Synthetic brake shoe for urban rail vehicle and manufacturing method thereof

A technology for synthesizing brake shoes and urban rails, applied in the field of transportation, can solve the problems of hot spot friction coefficient, metal inlay, falling too fast, etc., and achieve the effect of reducing friction coefficient, reducing metal inlay, and small thermal recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

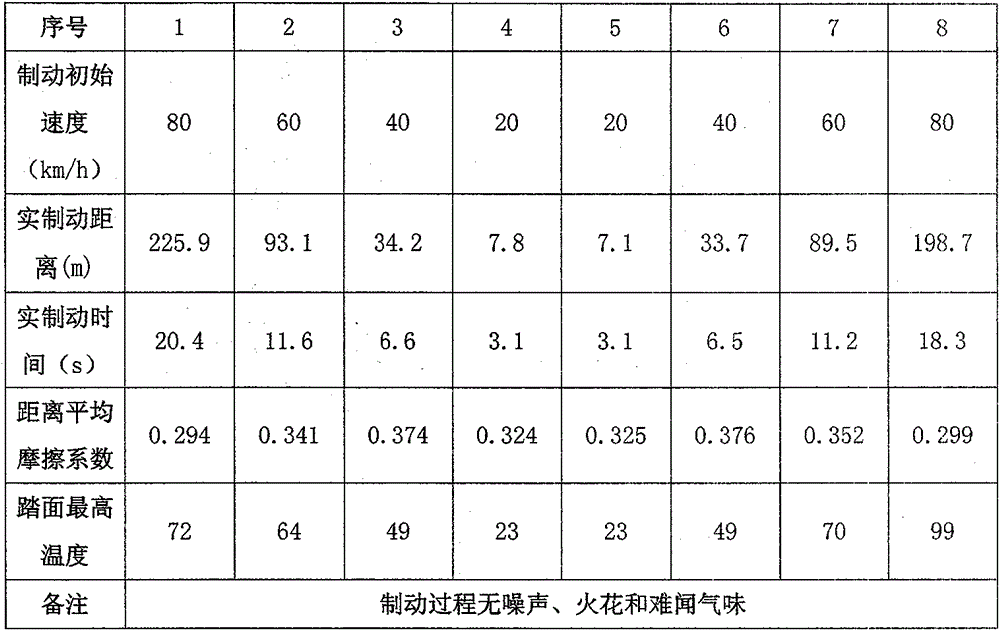

Embodiment 1

[0025] The weight of each component of synthetic brake shoes for urban rail vehicles: 300g of nitrile rubber, 600g of cashew nut shell oil modified phenolic resin, 180g of basalt fiber, 240g of carbon fiber, 450g of steel fiber, 150g of sepiolite fiber, hexamethylene tetra 60g of amine, 240g of iron oxide powder, 150g of flake graphite, 210g of chromite, 180g of barium sulfate, 90g of potassium feldspar, and 150g of friction powder.

[0026] making process:

[0027] (1) Ingredients: weigh various powder materials and fiber materials with an electronic scale in strict accordance with the formula requirements, and put them into the mixing cylinder;

[0028] (2) Stirring and mixing: select a plow-type mixer, put the ingredients into it, and after mixing for a specified time, discharge the material from the discharge hole and store it in the storage tank;

[0029] (3) Hot press forming: Put the processed brake shoe steel back into the mold cavity, preheat the mixture to 80°C, put...

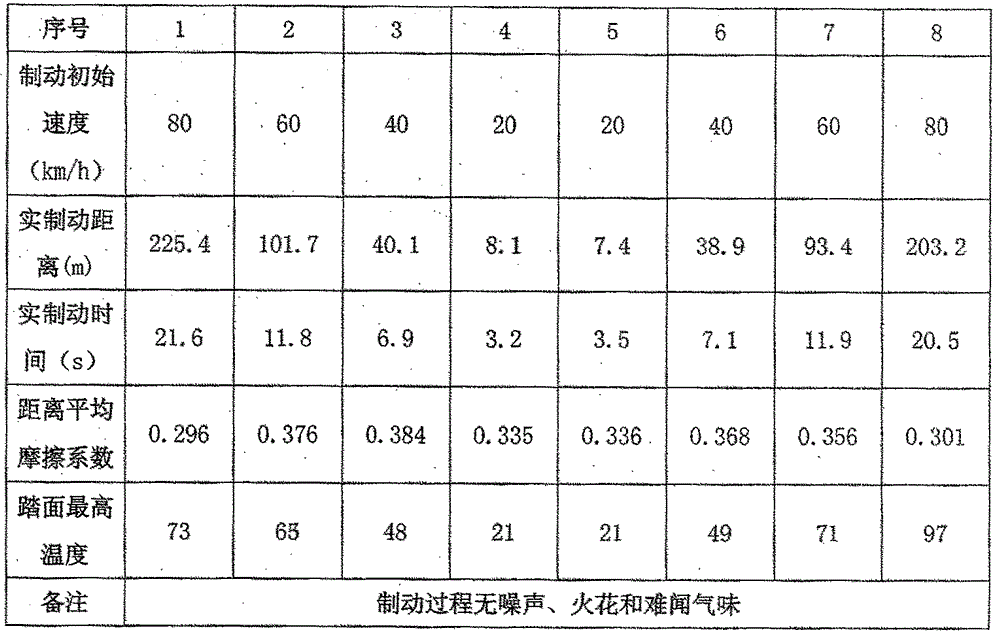

Embodiment 2

[0038] The weight of each component of synthetic brake shoes for urban rail vehicles: 330g of nitrile rubber, 540g of cashew nut shell oil modified phenolic resin, 210g of basalt fiber, 180g of carbon fiber, 390g of steel fiber, 180g of sepiolite fiber, hexamethylene tetra 90g of amine, 210g of iron oxide powder, 180g of flake graphite, 180g of chromite, 210g of barium sulfate, 120g of potassium feldspar, and 180g of friction powder.

[0039] making process:

[0040] (1) Ingredients: weigh various powder materials and fiber materials with an electronic scale in strict accordance with the formula requirements, and put them into the mixing cylinder;

[0041] (2) Stirring and mixing: select a plow-type mixer, put the ingredients into it, and after mixing for a specified time, discharge the material from the discharge hole and store it in the storage tank;

[0042] (3) Hot press forming: Put the processed brake shoe steel back into the mold cavity, preheat the mixture to 80°C, pu...

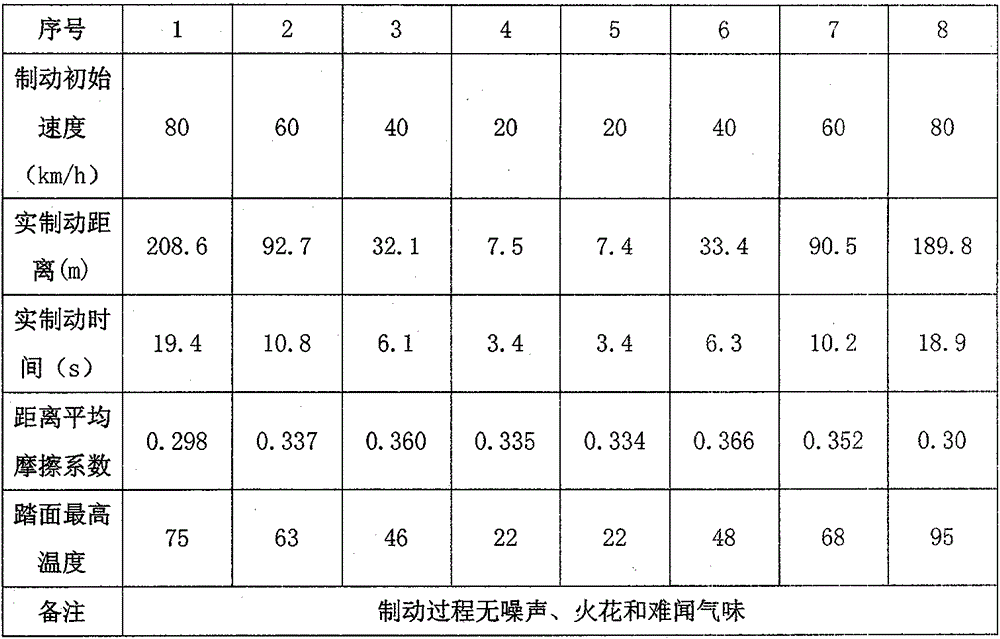

Embodiment 3

[0051] The weight of each component of synthetic brake shoes for urban rail vehicles: 390g of nitrile rubber, 480g of cashew nut shell oil modified phenolic resin, 240g of basalt fiber, 150g of carbon fiber, 270g of steel fiber, 210g of sepiolite fiber, hexamethylene tetra 120g of amine, 180g of iron oxide powder, 180g of flake graphite, 150g of chromite, 240g of barium sulfate, 150g of potassium feldspar, and 180g of friction powder.

[0052] making process:

[0053] (1) Ingredients: weigh various powder materials and fiber materials with an electronic scale in strict accordance with the formula requirements, and put them into the mixing cylinder;

[0054] (2) Stirring and mixing: select a plow-type mixer, put the ingredients into it, and after mixing for a specified time, discharge the material from the discharge hole and store it in the storage tank;

[0055] (3) Hot press forming: Put the processed brake shoe steel back into the mold cavity, preheat the mixture to 80°C, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com