Method for preventing crystallizer of continuous casting machine from sticking breakout

A cohesive and crystallizer technology, which is applied in the continuous casting process to prevent breakouts and the field of continuous casting machine crystallizer cohesive breakouts. It can solve the problems of shortening mold life, complicated installation, and false alarm rate and false alarm of breakouts. High efficiency and other problems, to achieve the effect of low purchase and maintenance costs, convenient installation, use and maintenance, and avoid steel leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

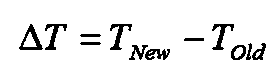

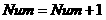

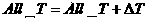

Method used

Image

Examples

specific Embodiment

[0044] First cast example:

[0045] The continuous casting machine starts to cast the third batch of molten steel. The casting speed of the continuous casting machine is 0.9m / min. The water temperature difference is 7.2°C, the water temperature difference on the left side of the narrow face is 8.1°C, and the water temperature difference on the right side of the narrow face is 7.3°C; the number of water temperature changes in the inner arc of the wide face is 6, and the number of water temperature changes in the outer arc of the wide face is 7 times, the number of water temperature changes on the left side of the narrow surface is 5 times, and the number of changes on the right side of the narrow surface is 3 times; the water temperature change range of the inner arc of the wide surface is -0.6°C, and the water temperature change range of the outer arc of the wide surface is -0.7°C , the change range of water temperature on the left side of the narrow surface is -0.5°C, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com