Thin-belt continuous casting method and apparatus

A continuous casting and thin strip technology, applied in the direction of metal rolling, etc., can solve the problems of thin strip continuous casting industrialization difficulties, difficult operation and sealing, complex equipment, etc., to reduce investment costs and maintenance costs, and improve surface cracks , The effect of flexible process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

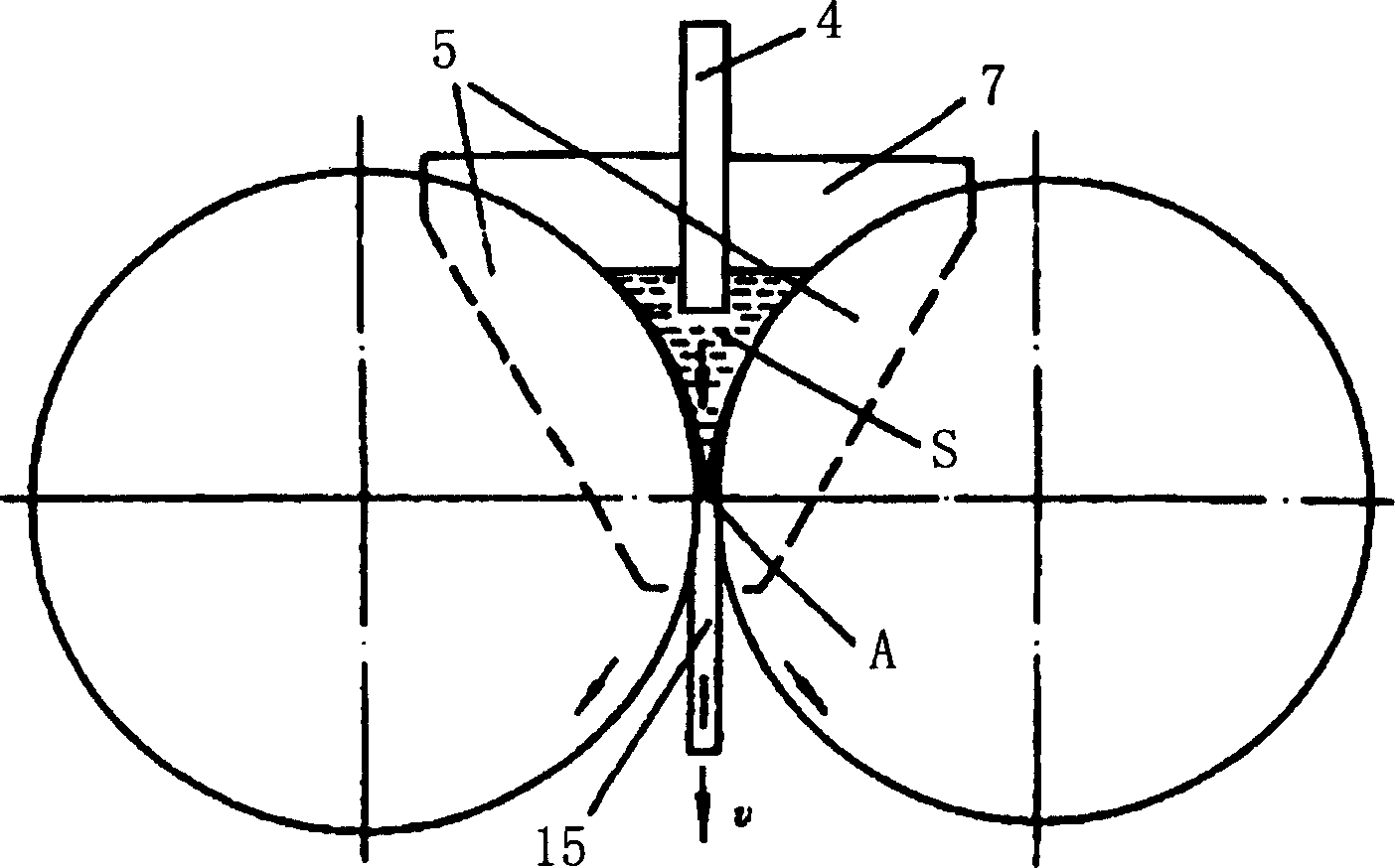

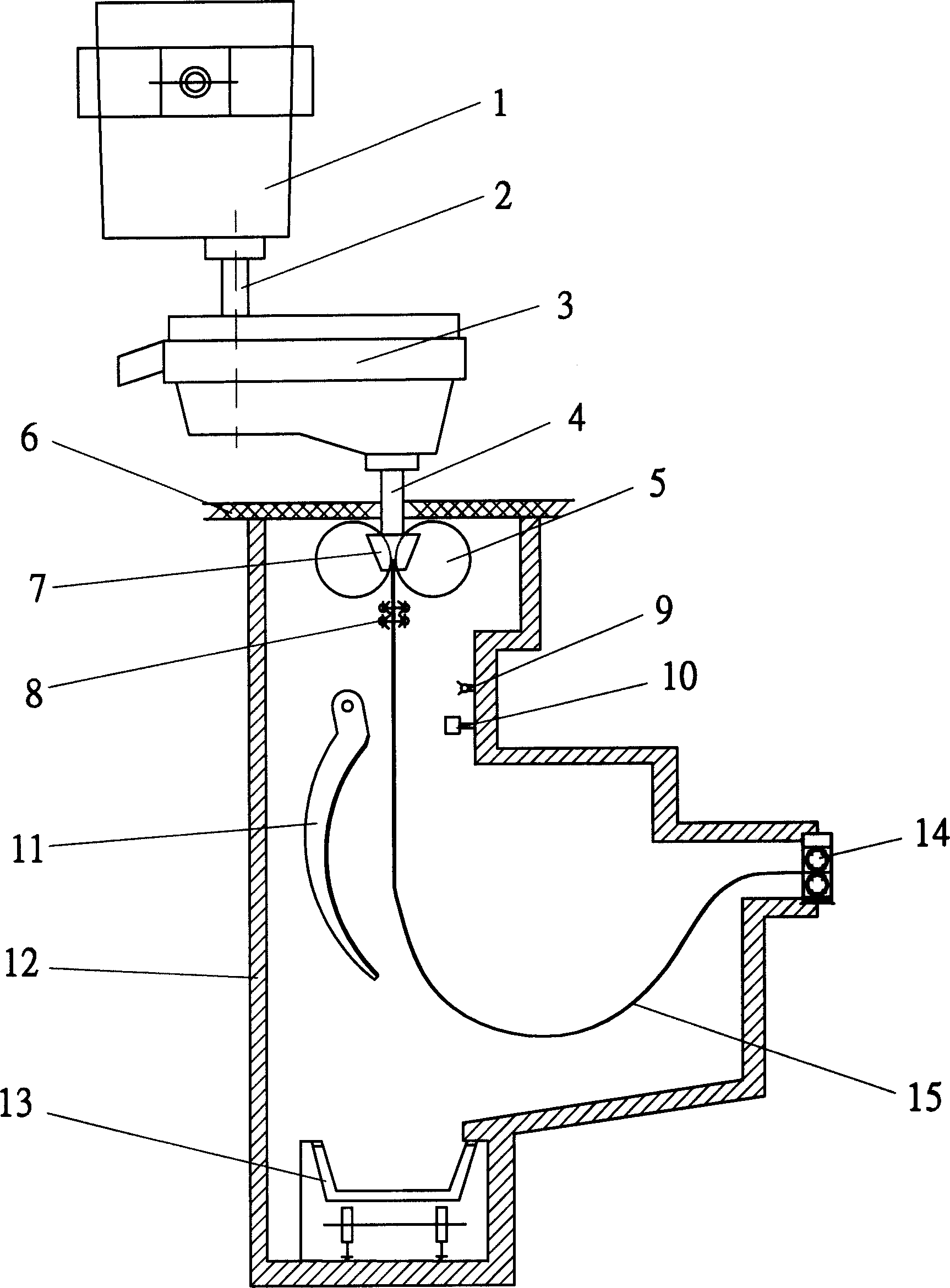

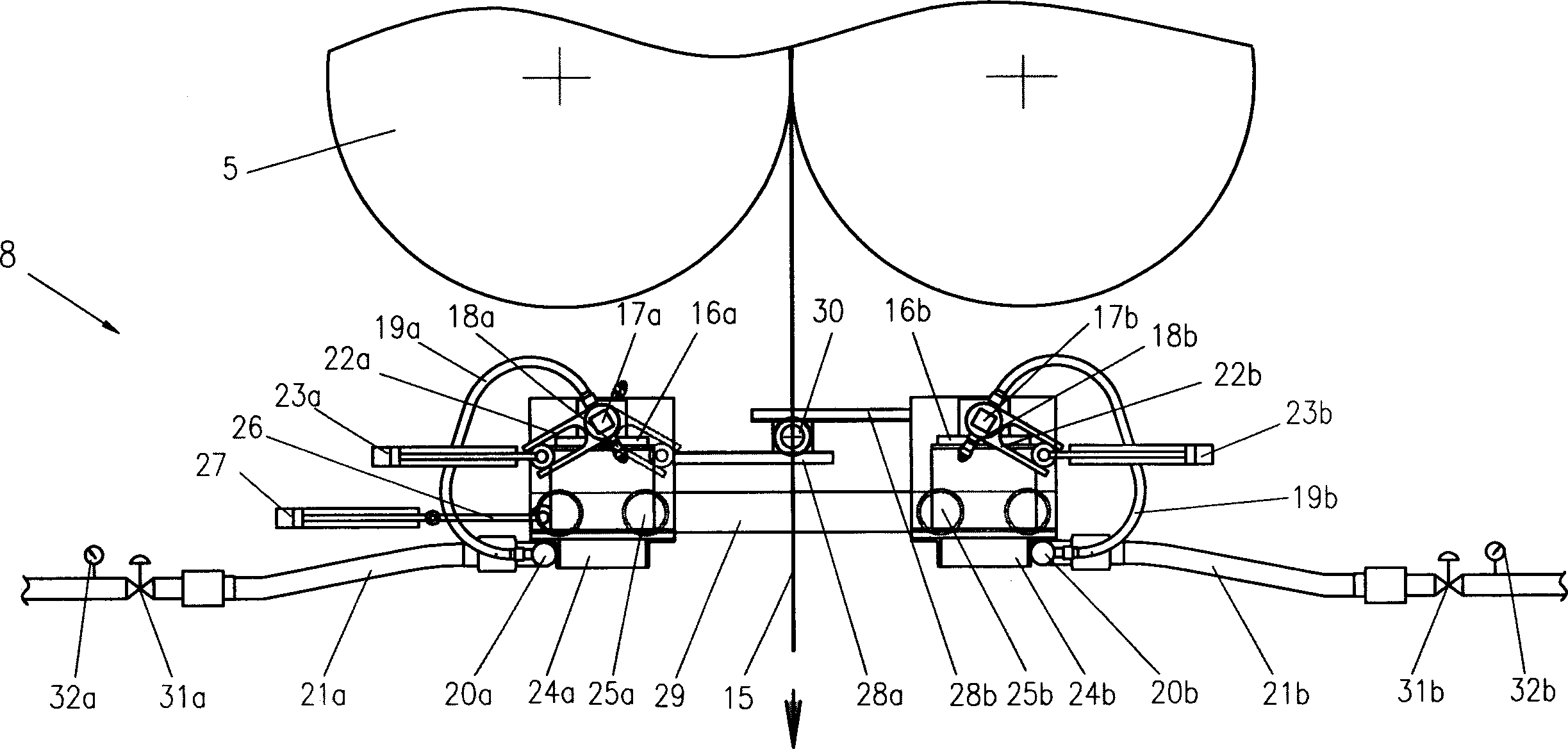

[0045] like figure 2 As shown, the molten steel S enters the molten pool formed by the rotating water-cooled crystallization roller 5 from the ladle 1 through the long nozzle 2, the tundish 3 and the submerged nozzle 4, and forms a casting belt 15 after being cooled by the water-cooled crystallization roller 5, and passes through the swing guide plate 11, The pinch roller 14 sends the cast strip 15 to hot rolling, and then through hot rolling, controlled cooling until coiling.

[0046] Since the temperature of the casting belt 15 reaches above 1300° C. at the place where the crystallization roller 5 exits, the high temperature strength of the casting belt 15 is very low. Cast belt 15 is prone to cracks or even breakouts at the exit under the effects of gravity, pinch roller 14 tension, etc. Therefore, in the present invention, by setting a control cooling device 8 at the outlet of the crystallization roller 5, different cooling processes are performed according to the high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com