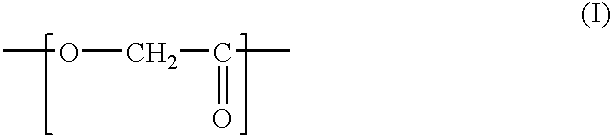

Crystalline polyglycolic acid, polyglycolic acid composition and production process thereof

a technology of polyglycolic acid and polyglycolic acid, which is applied in the field of crystalline polyglycolic acid, polyglycolic acid composition and production process thereof, can solve the problems of plastic waste disposal becoming a great problem, thermal properties not always suitable for melt processing, stretch processing, etc., and achieve excellent melt stability, excellent melt processability, and the effect of preventing the generation of gasses upon their melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

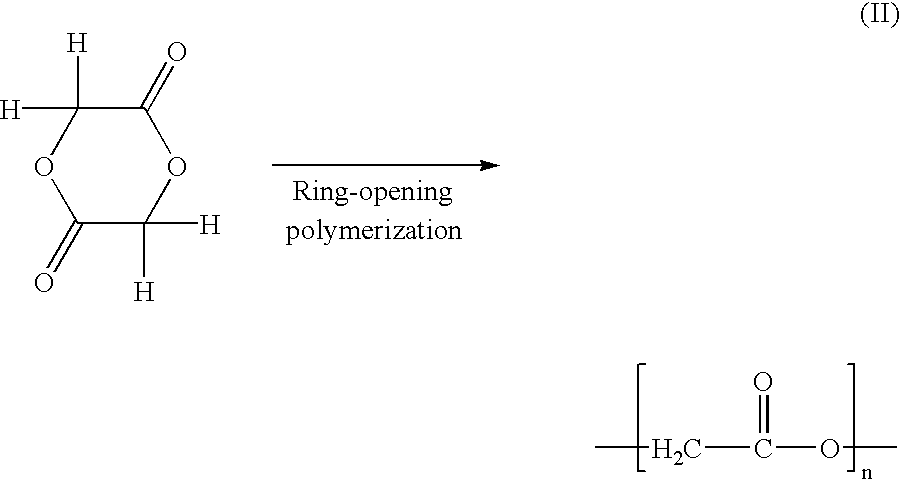

[0123] An aluminum pan was charged with 10 mg of polyglycolic acid (melting point Tm=222.degree. C., melt enthalpy of crystal=71 J / G) synthesized by ring-opening polymerization of glycolide, and the polyglycolic acid was heated from 50.degree. C. to a predetermined temperature at a heating rate of 10.degree. C. / min under a nitrogen atmosphere at 10 ml / min (first heating). After the polyglycolic acid was held for 2 minutes at the predetermined temperature, it was cooled to 50.degree. C. at a cooling rate of 10.degree. C. / min (first cooling). The melting point Tm was found from an endothermic peak attributable to the melting of the crystal upon the first heating, and the crystallization temperature Tc.sub.2 was found from an exothermic peak attributable to crystallization upon the first cooling. The measuring results including the crystallization temperatures Tc.sub.2 and the crystallization enthalpies (J / g) found from the area of the crystallization peak when the predetermined temper...

example 2

[0125] The same polyglycolic acid as that used in Example 1 was melted at 270.degree. C., formed into a sheet by a water-cooled press and cooled. As a result, a transparent sheet was obtained. This sheet was able to be stretched.

example 3

[0127] An aluminum pan was charged with 10 mg of polyglycolic acid (melting point Tm=222.degree. C., melt enthalpy of crystal=71 J / g) synthesized by ring-opening polymerization of glicolide, and the polyglycolic acid was heated from -50.degree. C. to a predetermined temperature A at a heating rate of 10.degree. C. / min under a nitrogen atmosphere at 10 ml / min (first heating). After the polyglycolic acid was held for 2 minutes at the predetermined temperature, it was cooled to -50.degree. C. at a cooling rate of 10.degree. C. / min (first cooling). The polyglycolic acid was heated again from -50.degree. C. to a predetermined temperature at a heating rate of 10.degree. C. / min (second heating). After the polyglycolic acid was held for 2 minutes at the predetermined temperature B, it was cooled to -50.degree. C. at a cooling rate of 10.degree. C. / min (second cooling). The predetermined temperatures A and B in the first heating and second heating were changed to 250.degree. C. and 250.degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature Tg | aaaaa | aaaaa |

| glass transition temperature Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com