Friction material and production method thereof

A technology of friction materials and abrasives, which is applied in the field of friction materials for medium/heavy-duty automobile drum brakes, can solve problems such as heat decay, wear resistance reduction, and low service life of friction materials, and achieve excellent friction, low product cost, and high manufacturing efficiency. good dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

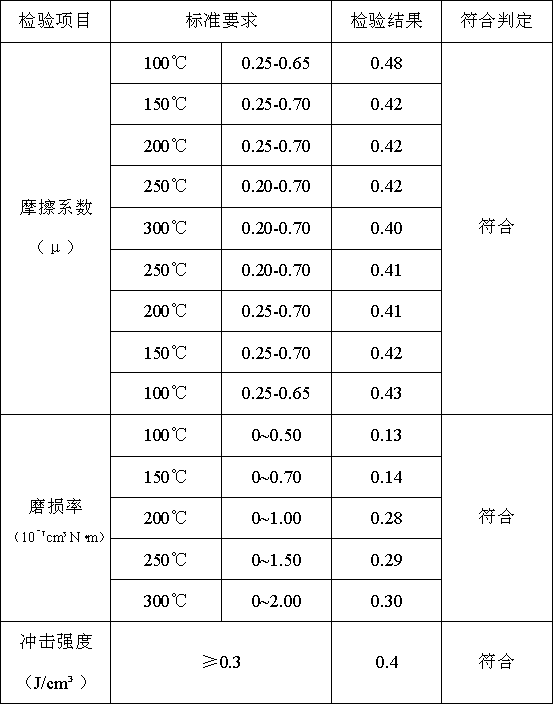

Examples

Embodiment 1

[0016] Embodiment 1, embodiment 2, embodiment 3 and embodiment 4 are the production method of abrasive in the present invention. Embodiment 5, Embodiment 6 and Embodiment 7 are a production method of a friction material of the present invention.

[0017] Embodiment 1: increase the production of abrasive, specifically as follows:

[0018] a. Prepare materials by weight percentage: 5-15% NBR, 0.2-1% Accelerator M, 0.2-1% Sulfur, 2-10% Zinc Oxide, 10-20% Light Calcium Carbonate , 3-15% lead-zinc ore powder, 5-20% calcined petroleum coke, 5-30% barite powder, 5-40% graphite, 3-10% glass fiber;

[0019] b. Refining with a closed rubber mixer: first put in NBR, then put in accelerator M, sulfur, zinc oxide, light calcium carbonate, lead-zinc ore powder, calcined petroleum coke, barite powder, graphite phosphide, Glass fiber mixing and discharging.

Embodiment 2

[0020] Embodiment 2: increase the production of abrasive, specifically as follows:

[0021] a. Prepare materials by weight percentage: 9% nitrile rubber, 0.3% accelerator M, 0.5% sulfur, 2.5% zinc oxide, 13% light calcium carbonate, 8% lead-zinc mineral powder, 13 % calcined petroleum coke, 17% barite powder, 33% graphite, 3.7% glass fiber;

[0022] b. Refining with a closed rubber mixer: first put in NBR, then put in accelerator M, sulfur, zinc oxide, light calcium carbonate, lead-zinc ore powder, calcined petroleum coke, barite powder, graphite phosphide, Glass fiber mixing and discharging.

Embodiment 3

[0023] Embodiment 3: increase the production of abrasive, specifically as follows:

[0024] a. Prepare materials by weight percentage: 10% nitrile rubber, 0.5% accelerator M, 0.6% sulfur, 5% zinc oxide, 15% light calcium carbonate, 6% lead-zinc ore powder, 15% % calcined petroleum coke, 15% barite powder, 30% graphite, 2.9% glass fiber;

[0025] b. Refining with a closed rubber mixer: first put in NBR, then put in accelerator M, sulfur, zinc oxide, light calcium carbonate, lead-zinc ore powder, calcined petroleum coke, barite powder, graphite phosphide, Glass fiber mixing and discharging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com