Polyether-polylactic acid composition and polylactic acid film containing same

A technology of polylactic acid and composition, applied in the field of polyether-polylactic acid composition, to achieve the effects of excellent exudation resistance, excellent melt stability and little odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

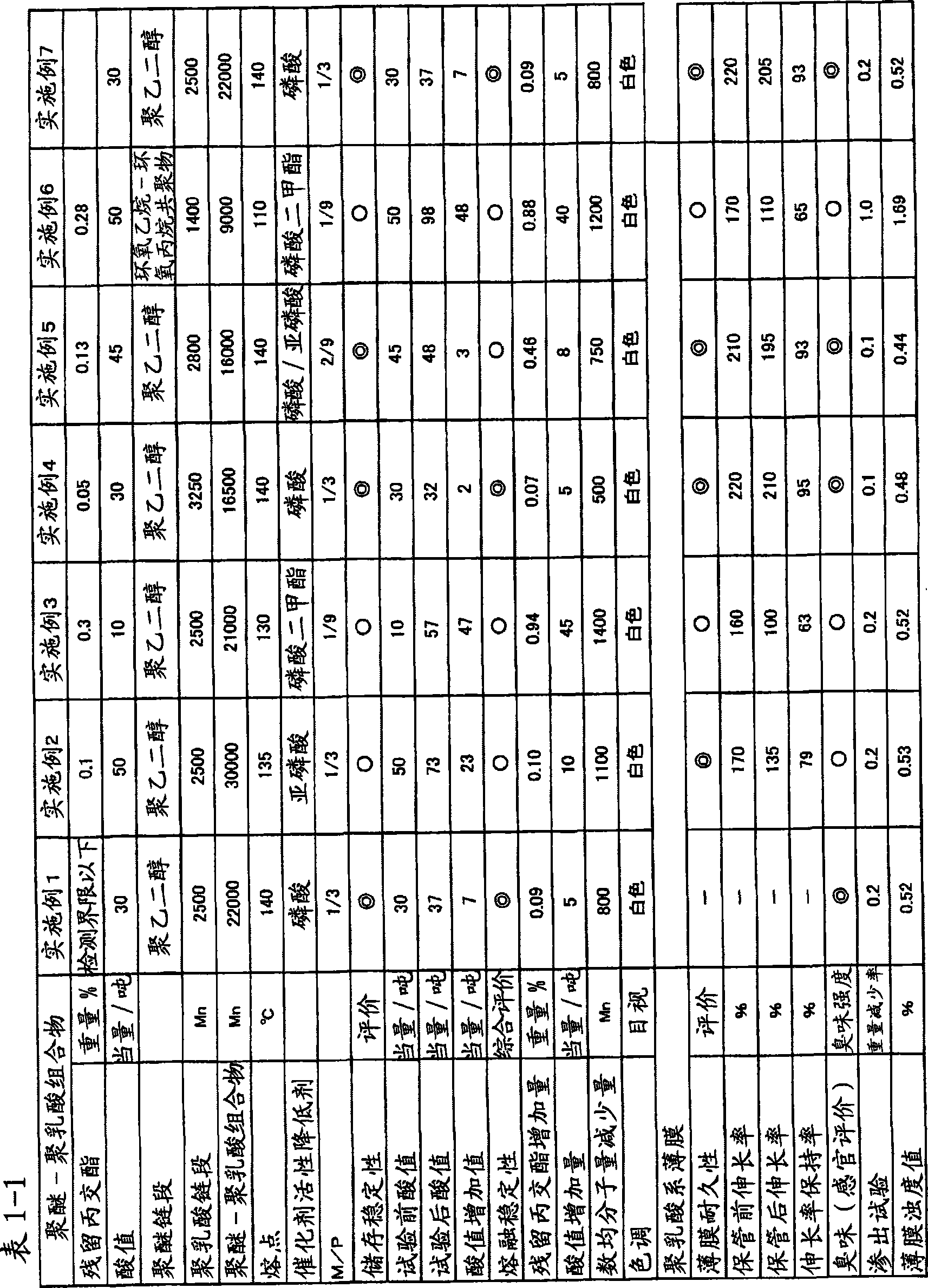

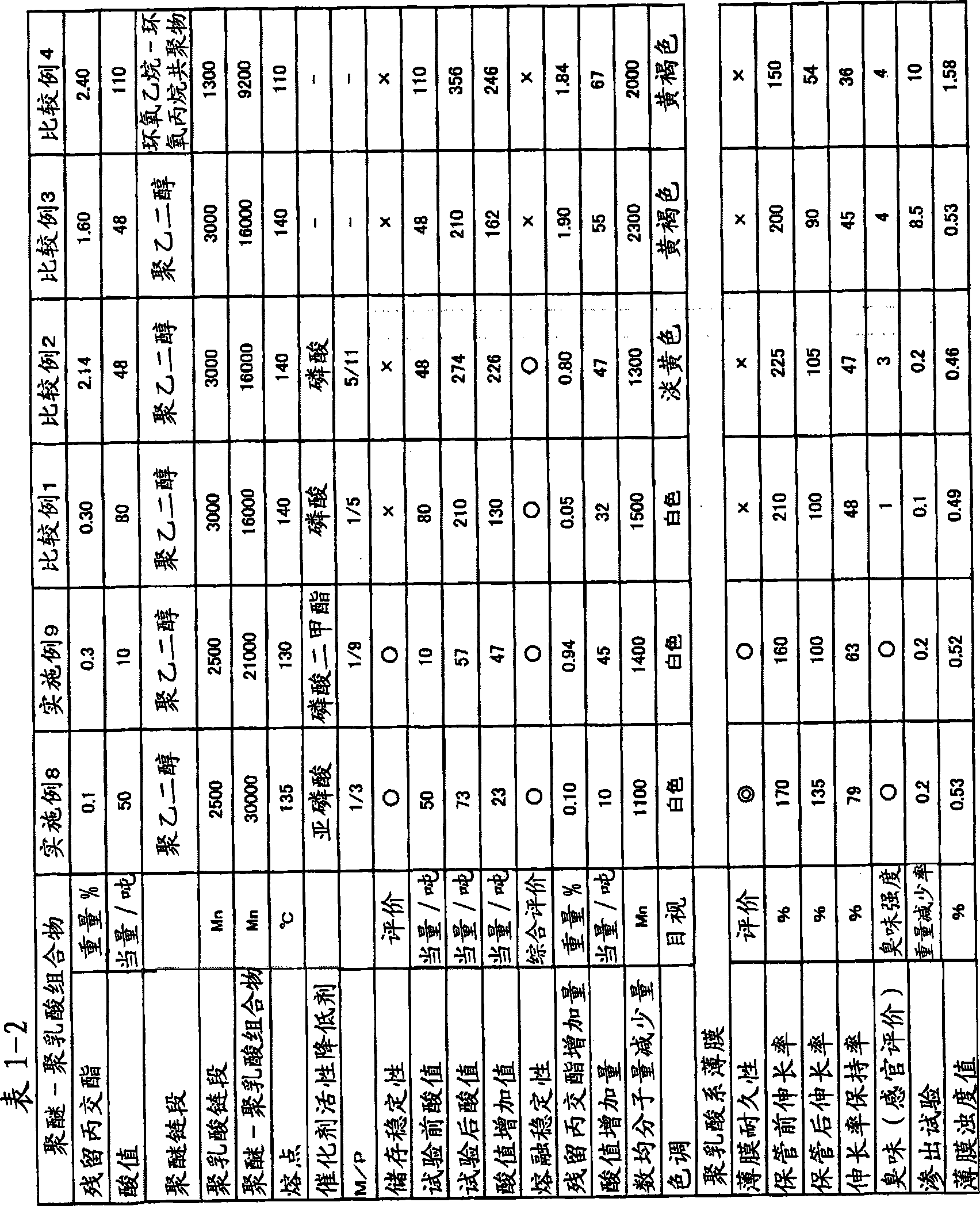

Examples

Embodiment 1

[0224] 63.3% by weight of polyethylene glycol (number-average molecular weight: 10,000) was dehydrated under reduced pressure at 140°C for 30 minutes, then 36.7% by weight of L-lactide was added, and the atmosphere was replaced with an inert gas. or melt mixing for 20 minutes, and 0.1% by weight of tin octoate was added as an esterification catalyst.

[0225] Then, it was stirred at 160° C. for 2 hours in a nitrogen atmosphere, and after the reaction was completed, 0.075% by weight of phosphoric acid crystals were added and stirred for 20 minutes to obtain a composition. From the results of the GPC measurement, it was confirmed that the number average molecular weight was larger than that of the raw material polyethylene glycol, and the number average molecular weight was 22,000 (polystyrene conversion) lactic acid-based polyester.

[0226] The peak of GPC is single, and a single copolymer is produced. Residual lactide was 2.2% by weight. Residual lactide in the lactic acid-...

Embodiment 2

[0228] 77.5% by weight of polyethylene glycol (number-average molecular weight: 20,000) was dehydrated under reduced pressure at 140°C for 30 minutes, then 22.5% by weight of L-lactide was added, and the atmosphere was replaced with an inert gas. or melt mixing for 20 minutes, and 0.15% by weight of tin octoate was added as an esterification catalyst.

[0229] Then, it was reacted at 160 degreeC in nitrogen atmosphere for 2 hours, and after completion|finish of reaction, 0.09 weight% of phosphorous acid was added, and it stirred for 20 minutes, and obtained the composition. From the results of GPC, it was confirmed that the number average molecular weight was larger than that of the raw material polyethylene glycol, and the number average molecular weight was 30,000 (polystyrene conversion) lactic acid-based polyester.

[0230] The peak of GPC is single, and a single copolymer is produced. Residual lactide was 2.2% by weight. Residual lactide in the lactic acid-based polyest...

Embodiment 3

[0232] 63.3% by weight of polyethylene glycol (number-average molecular weight: 10,000) was dehydrated under reduced pressure at 140°C for 30 minutes, then 41.1% by weight of L-lactide was added, and the atmosphere was replaced with an inert gas. or melt mixing for 20 minutes, and 0.1% by weight of tin octoate was added as an esterification catalyst.

[0233] Then react at 160° C. for 2 hours, add 0.28% by weight of dimethyl phosphate after the reaction, and stir for 20 minutes to synthesize a polyether-polylactic acid composition. It was confirmed that it was a composition with a number average molecular weight of 21,000 (in terms of polystyrene). Residual lactide was 2.8%. Residual lactide in the lactic acid-based polyester composition (polyether-polylactic acid composition) was removed at a vacuum degree of 4 torr at 160°C. After 40 minutes, lactide became 0.3% by weight. The acid value was 10 equivalent / ton, and no decrease in the number average molecular weight was obs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com