Method for realizing flexible process control of atomic layer deposition coating equipment

A technology of atomic layer deposition and coating equipment, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of many times of control program modification, many times of design and testing, and long process development cycle, etc. Achieve the effect of large degree of freedom in process debugging, save design and test time, and improve process development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

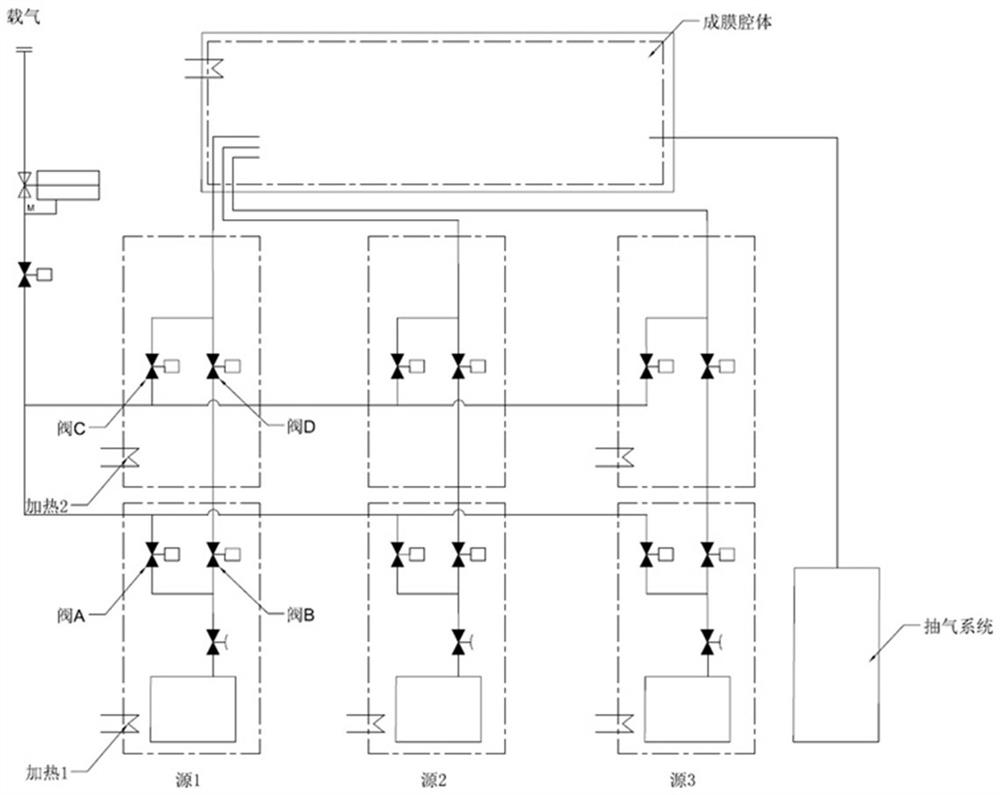

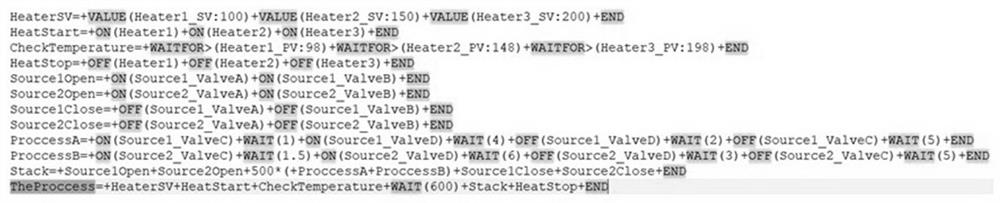

[0031] Embodiment: In this embodiment, the implementation method for flexible process control of atomic layer deposition coating equipment is to realize flexible process control by making process files of atomic layer deposition coating equipment. The process file refers to the file that essentially controls the working status of the atomic layer deposition coating equipment, that is, the process file can be read by the controller, and the controller uses the process information compiled in the process file as a reference to actually perform the atomic layer deposition coating The equipment is controlled to adjust its working parameters to meet the needs of different film-forming processes and facilitate the switching between different film-forming processes or the adjustment of film-forming processes.

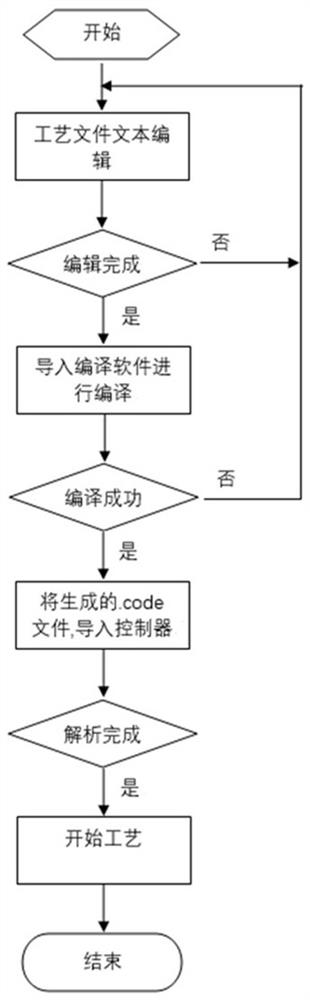

[0032] Such as image 3 As shown, start making craft text files from craft text editing. The editing rules of the process text file are determined according to the rules decl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com