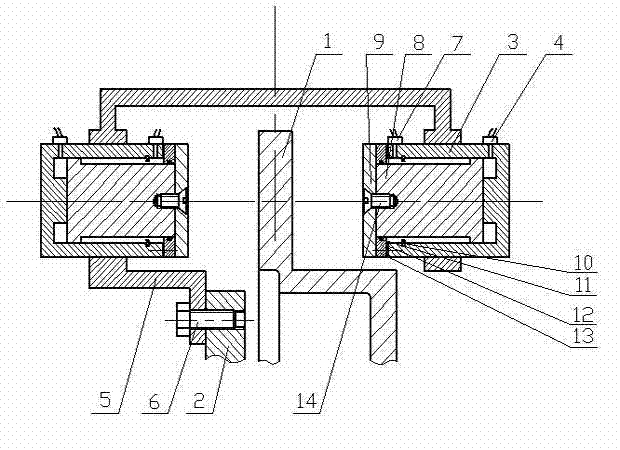

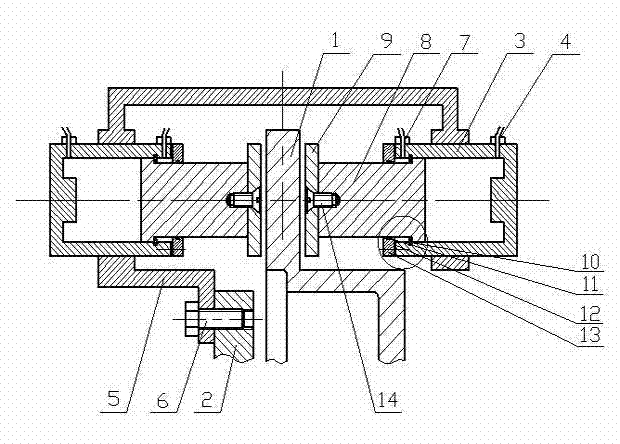

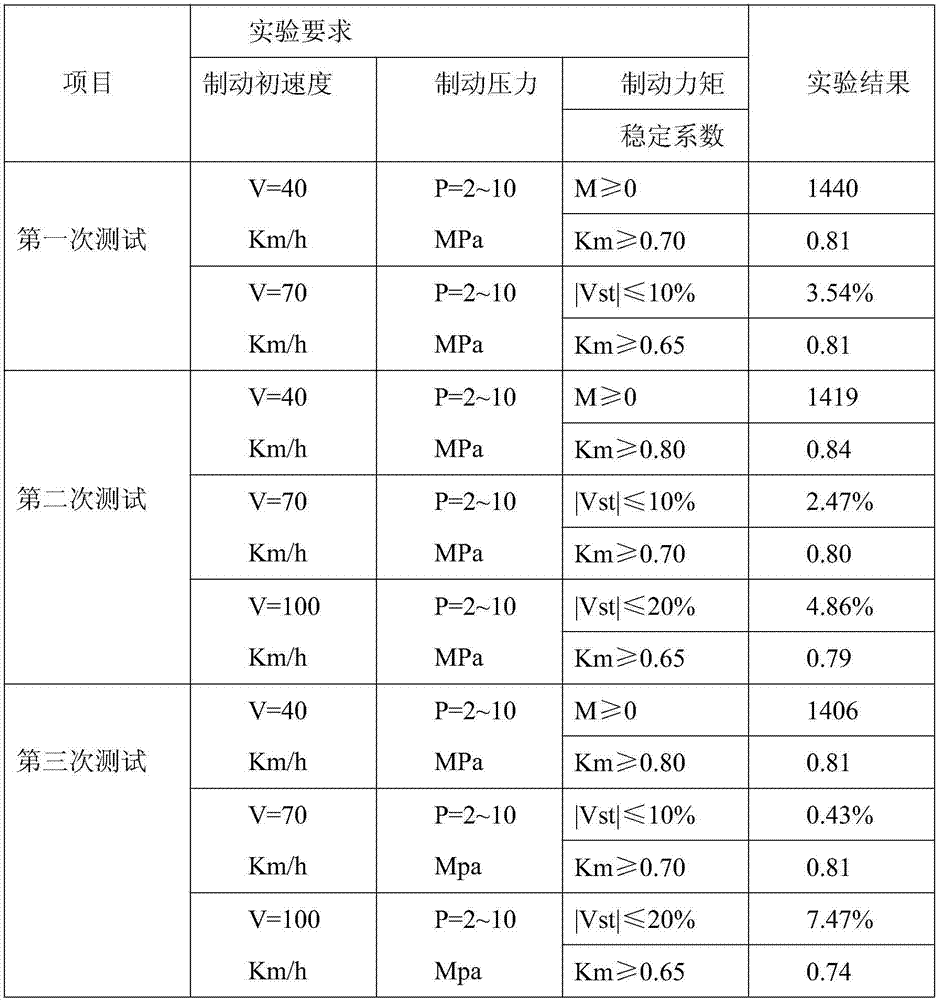

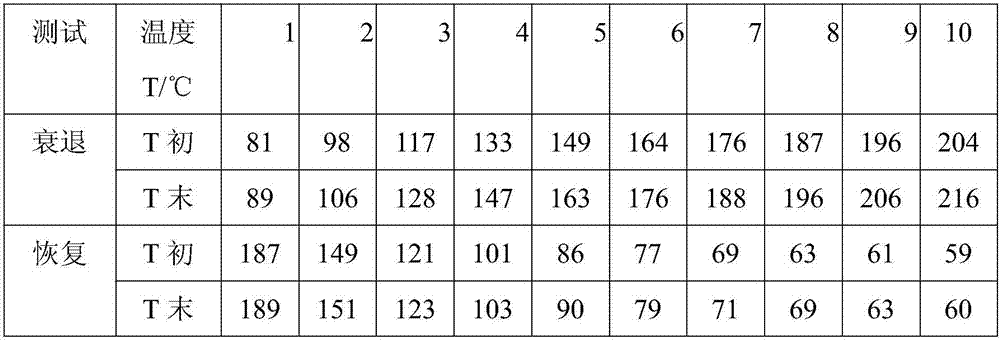

A ceramic/metal composite brake pad for high-speed trains and its preparation method

ActiveCN103075445BReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

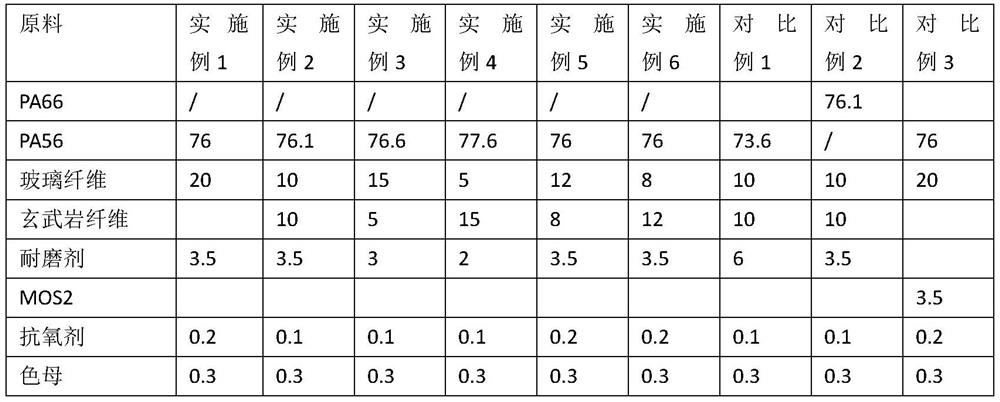

Novel bio-based high-strength wear-resistant nylon composite material and preparation method thereof

PendingCN112724671AReduce coefficient of frictionSolve stickyEconomic benefitsInjection molding machine

The invention discloses a novel bio-based high-strength wear-resistant nylon composite material and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by mass: 70-80% of nylon, 3-5% of a wear-resistant agent, 10-20% of a reinforcing agent, 0.2-0.5% of an antioxidant and 0.2-0.5% of color master batch. The preparation method mainly comprises the following steps: blending and extruding a strip-shaped blend by a double-screw extruder or an injection molding machine, cooling by circulating water, and granulating in a granulator to obtain the composite nylon particles. The wear-resistant material has the characteristics of high temperature resistance, wear resistance and good thermal decay resistance, is simple in preparation process, and effectively solves the problems of high wear rate, unstable friction coefficient, lower impact strength and the like of similar friction materials at high temperature in comparison with the conventional common method for improving the wear resistance of nylon by adding assistants such as PTFE and molybdenum disulfide; and meanwhile, the bio-based composite material has good economic benefits and environmental friendliness.

Owner:ZHEJIANG PRET NEW MATERIALS +3

Multi-dimensional nano-carbon reinforced friction material and preparation method thereof

ActiveCN112096764BReduce porosityReduce sheddingOther chemical processesFriction liningFiberCarbon fibers

The invention relates to a multi-dimensional nano-carbon reinforced friction material and a preparation method thereof, belonging to the technical field of composite friction materials, including a multi-dimensional nano-carbon reinforced friction material core layer using a base material of heat-resistant carbon fiber 65Mn reinforced material; The upper and lower ends of the base material are provided with multi-dimensional nano-carbon lining layers. The first step: weaving fiber cloth. The second step: crimp the fiber cloth, impregnate it with resin, dry it, solidify it and cool it. The third step: take the steel plate for stamping forming, hot leveling, heat treatment, cleaning and drying as the bottom steel core layer. The fourth step: ball milling alloying of nano-carbon and copper powder. Step 5: Use a press to embed the nano-carbon-containing copper powder in the gap of the nano-carbon lining layer on both ends of the formed friction plate. It has the characteristics of light weight, high specific strength, high friction coefficient, low wear rate, low product porosity, uniform and dense friction material and better thermal recession resistance. Extend product life and reduce fiber shedding.

Owner:杭州萧山红旗摩擦材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com