A method for thermally adjusting width of continuous casting crystallizer

A continuous casting mold and thermal width adjustment technology, applied in the field of metallurgical continuous casting, can solve problems such as improper control of key parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

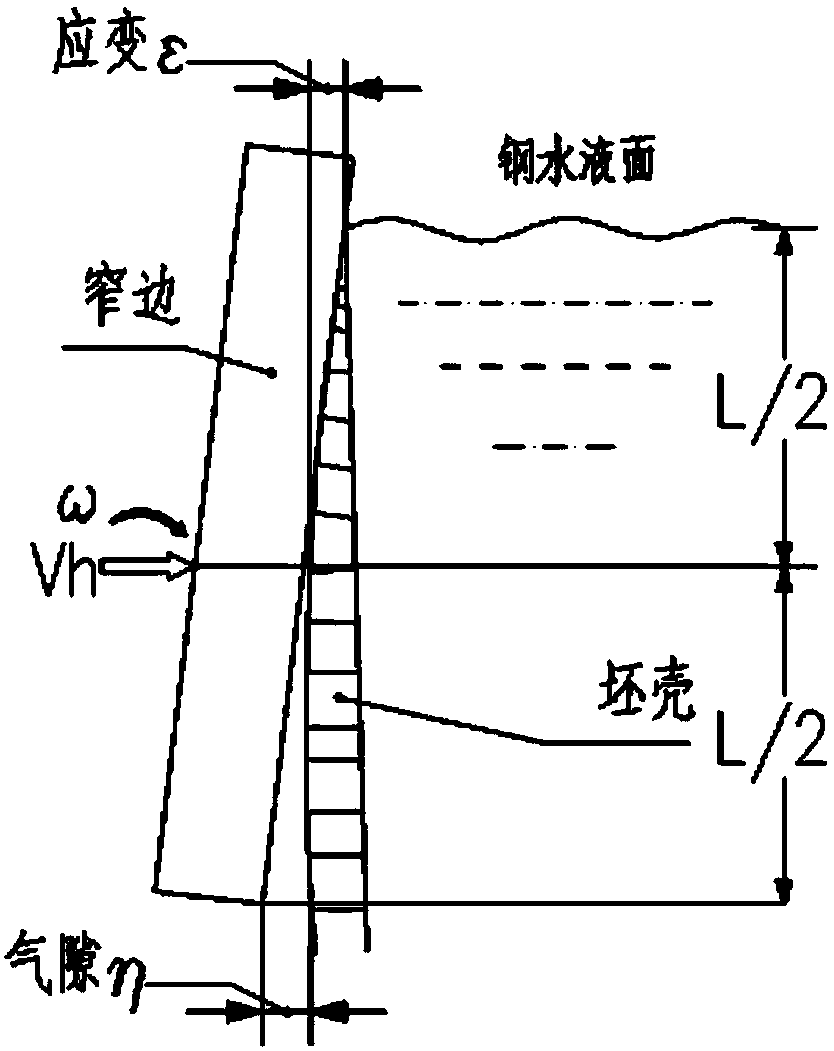

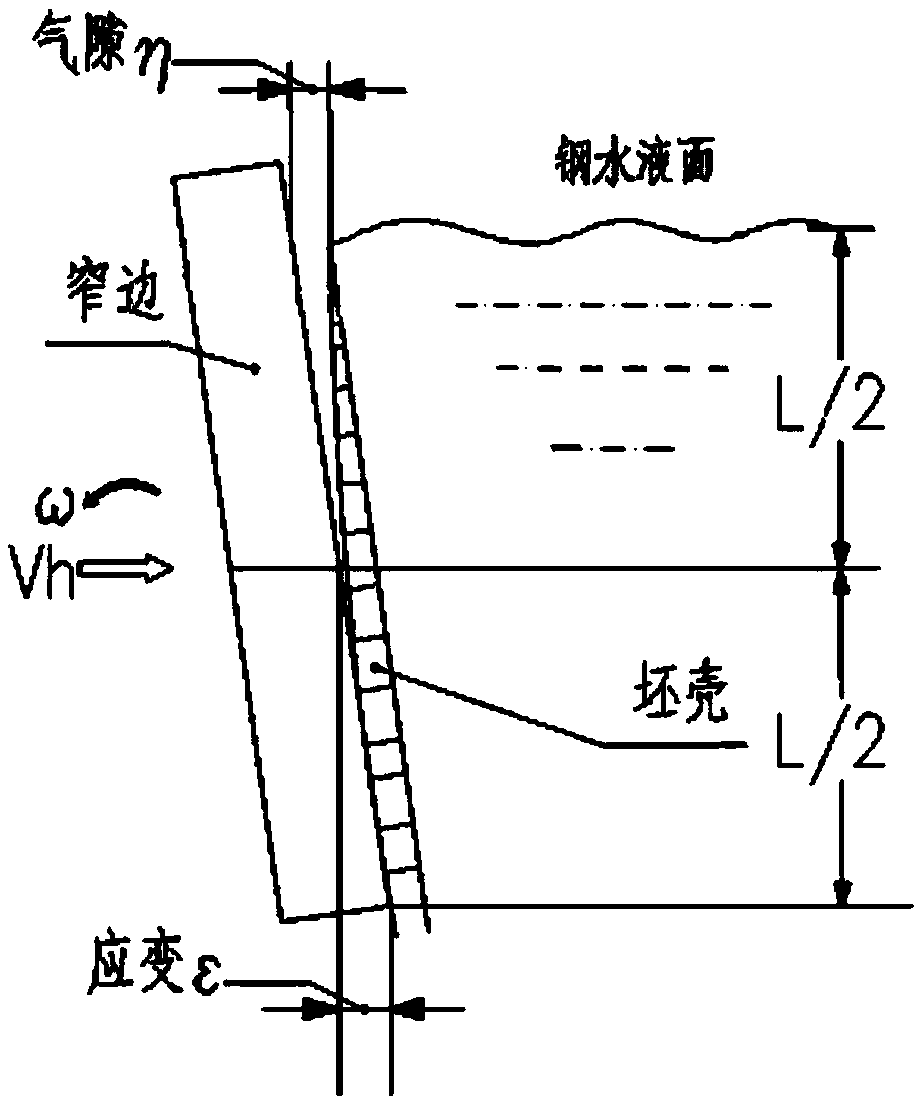

Method used

Image

Examples

Embodiment 1

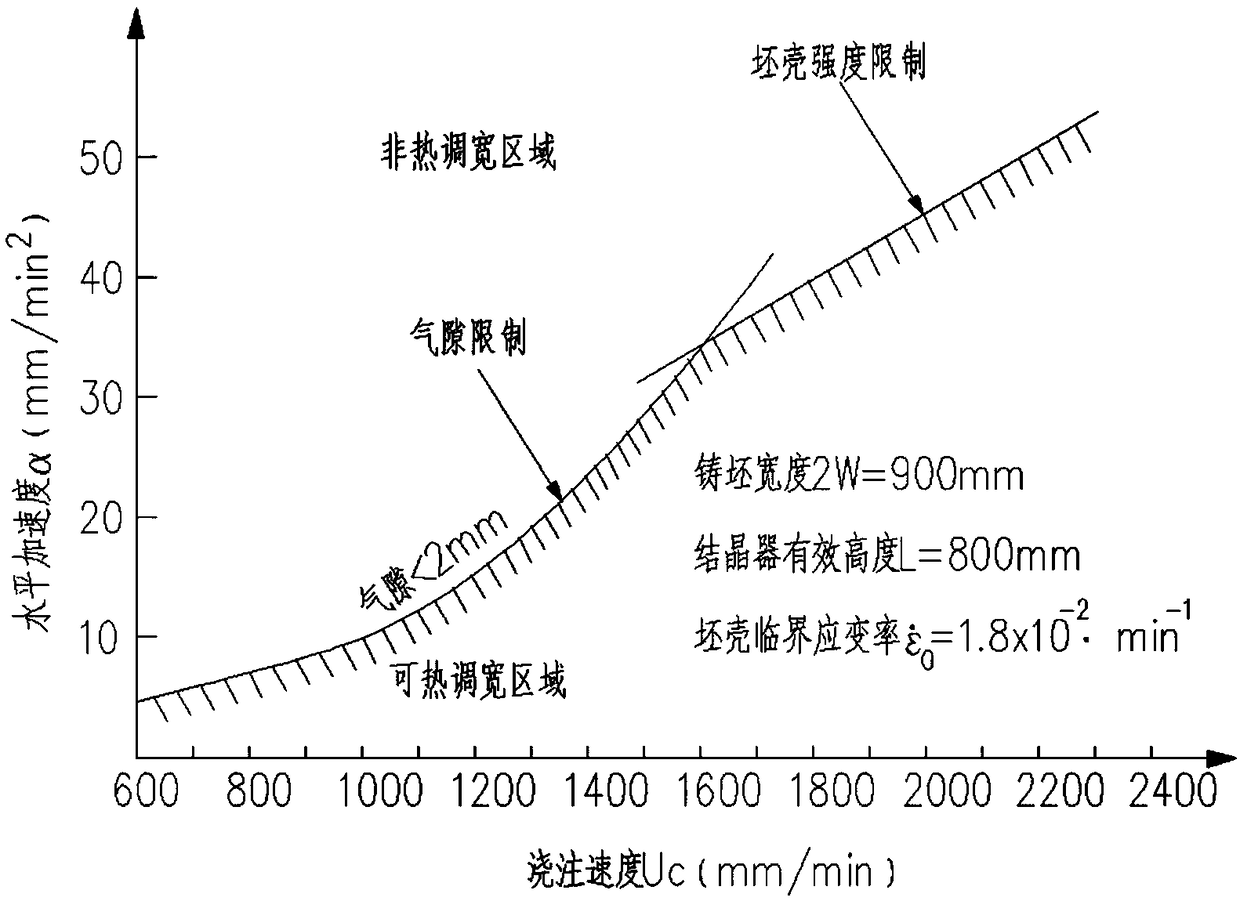

[0078] According to the production process experience, the critical strain rate (When the temperature of medium carbon steel billet is 1350℃), the maximum air gap η max = 2mm, the minimum width of the slab 2W = 900mm, the effective height of the continuous casting mold L = 800mm. According to the previous formula, the setting values of the model parameters can be obtained as shown in Table 1.

[0079] Table 1 Model parameter setting table

[0080]

Embodiment 2

[0082] Set the casting speed Uc=1200mm / min when adjusting the width, the effective height of the continuous casting mold L=800mm, and the process requirements: critical strain rate Maximum air gap η max = 2mm, the minimum width of the slab 2W = 900mm.

[0083] 1) Safe width adjustment area: the actual width adjustment horizontal acceleration is α=15mm / min 2 (less than the boundary condition α s =18mm / min 2 ), the angular velocity ω=0.0125rad / min, the air gap during the width adjustment process is η=1.67mm, the strain rate of the slab shell Then meet the maximum air gap limit condition (η≤η max ) and slab shell strength limit It can ensure that the narrow side of the continuous casting crystallizer is in close contact with the slab shell, fully and evenly cooled, prevents the narrow side from bulging, and at the same time ensures that the slab shell will not crack due to overpressure.

[0084]2) Unsafe width adjustment area: the actual width adjustment horizontal accel...

Embodiment 3

[0086] Assume that the casting speed Uc=1800mm / min when adjusting the width, the effective height of the continuous casting mold L=800mm, and the process requirements: critical strain rate Maximum air gap η max = 2mm, the minimum width of the slab 2W = 900mm.

[0087] 1) Safe width adjustment area: the actual width adjustment horizontal acceleration is α=32mm / min 2 (less than the boundary condition α s =36.45mm / min 2 ), then the angular velocity ω=0.018rad / min, the air gap during the width adjustment process is η=1·58mm, the strain rate of the slab shell Then meet the maximum air gap limit condition (η≤η max ) and the limit condition of slab shell strength It can ensure the close contact between the narrow side of the continuous casting crystallizer and the slab shell, fully and evenly cool down, prevent the narrow side from bulging, and at the same time ensure that the slab shell will not crack due to overpressure.

[0088] 2) Unsafe width adjustment area: the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com