Variable-speed transmission mechanism for relay transmission of variable-diameter gears

A technology of stepless speed change and transmission mechanism, which is applied to multi-ratio transmissions, transmission components, transmissions, etc., can solve problems such as bottlenecks in technological development, and achieve the effects of firm structure, low manufacturing cost, and overcoming thermal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

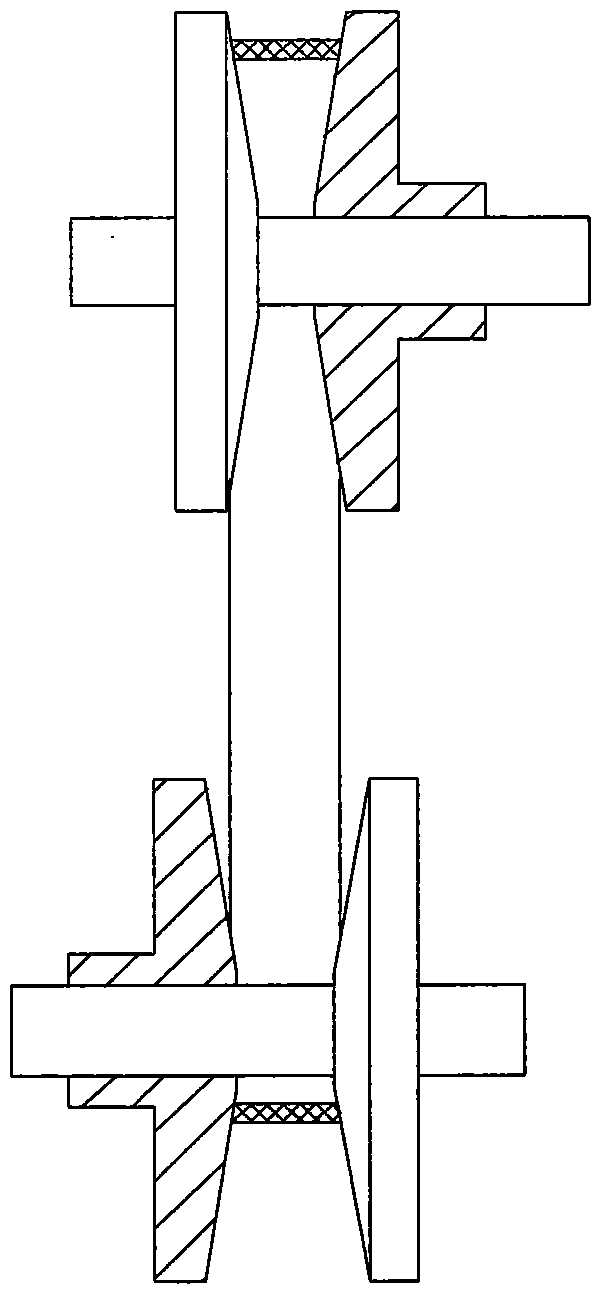

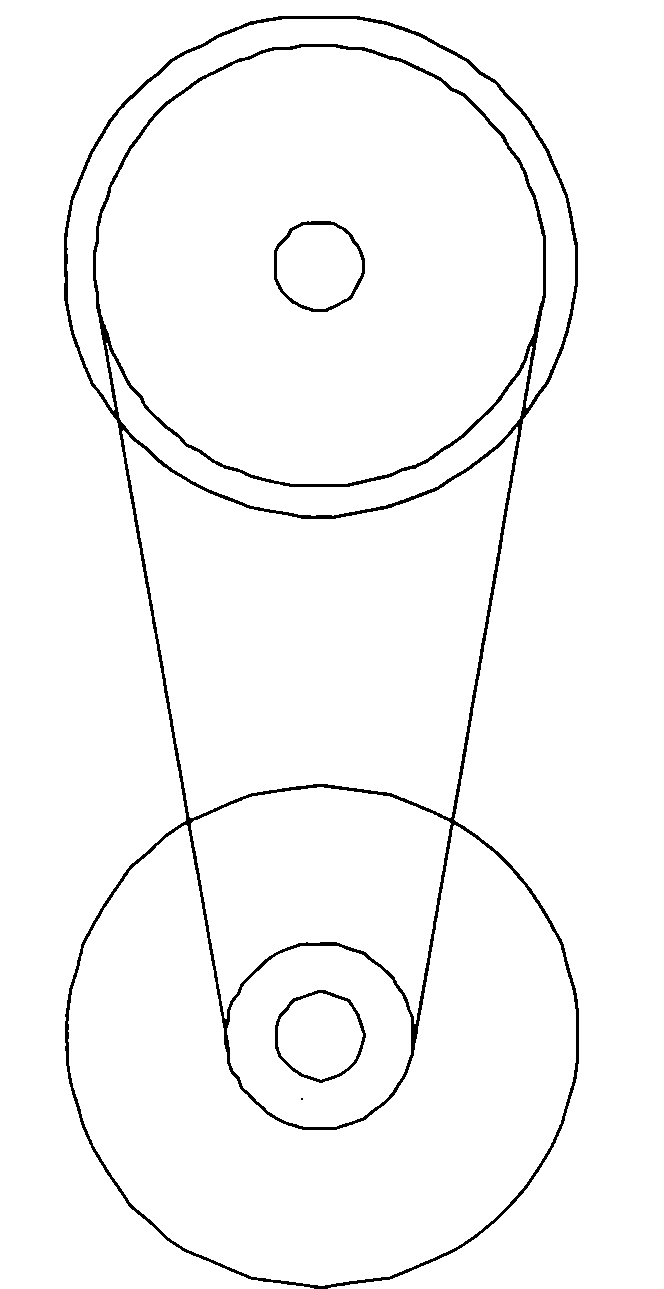

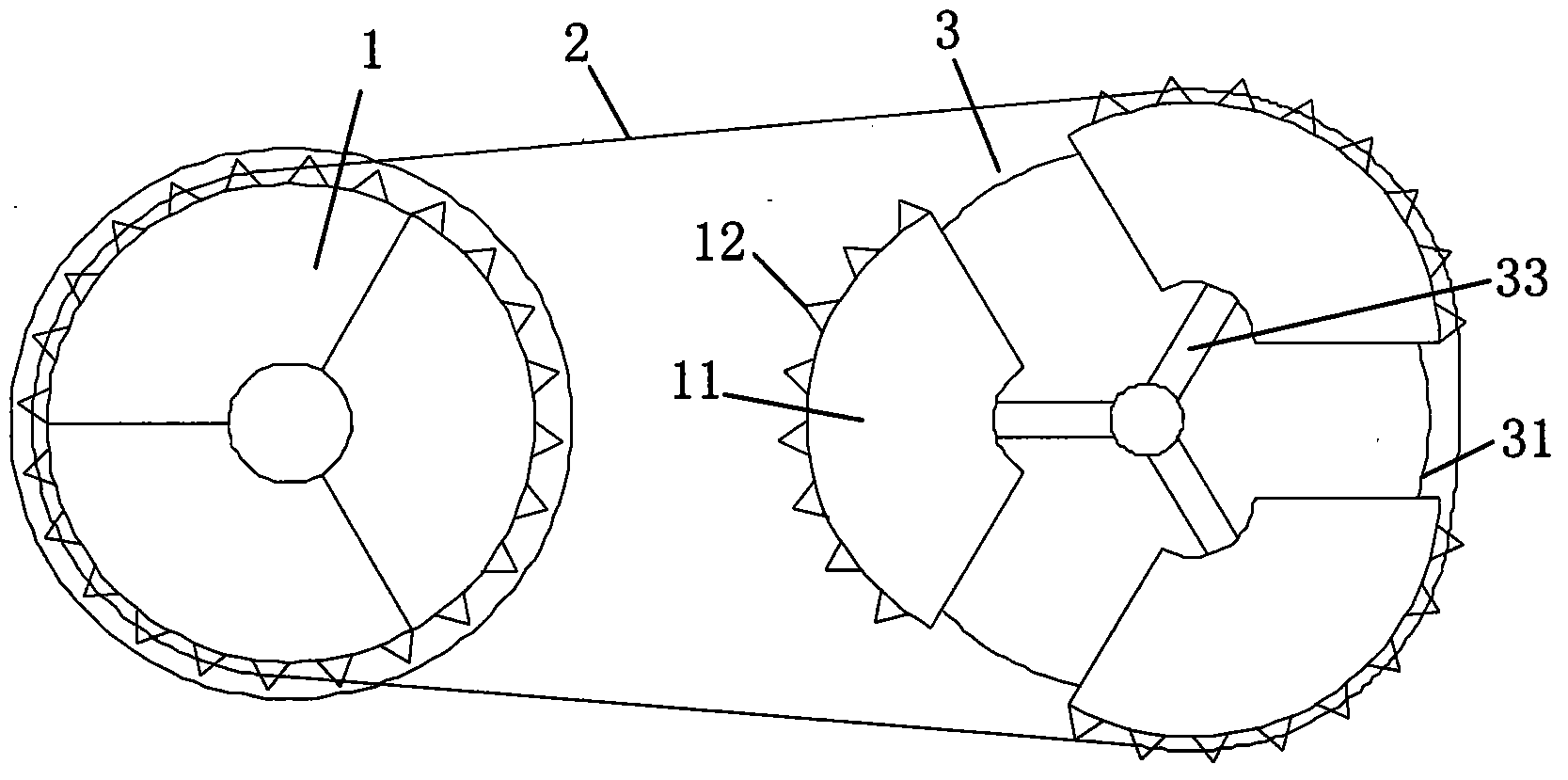

[0036] like Figure 3 to Figure 4 As shown, the continuously variable transmission mechanism of the relay transmission of the variable diameter gear includes three parts: the transmission toothed belt group 2, two relay transmission gears 1 and two variable diameter adjustment mechanisms 3, wherein the power input shaft 4 is connected to a variable diameter adjustment mechanism 3. The diameter adjustment mechanism is connected, and the power output shaft 5 is connected with another diameter reduction adjustment mechanism to realize the transmission of stepless speed change. The specific structure of each part is as follows:

[0037] There are two relay transmission gears in a pair, one is the driving wheel and the other is the driven wheel, which are connected and driven by the transmission toothed belt group. The reduction adjustment of the transmission gear can change the transmission ratio between the driving and driven wheels. Its specific structure includes a variable-d...

Embodiment 2

[0044] like Figure 5 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the relay transmission gear in this embodiment adopts the setting of 5 petals. It is relatively balanced, and the transmission toothed belt group moves more smoothly and stably during transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com